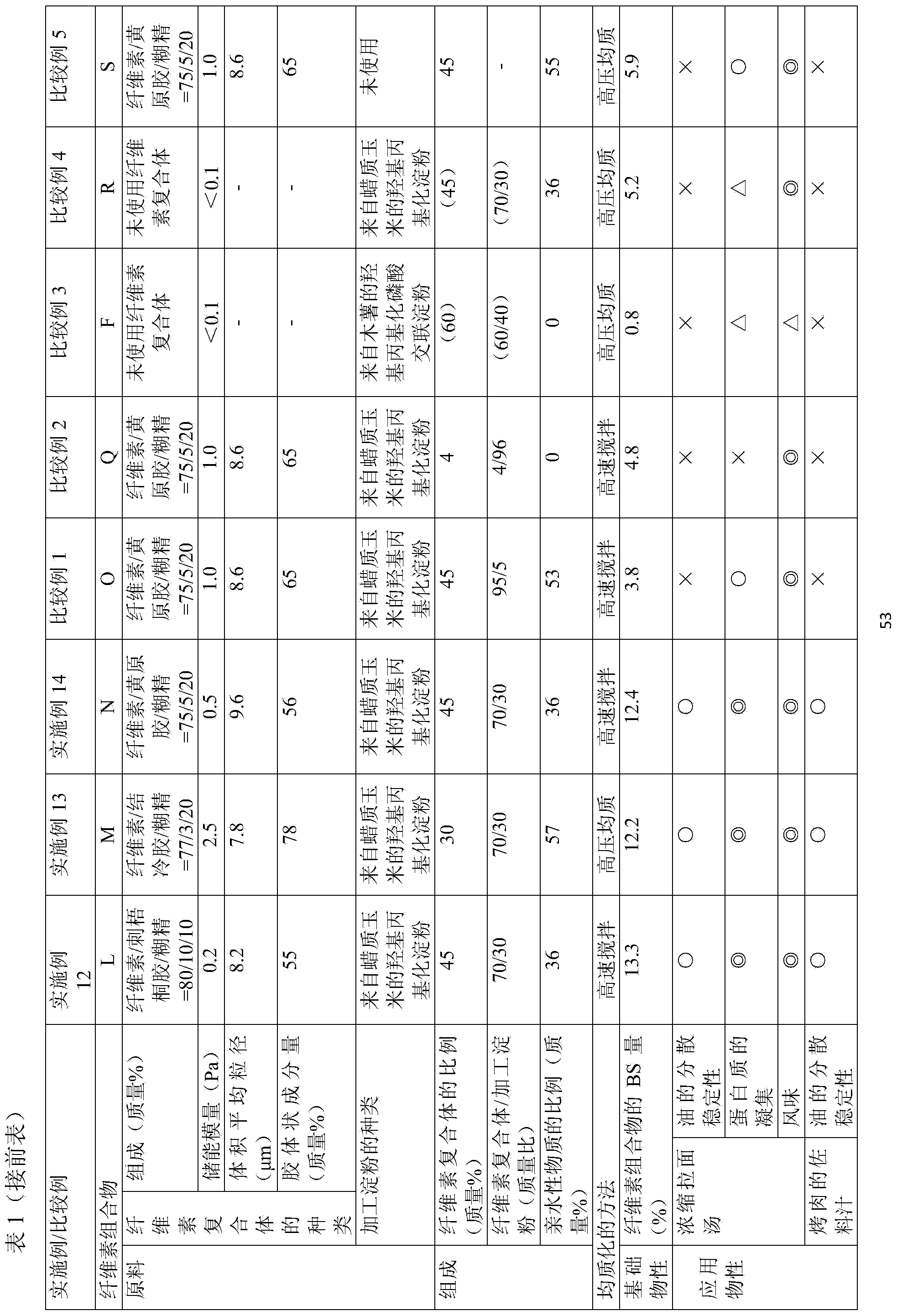

Patents

Literature

251results about How to "Crunchy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

Healthcare potato chip and processing method thereof

The invention discloses a healthcare potato chip and a processing method of the healthcare potato chip. The healthcare potato chip is composed of the following raw materials in percentage by weight: 72-85% of potato, 5-10% of glutinous rice flour, 2-5% of palm oil, 1-3% of Chinese herbal medicine, 0.5-2% of a condiment and the balance of water, wherein the Chinese herbal medicine is composed of 8-15 parts of liquorice, 5-11 parts of peppermint, 1-3 parts of corktree and 3-8 parts of chrysanthemum, and the Chinese herbal medicine is processed by steps of treating the raw materials, hot ironing and freezing, preparing additives, dipping, coating lining, microwave roasting and cooling, packaging, and the like. The healthcare potato chip has the characteristics of good taste, low heat and green health, the microwave roasting procedure is used for saving oil consumption and reducing the production cost, and the oil content of the chip is low, thereby capable of being stored for a long time.

Owner:王惠莹

Angelica keiskei flavor calcium fruit biscuit

InactiveCN105901088AEffectively removes bitternessEliminate bitternessDough treatmentBakery productsPectinaseNutritive values

The invention discloses an angelica keiskei flavor calcium fruit biscuit. Angelica keiskei and calcium fruit are taken as raw materials, and meanwhile tortoise shells and radix polygonati officinalis are added, so that the angelica keiskei flavor calcium fruit biscuit is prepared. The nutritive value of angelica keiskei and calcium fruit are sufficiently utilized, and the angelica keiskei and calcium fruit are mutually compatible with traditional Chinese medicine and has synergistic interaction, so that the biscuit has the effects of tonifying liver, benefitting kidney and cooling blood to stop bleeding. According to the angelica keiskei flavor calcium fruit biscuit, the angelica keiskei is firstly fermented by liqueur koji, and a mellow flavor is added into the finished product; combined enzymolysis is carried out on the raw material calcium fruit by using cellulose, hemicellulase and pectinase, so that the bitter taste of the calcium fruit is effectively removed; the prepared finished product is crisp and fragrant in taste and unique in flavor, and is suitable for people of all ages; the healthcare function of the biscuit is outstanding, and the discomfort of people with dizziness, swelling and eye pain can be obviously improved after long-term eating. The biscuit is simple in manufacturing technology, easy to realize, convenient to carry and wide in market prospect, and large-scale production can be realized.

