Patents

Literature

46results about How to "Delicate organizational structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

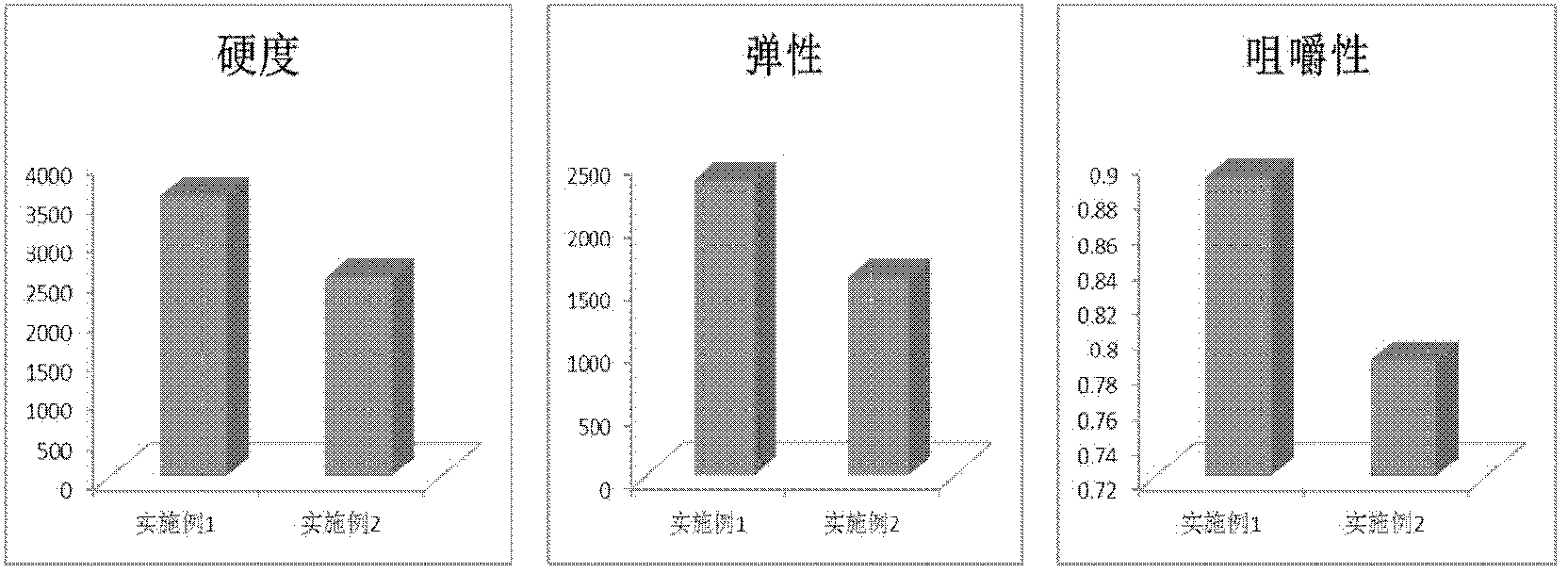

Low-temperature acid-induced minced fish product with high gel strength and production method of minced fish product

ActiveCN104382097AHigh strengthIncrease elasticityFood preparationUltimate tensile strengthFish products

