Cutting device for die part production

A cutting device and parts technology, which is applied in the field of cutting devices for mold parts production, can solve the problems of inability to change, loose fixation, and inability to cut the cutting position of circular parts, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

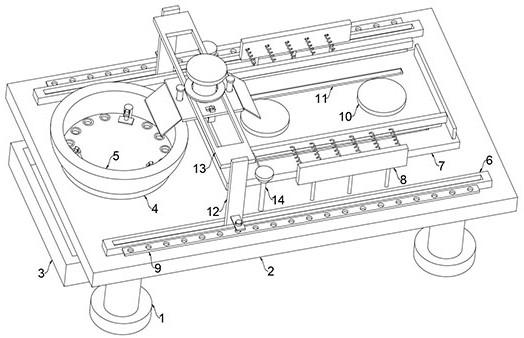

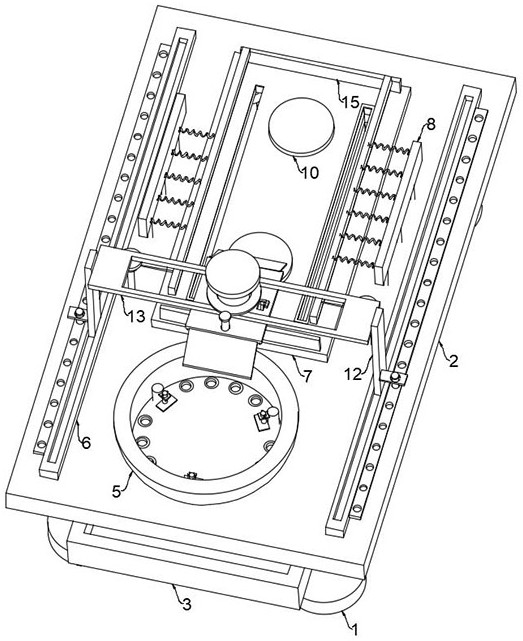

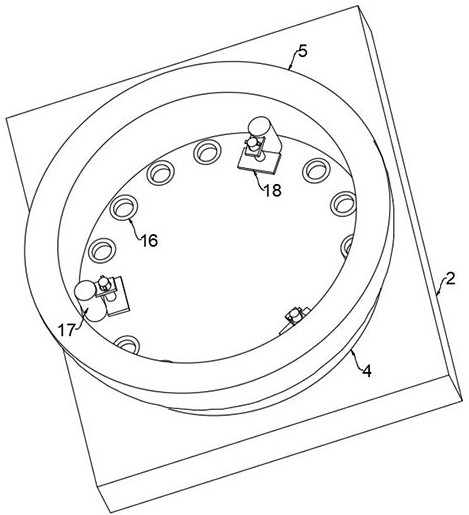

[0046] refer to Figure 1-4 , a cutting device for mold parts production, comprising an operating platform 2 fixedly installed on a plurality of support columns 1, a disc 4 and a fixed plate 7 are fixedly installed on the operating platform 2, and a plurality of fixed rods 17 pass through the disc 4 A plurality of straight plates 20 are fixedly installed, and each straight plate 20 is equipped with a pressing plate 18 through a pressing mechanism;

[0047] There are two points worth noting above:

[0048] 1. A straight plate 20 is fixedly installed on the fixed rod 17. A threaded rod 19 is threaded on the straight plate 20. The lower end of the threaded rod 19 is fixedly mounted with a limit shaft, and the pressing plate 18 is rotated and installed on the limit shaft. The pressing plate 18 and the straight plate Two limit springs are fixedly installed between 20, and the round part is placed in the disc 4, and the threaded rod 19 is rotated to drive the pressing plate 18 to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com