Owner:叶群

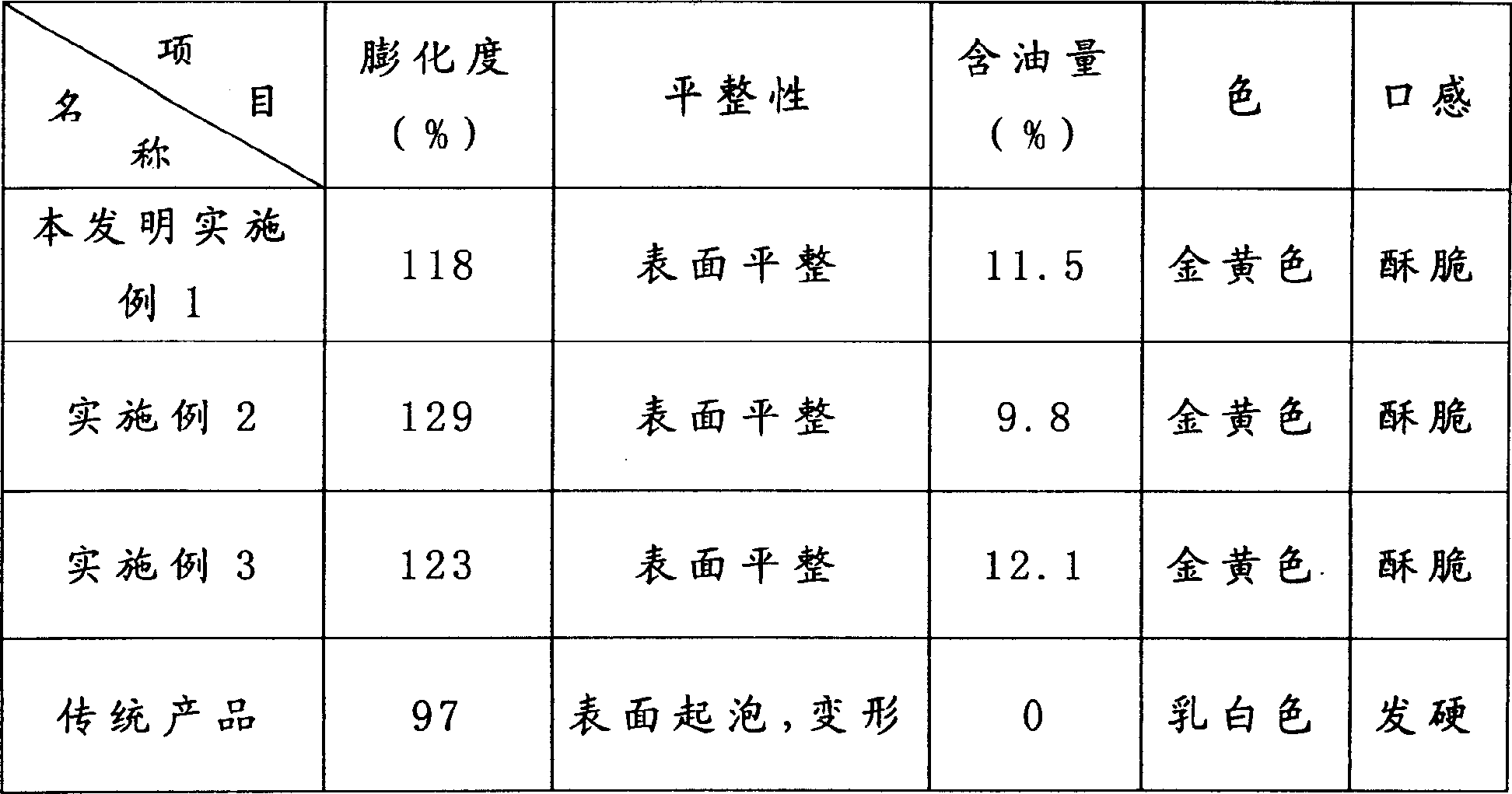

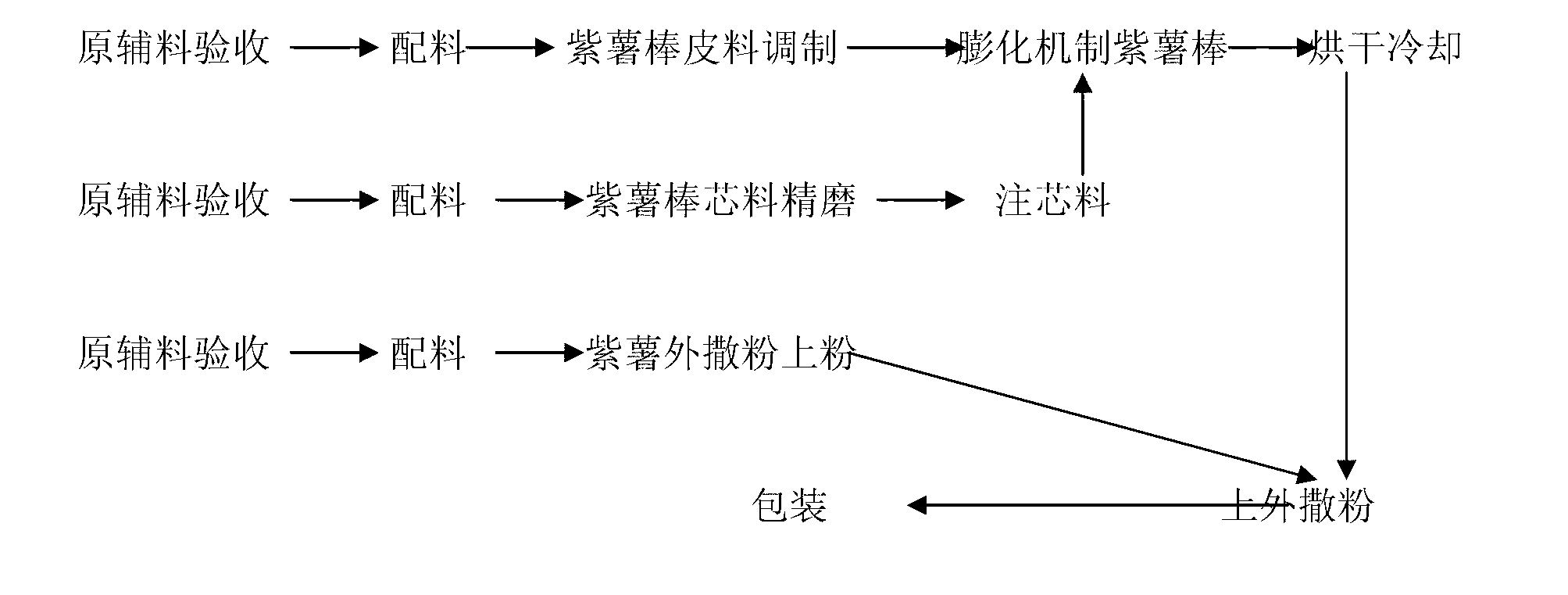

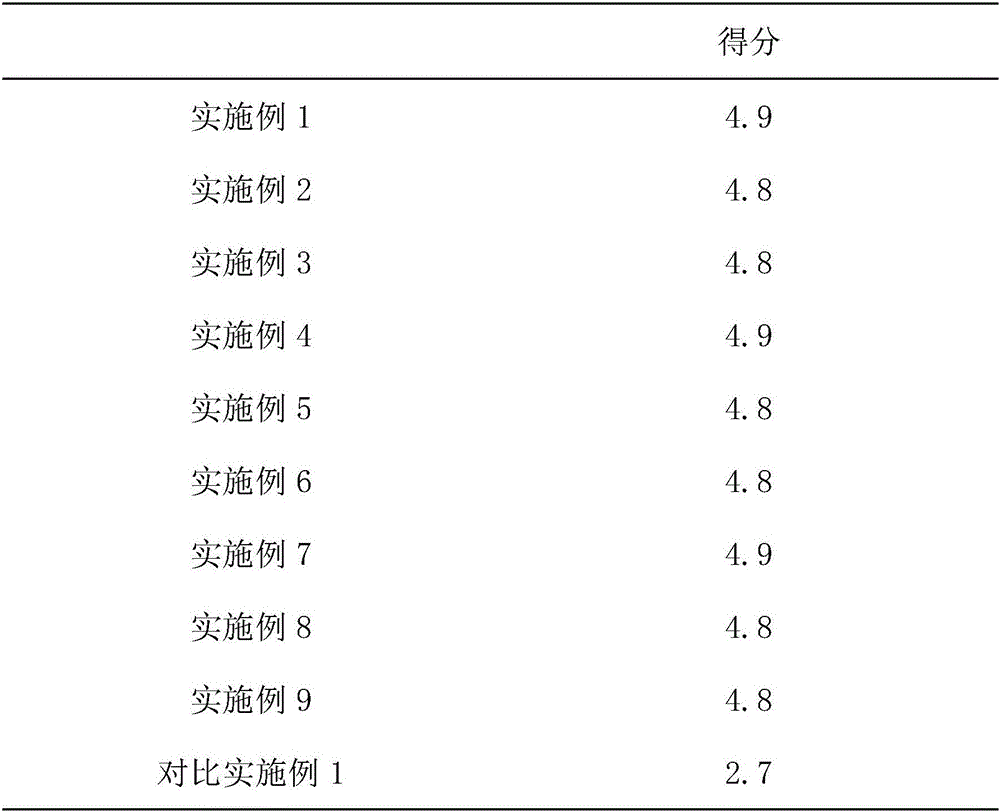

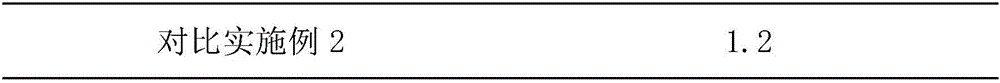

Purple potato bar sandwich rice cracker and making method thereof

InactiveCN103229819AEasy to prepareLow costDough treatmentBakery productsDietary fiberAdditive ingredient