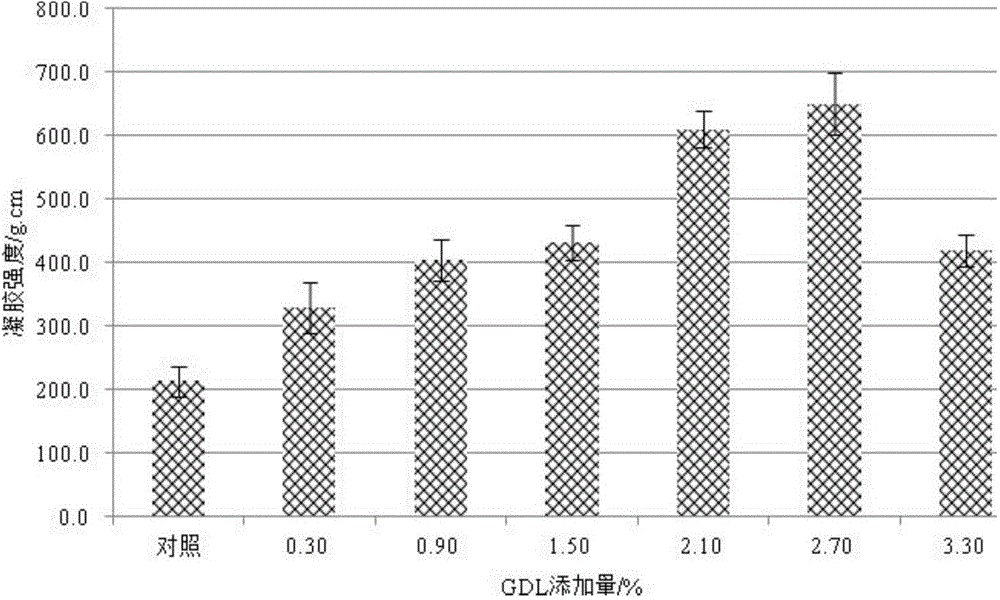

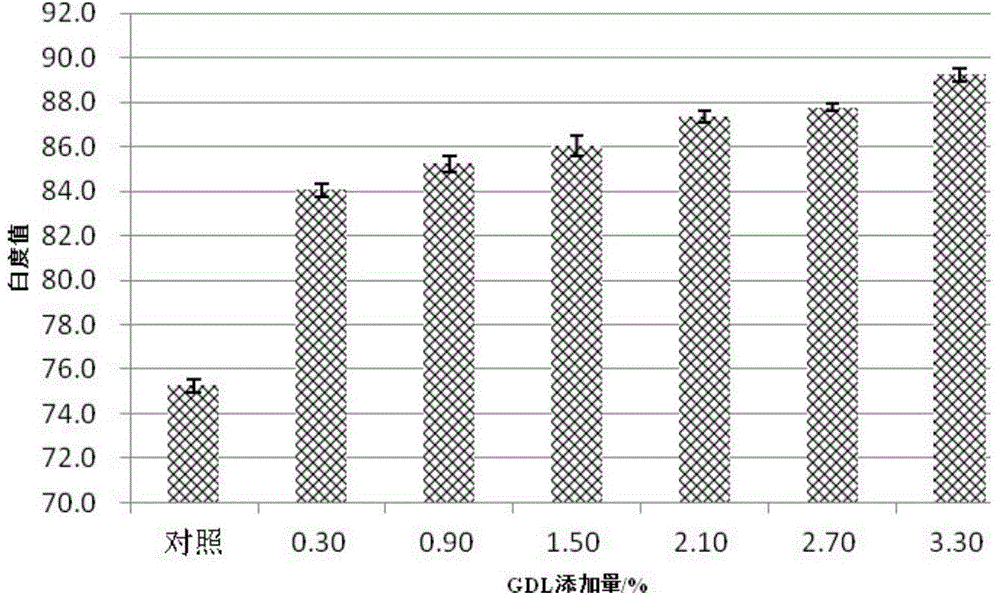

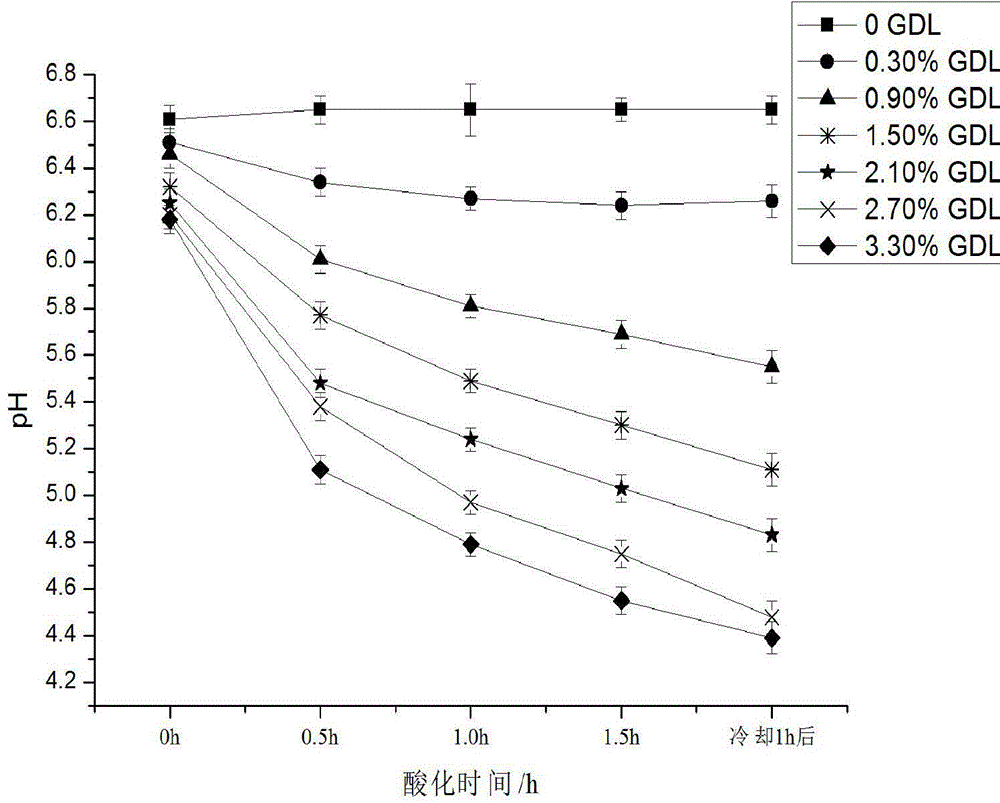

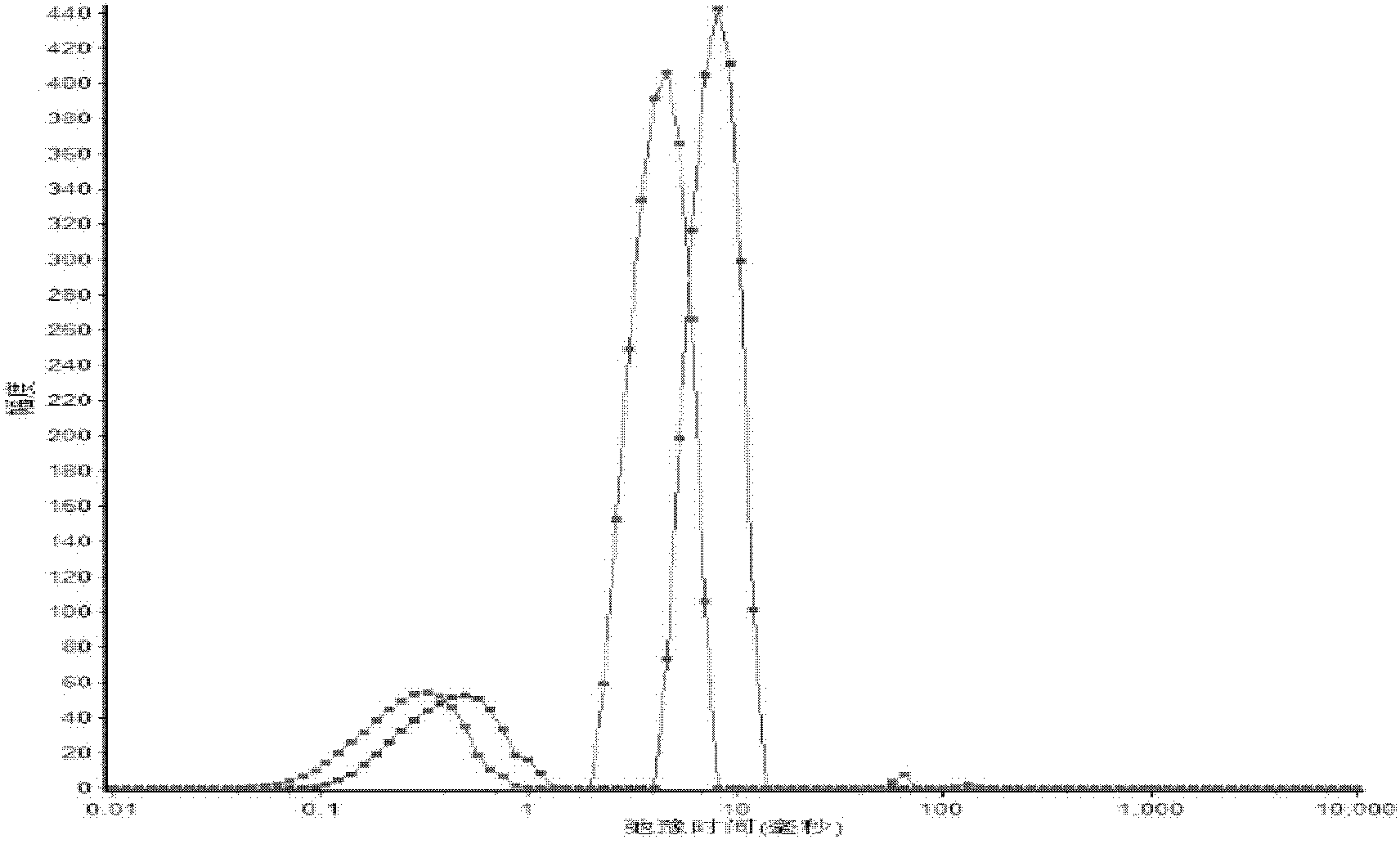

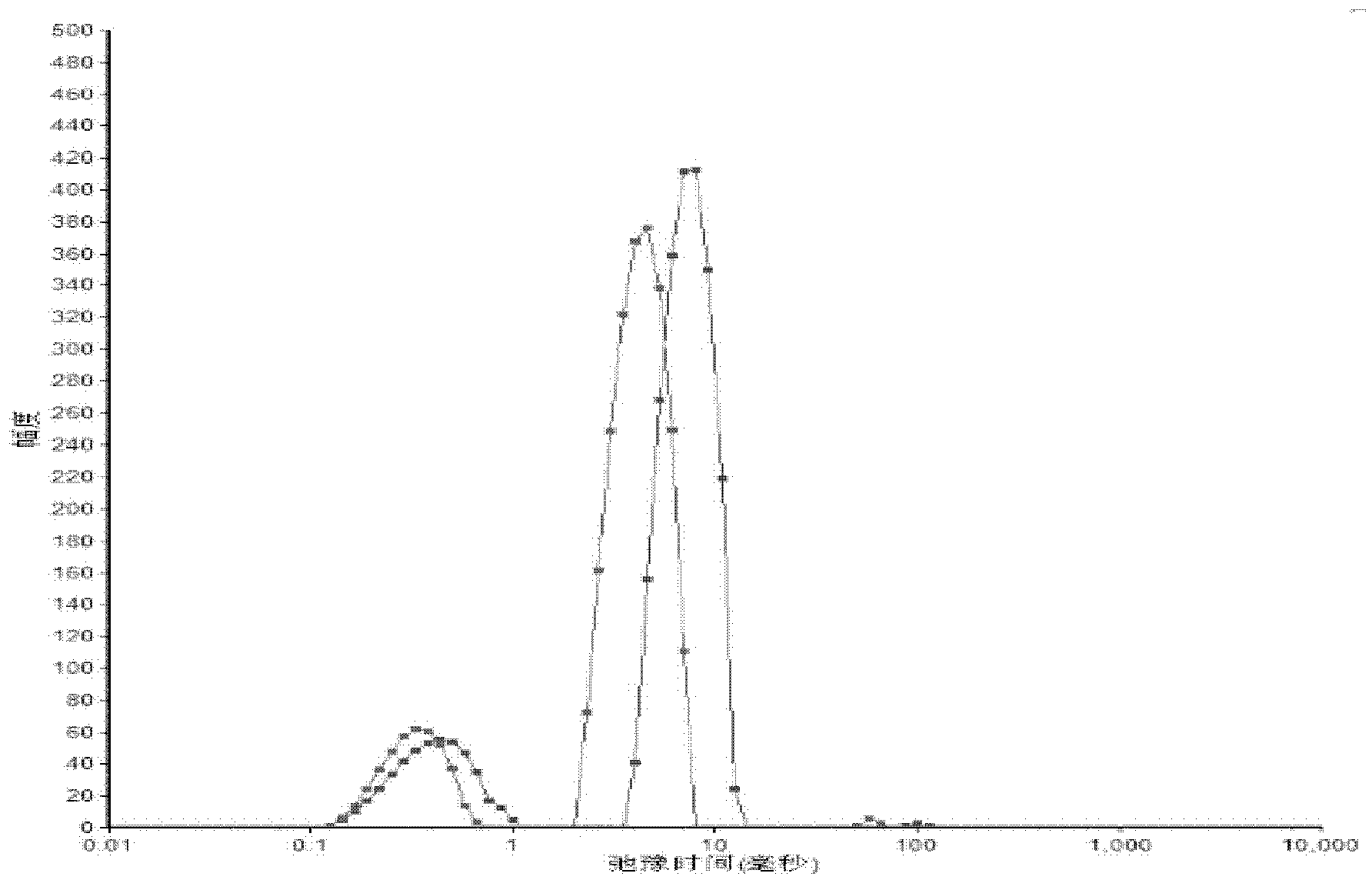

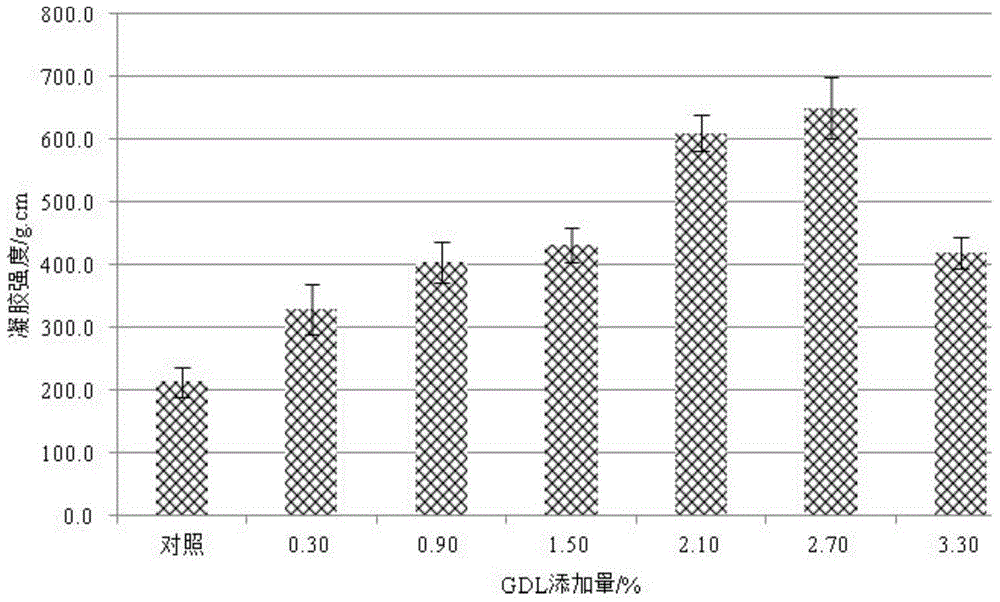

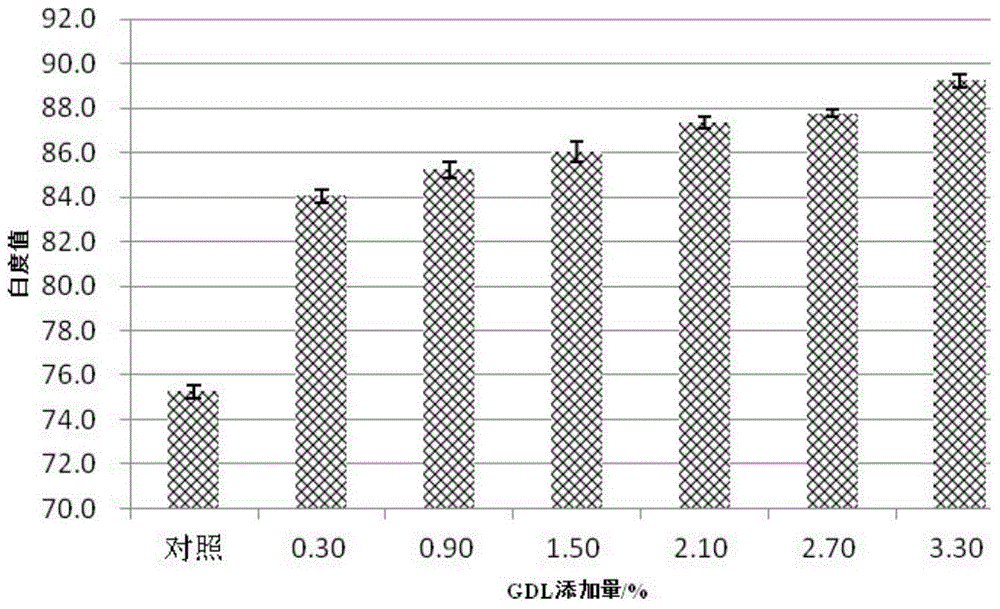

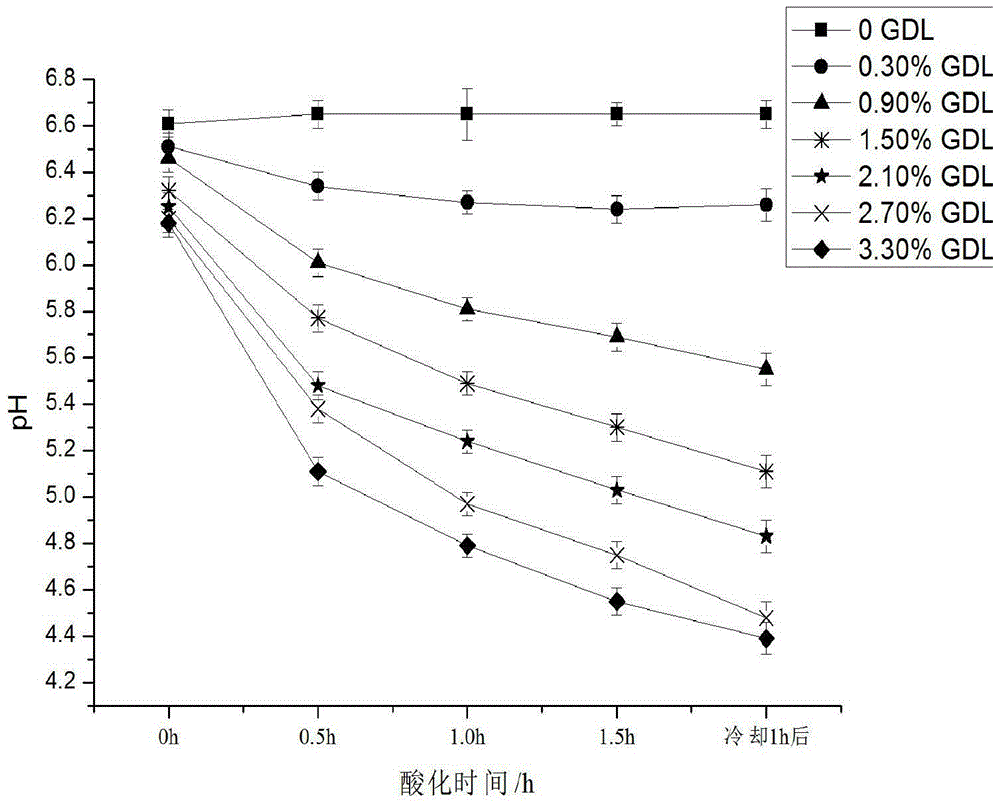

The invention relates to a low-temperature acid-induced minced fish product with high gel strength and a production method of the minced fish product. The production method comprises the steps of unfreezing, chopping via air, chopping via salt, chopping mixture and forming. The gel is induced by acid by slowing hydrolyzing glucolactone and acting on the minced fish protein; compared with the gel strength of the conventional hot gel, the gel strength is improved by over 140%; the texture structure is relatively fine and smooth; the elasticity is improved by over 10%; the whiteness is increased by over 12%; the low-temperature acid-induced minced fish product with high gel strength is a novel instant refrigerated low-temperature acid-induced minced fish product.

Owner:FUJIAN ANJOY FOODS CO LTD +4

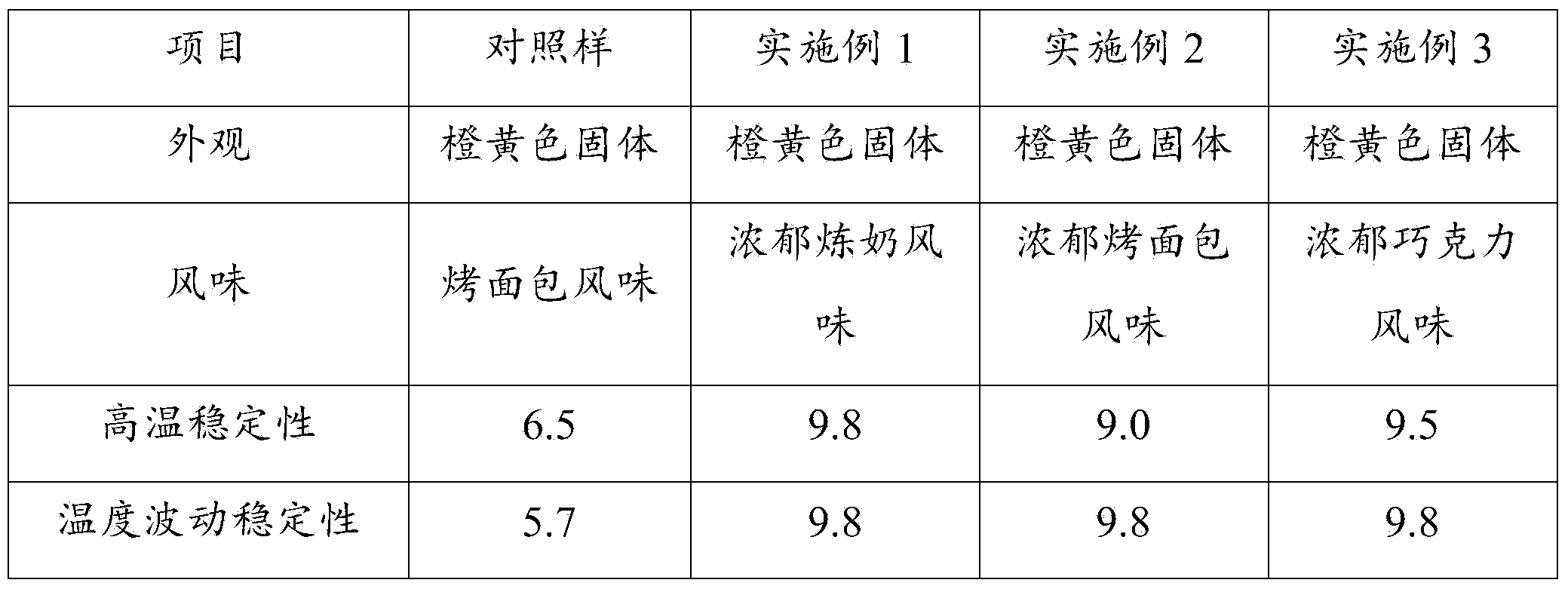

Sweet cream and its preparation method

ActiveCN103815050AImprove fatty acid profileImprove stabilityEdible oils/fats production/working-upGlycerolOil phase

The invention discloses sweet cream and its preparation method, and the sweet cream is prepared from the following raw materials by weight: 30.0-60.0% of base oil, 8.0-15.0% of a sweetening agent, 0.1-0.5% of a thickening agent, 5.0-15.0% of a filler, 0.5-2.0% of glycerol, 0.1-0.5% of an aqueous phase emulsifier, 0.2-0.5% of an oil phase emulsion, 0.1-0.3% of an edible essence, 0.0005-0.0015% of beta carotene and the balance of water. The sweet cream has good high temperature stability, may not precipitate by 30min of high temperature cooking at 100 DEG C, may not sugar by 7 cycles of repeated temperature fluctuations with each cycle comprising 12h of placing at 5 DEG C and 12h of placing at 20 DEG C, and has a stable organizational structure.

