Focusing device and laser cutting device with the same

A focusing device and laser cutting technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unfavorable laser cutting promotion and increased equipment use costs, and achieve a wide cutting range, simplify the preparation process, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

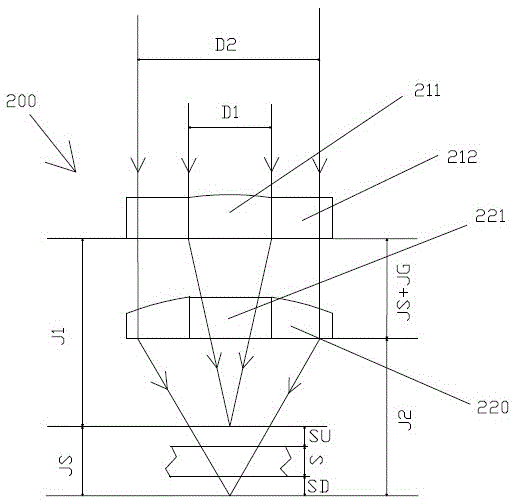

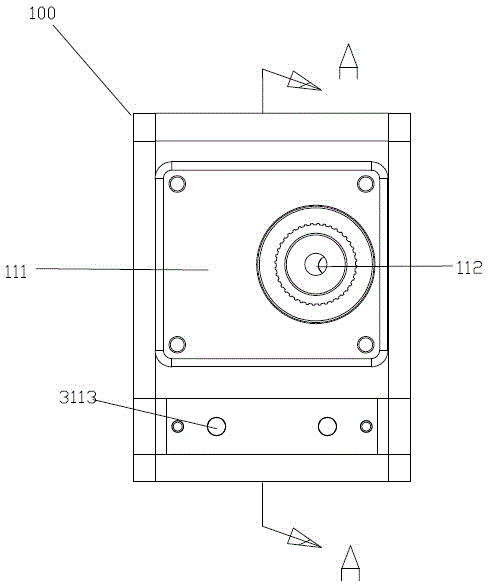

[0035] see Figure 2 to Figure 12 , the focus device (not labeled) used in the laser cutting device of the present invention is provided with a lens 200, an adjustment mechanism 300 for adjusting the position of the lens 200, and a housing 100 for accommodating the adjustment mechanism 300. The housing 100 is provided with a front wall 110 and a The front wall 110 is opposite to the rear wall 120, and the front wall 110 is provided with an openable protective cover 111, which is convenient for adjustment operation. The focusing device also includes an aperture drawer 400 in which the two focal points of the auxiliary adjustment lens 200 are located on the same optical axis.

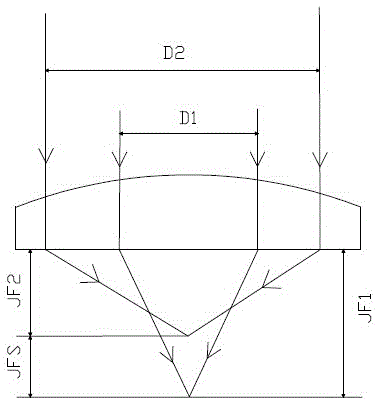

[0036] The lens 200 includes a central focusing film 210 and a ring focusing lens 220 . The central focusing sheet 210 is provided with a central focusing lens 211 and an annular plane mirror 212 surrounding the central focusing lens 211 and used for fixing the central focusing lens 211 . The outer diam...

Embodiment 2

[0049] see Figure 13 It is the optical path diagram of the bifocal lens of another preferred embodiment of the present invention, which differs from Embodiment 1 only in that the first focus is located above the upper surface of the workpiece, and the second focus is located below the lower surface of the workpiece. Generally, the diameter of the laser cutting nozzle 500 is relatively small. In the above-mentioned embodiment, the diameter of the laser beam focused by the lens 200 is relatively large, and part of the light may be blocked by the laser cutting nozzle 500, or the laser cutting nozzle 500 needs to be The diameter should be designed larger. In this embodiment, the diameter of the laser beam focused by the lens 200 is relatively small, and all light rays can be emitted from the laser cutting nozzle 500 .

[0050] The beneficial effects of the present invention are: compared with the prior art, the focusing device of the present invention forms two focal points thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com