The invention provides a purple potato bar sandwich rice cracker which comprises a purple potato bar, a core material filled in the purple potato bar and a purple potato powder layer scattered outside the purple potato bar. The purple potato bar is made from the following components by weight: rice flour, corn flour, purple potato whole flour, wheat flour, calcium carbonate, refined salt and water. The core material is made from the following components by weight: salad oil, lecithin, white granulated sugar, glucose powder, purple potato whole flour, powdered soy, bread flour scrap and roast potato essence. The purple potato powder layer is made from the following components by weight: purple potato whole flour and salad oil. A making method of the purple potato bar sandwich rice cracker is further provided. The making method is simple and low in cost. Nutritional ingredients including the rice flour, the purple potato and the like can be provided by combining of the purple potato bar, the core material and the purple potato powder layer. The made rice cracker is abundant in nutrition, scientific and reasonable in matching, crispy in taste and abundant in taste. The purple potato bar sandwich rice cracker is rich in various coarse food grains including the purple potato, increases dietary fibers and various microelement and is high in nutritional value.

Owner:MASHI MANOR NANJING FOOD

A kind of processing method of tea-flavored crispy rice

The invention relates to a food processing method, in particular to a rice crispy processing method. A method for processing tea-flavored crispy rice comprises the following steps: extracting tea juice, soaking rice, steaming, cooling, adding ingredients, slicing, frying, seasoning, packaging, packaging and sealing with aluminum-plastic film bags, and forming a product. It has a strong tea aroma, crisp taste, delicious taste, and contains a variety of minerals and vitamins.

Owner:成都市龙泉龙喜食品有限责任公司

Industrial process of producing parched rice

The industrial process of producing parched rice includes the steps of: soaking, washing, dripdrying and steaming of Indica rice or glutinous rice; freezing of the steamed rice at temperature of minus 5 deg.c and humidity lower than 30 % inside a refrigerator; low temperature drying at 0-5 deg.c temperature and 10 % below humidity inside a drying equipment; and parching. The parched rice is crisp. The process is independent of weather condition and suitable for production all the year around. The parched rice has long guarantee period and may be packed together with seasoning packet inside degradable package to form instant food.

Owner:叶键

Apple planting method capable of being suitable for south

InactiveCN102511352AMature earlyPromote fruit settingCultivating equipmentsHorticultureSeedlingRootstock

The invention discloses an apple planting method capable of being suitable for the south, which comprises a step of grafting. In spring or autumn, more than two kinds of apple seedlings are grafted to an identical rootstock having genetic relationship with the seedlings. By grafting more than two kinds of apple seedlings on the identical rootstock having genetic relationship with the seedlings, apple trees adopting the grafting method can be suitable for the environments with high temperature and high humidity in the south and grow up and fruit normally.

Owner:GUIYANG JINDUN SOUTH APPLE

Mushroom biscuit processing technology

InactiveCN105394135ACrunchyFine cross-sectional structureDough treatmentBakery productsBaking powderMushroom

The invention discloses a mushroom biscuit processing technology; palm oil, baking powder, salt and water are added so as to provide crispy mouthfeel for the mushroom biscuit; a section structure is fine, and a baking time and temperature can be controlled so as to enable the biscuit to be uniform in shape and good in color; the mushroom biscuit processing technology is simple and easy, and the mushroom biscuit prepared by the technology is rich in gloss and crispy in mouthfeel, thus providing wide market prospect.

Owner:ANHUI XIANZHIYUAN FOOD

Process for making low-temperature vacuum fried anchovy

The invention discloses a process for making low-temperature vacuum fried anchovy. The invention effectively solves the problem that an anchovy product is hard in meat quality, insufficient in crisp degree and not easy to chew because the anchovy is easy to rot and deteriorate in a processing procedure. The process comprises the following steps of: (1) raw material preprocessing; (2) deodorization; (3) dipping; (4) baking at a low temperature; (5) freezing; (6) frying in vacuum; and (7) deoiling. In the dipping step of the process, additives composed of 30-35% of dehydrated celery powder, 2-5% of protamine, 20-30% of microcrystalline cellulose, 30-35% of methylcellulose, 2-5% of sodium hydrogen sulfite and 3-8% of vitamin C by weight percentage are added. The process provided by the invention is simple and practicable, convenient to operate and suitable for factorized production and application; the anchovy in the making process is unlikely to rot and deteriorate; and the low-temperature vacuum fried anchovy obtained through the process provided by the invention is less in fishy smell, good in color and luster, crisp in taste, low in oil content and low in nutrition loss.

Owner:ZHEJIANG MARINE DEV RES INST

Wafer chocolates and preparation method thereof

The invention provides a preparation method of wafer chocolates. By selecting of raw material proportion, and controlling of conditions of baking, fine grinding and pouring, the wafer chocolates with crisp mouthfeel, strong egg flavor, and strong fragrance, and being fine and smooth, and just melt in the mouth are obtained. The preparation method provided by the invention can be simultaneously suitable for preparation of original flavor, milk flavor and yogurt flavor chocolates. The invention further provides the wafer chocolates prepared by the method.

Owner:SICHUAN MAOHUA FOOD

Seafood moon cake and preparation method thereof

InactiveCN104663834ARich in proteinRich in vitaminsDough treatmentBakery productsAlkaline waterCuttlefish

The invention discloses a seafood moon cake and a preparation method thereof. The seafood moon cake is prepared from the following raw materials in parts by weight: abalones, sandworms, sleeve-fishes, cuttlefishes, sesame oil, rice meal, flour, oat powder, white granulated sugar, wheat flour, tapioca starch, malt sugar, water, sodium dehydroacetate, sodium propionate, calcium propionate, potassium sorbate, spices and alkaline water. The preparation method comprises the following steps: getting raw materials, pre-processing, weighing, preparing stuffing and wrappers, filling wrappers, forming, roasting, cooling, packaging and obtaining finished products. The seafood moon cake disclosed by the invention has the characteristics that the product is rich in protein and vitamin, and relatively low in fat content; a large number of vitamins are taken to prevent and treat cardiovascular disease, resist ageing and realize nutrition and safety. The processing method is simple, and the finished product is crisp in mouthfeel and convenient to eat.