Owner:广州市雅禾生物科技有限公司

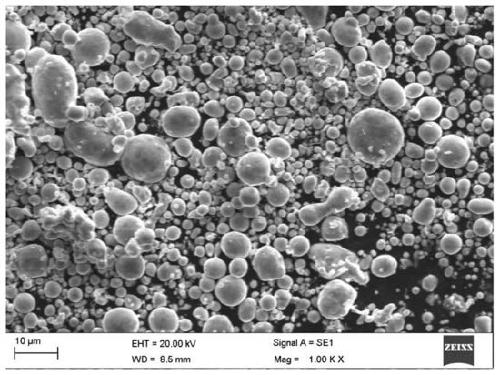

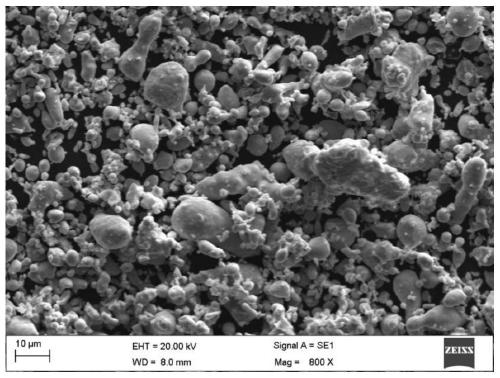

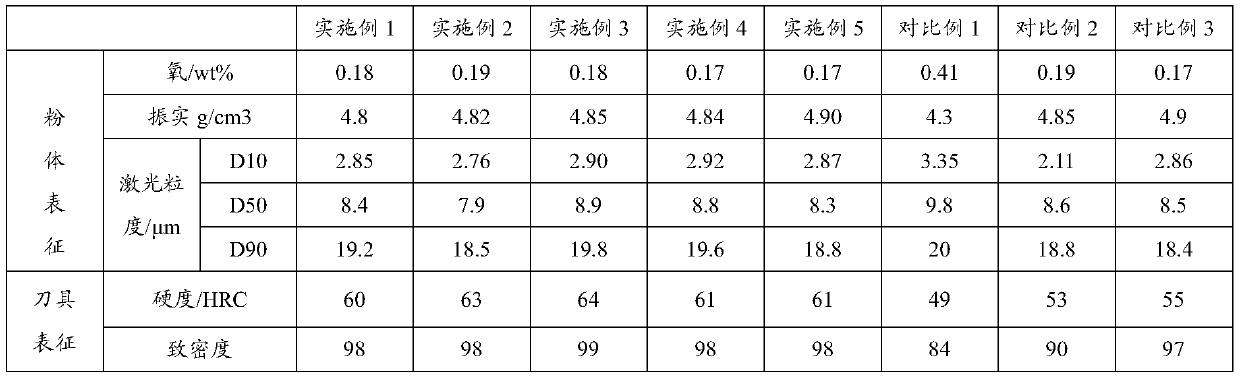

Metal injection molding (MIM) high-end cutter, metal powder and preparation method of metal powder

ActiveCN109877311AFine granularityGood sphericityTurbinesOther manufacturing equipments/toolsBatch processingImpurity

The invention discloses a metal injection molding (MIM) high-end cutter, metal powder and preparation method of the metal powder. The metal powder is prepared from the following raw material elementsin percentage by mass: 12.0-16.0% of Cr, 2.0-4.0% of Mo, 1.0-4.0% of W, 1.0-3.0% of V, 1.0-1.5% of Cu, 0.5-1.0% of Sn, 0.5-0.7% of Si, 0.5-1.5% of C, 72.0-81.5% of Fe. The metal powder is prepared through a water-gas combined atomization powder-preparing mode. The preparation method comprises the technical processes of medium-frequency induction melting of the alloy elements, water-gas combined atomization, vacuum drying, powder classification and screening, batch processing and the like. The prepared alloy powder has the advantages of uniform alloy composition, uniform organization structure,fine powder granularity, reasonable powder distribution, good sphericity, low impurity content and the like, and can serve as a raw material of the MIM high-end tool to be widely applied.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Method for making steamed buns through utilizing Lactobacillus plantarum

ActiveCN103284063AImprove growth characteristicsIncrease inoculum volumeFood preparationBiotechnologyYeast

The invention relates to a method for making steamed buns. The method comprises the following steps: activating Lactobacillus plantarum, making a sour dough containing Lactobacillus plantarum, fermenting by utilizing Lactobacillus plantarum to make a steamed bun dough, fermenting small doughs obtained after dividing the steamed bun dough, and steaming the small doughs. The method uses the Lactobacillus plantarum CCFM8661 to ferment in order to make steamed breads and uses no commercial yeasts, the steamed buns made through the method have a rich flavor, and an insufficient flavor disadvantage caused by the use of a single yeast to ferment of products mode in the present market is overcome; and the steamed buns made through the method have the advantages of fine construction structure, good batch stability, and high safety.

Owner:JIANGNAN UNIV

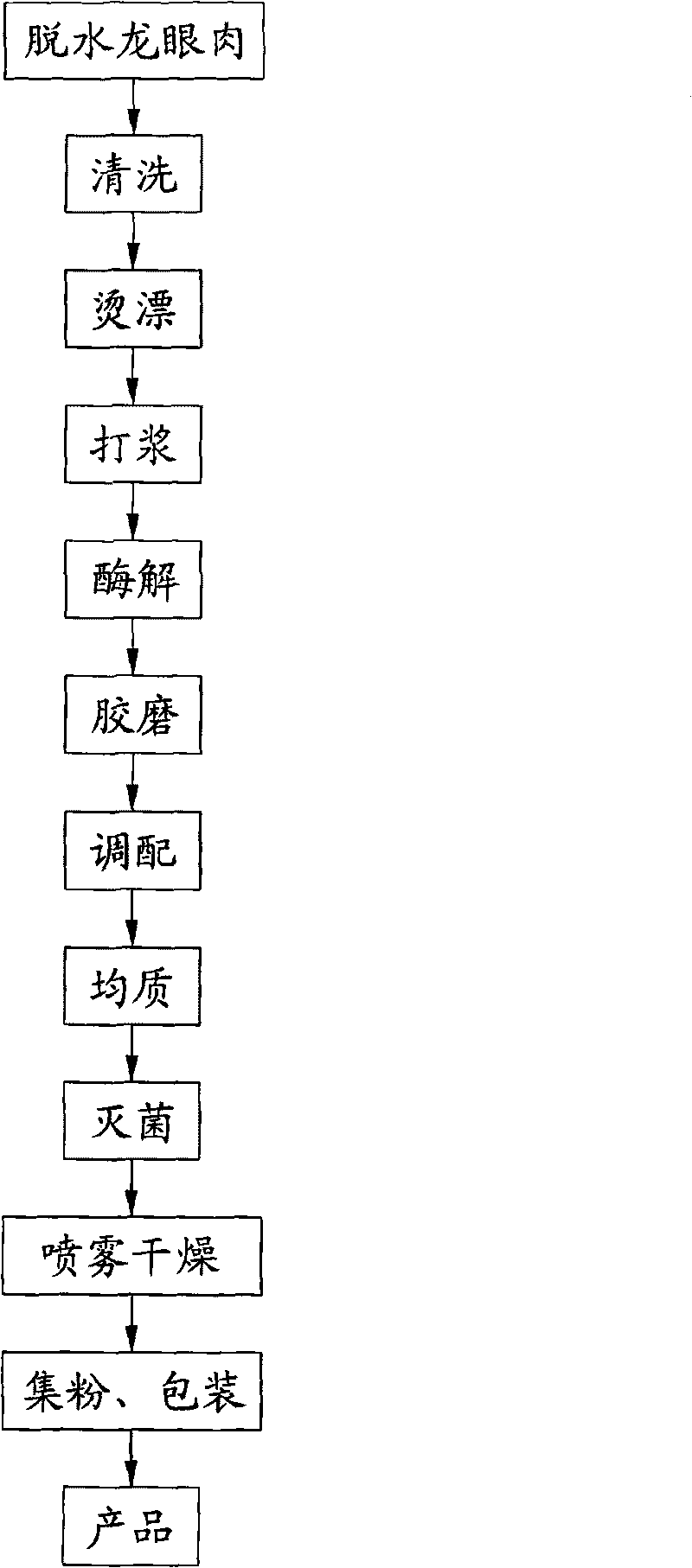

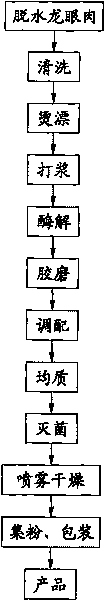

Method for making natural longan powder

InactiveCN101690566ASolve the problem of coloringSolve the taste problemFood shapingFood preparationSolubilityFlavor

The invention discloses a method for making natural longan powder, which carries out the steps of cleaning of dried longan fruit pulp, blanching, beating, enzymatic hydrolysis, colloid milling, blending, homogenizing, sterilization, drying, powder collection, screening and the like, thereby preparing a longan powder product; and the processing is completed by adopting the mechanized continuous operation way. The longan powder prepared by the method can solve the problems of poor color, luster and solubility of the existing products, low product yield and the like. The technical scheme is characterized by introducing the treatment technologies of color protection, enzymatic hydrolysis and spray drying. The product keeps the flavor and the nutritional ingredients of longan and has natural color and luster, high solubility and good taste, and the making process does not add any pigments, essences, preservatives and other chemical substances, thereby having no side effects and being the pure natural fruit powder.

Owner:JIMEI UNIV

Production process of goose liver paste

The invention relates to a production process of foie gras, comprising the following steps of: putting goose livers into a vacuum cut mixer to roughly cut after clearing and cleaning; putting the goose livers and ingredients into the vacuum cut mixer again to finely cut; cutting and mixing the goose livers into foie gras; and finally, canning, sealing in vacuum, sterilizing at high temperature, cooling by spraying water, entering a constant-temperature tank and canning at the temperature of 37 DEG C sequentially. The invention has simple process and low production cost and can effectively eliminate fishy smell and peculiar smell in the foie gras by cutting and mixing the goose livers at high temperature and high speed, and the foie gras has fine mouthfeel and just melts in the mouth.

Owner:天津宝鹅园鹅业发展有限公司

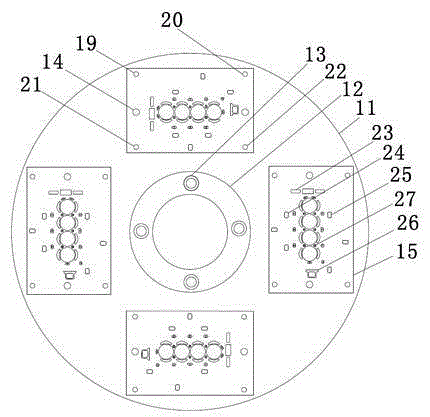

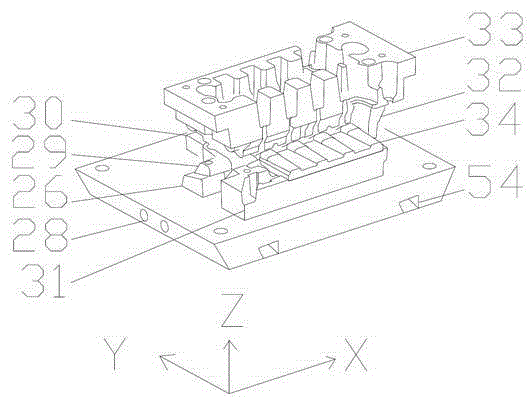

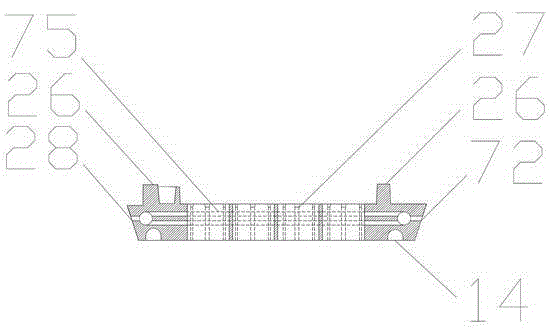

Device for casting cylinder cover

ActiveCN105397035AMeet quality requirementsConforms to the solidification rateFoundry mouldsFoundry coresThree stageEngineering

A device for casting a cylinder cover comprises a die. The die comprises a bottom die body, a side die body and a core assembling tool. The core assembling tool comprises core assembling plates and sand cores installed on the core assembling plates. The core assembling plates are in a wedge shape. Cooling channels are formed in the core assembling plates. The bottom die body comprises a bottom die body frame and a bottom die body core. A wedge-shaped groove is formed in the upper portion of the middle of the bottom die body frame. A second venting hole and a second air inlet are formed in the groove wall of the wedge-shaped groove. An installation groove communicated with the wedge-shaped groove is formed in the lower portion of the middle of the bottom die body frame. The bottom die body core is installed in the installation groove. A sealing hatch cover is arranged at the lower end of the bottom die body core. When the core assembling plates and the wedge-shaped groove are assembled, the second air inlet is communicated with the second venting hole through the cooling channels so that an exhaust channel can be formed; an inner cavity of the sealing hatch cover serves as a sealed hatch, one end of a pipe connected with a compressed air source is connected with the sealing hatch cover, and the other end of the pipe is connected to the second air inlet. According to the device for casting the cylinder cover, the temperature gradient difference is formed through a three-stage cooling step, so that stress cracks of a casting are eliminated; the die is distributed in a split mode, online operation is convenient, and casting requirements for cylinder cover scale production can be met.

