Sweet cream and its preparation method

A cream and glycerin technology, applied in the field of oil deep processing, can solve the problems of human health threats and harsh storage conditions, and achieve good high temperature stability and stable tissue structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

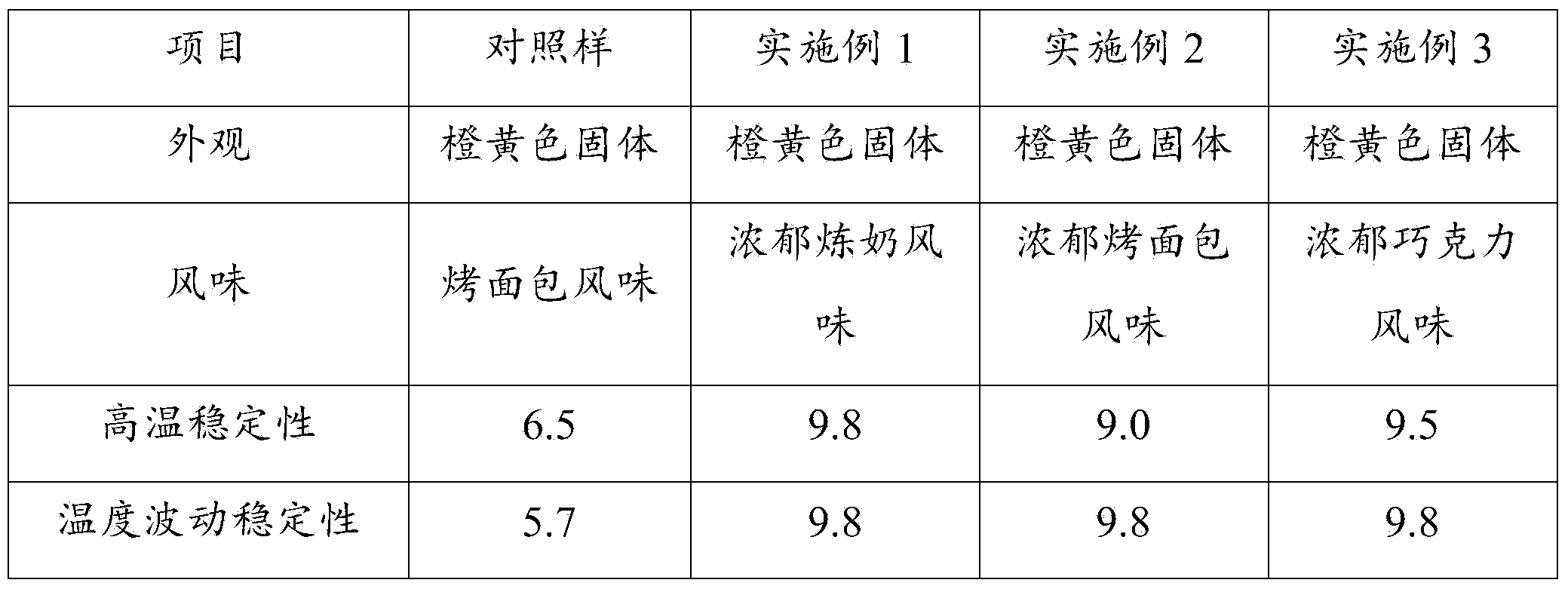

Embodiment 1

[0038] A sweet cream prepared from:

[0039] Base oil (refined palm oil 70.0wt%, refined palm kernel oil 20.0wt%, refined soybean oil 10.0wt%) 300.0kg, white sugar (sweetener) 100.0kg, lactose (sweetener) 50.0kg, alginic acid Sodium (thickener) 5.0kg, whey powder (filler) 120.0kg, glycerin 20.0kg, sucrose fatty acid ester (HLB=15.0) (water phase emulsifier) 2.0kg, polyglycerol fatty acid ester (water phase emulsifier) agent) 3.0kg, propylene glycol fatty acid ester (oil phase emulsifier) 2.0kg, polyglycerol ricinoleate (PGPR) (oil phase emulsifier) 3.0kg, edible condensed milk flavor (edible flavor) 3.0kg, β-carrot Vegetables 0.01kg, deionized water 391.99kg.

[0040] Base oil SFC (Solid Fat Content) is: 10°C (38.8), 20°C (24.6), 25°C (21.7), 30°C (15.4), 35°C (10.0).

[0041] The preparation method comprises the following steps:

[0042] (a) Put sterilized deionized water into a clean stainless steel tank, weigh sweetener, thickener, filler, glycerin, and water phase...

Embodiment 2

[0047] A sweet cream prepared from:

[0048]Base oil (refined palm oil 70.0wt%, refined coconut oil 20.0wt%, refined rapeseed oil 10.0wt%) 600.0kg, glucose (sweetener) 50.0kg, lactose (sweetener) 30.0kg, xanthan gum (thickener) 1.0kg, whey powder (filler) 50.0kg, glycerin 5.0kg, sucrose fatty acid ester (HLB=11.0) (water phase emulsifier) 2.0kg, polyglycerol ricinoleate (oil phase emulsifier) agent) 0.5kg, mono- and diglyceride fatty acid ester (oil phase emulsifier) 3.0kg, edible toast flavor (edible flavor) 1.0kg, β-carotene 0.005kg, deionized water 257.495kg.

[0049] Base oil SFC is: 10°C (38.5), 20°C (24.7), 25°C (21.9), 30°C (16.1), 35°C (11.3).

[0050] Embodiment 2 preparation method is the same as embodiment 1.

Embodiment 3

[0052] A sweet cream prepared from:

[0053] Base oil (refined palm oil 70.0wt%, refined coconut oil 22.0wt%, refined corn oil 8.0wt%) 400.0kg, xylitol (sweetener) 20.0kg, lactose (sweetener) 100.0kg, pectin (thickener) 1.0kg, gelatin (thickener) 3.0kg, maltodextrin (filler) 70.0kg, whole milk powder (filler) 80.0kg, glycerin 10.0kg, Tween (60) (water phase emulsification agent) 1.0kg, sodium caseinate (water phase emulsifier) 3.0kg, polyglycerol ricinoleate (oil phase emulsifier) 1.0kg, phospholipid (oil phase emulsifier) 2.0kg, edible chocolate flavor (edible flavor) 2.0kg, β-carotene 0.015kg, deionized water 306.985kg.

[0054] Base oil SFC is: 10°C (40.1), 20°C (23.9), 25°C (22.0), 30°C (16.3), 35°C (11.8).

[0055] Embodiment 3 preparation method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com