Owner:GUANGXI JIANMEILE FOOD

Normal temperature preserving agent for lingwu date and fresh-keeping method thereof

InactiveCN101185459AExtended shelf lifeCrunchyFruit and vegetables preservationEthyl hydroxybenzoateVitamin C

The invention provides a normal temperature fresh-keeping agent of Lingwu long jujube and a fresh-keeping method thereof. The fresh-keeping agent consists of raw materials by the mass ratio that: 5.0-20.0 percent of magnolia officinalis extract, 5.0-20.0 percent of forsythia extract, 0.1-1.0 percent of sodium dehydroacetate, 0.01-0.1 percent of ethyl p-hydroxybenzoate, 0.5-5 percent of calcium chloride, 50-100ppm of gibberellin and the rest is water. The effective disease resistant and bacteriostatic fresh-keeping agent is used for pretreating the long jujube and then PE fresh-keeping bags with drilling holes are used for packing; after stored for 30 days at the normal temperature of 18-22 DEG C, good fruit rate reaches 93 percent; furthermore, appearance is fresh; crunchy mouth feeling is obtained; nutrition and flavor is kept constantly; the rigidity of the fruit reaches 13.3kg / cm<2> and vitamin C content reaches more than 60 percent; furthermore, investment on freezer and refrigeration equipment is not needed; due to no residual toxicity, the fruit stored can be eaten directly without doing any harm to the health of human beings.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY +1

Preparation method of seasoned ready-to-eat lentinus edodes

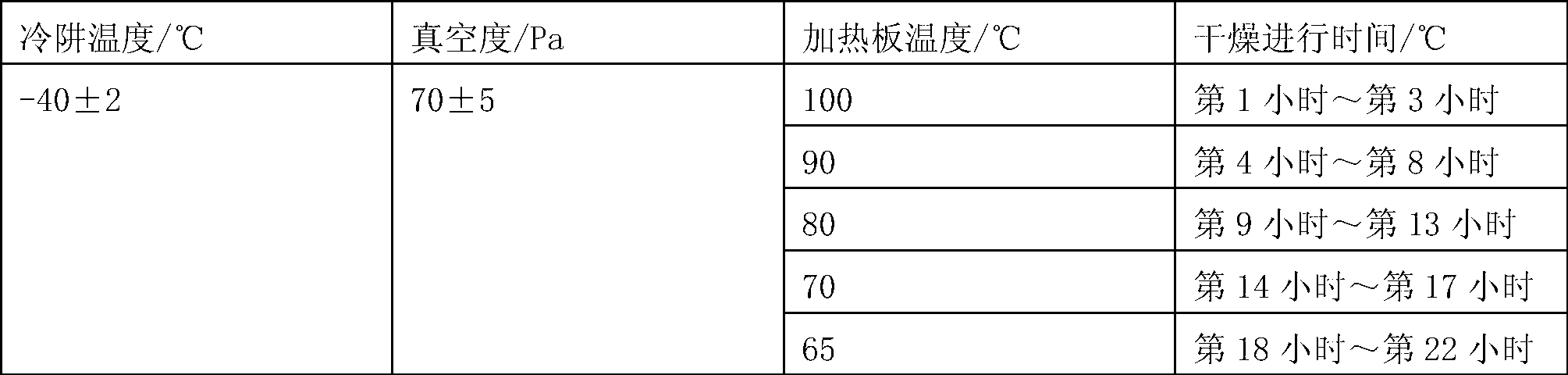

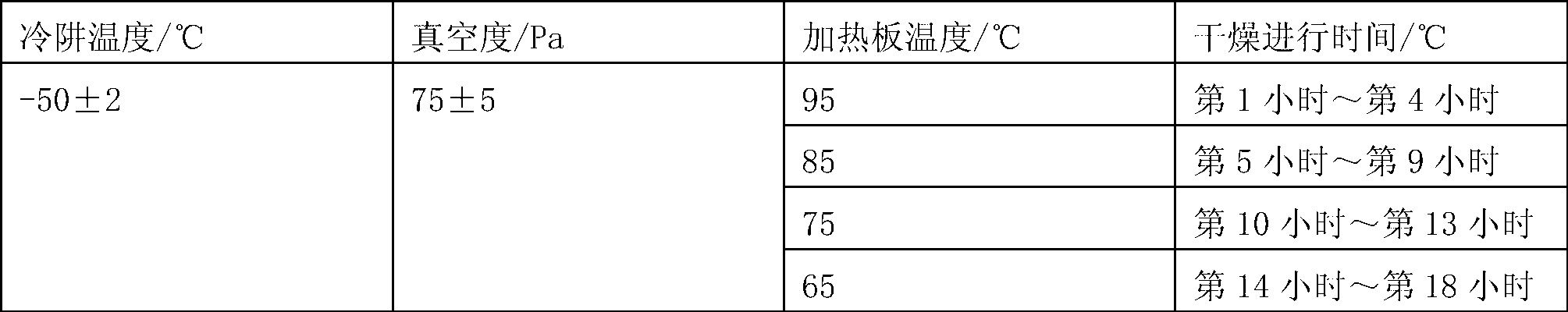

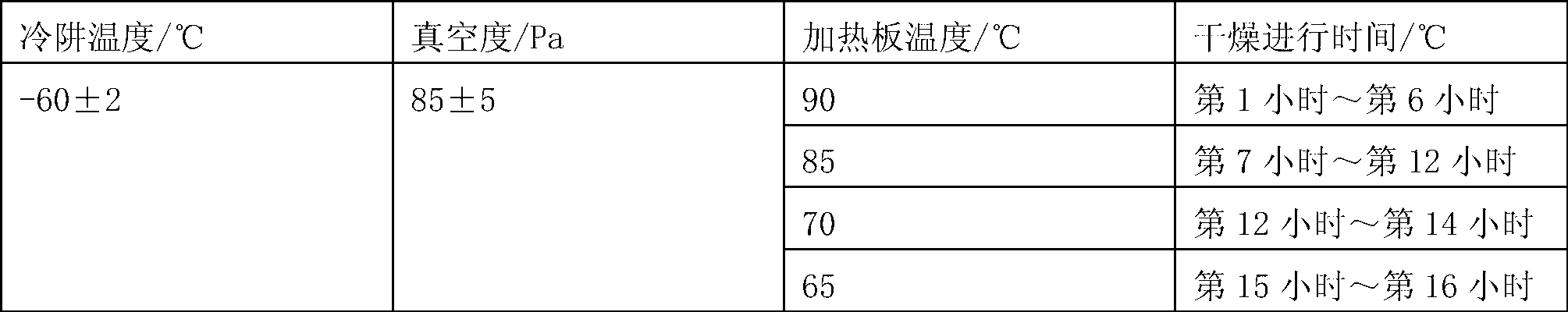

The invention discloses a preparation method of seasoned ready-to-eat lentinus edodes, and the prepared raw materials in parts by weight comprise 50-150 parts of fresh lentinus edodes, 5-15 parts of soy sauce, 1-6 parts of white granulated sugar and 0.5-3 parts of glucose. The preparation method comprises steps of: sorting the fresh lentinus edodes, washing, cutting into slices or dices, precooking by steam or cooking thoroughly by blanching, dewatering, adding the soy sauce, the white granulated sugar and the glucose and mixing, traying, and freezing to -20 to -30 degrees centigrade for 2-4 hours; putting the frozen lentinus edodes into a vacuum freeze drier, in which the vacuum degree is controlled to be 65-90 Pa, the temperature of a cold trap is -38 to -62 degrees centigrade, the temperature of a heating plate is 65-100 degrees centigrade, and the drying time is 16-22 hours; thus obtaining the seasoned ready-to-eat lentinus edodes. The preparation method provided by the invention mainly comprises the steps of precooking the lentinus edodes, adding the soy sauce, sugar and other seasonings and mixing, and then drying by the advanced vacuum freeze drier; and therefore, the prepared seasoned lentinus edodes preserve original shape, smell and nutritional ingredients, can be ready to eat, and are crisp in taste and good in flavor. The seasoned ready-to-eat lentinus edodes are not only the ideal companion to dishes, but also capable of serving as leisure foods.

