Suspension system of pneumatic tire roller

A tire roller and suspension system technology, applied in the directions of suspension, elastic suspension, transportation and packaging, can solve the problems of small ground specific pressure of a single tire, low compaction capacity of the road roller, and large width of the whole machine. The effect of improving the grounding specific pressure, convenient transportation and reducing the width of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

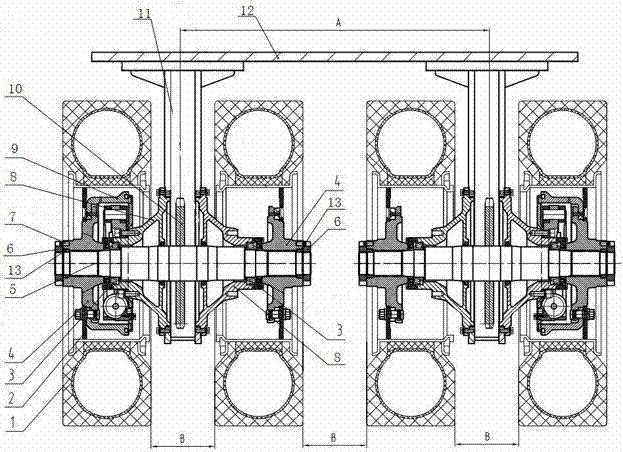

[0013] see figure 1 , the present invention relates to a tire roller suspension system, comprising two groups of suspension devices on the left and right, the tops of the two groups of suspension devices are symmetrically installed on the bottom of the rear floor 12 of the vehicle frame, and the suspension devices include a support box 11, a shaft 5 and Tire 1, the support box 11 is in the shape of a "T", the top of the support box 11 is fixed to the frame rear floor 12, the lower part of the support box 11 is provided with a bearing seat 8, and the shaft 5 passes through the tapered roller bearing 3 is installed on the bearing seat 8.

[0014] The left and right ends of the shaft 5 are all connected to the hub 4 through splines, and the drum brake 9 is installed on the hub 4, and the drum brake 9 is used to control the driving brake of the vehicle. The rim 2 is fixed by bolts, the outer side of the rim 2 is connected with the tire 1, a positioning ring 13 is provided between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com