Owner:湖北长鑫源汽车实业有限公司

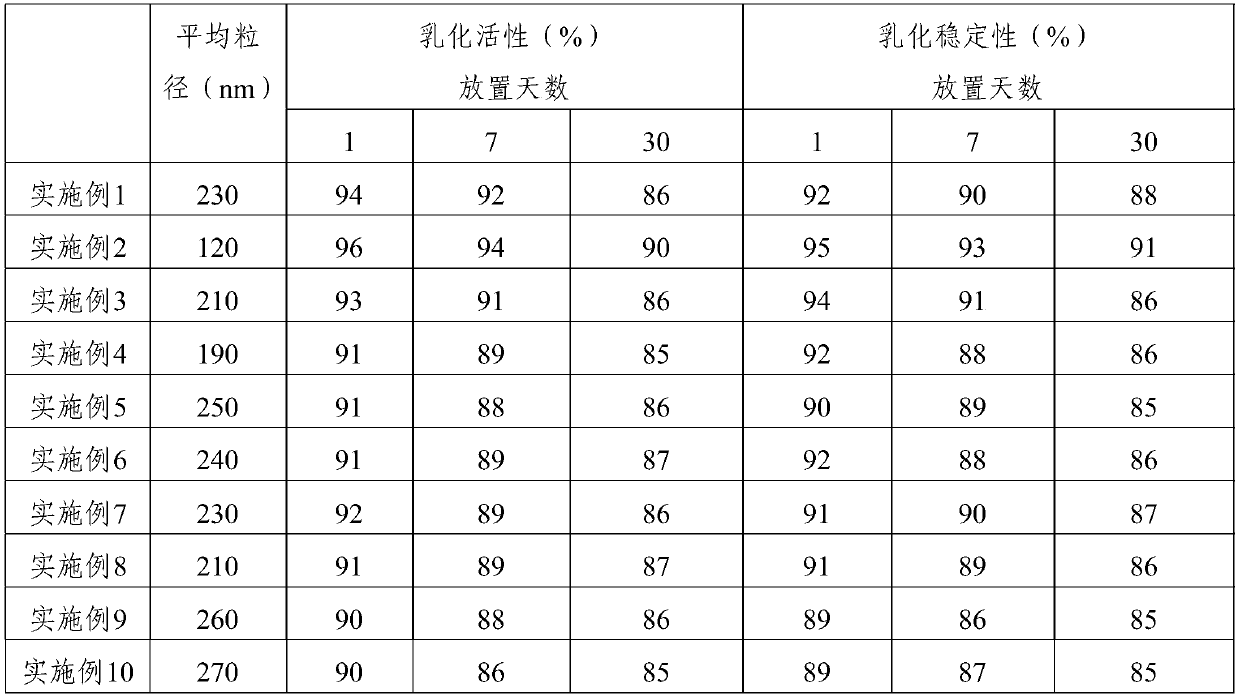

Potato pectin-protein composite emulsified liquid, and preparation method and application thereof

InactiveCN110192643ARich varietyVersatilityCosmetic preparationsToilet preparationsNatural productVegetable oil

The invention provides a potato pectin-protein composite emulsified liquid, and a preparation method and an application thereof. The emulsified liquid is obtained by mixing a potato pectin aqueous solution with a protein and plant oil and homogenizing under high pressure, or by supplementing with at least one of high-pressure micro-jet, nano-ball milling or high hydrostatic technology after homogenizing under high pressure. The obtained emulsified liquid has uniform distribution of water and oil phases, delicate structure, long-term placement without stratification, no addition of other chemical emulsifiers, pure natural products, and good emulsifying activity and emulsifying stability, and can be widely applied in the fields of food, health care products, medicine and cosmetics. The preparation method of the emulsified liquid is simple to operate and prone to industrialized production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

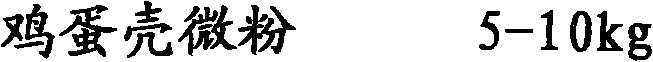

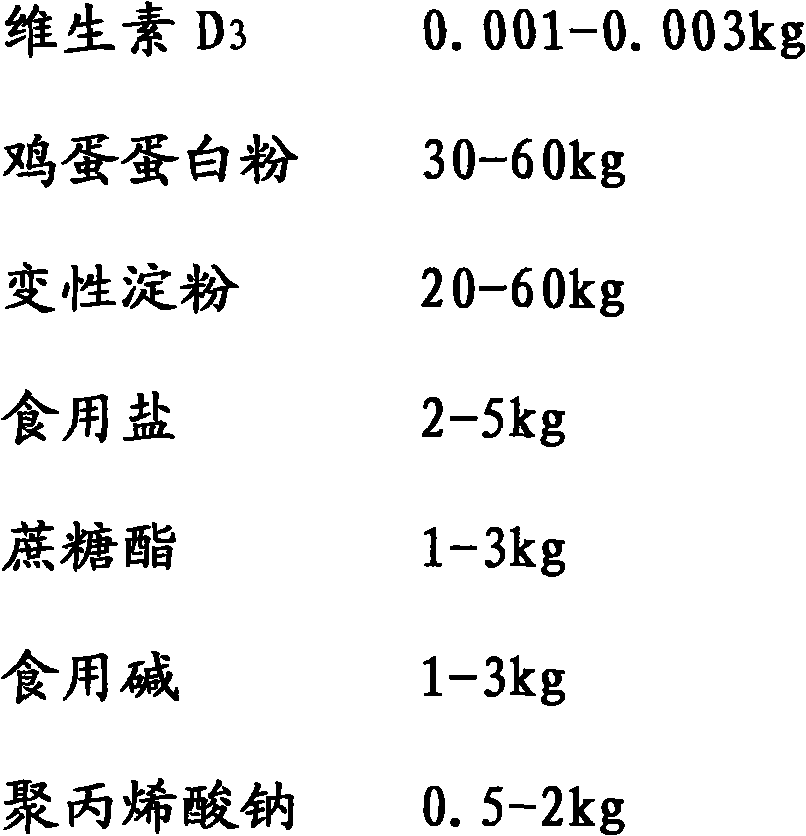

Biological calcium supplement special for flour

InactiveCN103238643APromote absorptionImprove qualityDough treatmentAnimal scienceCalcium supplement

The invention provides a biological calcium supplement special for flour. The main ingredient is egg shell micro-powder, with vitamin D3, egg protein powder and the like. Calcium absorption of human bodies is strengthened, protein nutrition is increased, and quality of the flour can be significantly improved, so that toughness, elasticity and chewiness of noodles and dumpling wrappers can be improved, the noodles and the dumpling wrappers can be prevented from being overcooked, and the soup can be prevented from being thick; and steamed buns and stuffed buns are large in size, fine in organizational structure and good in taste. By the process, a V-shaped powder mixer is utilized, weighting is performed according to the mass proportion, the powders are inputted into the V-shaped powder mixer through a feeder and then mixed for 20 minutes, and the biological calcium supplement special for the flour is obtained.

Owner:HEBEI TONGHE BIOLOGICAL PROD

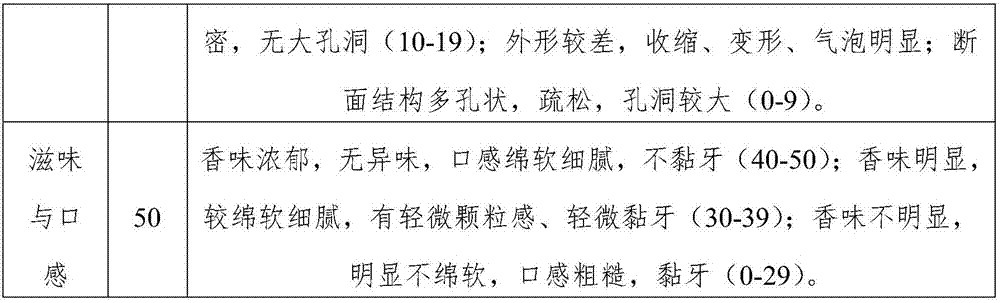

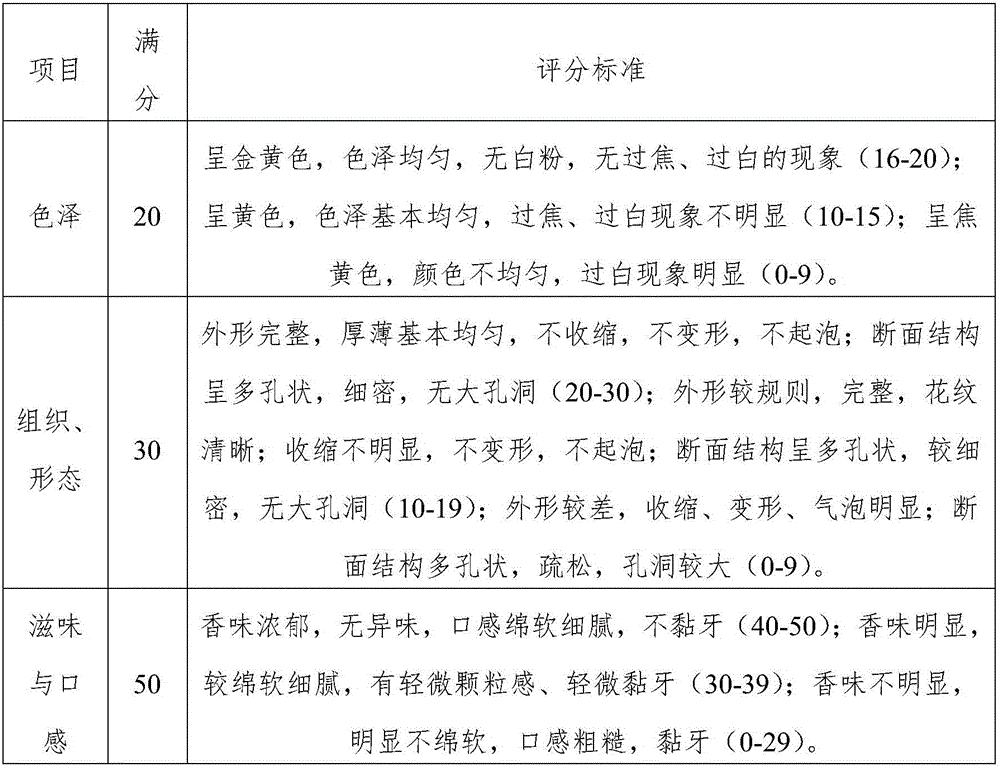

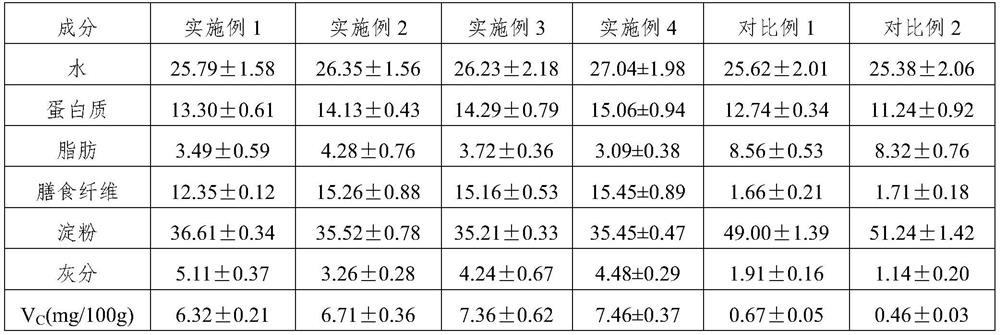

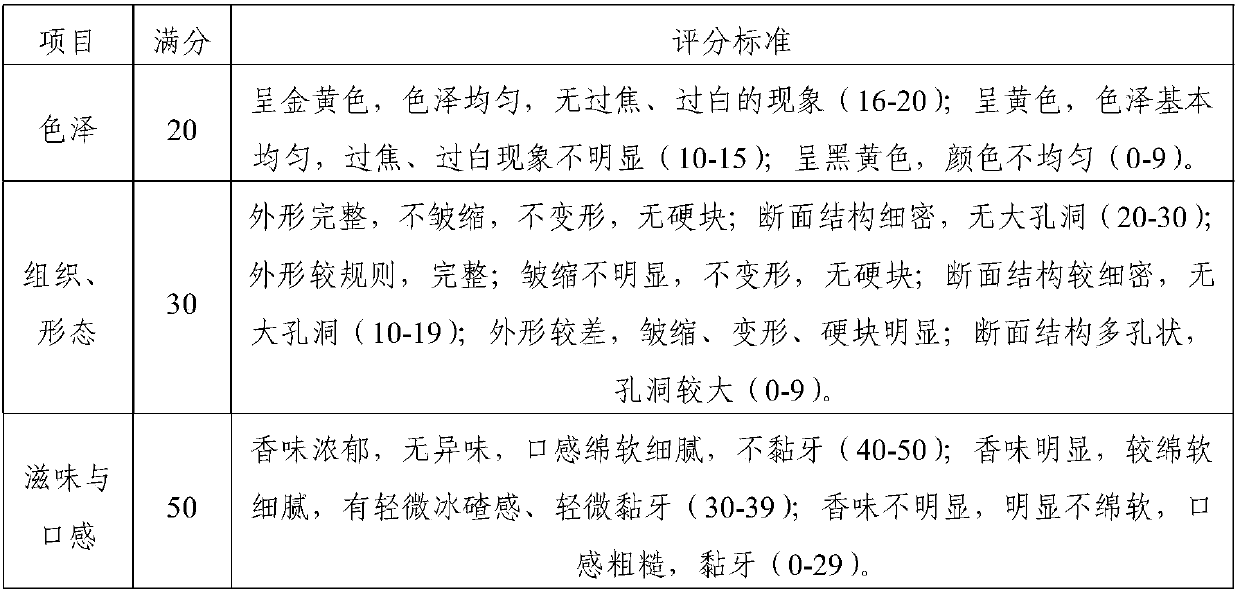

Gluten-free protein whole-potato yogurt cake containing smashed potatoes, and preparation method thereof

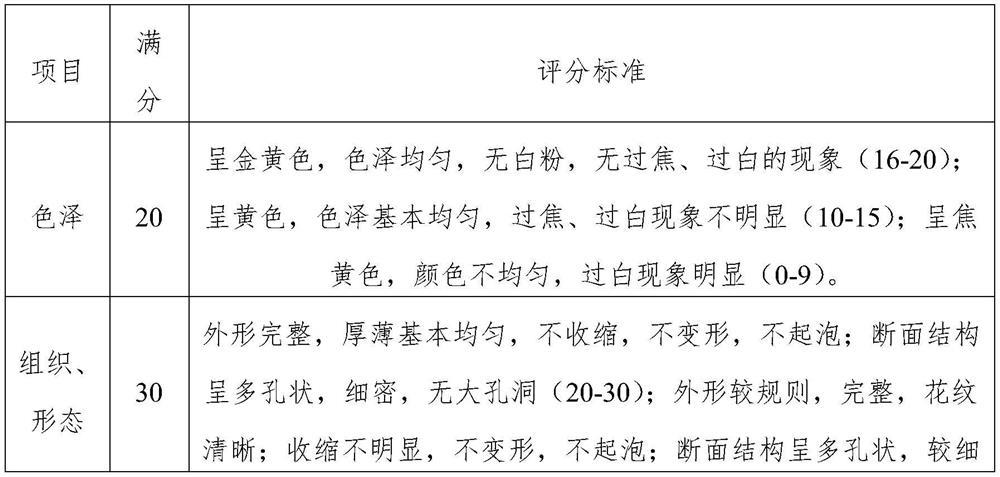

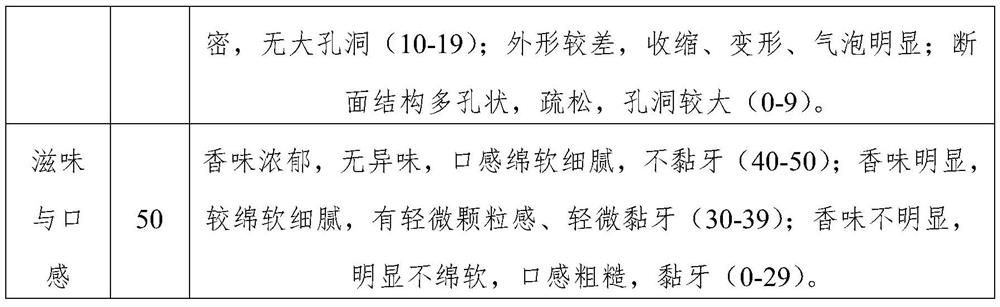

ActiveCN107041531AGolden colorDelicate organizational structureMilk preparationFood preservationWheat hypersensitivityAdditive ingredient