Owner:广西家里人食品有限公司

Biscuits capable of cleansing colon, expelling toxin, maintaining beauty and keeping young and preparation method thereof

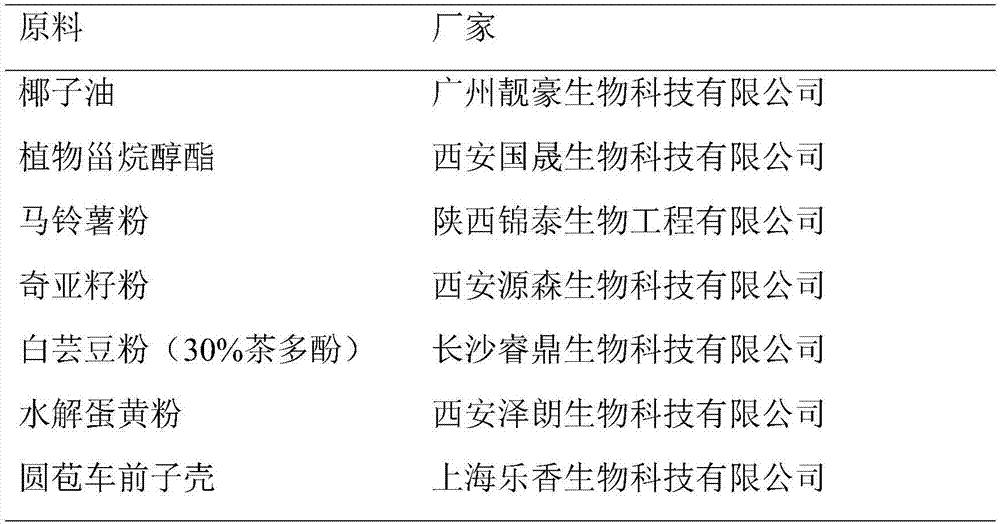

The invention belongs to the field of health care products, and specifically relates to biscuits capable of cleansing colon, expelling toxin, maintaining beauty and keeping young and a preparation method thereof. The biscuits are prepared by raw materials including, by mass, 10-25% of oat powder, 10-15% of Chenopodium quinoa powder, 0.1-0.3% of resistant dextrin, 3-5% of coconut oil, 1-3% of plant stanol ester, 2-6% of chia seed powder, 1-3% of potato powder, 1-4% of white kidney bean powder, 1-3 % of whey protein powder, 0.02-0.05% of hydrolyzed yolk powder, 3-8% of psyllium husk powder, 1-3% of trehalose, and residual water. The biscuits can be used as meal replacement biscuits, have the characteristics of low calorie, high dietary fiber and high protein, and have mouthfeel of crisp biscuits, and animal tests have proved that the biscuits have a certain fat-reducing effect.

Owner:HUIZHOU TONGFUKANG BIOTECHNOLOGY LTD

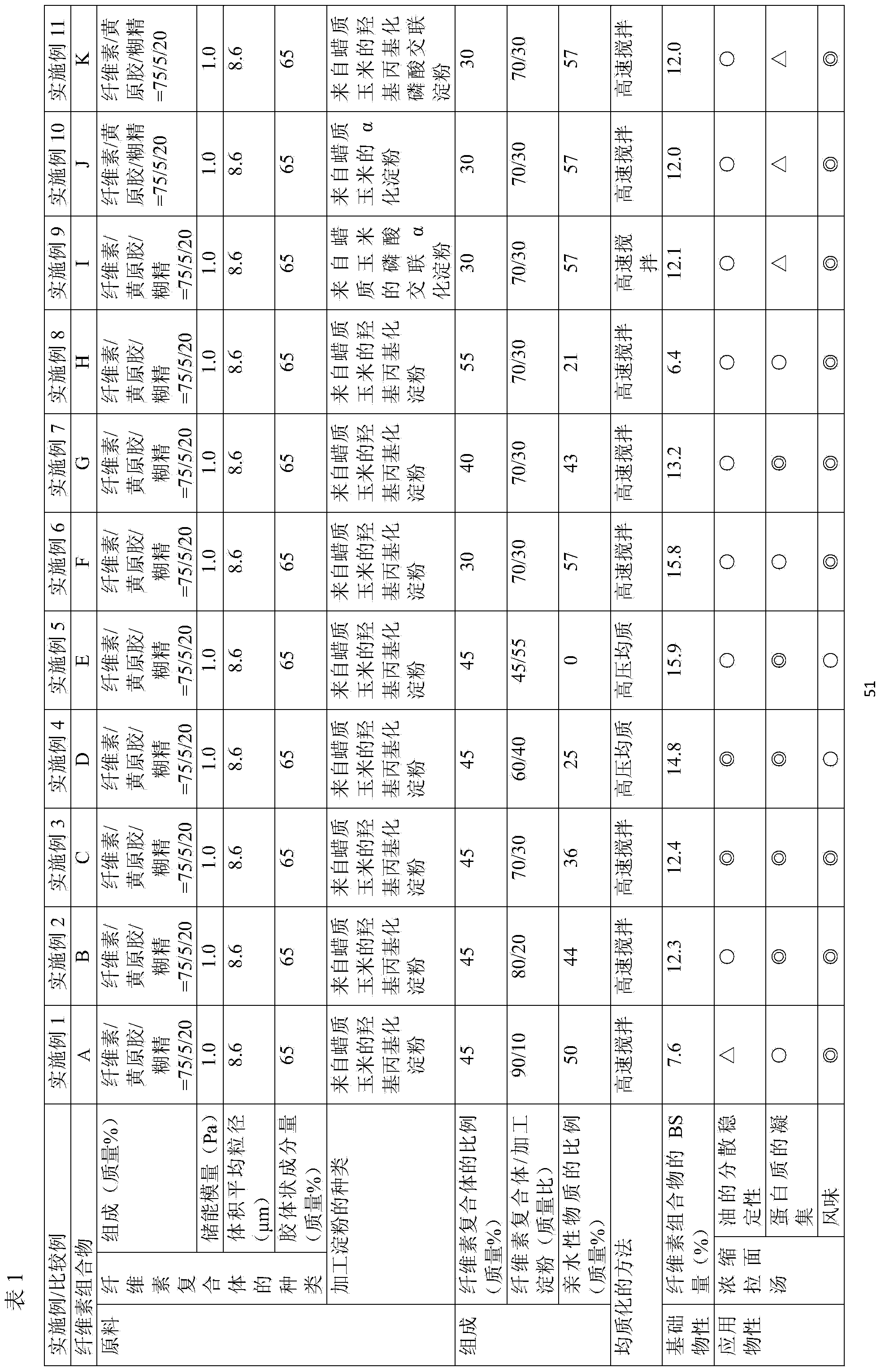

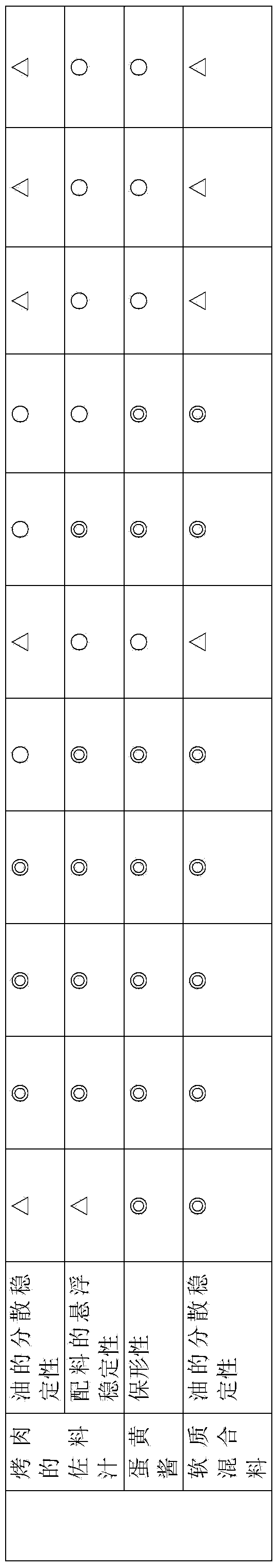

Cellulose composition

InactiveCN104114037AGood dispersionImprove dispersion stabilityDough treatmentDough/pre-mixesCelluloseWater soluble polysaccharides

