Multifunctional computer rope saw

A multi-functional, computerized technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low working efficiency of computer special-shaped cutting machines, rough processing surface of finished products, time-consuming and labor-consuming installation, etc., to achieve the utilization of raw materials. The effect of high rate, reduced processing cost and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

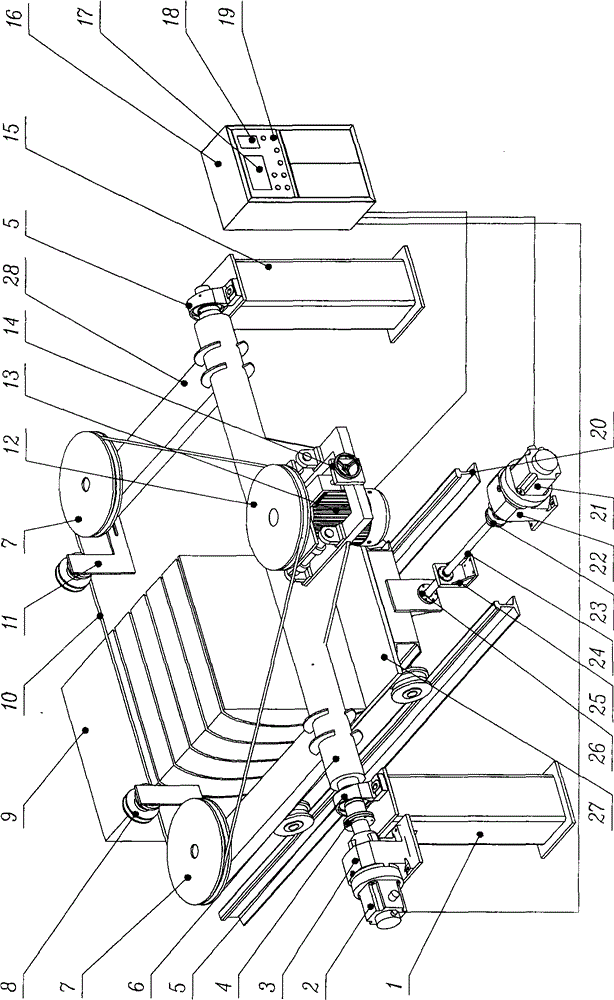

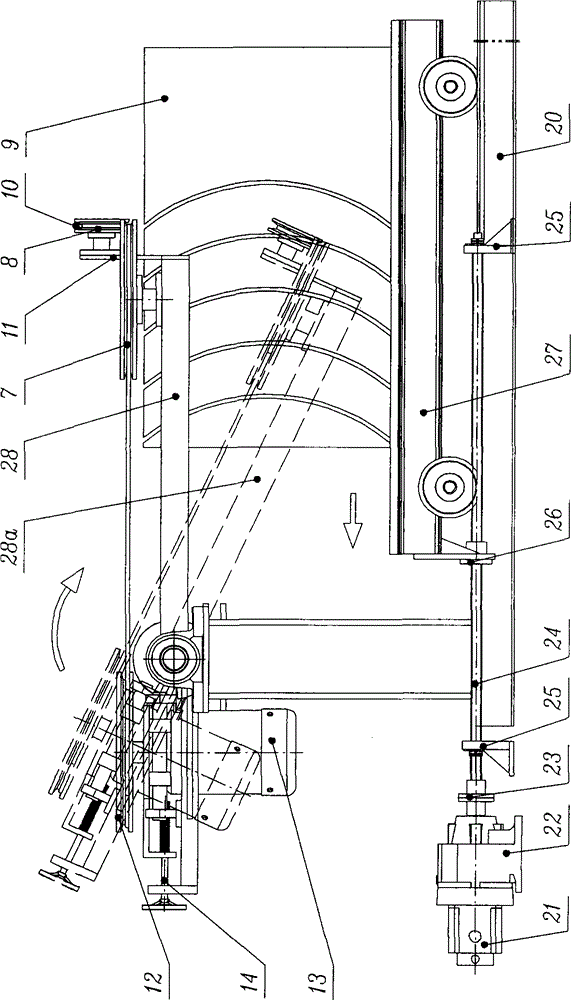

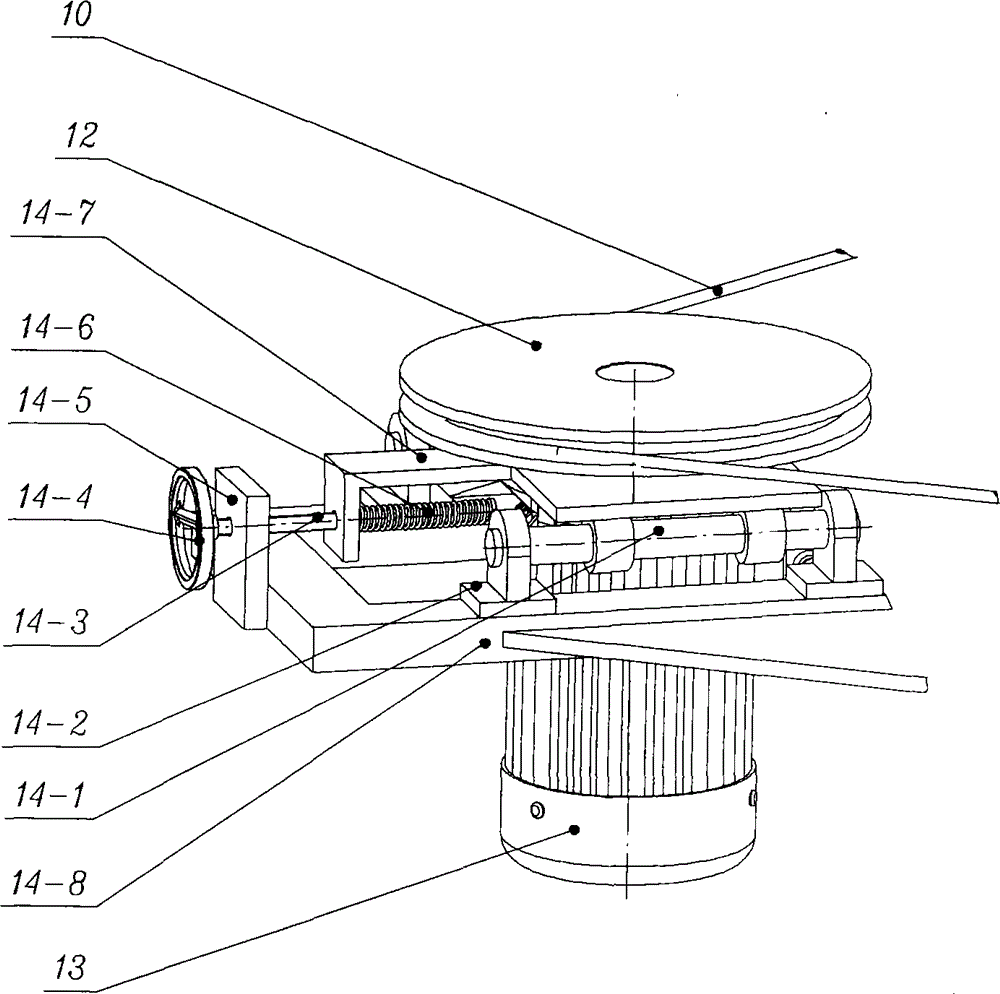

[0030] Depend on Figure 1-Figure 3 It can be seen that the multi-functional computer wire saw of the present invention includes a cutting mechanism, a rotary feeding mechanism, a feeder feeding mechanism, a control system, and also includes a diamond beaded rope tensioning mechanism, wherein:

[0031] Rotary feed mechanism: refer to figure 1 , figure 2 .

[0032] Described rotary feed mechanism comprises rotating shaft 6, rotating arm 28 and first driving device; This first driving device comprises first servo motor 2, first speed reducer 3, first shaft coupling 4; Its connection relation is: The first servo motor 2 is directly connected to the first reducer 3 , and is connected to one end of the rotating shaft 6 through the first coupling 4 . The rotating shaft 6 is supported and installed on the column A1 and the column B15 through a pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com