The invention relates to gluten-free protein whole-potato yogurt cake containing smashed potatoes. The gluten-free protein whole-potato yogurt cake containing smashed potatoes is prepared from following raw materials: crude smashed potatoes, high pressure homogenized smashed potatoes, super high pressure-enzyme method modified smashed potatoes, high pressure microfluidic nano smashed potatoes, nonmodified starch, modified starch, milk, a composite bacteria suspension solution, yeast, food gum, plant-sourced polyphenol, protein, sugar, egg, edible oil, and water. The gluten-free protein whole-potato yogurt cake is capable of avoiding the defects of wheat yogurt cake and potato yoghourt cake, contains no gluten, is suitable for people with wheat hypersensitivity or celiac disease to eat, is comprehensive in nutrients, and possesses health care functions.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

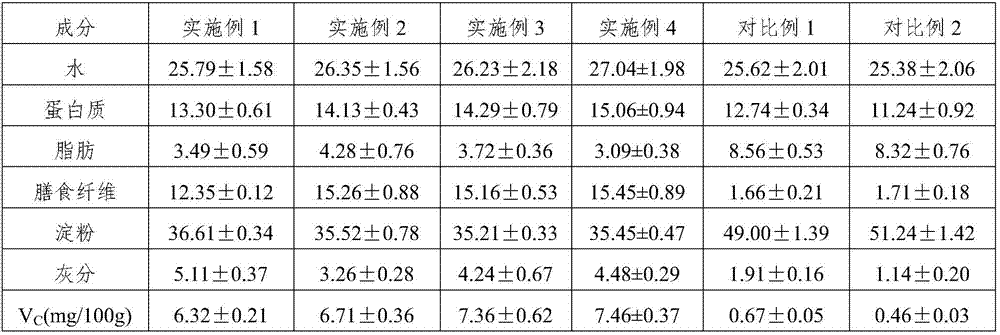

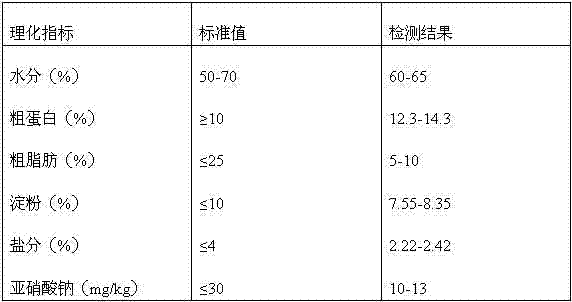

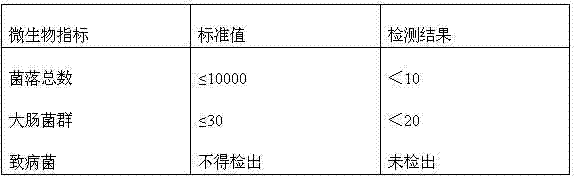

Egg sausage with high elasticity and brittleness and preparation method thereof

InactiveCN108185325ANo eggy smellDelicate organizational structureFood ingredient as thickening agentYeast food ingredientsMonosodium glutamateBiotechnology

The invention discloses an egg sausage with high elasticity and brittleness. The egg sausage comprises the following components in parts by weight: 50 to 80 parts of a fermented egg liquid, 30 to 50 parts of emulsified pig skins, 0.2 to 2 parts of table salt, 2 to 5 parts of white granulated sugar, 0.1 to 0.5 part of monosodium glutamate, 0.5 to 3 parts of ginger juice, 0.5 to 3 parts of soy sauceand 1 to 5 parts of pre-gelatinized starch. The egg sausage has a rich and full egg fragrance and no objectionable odor such as egg fishy smell, and is fine, compact and uniform in organization structure, rich in collagen, high in elasticity and brittleness, and rich and healthy in nutrients.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Making technology of Jinqian steamed bean curd rolls

InactiveCN107821626APure Bean FlavorReduce moisture contentCheese manufactureFood scienceAlkaline waterPasteurization

The invention discloses a making technology of Jinqian steamed bean curd rolls. The making technology comprises steps as follows: S1, preparation of thin bean curd sheets; S2, soaking; S3, pressing; S4, dicing and wrapping; S5, bundling; S6, heating and shaping; S7, removal of cloth and spreading for cooling; S8, packaging, pasteurization, secondary cooling and product obtaining, wherein in the step S2, alkaline water contains water and sodium carbonate, and a weight ratio of sodium carbonate to the thin bean curd sheets in parts is (0.08-0.16):1. The Jinqian steamed bean curd rolls prepared with the technology have the advantages of firm taste and good toughness and elasticity.

Owner:安吉祖名豆制食品有限公司

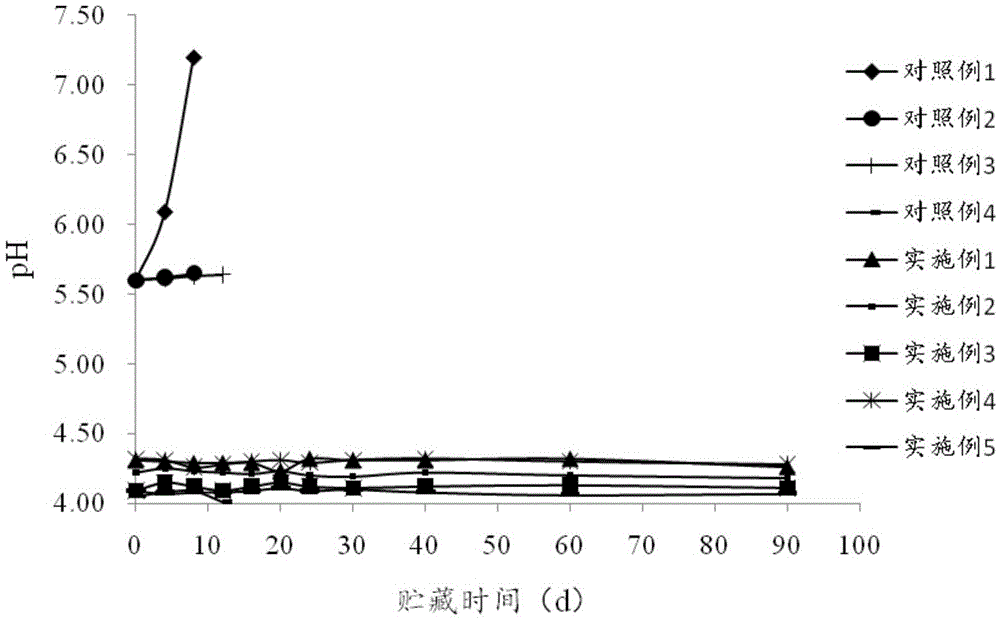

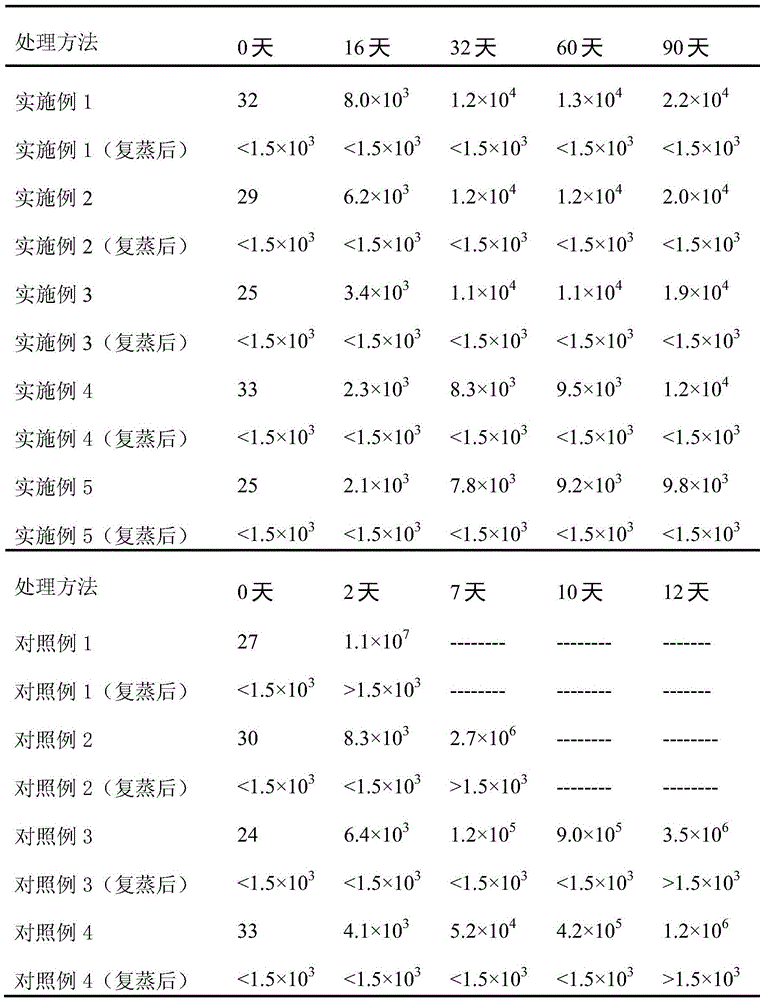

Lactic acid bacteria steamed bread processing and room temperature preservation method

The invention discloses a method for processing and fresh-keeping lactic acid bacteria steamed buns at room temperature, comprising: using lactic acid bacteria fermented dough to prepare lactic acid bacteria steamed buns; package, and put a deoxidizer or a deoxidizer and an alcohol slow-release agent in the sealed package, and then store the sealed packaged lactic acid bacteria steamed buns at room temperature. Utilizing the process of the present invention, the lactic acid bacteria steamed buns produced are rich in flavor, moderate in sourness without irritation, delicate in structure and rich in nutrition, and under normal temperature conditions without adding chemical preservatives, the shelf life of the lactic acid bacteria steamed buns can be as long as 3 months or more , and keep the color, texture and flavor of lactic acid bacteria steamed buns well during storage, and the steamed buns after re-steaming are white and soft, with pleasant wheat aroma and excellent taste. The invention has the advantages of simple process, safety and reliability, low cost and short production period, and fully meets the needs of industrialized production of steamed bread products.

