Disc chipper for micrometer long fibers

A technology of micron fiber and cutter head, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of inability to adjust the distance, narrow cutting range, decreased productivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

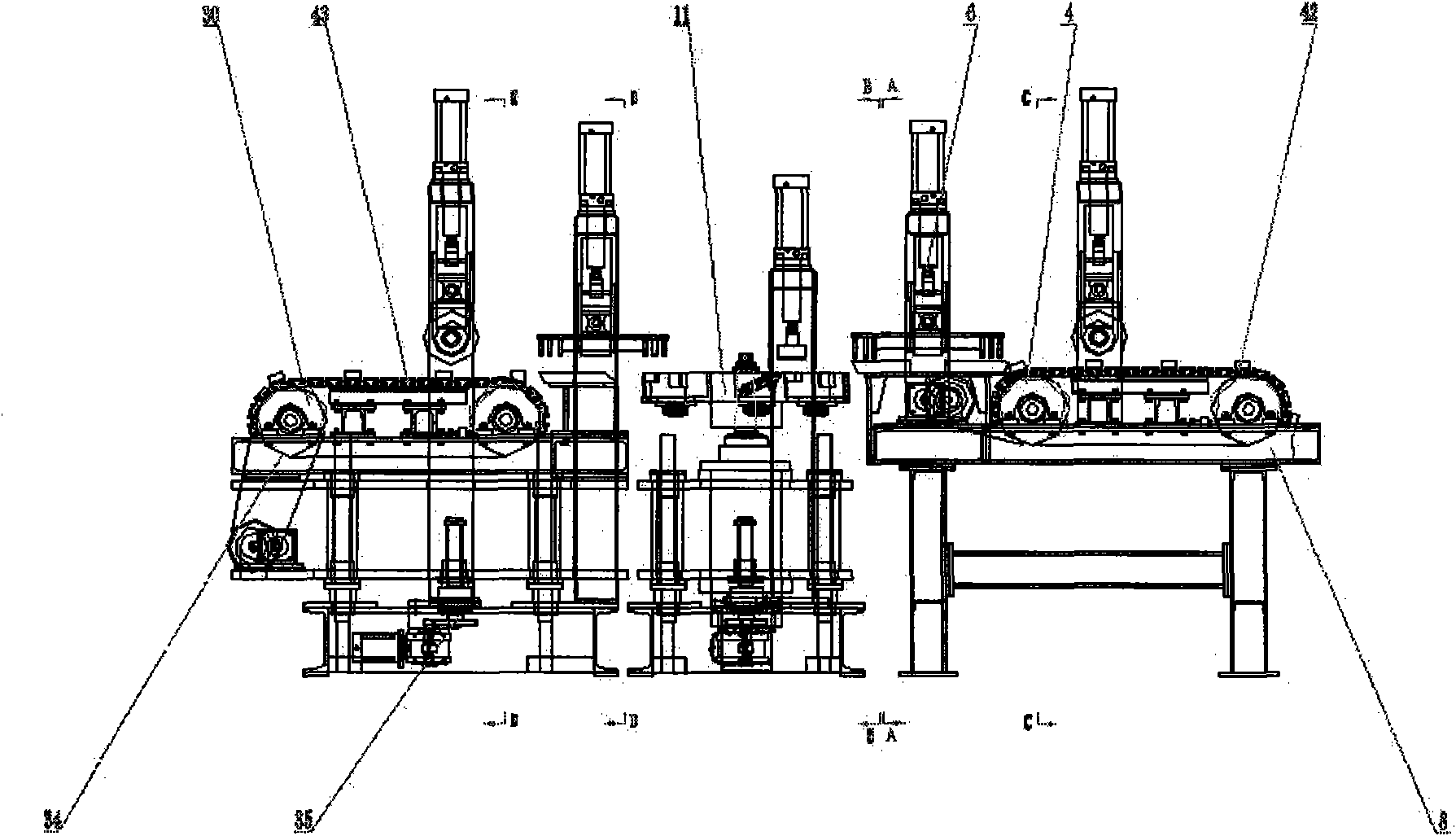

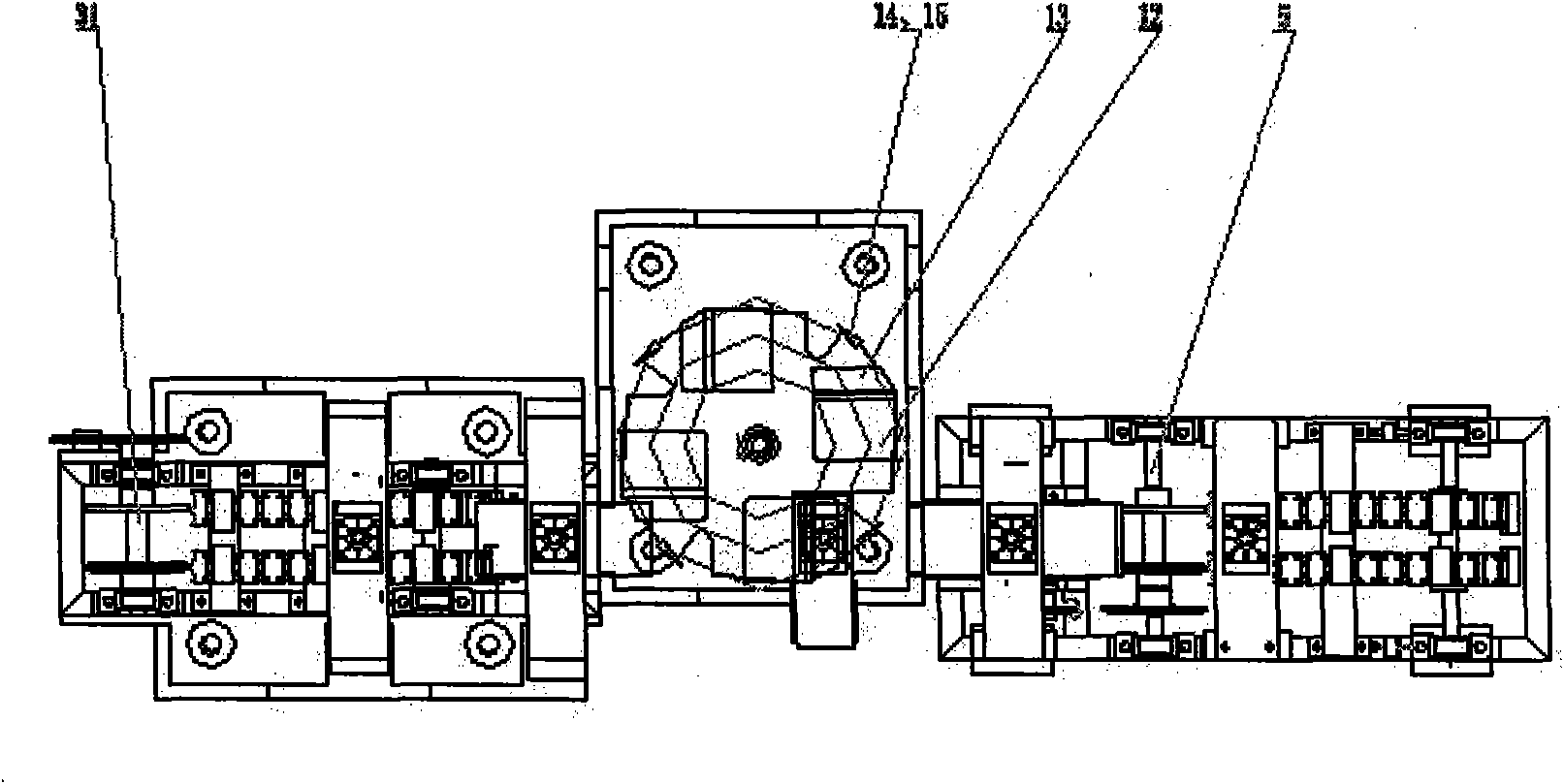

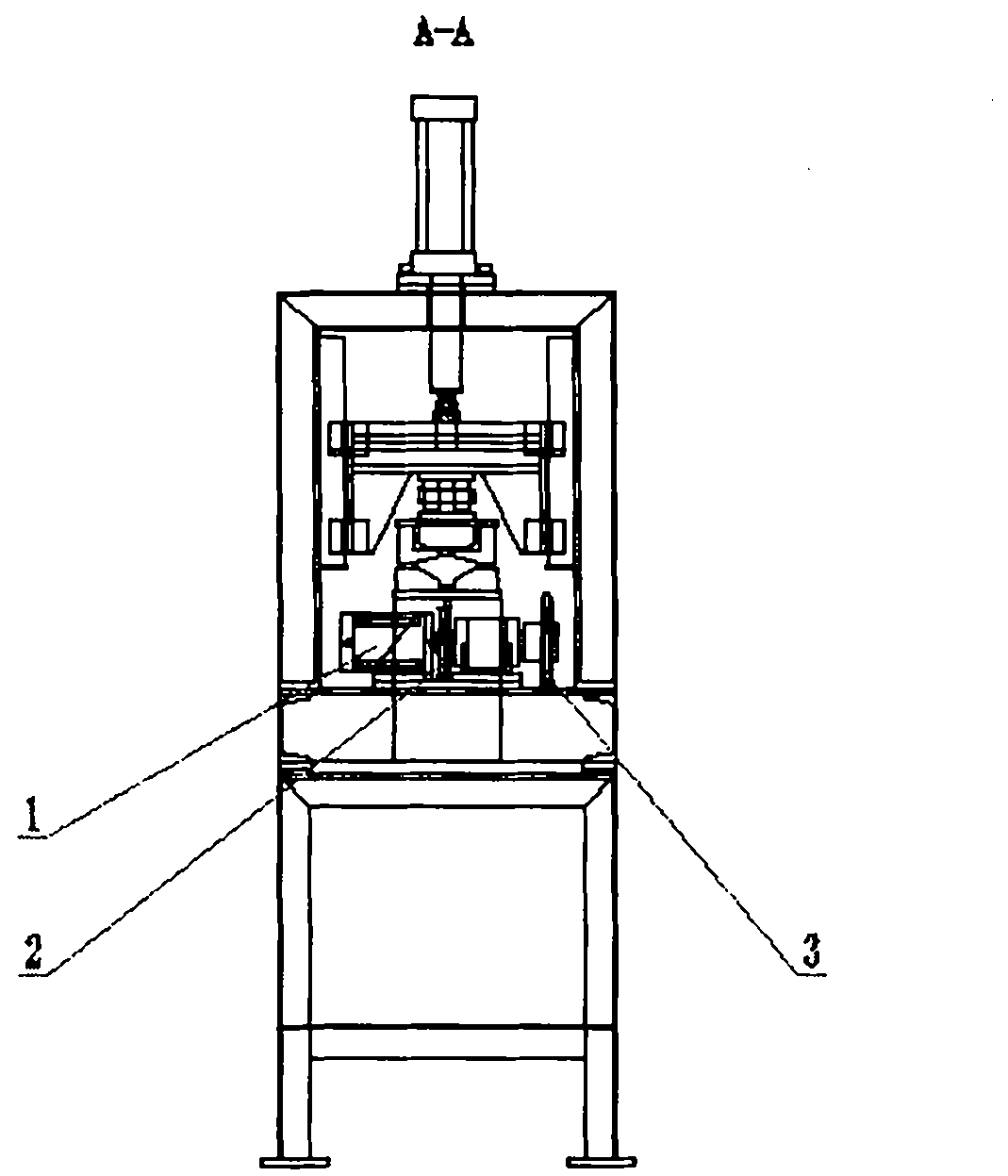

[0021] 1. Feeding mechanism - located on the right side of the whole machine, it is composed of servo motor 1, gear reducer 2, small sprocket 3, large sprocket 4, transmission shaft 5, pressing device 6, rolling pressing device 7, Feeding platform 8, feeding platform frame 9, feeding work chain 42 are formed. Servo motor 1 is fixed on the upper left side of feeding table 8, feeding table 8 is fixed on feeding table frame 9, gear reducer 2 is fixed on feeding table 8, is connected with servo motor 1, gear reducer 2 is connected with small The sprocket 3 is connected by a bearing, the large sprocket 4 is fixed on the transmission shaft 5, and is connected with the small sprocket 3 through the feeding working chain 42, the transmission shaft 5 is fixed on the feeding platform 8, the pressing device 6 and the rolling pressing Device 7 is all fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com