Positioning, marking and cutting device for lathe machining and implementation method of positioning, marking and cutting device

A cutting device and lathe processing technology, used in auxiliary devices, metal processing equipment, automatic lathes/semi-automatic lathes, etc., can solve problems such as affecting the production process, wasting production time, errors, etc., to improve work efficiency, cutting Wide-ranging, highly usable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

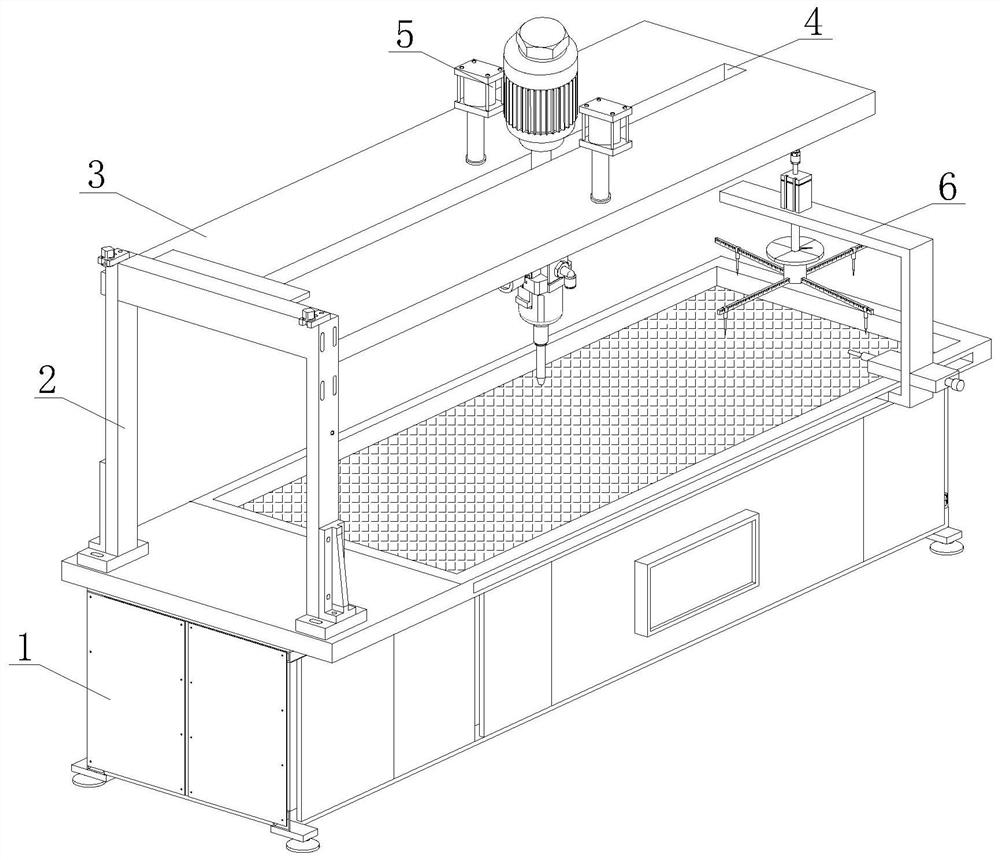

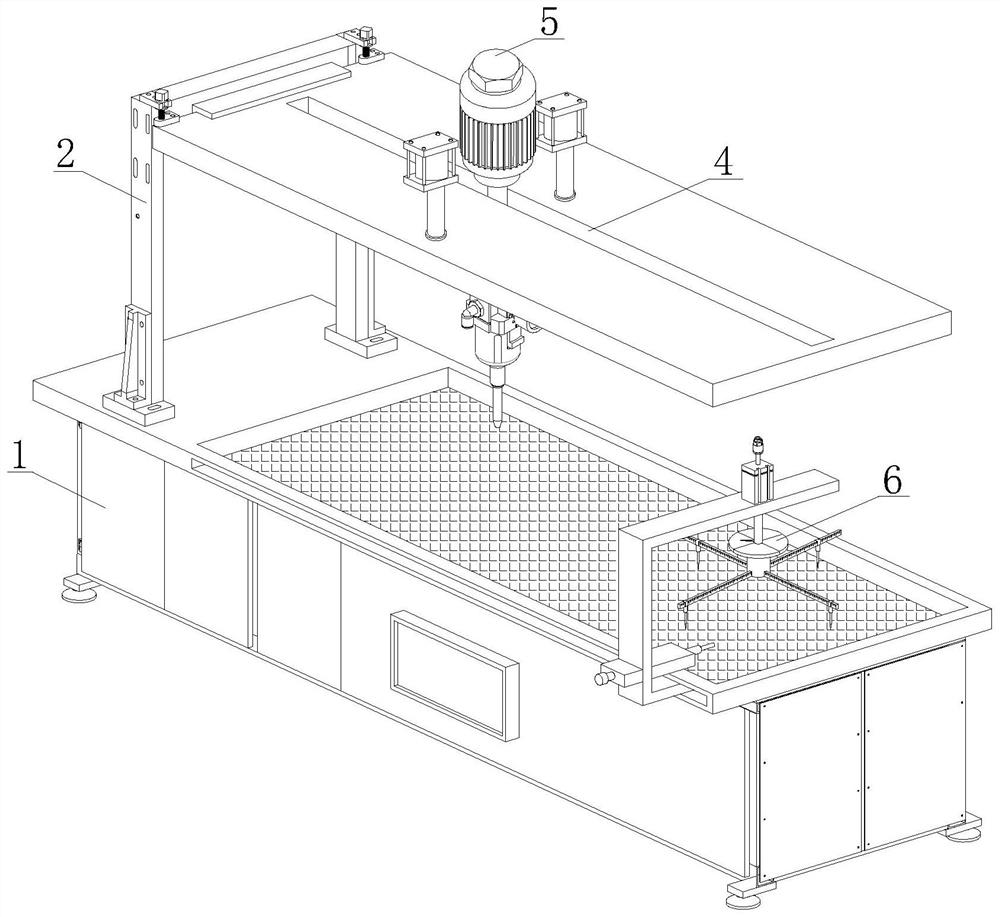

[0037] see Figure 1-2, a kind of positioning marking cutting device for lathe processing, comprising a lathe workbench 1, one side of the upper end surface of the lathe workbench 1 is provided with a support frame group 2, used to support the top plate 3, to prevent the top plate 3 from being insufficiently supported during long-term work Stability causes the falling of the top plate 3 to damage the equipment, so as to improve the stability of equipment installation. The bottom end of the support frame group 2 is welded on the lathe workbench 1, and the top side of the support frame group 2 is vertically connected to the top plate 3, and the top plate 3 There is a chute 4 horizontally in the center of the surface, which is convenient for the cutting mechanism 5 to slide back and forth in the chute 4 to realize multi-directional cutting with a wide cutting range and high practicability of the equipment. The upper and lower end faces and the chute 4 are movably connected with a...

Embodiment 2