Owner:JIANGNAN UNIV

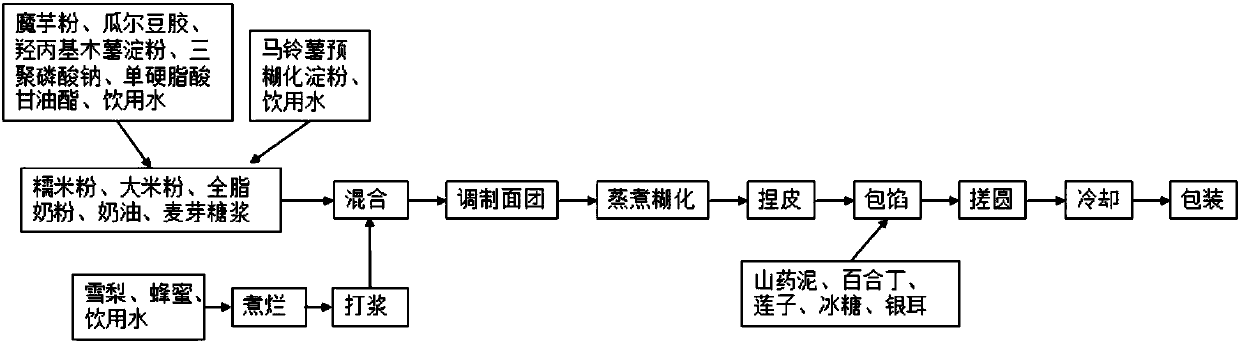

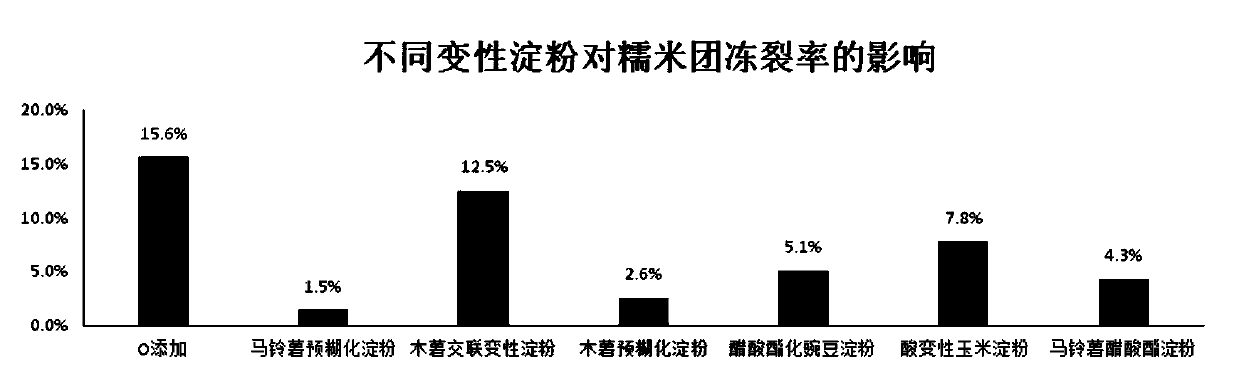

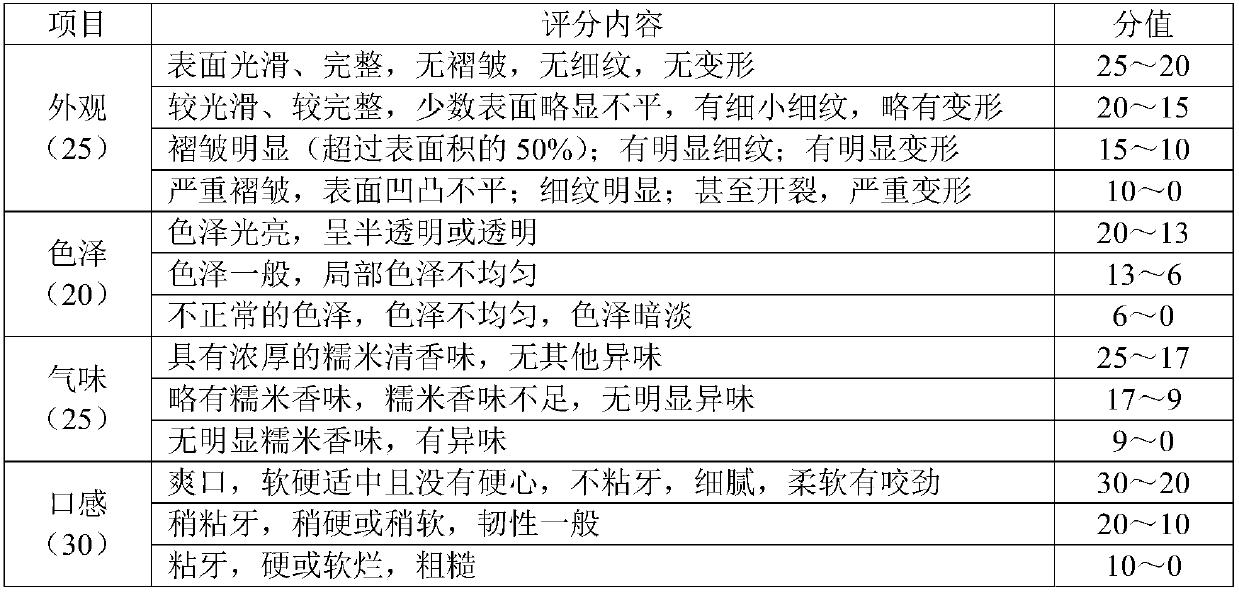

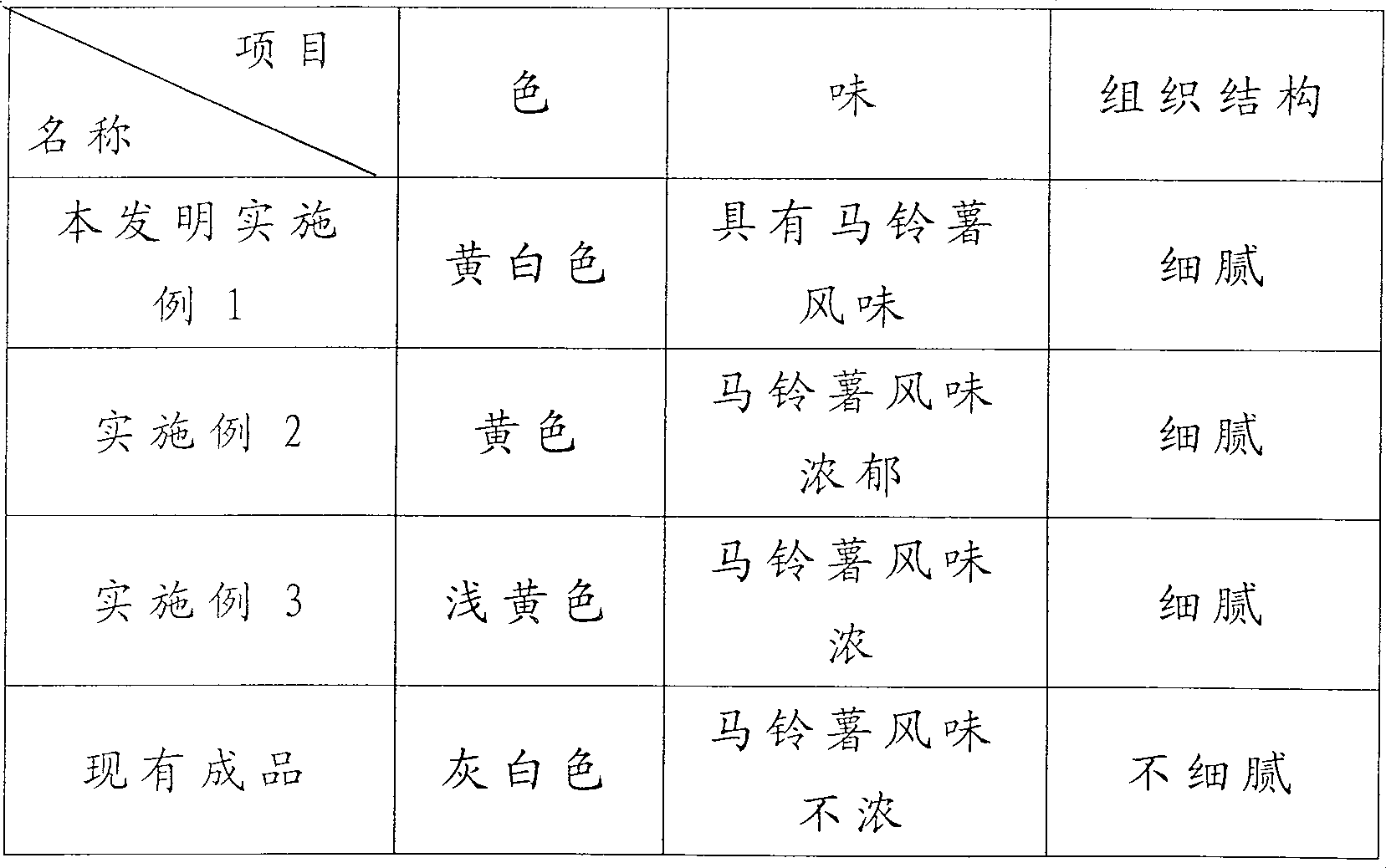

Lung-heat clearing glutinous rice ball and making method thereof

ActiveCN108013334ASimple processNo hard heartFood coatingFood ingredient as mouthfeel improving agentFrost crackFine line

The invention provides a lung-heat clearing glutinous rice ball containing Chinese yam, tremella, snow pear, lotus seed, lily, honey and other health care food materials. The glutinous rice ball is refreshing, neither too hard nor too soft, is free of hard core, non-sticky to teeth, fine in taste, soft and al dente, and has good elasticity, the glutinous rice ball has a smooth and complete surface, is free of fold, fine line and deformation, and has a fine texture structure. And after refrigeration or freezing, the frost crack rate is low, and the product defect rate is low. The invention alsoprovides a making method of the lung-heat clearing glutinous rice ball, the making process is simple, avoids starchy sauce boiling, blanching or other procedures, and is more suitable for enlarged production.

Owner:COFCO GROUP +1

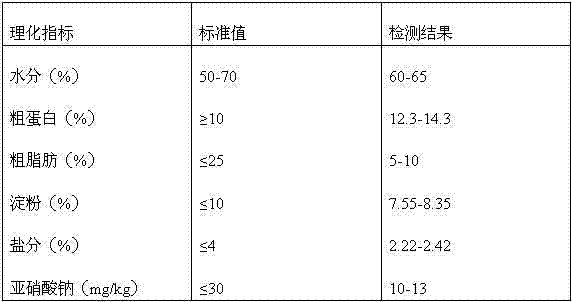

Extruded-puffed potato full-powder food and its processing method

Owner:HUNAN AGRICULTURAL UNIV

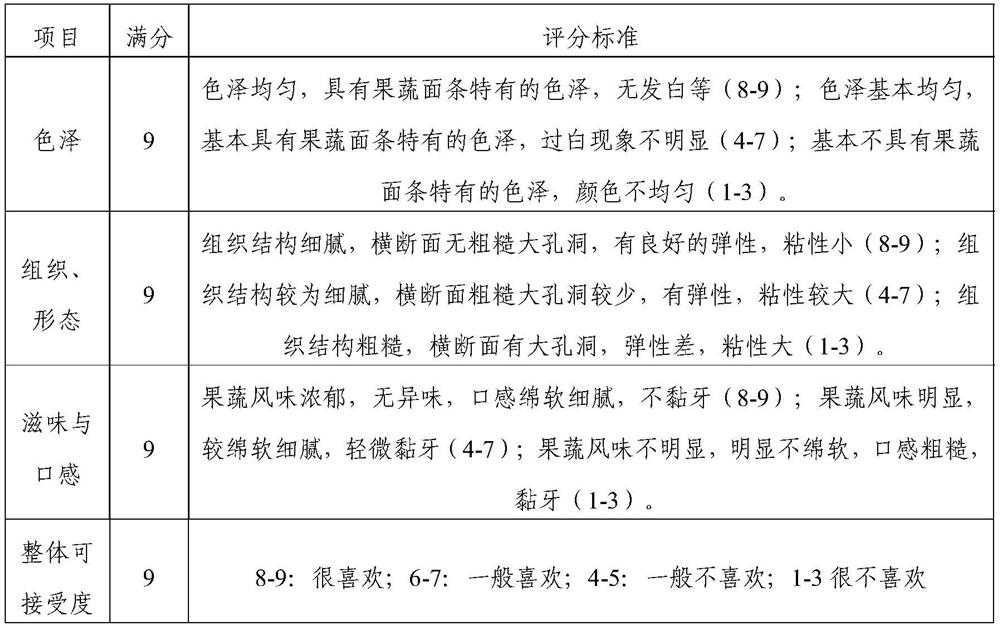

Noodle product based on fruit and vegetable puree and preparation method thereof

InactiveCN112189788AEasy to prepareEasy to operateFood ingredient as mouthfeel improving agentPolysaccharide/gum food ingredientsBiotechnologyPolysaccharide

The invention belongs to the technical field of food processing, and particularly relates to a noodle product based on fruit and vegetable puree and a preparation method thereof. The preparation method comprises the following steps: cooking fruit and vegetable raw materials to obtain cured fruits and vegetables; mashing the cured fruits and vegetables into paste, and adjusting the pH value to 5-9by using an acidic reagent or an alkaline reagent; adding 0.1-1.5 wt% of salt into the fruit and vegetable puree of which the pH value is adjusted; and putting 10~70 parts by weight of the fruit and vegetable puree added with salt into a hammering device, adding 20~60 parts by weight of starch, 0.5~10 parts by weight of protein and 0.5~10 parts by weight of polysaccharide, uniformly mixing, hammering to obtain a composite fruit and vegetable puree ball, putting the composite fruit and vegetable puree ball into a noodle maker, extruding, boiling, forming and cooling to obtain the noodle productbased on fruit and vegetable puree. According to the invention, the noodle product based on fruit and vegetable puree has the advantages of high tensile strength, good color and luster, low viscosity, good taste and rich nutrition, and is very conductive to industrial production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Preparation method of flavored dried bean curds

The present invention discloses a preparation method of flavored dried bean curds and relates to the technical field of dried bean curds. The preparation method comprises the following steps: (1) slurry grinding; (2) boiling; (3) curdling; (4) shaping; (5) pickling; and (6) packaging. The prepared flavored dried bean curds have more flavor materials, particularly can reduce a content of a beany flavor alcoholic substance, increases contents of fragrant aldehydes, ketones and other substances, and has a caramel aroma.

Owner:HEFEI FENGLUOHE BEAN FOOD

Sweet cream and its preparation method

ActiveCN103815050BImprove fatty acid profileImprove stabilityEdible oils/fats production/working-upBeta-CaroteneGlycerol

The invention discloses sweet cream and its preparation method, and the sweet cream is prepared from the following raw materials by weight: 30.0-60.0% of base oil, 8.0-15.0% of a sweetening agent, 0.1-0.5% of a thickening agent, 5.0-15.0% of a filler, 0.5-2.0% of glycerol, 0.1-0.5% of an aqueous phase emulsifier, 0.2-0.5% of an oil phase emulsion, 0.1-0.3% of an edible essence, 0.0005-0.0015% of beta carotene and the balance of water. The sweet cream has good high temperature stability, may not precipitate by 30min of high temperature cooking at 100 DEG C, may not sugar by 7 cycles of repeated temperature fluctuations with each cycle comprising 12h of placing at 5 DEG C and 12h of placing at 20 DEG C, and has a stable organizational structure.