[Problem] To provide a cellulose composition which can be easily dispersed in an aqueous medium having a high salt concentration, and which, particularly when used in a food or drink having a high oil content, has a high dispersion stabilizing effect for unemulsified oils, as well as a suspension stabilizing effect and a shape retaining effect. Also, to improve the quality and production suitability of low-density confectionery having a delicate texture, and improve the texture of bakery products using said cellulose composition. [Solution] A cellulose composition including cellulose, a water-soluble polysaccharide, and a modified starch, said cellulose composition having, when dispersed in an aqueous solution of 5 mass% sodium chloride such that the concentration of said cellulose composition therein is 0.01 mass% and subjected to sonication for two minutes, a particle size distribution of 6% or greater of 1-mum or smaller components in an area frequency histogram obtained by measuring using a laser diffraction / scattering particle size distribution analyzer at a refractive index of 1.04.

Owner:ASAHI KASEI KK

Processing technique of baked fish bone

ActiveCN103610119AUniform size and thicknessComplete structureFood freezingFood ingredient as taste affecting agentAdditional valuesHigh pressure

The invention discloses a processing technique of baked fish bone. The processing technique comprises the following steps of (1), cleaning; (2), removing the fish smell; (3), softening at a high pressure; (4), dipping; (5), freezing; (6), wrapping; (7), frying; (8), baking; and (9), improving the fragrance. Through optimizing the processing technique of the baked fish bone, by adopting a self-made fish smell removing solution and a swelling agent, the made baked fish bone is uniform in size and thickness, compact in structure, crisp in mouth feel and easy to chew, is greatly improved in additional value of the fish bone, and also provides a convenient calcium supplementing manner for people.

Owner:ZHEJIANG OCEAN UNIV

Rice food and production method thereof

The invention discloses a rice food and a production method thereof. The rice food comprises the following raw material components in part by weight: rice, soy sauce, disodium ribonucleotide, white sugar, garlic powder and the like. The production method comprises the following steps: rinsing, soaking, steaming and refrigerating the rice to form a rice cake; cutting the rice cake, drying, baking,sorting, and seasoning with seasoning liquid; and drying, sorting, metering and packaging finished products, and storing in a finished product warehouse. The puffing degree and mouthfeel of the rice food are greatly improved, so the rice food is more crispy and delicious; and the rice food is particularly added with nutrition elements of calcium, iron and zinc, so the applicable users of the ricefood are widened to the old with weak chewing capacity from the main users of children and the youth, and the leisure food has the function of supplementing the nutrition elements.

