Rake tooth with sharp ridge and curved surface

A rake tooth and curved surface technology, applied in the field of rake head accessories, can solve the problems of increasing dredging costs, etc., and achieve the effects of reducing soil resistance, saving energy consumption, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

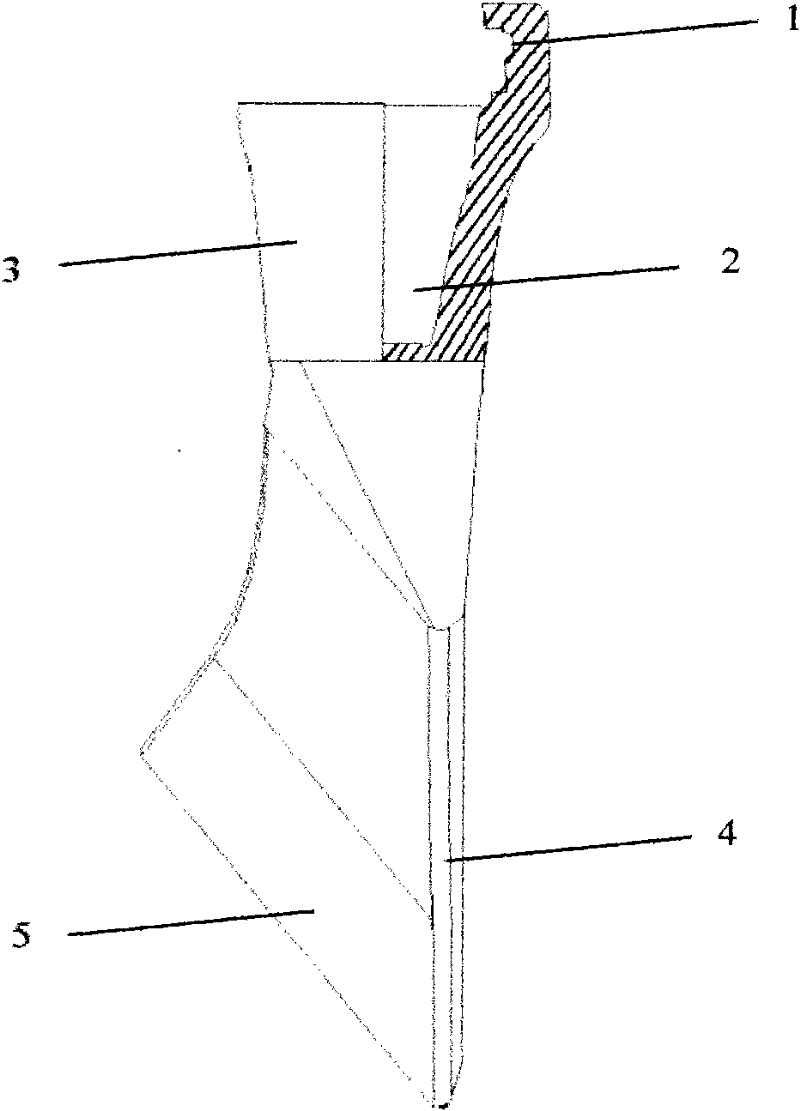

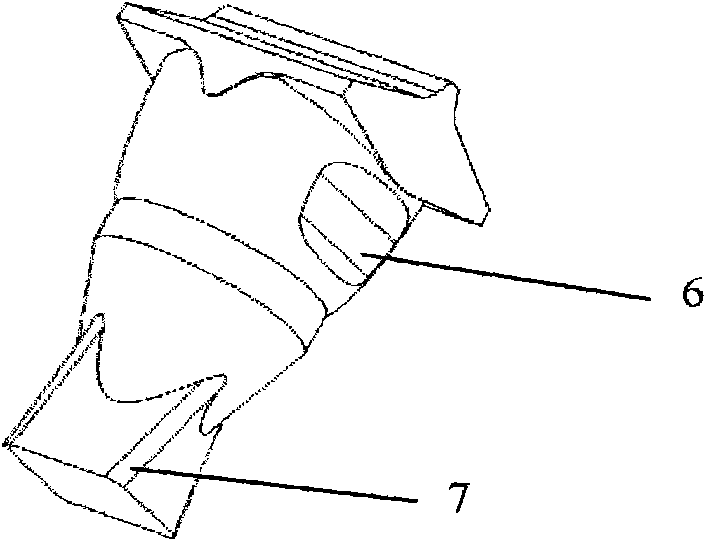

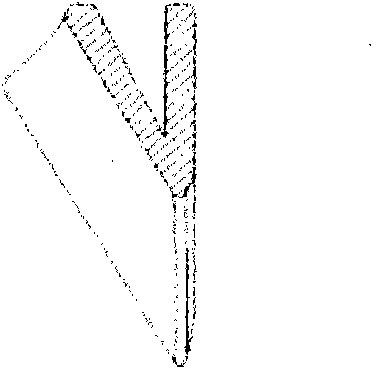

[0009] In this method, the dedendum 3 and the tooth tip 5 are cast into one body, and the rake teeth ( figure 1 ) can be made into left rake teeth ( figure 1 ) or right tine ( Figure 4 ), the left and right rake teeth are symmetrical in shape, the root of the rake teeth is basically square and conical, and the center of the conical body is made into a conical hole 2 ( figure 1 ) is used to set the tine on the tine seat ( figure 2 ); there is a hook-like body 1 ( figure 1 ), the hook-shaped body 1 is set into the transverse pin groove 6 of the tooth holder ( figure 2 ) and fasten the rake tines with pins. The cross-section of the tooth tip is a triangle with an open rear side ( image 3 ), the tip angle of the triangular section of the tooth tip is between 15° and 45°; the tooth surfaces on both sides of the tooth tip are in the shape of an arc surface, and the tooth surfaces on both sides intersect to form a tooth ridge 4 ( figure 1 ).

[0010] The rake teeth made by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com