Owner:广州市雅禾生物科技有限公司

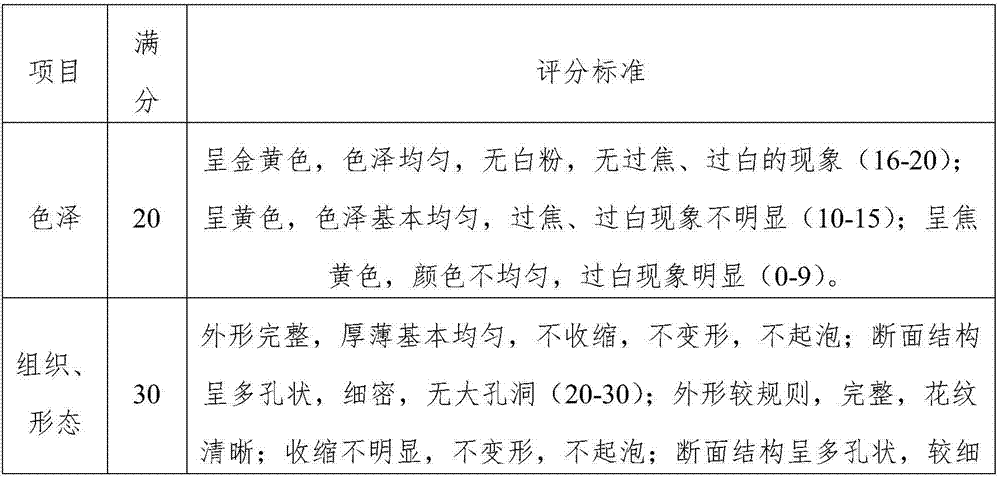

High-fiber yoghourt cakes rich in potato residues and preparation method of high-fiber yoghourt cakes rich in potato residues

InactiveCN107173408AGolden colorDelicate organizational structureDough treatmentModified nutritive productsChemistryEdible oil

The invention relates to high-fiber yoghourt cakes rich in potato residues. The high-fiber yoghourt cakes rich in potato residues are prepared from raw materials of potato residue raw powder, potato residue high-pressure homogenizing powder, potato residue superhigh pressure-enzymolysis modified powder, wheat flour, starch, milk, compound microbe suspension, yeast, food gum, plant-derived polyphenol, protein, sugar, eggs, edible oil and water. According to the high-fiber yoghourt cakes rich in potato residues provided by the invention, defects existing in wheat yoghourt cakes and defects existing in potato yoghourt cakes are overcome, the high-fiber yoghourt cakes rich in potato residues are comprehensive in nutrient components, good in mouth feel and low in cost and have health-care efficacy, and industrialized popularization is easy to realize.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

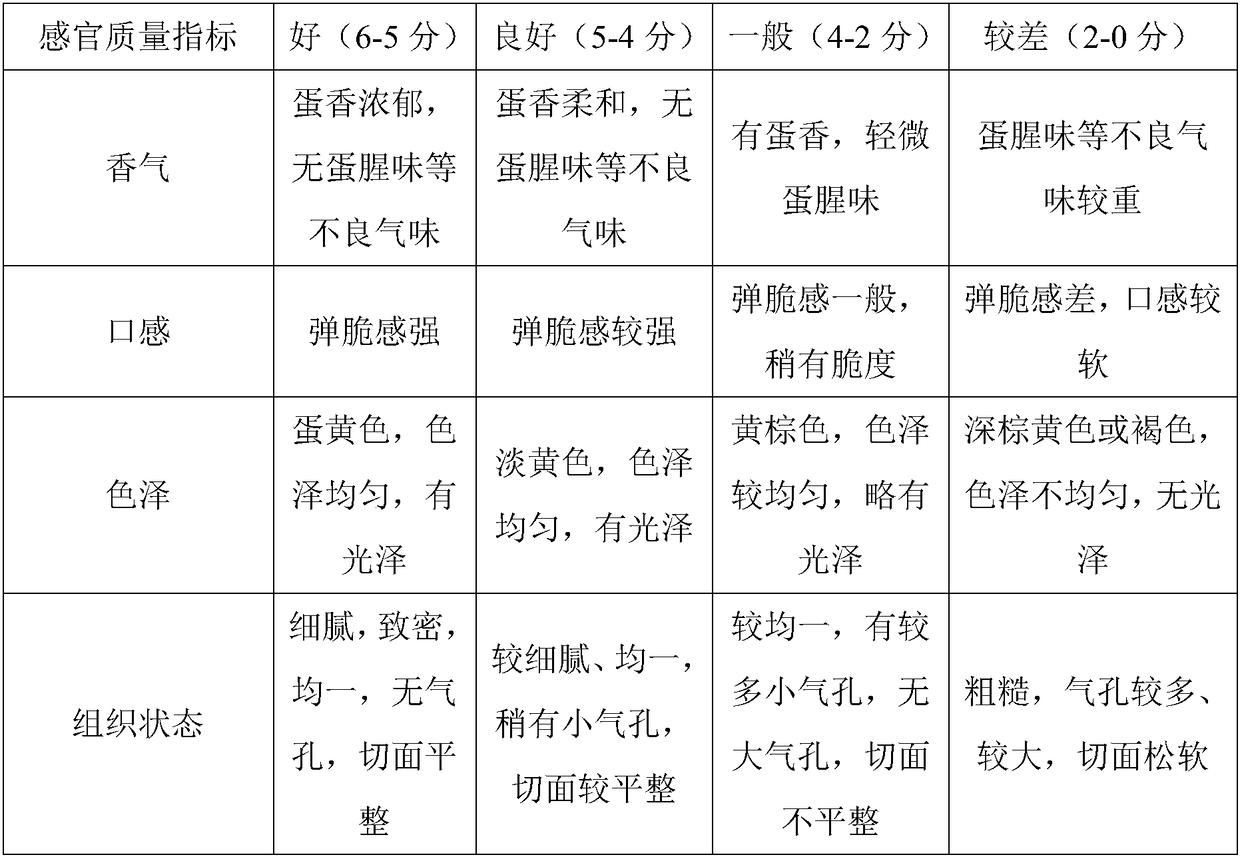

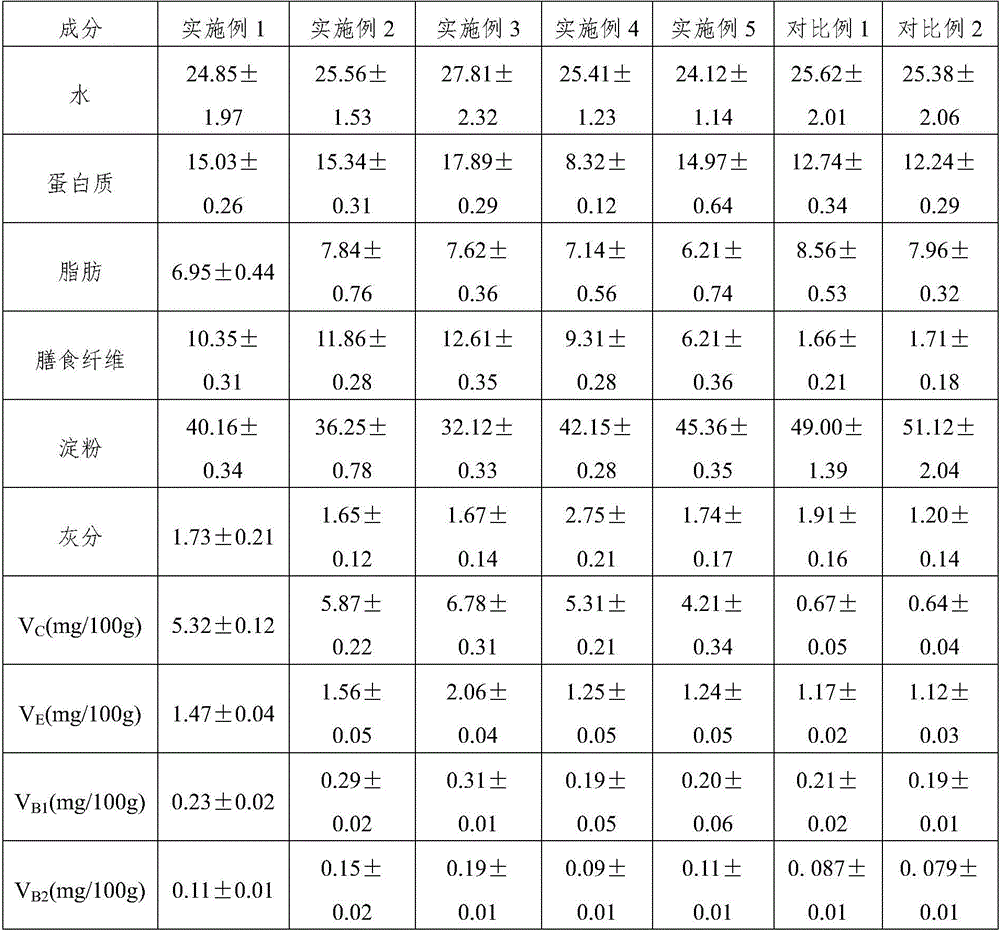

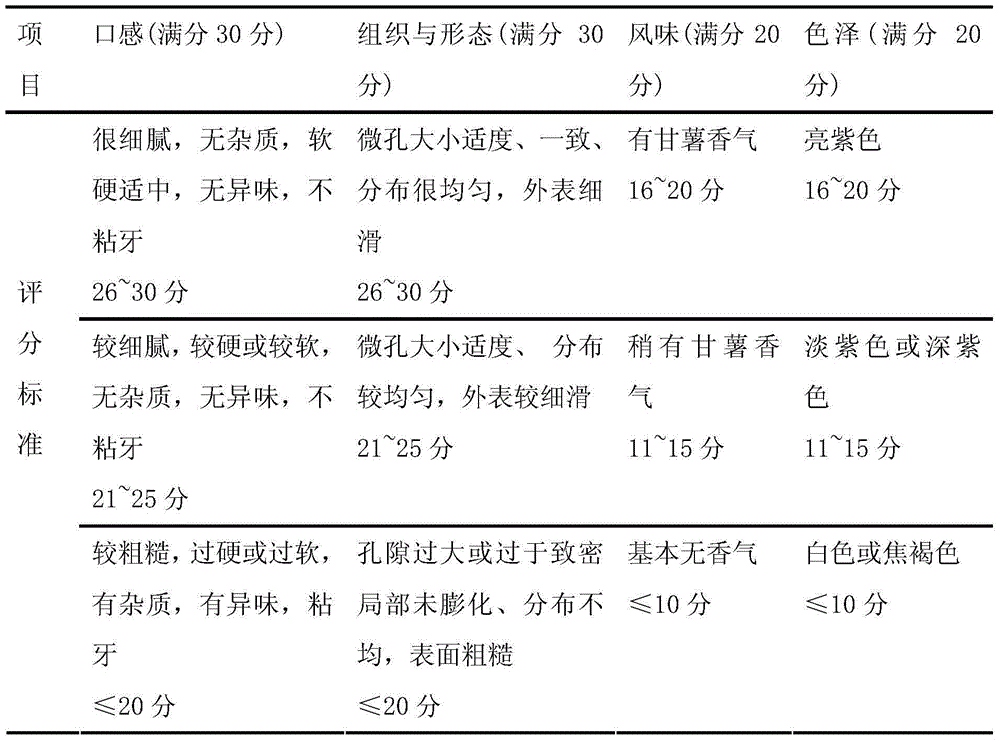

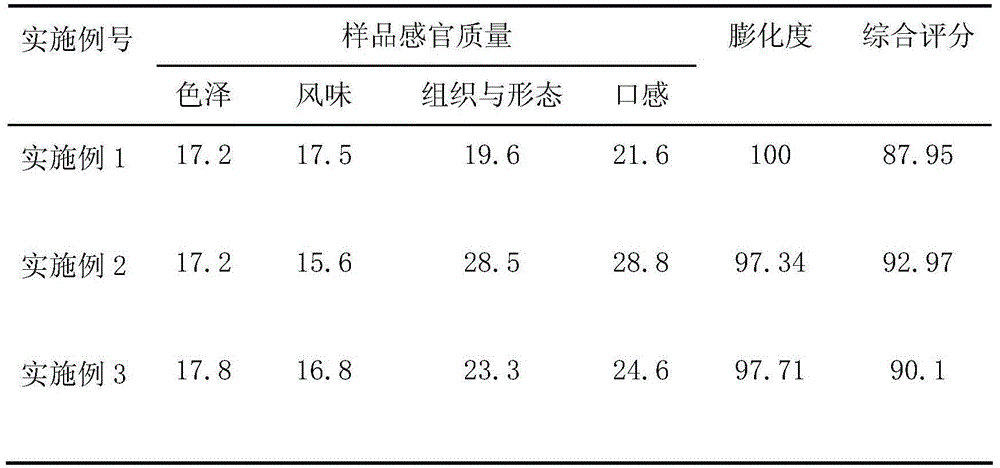

Preparation method for purple potato puffed food

InactiveCN105011061ABroaden the field of useNatural colorFood shapingFood preparationPolyphenolCitric acid

A preparation method for purple potato puffed food includes the step that a base material, salt and a composite additive are mixed evenly, humidified by adding water, extruded and puffed to obtain the puffed food. The base material is composed of 10-40% of whole purple potato flour and 60-90% of wheat flour by weight, the adding quantity of the salt is 7-9% of the weight of the base material, the adding quantity of the composite additive is 1.1-1.3% of the weight of the base material, and the water content of the materials is 10-12% after the materials are humidified by adding the water. In the process of preparing the whole purple potato flour, while crushed into potato particles, purple potatoes are sprayed with a color-protecting solution formed by mixing citric acid and disodium hydrogen phosphate; the potato particles obtained after crushing are fast immersed in the color-protecting solution, spun dry at the rotating speed of 3000-4500 r / min in a centrifugal mode, and blown dry at the temperature of 30 DEG C-45 DEG C until the water content of the potato particles is 8-9%, and finally the potato particles and tea polyphenol are mixed, crushed and screened to obtain the purple potato puffed food. The purple potato puffed food has natural color and luster, and the nutrition and health care value of the purple potato puffed food is improved as the purple potato flour and the tea polyphenol are added.

Owner:HUNAN AGRICULTURAL UNIV +1

Collagen-rich spicy Sichuan style granule sausage

ActiveCN103750381ACrunchyRich structureFood mechanical treatmentFood ingredient as taste affecting agentMonosodium glutamateBoiled skin

The invention provides a collagen-rich spicy Sichuan style granule sausage. According to a formula, the granule sausage is characterized by comprising the following raw materials in parts by mass: 50-80 parts of pork, 200-500 parts of chicken breast, 20-30 parts of soybean protein, 5-10 parts of edible salt, 1-5 parts of a water retention agent, 0.001-0.003 part of TG (transglutaminase), 0.01-0.05 part of sodium nitrite, 0.01-0.05 part of cochineal, 50-80 parts of chicken gristle, 20-50 parts of boiled skin granules, 0.5-1 part of monosodium glutamate, 0.5-1 part of potassium sorbate, 20-50 parts of starch, 10-20 parts of white granulated sugar, 0.8-1.2 parts of white pepper powder, 1-1.5 parts of pepper powder, 3-6 parts of chili powder, 0.2-0.6 part of aroma spicy-hot oil and 50-80 parts of ice water. The collagen-rich spicy Sichuan style granule sausage is chewy, is crisp in taste, is rich in collagen and has special Sichuan spicy-hot flavors.

Owner:SICHUAN GAOJIN FOOD CO LTD

Production process of goose liver paste

InactiveCN101828688BTo achieve a lubricating feelingReduce tensionFood preparationAdditive ingredientWater cooling

The invention relates to a production process of foie gras, comprising the following steps of: putting goose livers into a vacuum cut mixer to roughly cut after clearing and cleaning; putting the goose livers and ingredients into the vacuum cut mixer again to finely cut; cutting and mixing the goose livers into foie gras; and finally, canning, sealing in vacuum, sterilizing at high temperature, cooling by spraying water, entering a constant-temperature tank and canning at the temperature of 37 DEG C sequentially. The invention has simple process and low production cost and can effectively eliminate fishy smell and peculiar smell in the foie gras by cutting and mixing the goose livers at high temperature and high speed, and the foie gras has fine mouthfeel and just melts in the mouth.