Owner:安徽阿幸食品有限公司

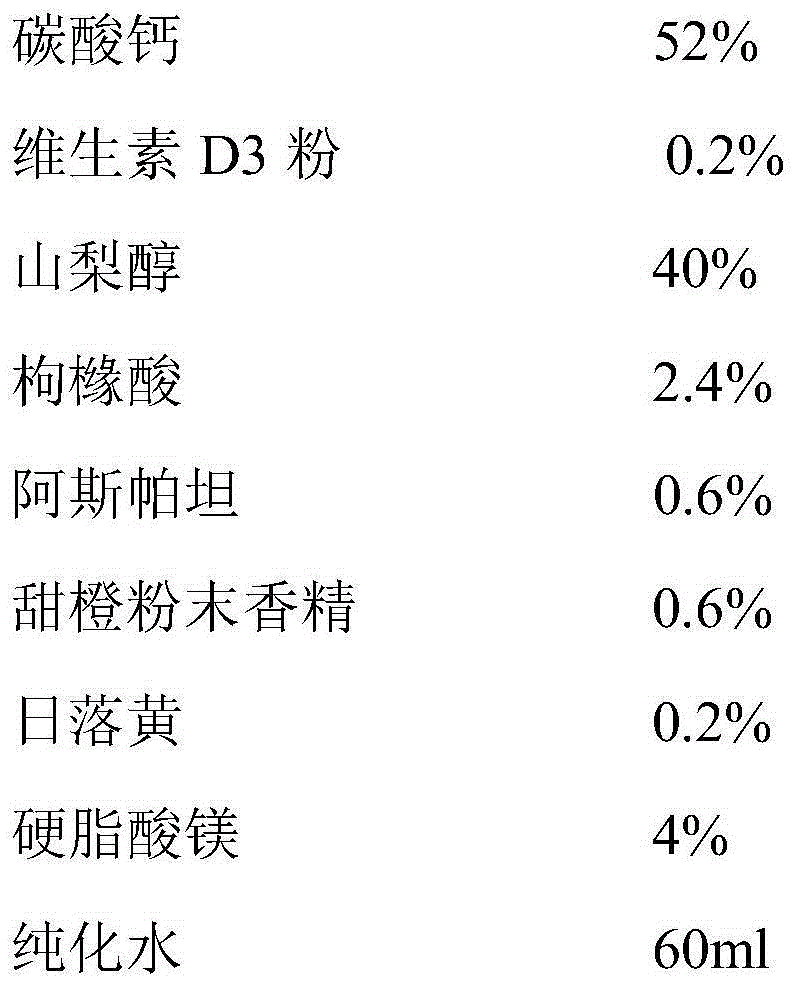

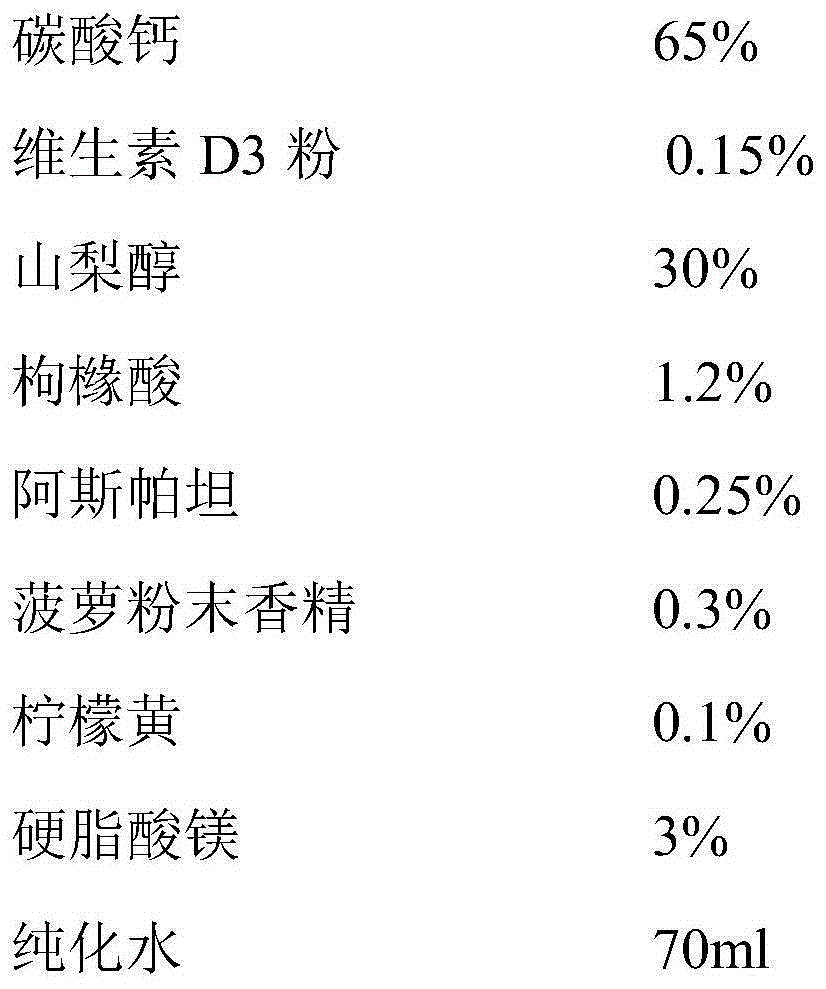

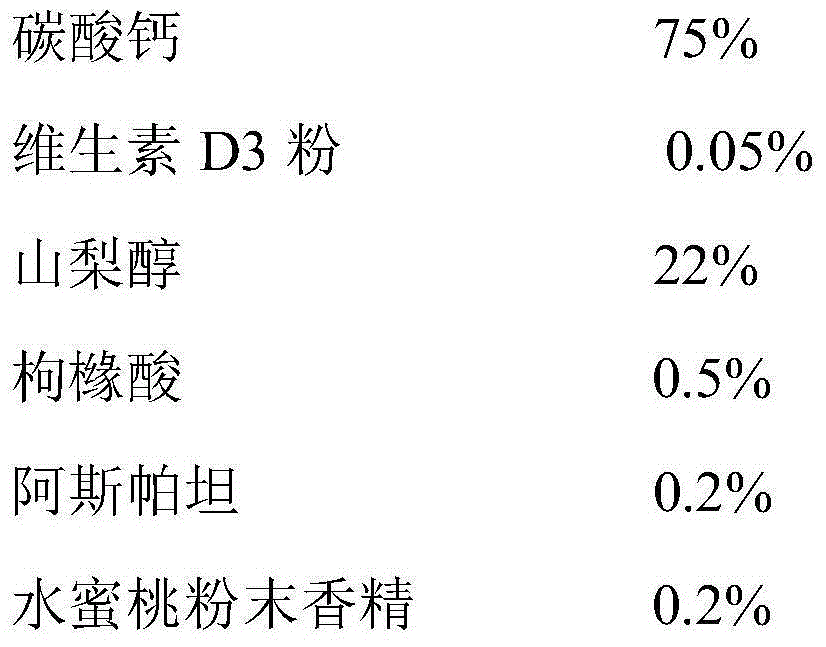

Composite calcium carbonate and vitamin D3 chewable tablet for children and preparation method thereof

InactiveCN105168243AUniform particle size distributionImprove liquidityOrganic active ingredientsMetabolism disorderVitaminCitric acid

The invention relates to the field of pharmaceuticals, in particular to a composite calcium carbonate and vitamin D3 chewable tablet for children and a preparation method thereof. The chewable tablet is composed of, by weight, 50-75% of calcium carbonate, 0.05-0.2% of vitamin D3 powder, 22-40% of sorbitol, 0.6-2.4% of citric acid, 0.1-0.6% of aspartame, 0.2-0.6% of essence, 0.05-0.2% of pigment and 2-6% of magnesium stearate. The chewable tablet is suitable for large-scale industrial production, and taste, color and smell of the chewable tablet are adjusted by reasonably proportioning the components and content, so that medication compliance of the children is improved.

Owner:GUANGZHOU BAIYUSN GUANGHUA PHARMA

Processing method of ginkgo leisure food

ActiveCN104013036ARich eating habitsRich varietyFood freezingFood thermal treatmentGinkgo GenusHigh pressure

The invention relates to a processing method of a ginkgo leisure food. The processing method comprises the following specific steps: soaking core-free ginkgo kernels, then autoclaving, and quick-freezing for crystallizing; and then deep-frying in vacuum and at a low temperature, and adding seasonings after deoiling to obtain the ginkgo leisure food, wherein the core-free ginkgo kernels are obtained through three procedures of shelling, hulling and coring of normal ginkgo, and the three procedures are free from sequence limitation. The processing method is simple in operation, short in production period, low in requirements on factories and equipment, and low in energy consumption, maintains complete shapes and no nutrient loss of ginkgo, and also keeps an original flavor of ginkgo.

Owner:李东红

Puffed rice production technique

InactiveCN101449777AExtended shelf lifeSweet smellFood preparationDevelopmental stageAdditive ingredient

The invention provides a preparing process for fried rice, and relates to a preparing process for health food, which is characterized in that the preparing process includes: choosing material, soaking, braising, drying, grinding by hand, resunning, storing, frying by oil with sandstone, sieving, removing sandstone, metering and packaging. The fried rice has advantages of industrial production, long storage life, novel formula and comprehensive nutrient compositions, can satisfy requirement of trace element intake for weak elder and patient and children in growth developmental stage, has health care efficacy, golden color, fragrant smell and crisp taste, is easy to store, can be eaten directly or soaked by boiled water, and is good raw material for parched rice cake.

Owner:TIANJIN ZHONGYING HEALTH FOOD

Preparation technology of dried mulberry fruit/mulberry powder, and product and derivative of dried mulberry fruit/mulberry powder

InactiveCN105192050AExtended shelf lifeSolid shape unchangedDough treatmentPre-extraction tea treatmentAdditive ingredientFreeze-drying

The invention discloses a preparation technology of dried mulberry fruit / mulberry powder, and a product and a derivative of the dried mulberry fruit / mulberry powder. The processing method of the dried mulberry fruit / mulberry powder adopts a vacuum freeze drying technology, so that the fresh taste, the nutritional components, the color and the fragrance of mulberries are successfully retained, and the prepared dried mulberry fruit / mulberry powder can be either directly eaten or used as a raw material for food processing. The dried mulberry fruit can be further prepared into scented tea, and the prepared scented tea tastes sour and sweet, and has mellow flavor and flower fragrance; the dried mulberry powder is further prepared into cookies; the cookies taste crispy, has a special flavor, is low in fact content and sugar content and rich in nutrition, and is favorable for the health of people.

Owner:SOUTHWEST UNIVERSITY

Grilled fish bone swelling agent, and preparation method and application of swelling agent

The invention discloses a grilled fish bone swelling agent which comprises the following components by mass percentage: 30-40% of sodium bicarbonate, 10-15% of monocalcium phosphate, 0.5-1% of xanthan gum, 40-50% of gluconic acid-delta-lactone, and 5-9% of soybean phosphatide powder. The swelling agent is reasonable in formula, and good in swelling effect and storability, and can allow a grilled fish bone to have a loose structure and a crispy taste and be easy to chew. The invention further discloses a preparation method of the grilled fish bone swelling agent. The method comprises the step of uniformly mixing sodium bicarbonate, xanthan gum, gluconic acid-delta-lactone and soybean phosphatide in proportion. The preparation method is simple in processing step, high in operability and low in cost, and is suitable for industrial production.

Owner:ZHEJIANG OCEAN UNIV

Method for manufacturing leisure body-beneficial bacterial dry tempeh

The present invention describes a method for manufacturing leisure body-beneficial bacterial dry tempeh, and belongs to the technical field of food processing. The present invention uses bacillus subtilis subsp subtilis as a strain. The strain liquid based on the inoculation amount with a mass ratio of 5-7% is vaccinated in soybean which is sterilized at 121 DEG C for 35 min and cooled to about 40 DEG C. The bacterial tempeh is produced by constant-temperature fermentation at 38-42 DEG C for 18-22 h, and then 0.5-2% of trehalose, 1-4% of spice and 1-2.5% of salt are added and mixed uniformly. The functional leisure bacterial dry tempeh having tempeh plasmin, antioxidant activity, bacillus subtilis probiotics vigour is prepared by standing at 4 DEG C for 8-12 h, freezing at -30 DEG C or below for 1-6 h, and freeze drying for 12-20 h by putting in a freeze dryer with a freezing tank temperature of below -45 DEG C and vacuum degree below 8 kPa. The method helps to change the conventional dietary pattern just taking the tempeh as a condiment. The dry tempeh is convenient for eating, is conducive to promotion, and can play a health role of bacterial tempeh.