[0043] see Figure 1-2 , a kind of positioning marking cutting device for lathe processing, comprising a lathe workbench 1, one side of the upper end surface of the lathe workbench 1 is provided with a support frame group 2, used to support the top plate 3, to prevent the top plate 3 from being insufficiently supported during long-term work Stability causes the falling of the top plate 3 to damage the equipment, so as to improve the stability of equipment installation. The bottom end of the support frame group 2 is welded on the lathe workbench 1, and the top side of the support frame group 2 is vertically connected to the top plate 3, and the top plate 3 There is a chute 4 horizontally in the center of the surface, which is convenient for the cutting mechanism 5 to slide back and forth in the chute 4 to realize multi-directional cutting with a wide cutting range and high practicability of the equipment. The upper and lower end faces and the chute 4 are movably connected with ...

Embodiment approach

[0048] In order to better demonstrate the implementation method of the positioning scribing and cutting device for lathe processing, this embodiment now proposes the implementation method of the positioning and scribing and cutting device for lathe processing, including the following steps:

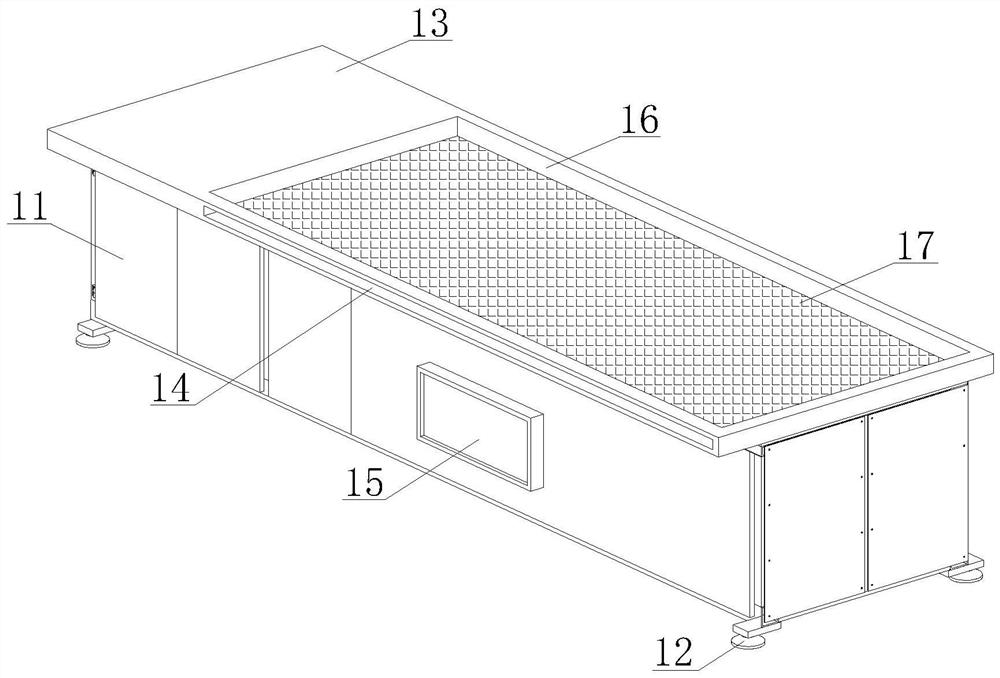

[0049] Step 1: First, the staff puts the metal object to be processed into the placement table 17 of the cutting support groove 16, and the L-shaped bracket 601 or U-shaped bracket 614 slides in the guide rail 14 through the first slider 602 and the second slider 615 .

[0050] Step 2: Secondly, the cylinder drives the piston rod to move up and down at a constant speed, so that the protractor can measure the precise angle and position on the metal plate.

[0051] Step 3: Finally, mark the measured angle and position with a scribe pen, and control the motor 51 by operating the controller 15 to drive the cutting knife 59 to cut up, down, back and forth.

[0052] To sum up, the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com