Owner:天津宝鹅园鹅业发展有限公司

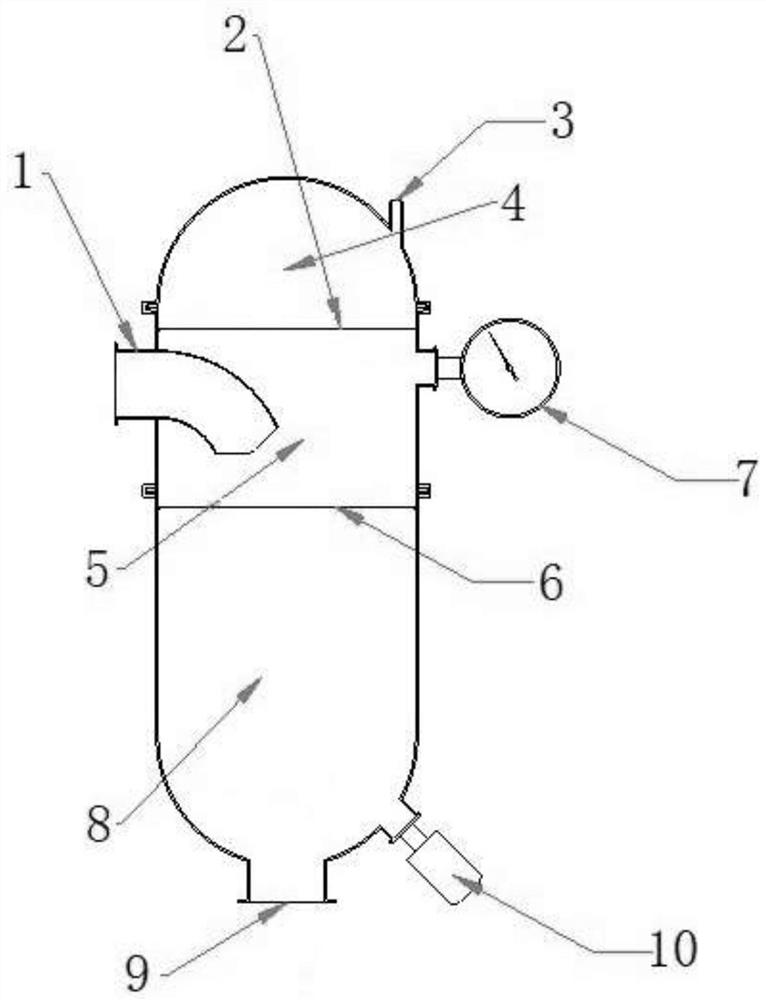

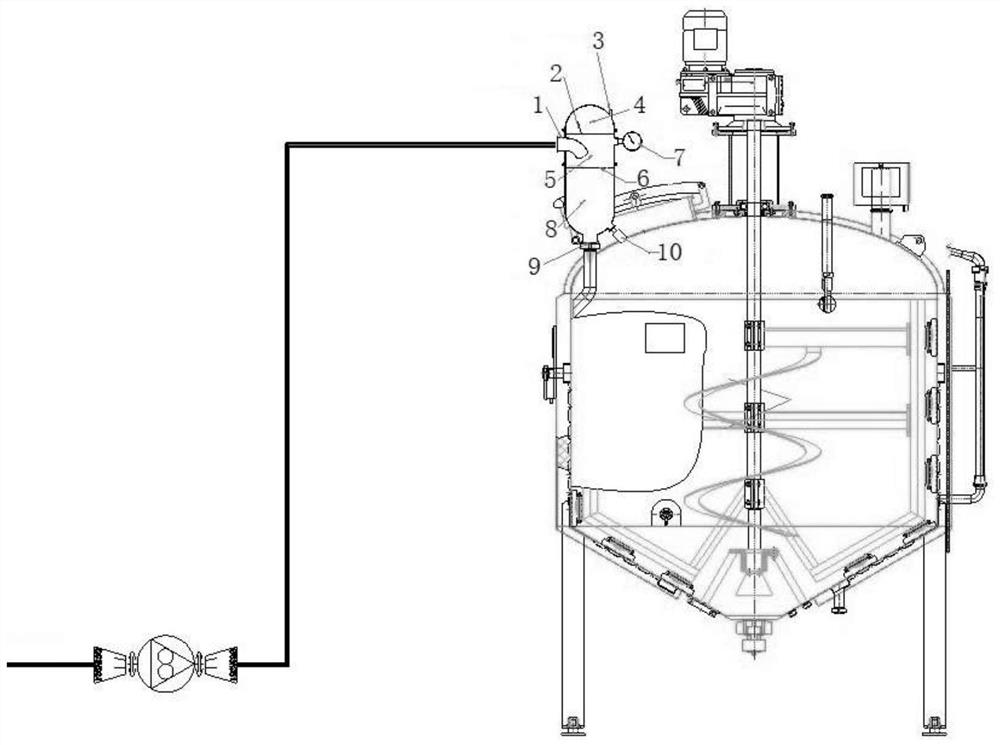

On-line bubble removing device and method for cream production line

PendingCN112021411AReduce the presence of air bubblesRelieve pressureMilk treatmentOther dairy technologyThermodynamicsProcess engineering

The invention discloses an on-line bubble removing device and method for a cream production line. The device comprises a degassing cavity, an aeration cavity and a material cavity which are sequentially arranged from top to bottom, wherein an upper pore plate is arranged between the degassing cavity and the aeration cavity; a lower pore plate is arranged between the aeration cavity and the material cavity; the degassing cavity is provided with a vacuum system interface; a material spray pipe is arranged in the aeration cavity, and the inlet end of the material spray pipe extends to the outsideof the on-line bubble removal device; and a material outlet is formed in the material cavity. The method comprises the following steps that materials in production equipment are conveyed into the aeration cavity through a high-pressure water pump, the materials are sprayed on the lower pore plate, and bubbles in the materials collide with the lower pore plate to be broken; the degassed materialsenter the material cavity, and gas in the materials enters the degassing cavity under the action of negative pressure; and a vacuumizing device vacuumizes the degassing cavity, and the gas is vacuumized and discharged out of the degassing cavity. The on-line bubble removing device and the method have the beneficial effects that bubbles in cream are reduced, the product quality is improved, and thewhipped cream is finer, smoother and better in stability.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

A method for inducing and improving surimi gel by adding gluconolactone and products processed by the method

ActiveCN104382097BHigh strengthIncrease elasticityFood scienceUltimate tensile strengthFish products

The invention relates to a low-temperature acid-induced minced fish product with high gel strength and a production method of the minced fish product. The production method comprises the steps of unfreezing, chopping via air, chopping via salt, chopping mixture and forming. The gel is induced by acid by slowing hydrolyzing glucolactone and acting on the minced fish protein; compared with the gel strength of the conventional hot gel, the gel strength is improved by over 140%; the texture structure is relatively fine and smooth; the elasticity is improved by over 10%; the whiteness is increased by over 12%; the low-temperature acid-induced minced fish product with high gel strength is a novel instant refrigerated low-temperature acid-induced minced fish product.

Owner:FUJIAN ANJOY FOODS CO LTD +4

Gluten-free whole potato yogurt cake containing potato mash and preparation method thereof

ActiveCN107041531BGolden colorDelicate organizational structureMilk preparationFood preservationBiotechnologyFree protein

The invention relates to a gluten-free whole potato yogurt cake containing mashed potatoes, which is prepared from raw materials comprising: coarse mashed potatoes, high-pressure homogeneous mashed potatoes, ultra-high pressure-enzymatically modified mashed potatoes, and high-pressure micro-jet Nano potato mash, non-modified starch, modified starch, milk, complex bacterial suspension, yeast, food glue, plant-derived polyphenols, protein, sugar, eggs, edible oil and water. The gluten-free whole potato yogurt cake provided by the invention overcomes the defects of wheat yogurt cake and potato yogurt cake, does not contain gluten, is suitable for people allergic to wheat or celiac disease patients, has comprehensive nutritional components, and has health care functions.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

A Collagen-rich Sichuan Spicy Granular Sausage

ActiveCN103750381BCrunchyRich structureFood mechanical treatmentFood ingredient as taste affecting agentBiotechnologyMonosodium glutamate

The invention provides a collagen-rich spicy Sichuan style granule sausage. According to a formula, the granule sausage is characterized by comprising the following raw materials in parts by mass: 50-80 parts of pork, 200-500 parts of chicken breast, 20-30 parts of soybean protein, 5-10 parts of edible salt, 1-5 parts of a water retention agent, 0.001-0.003 part of TG (transglutaminase), 0.01-0.05 part of sodium nitrite, 0.01-0.05 part of cochineal, 50-80 parts of chicken gristle, 20-50 parts of boiled skin granules, 0.5-1 part of monosodium glutamate, 0.5-1 part of potassium sorbate, 20-50 parts of starch, 10-20 parts of white granulated sugar, 0.8-1.2 parts of white pepper powder, 1-1.5 parts of pepper powder, 3-6 parts of chili powder, 0.2-0.6 part of aroma spicy-hot oil and 50-80 parts of ice water. The collagen-rich spicy Sichuan style granule sausage is chewy, is crisp in taste, is rich in collagen and has special Sichuan spicy-hot flavors.

Owner:SICHUAN GAOJIN FOOD CO LTD

Corn straw food and making method thereof

InactiveCN105211730AFull of nutritionDelicate organizational structureFood preparationBiotechnologyCorn flour

The invention provides corn straw food and a making method thereof, and belongs to the technical field of agricultural product processing. The food is made from 20-80 parts of corn straw, 0-20 parts of corn flour, 5-20 parts of starch, 1-5 parts of white granulated sugar, 1-7 parts of whole milk powder, 1-2 parts of salt and 1-20 parts of water. By smashing corn straw, adding water, conducting fermenting through cellulose, conducting mixing and stirring and conducting double-screw extruding and expelling, the corn straw food is made; the extruded and expelled corn straw food produced through the process is rich in nutrient, fine and smooth in tissue structure, good in color and luster, rich in flavor, rich in aroma, simple in preparation process, mild in condition and beneficial to industrial production.

Owner:陈启芬

A kind of fermented chili cheese and preparation method thereof

The invention relates to a fermented pimento cheese and a preparation method thereof. The fermented pimento cheese is prepared from following raw materials and auxiliary materials by weight percent: 1.5-4.5% of fermented pepper particles, 94.0-96.0% of milk cured particles, and 1.5-2.5% of salt. The preparation method comprises following steps of adding the fermented pepper particles without seeds and kernels into the milk cured particles without whey, mixing uniformly to obtain a mixture, filling a die with the mixture, squeezing, demoulding, packaging, and fermenting till maturing so as to obtain the fermented pimento cheese. The fermented pimento cheese has the bright pepper color, the high grade appearance, and the uniform and delicate texture, has the low possibility of being contaminated by bacteria, and has the fresh, cool and soft sour-hot flavor.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION BUFFALO INST

Frozen ready-to-eat roasted vegetables and fruits and making method thereof

ActiveCN108030008AEasy to prepareEasy to operateFood freezingFood thermal treatmentFood additiveReady to eat

The invention relates to the field of food processing, in particular to frozen ready-to-eat roasted vegetables and fruits and a making method thereof. The making method comprises the following steps of 1) roasting raw materials of vegetables and fruits for being processed under 200-280 DEG C for 20-80min; and 2) performing alternate refrigerating cycle treatment on the product obtained in the step1) within the range of minus 20 DEG C-minus 80 DEG C for 1-4 times, so as to obtain the frozen ready-to-eat roasted vegetables and fruits. The making method disclosed by the invention has the following notable advantages that the frozen ready-to-eat roasted vegetables and fruits have the original flavor of the vegetables and fruits, are artistic in color and luster, fine and smooth in tissue structure of the obtained food, and good in mouth feel; the original structure and the original shape of the vegetables and fruits are reserved; in the processing course, no food additive is added, so that nutrient components of the vegetables and fruits are completely reserved; the quality guarantee period is long, so that the requirement that consumers eat vegetables and fruits in four seasons can be met; the frozen ready-to-eat roasted vegetables and fruits are rich in vitamin C, beta-carotene and polyphenols substances, and have high antioxidant activity, so that the frozen ready-to-eat roasted vegetables and fruits have certain effects on promoting body health; and the making method is easy to operate, and industrial production is easy.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

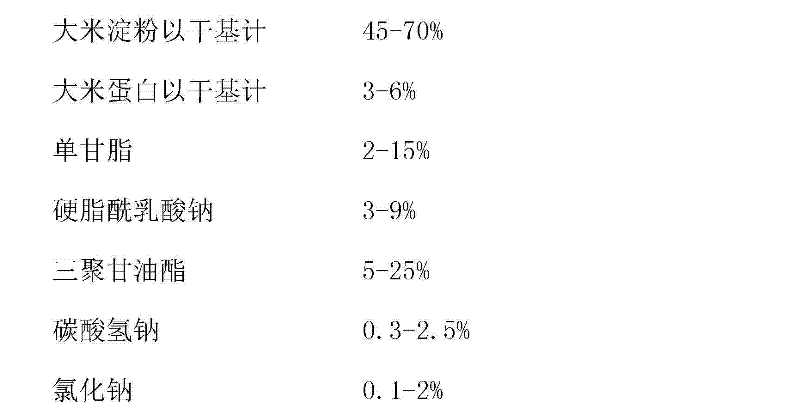

Edible foaming agent produced from rice starch, rice protein and emulsifier and production method thereof

InactiveCN102177935BIncrease the proportionHigh densityDough treatmentBiotechnologySodium bicarbonate

The invention discloses an edible foaming agent produced from rice starch, rice protein and an emulsifier and a production method thereof. The edible foaming agent is prepared from the rice starch, the rice protein, glycerin monostearate (GSM), sodium stearoyl lactylate, tripolyglycerol monostearates, sodium bicarbonate and sodium chloride. The edible foaming agent has the advantage of available raw materials and convenience in production.

Owner:凯爱瑞食品(南通)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com