Owner:HANSHAN NORMAL UNIV

Roasted starch rod

InactiveCN101991152ADelicate tasteCrude fiber content retentionFood preparationFiberAdditive ingredient

The invention discloses a roasted starch rod. The preparation method of the roasted starch rod comprises the following steps: firstly, washing potatoes and other raw materials, peeling, grinding the peeled raw materials into thick liquid, settling and taking wet starch of the thick liquid; adding a defined amount of soda ash, black pepper powder, shallot and salt, evenly stirring the mixture, and extruding the mixture by utilizing a screw; and preparing the extruded mixture into a hollow rod by utilizing a hollow forming unit, rapidly roasting the hollow rod to be ripe by utilizing an electric heating apparatus connected behind the forming unit, carrying out air cooling on the ripe hollow rod until the temperature of the ripe hollow rod reaches room temperature, cutting the hollow rod into short rods the lengths of which are equal, and bagging the short rods. The snack foods prepared by the method are ripened by roasting without frying, thus the snack foods do not contain trans fats harmful to human body. The starch rod has the advantages that the settled wet starch is utilized as a main raw material, and crude fibre compositions in raw materials are removed, thus the starch rod has delicate taste; and the soda ash and other fluffing agents ensure that the interior of the product is full of holes, thus the starch rod has fluffy and crispy taste after being ripened by heating.

Owner:冷博

Preparation technology of composite potato chips

InactiveCN104323175AAttractive colorCrunchyInorganic compound food ingredientsFood ingredient functionsNutritive valuesDisease

The invention relates to a preparation technology of composite potato chips. The composite potato chips are prepared from the following raw materials in parts by weight: 50-55 parts of potato starch, 20-25 parts of Chinese yam powder, 15-20 parts of wheat starch, 5-8 parts of maltodextrin, 0.4-0.6 part of fatty acid sucrose ester, 0.8-1.2 parts of edible salt and 0.08-0.12 part of tricalcium phosphate; the composite potato chips are prepared by the steps of treating the raw materials, blending, mixing, tabletting, cutting into slices, frying, seasoning, cooling and the like. The potato starch is taken as a main raw material and supplemented with a right amount of Chinese yam powder, and the ratios of all the materials are reasonably regulated, so that the prepared composite potato chips are attractive in color, crisp in mouth feel, rich in flavor and high in nutritive value, have a health care function, have nourishing effects such as tonifying middle-jiao and qi, strengthening tendon and tonifying spleen, producing saliva and tonifying lung, tonifying kidney and arresting seminal emission, invigorating stomach and helping digestion, and the like, and have a good dietary therapy function for spleen deficiency and diarrhea, lung deficiency and cough, diabetes, gastrointestinal disease such as dyspepsia and the like; the preparation method is simple and easy to operate.

Owner:QINQIN INC CO LTD FUJIAN

Super light wt. fish bait

InactiveCN1718083AHigh degree of puffingCrunchyClimate change adaptationAnimal feeding stuffYeastShrimp

Owner:林震能

Chive soda biscuit

The invention relates to a chive soda biscuit. The chive soda biscuit comprises, by weight, 30 parts of stuffed straight as a main ingredient, 5 parts of palm oil, 0.03 part of citric acid, 0.2 part of fresh yeast, 0.003 part of fresh creamer, 0.05 part of edible essence, 0.002 part of zymin, 0.003 part of sodium pyrosulfite, 0.6 part of chive and 0.6 part of salt as the seasoner. The stuffed straight as the main ingredient is formed by mixing 40% of wheatmeal with the wet gluten being 25% and 60% of wheatmeal with the wet gluten being 30%. Two kinds of wheatmeal with different wet gluten contents are adopted to be mixed according to a certain component ratio, so that the produced soda biscuit tastes fragile and is smooth in surface; the fermentation time is shortened, the fermentation times are reduced, and therefore the yield can be improved; the biscuit tastes delicious by adding the chive as an auxiliary material.

Owner:JIANGSU MEIZIZI FOOD

Health-care fresh biscuit for preventing hyperlipidemia and manufacturing method thereof

InactiveCN104255882AImprove immunityFunction increaseDough treatmentBakery productsPollenDietary fibre

The invention discloses health-care fresh biscuit for preventing hyperlipidemia and a manufacturing method thereof. The biscuit comprises 55-75% of low-gluten flour, 1.5-3% of white rib extract, 0.5-2% of ipomoea pescaprae extract, 0.5-2% of article ficuscunia extract, 1.5-3% of moso bamboo shoot head extract, 2-5% of locust pollen, 5-7% of abelmoschus manihot seed oil, 1.5-3% of pectin, 5-7% of palatinitol, 1.5-3% of dried skim milk, 0.3-0.5% of bamboo salt, 5-8% of partridge egg and 0.7-1.5% of instant dry yeast by weight. The raw materials are processed reasonably to form biscuit, the prescription is reasonable, the synergistic effect of the raw materials is strong, the sensing quality of the biscuit is improved, the shelf life is improved, and the nutritive elements are better balanced and richer; the health-care fresh biscuit for preventing hyperlipidemia is featured with crisp, delicious and sweet mouth feel, low energy, high dietary fiber content and low fatness and capable of preventing hyperlipidemia, lowering lipid and protecting health by means of regular intake. The health-care fresh biscuit for preventing hyperlipidemia is especially suitable for the hypertension and hyperlipidemia patients and obesity.

Owner:陆建益

Leisure food prepared from potato flour and production process thereof

The invention discloses a leisure food prepared from potato flour and a production process thereof. The leisure food is characterized by consisting of the following materials: 50 to 60 percent of mixture of wheat flour and potato flour, 5 to 10 percent of plant oil, 5 to 10 percent of white granulated sugar, 8 to 12 percent of benne, 1 to 2 percent of leavening agent, 0.3 to 0.5 percent of flavor, 15 percent of surface paint, 8 to 10 percent of surface-scattered flavoring and a proper amount of water; the leisure food has the characteristics of easy forming, good appearance, good mouthfeel and capability of meeting the requirements of changing the flavor of the potato of people; and the leisure food and the production process do not have high requirements on the quality and type of the potato, can make full use of the potato, do not cause waste and can be widely popularized to the leisure foods of the people.

Owner:GUANGDONG JIASHILI FOOD GRP CO LTD

Bighead atractylodes rhizome poria cocos butter biscuits

InactiveCN103564023AFine particleEvenly layeredDough treatmentBakery productsSodium bicarbonateAntioxidant

The invention discloses bighead atractylodes rhizome poria cocos butter biscuits. According to the formula, raw materials for making the bighead atractylodes rhizome poria cocos butter biscuits comprise 96kg of wheat flour, 4kg of starch, 34kg of white granulated sugar powder, 4kg of malt sugar, 8kg of refined oil, 18kg of margarine, 5kg of milk powder, 3kg of eggs, 3.5kg of poria cocos, 3.46kg of bighead atractylodes rhizome, 0.5kg of table salt, 0.3kg of sodium bicarbonate, 0.2kg of ammonium bicarbonate, 0.035kg of vanillin, 0.003kg of citric acid and 0.002kg of antioxidants. The bighead atractylodes rhizome poria cocos butter biscuits have the effects of protecting health, preventing tumors, protecting the livers, invigorating spleen and supplementing qi, preventing miscarriage, adjusting gastrointestinal motility, preventing anabrosis, enhancing body immunity, resisting stress and enhancing the hematopoietic function.

Owner:JIANGXI YUQINSAO FOOD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com