Patents

Literature

73results about How to "Good bulkiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spontaneously degradable fibers and goods made thereof

InactiveUS6844062B2Easy to splitGood bulkinessSynthetic resin layered productsFilament/thread formingYarnPolyester

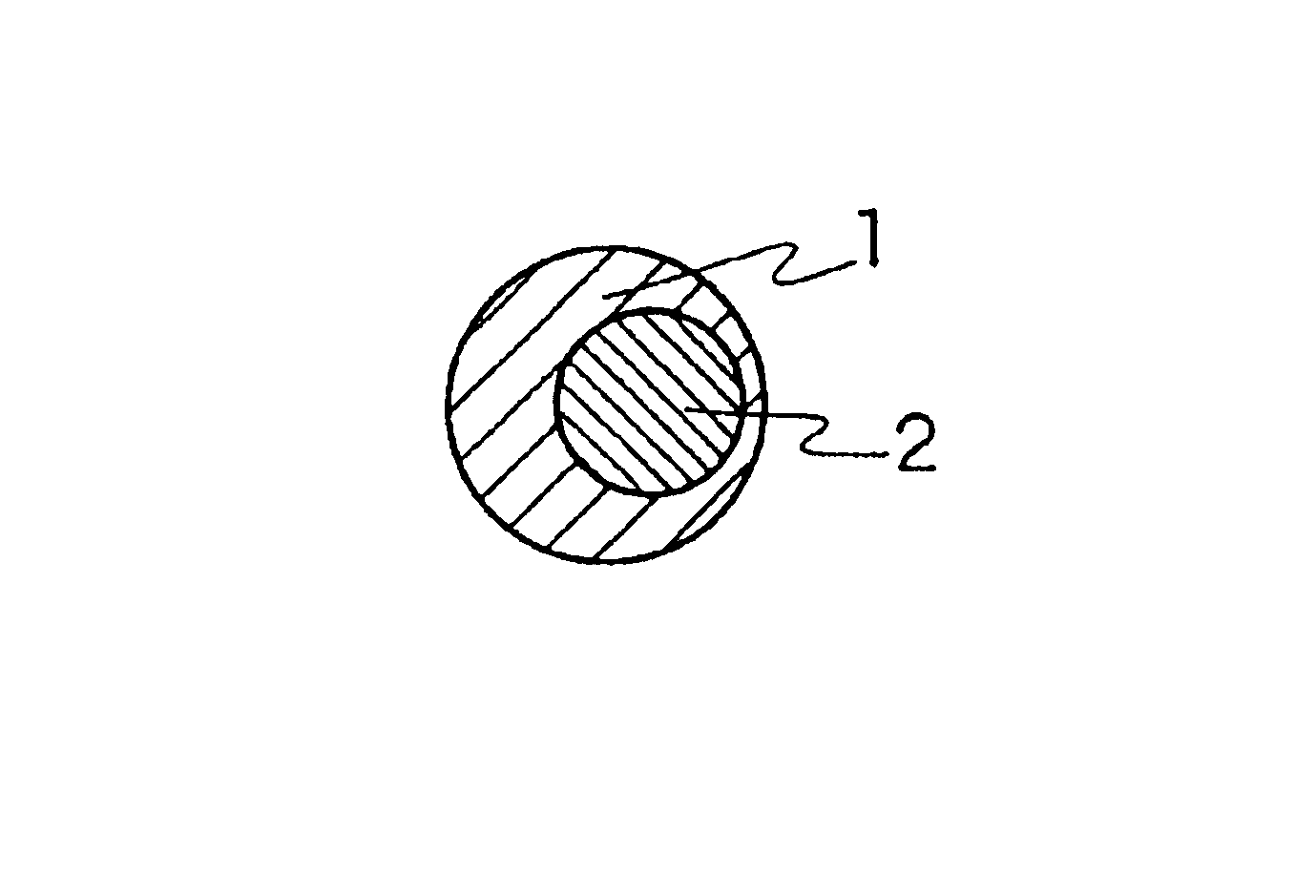

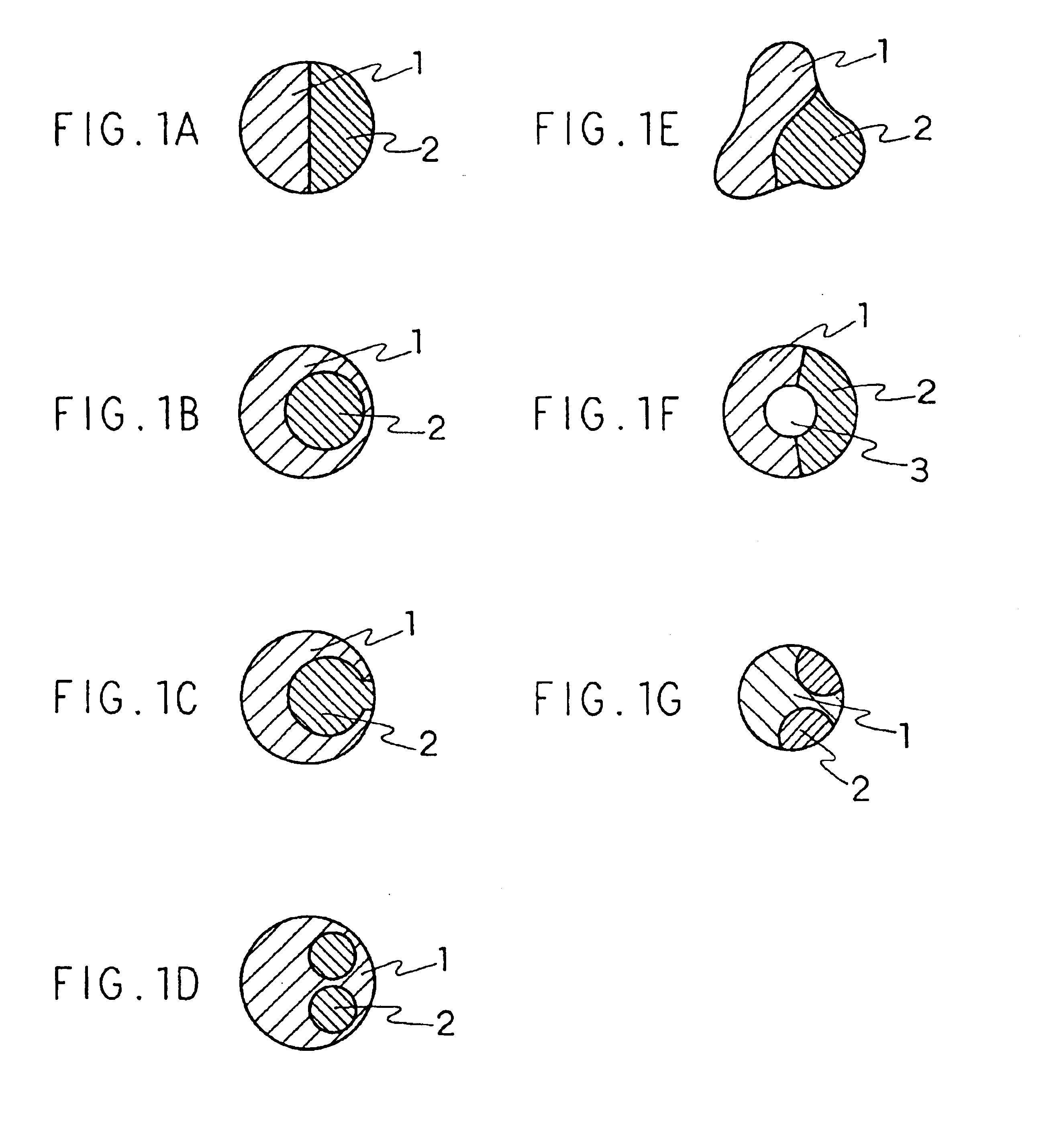

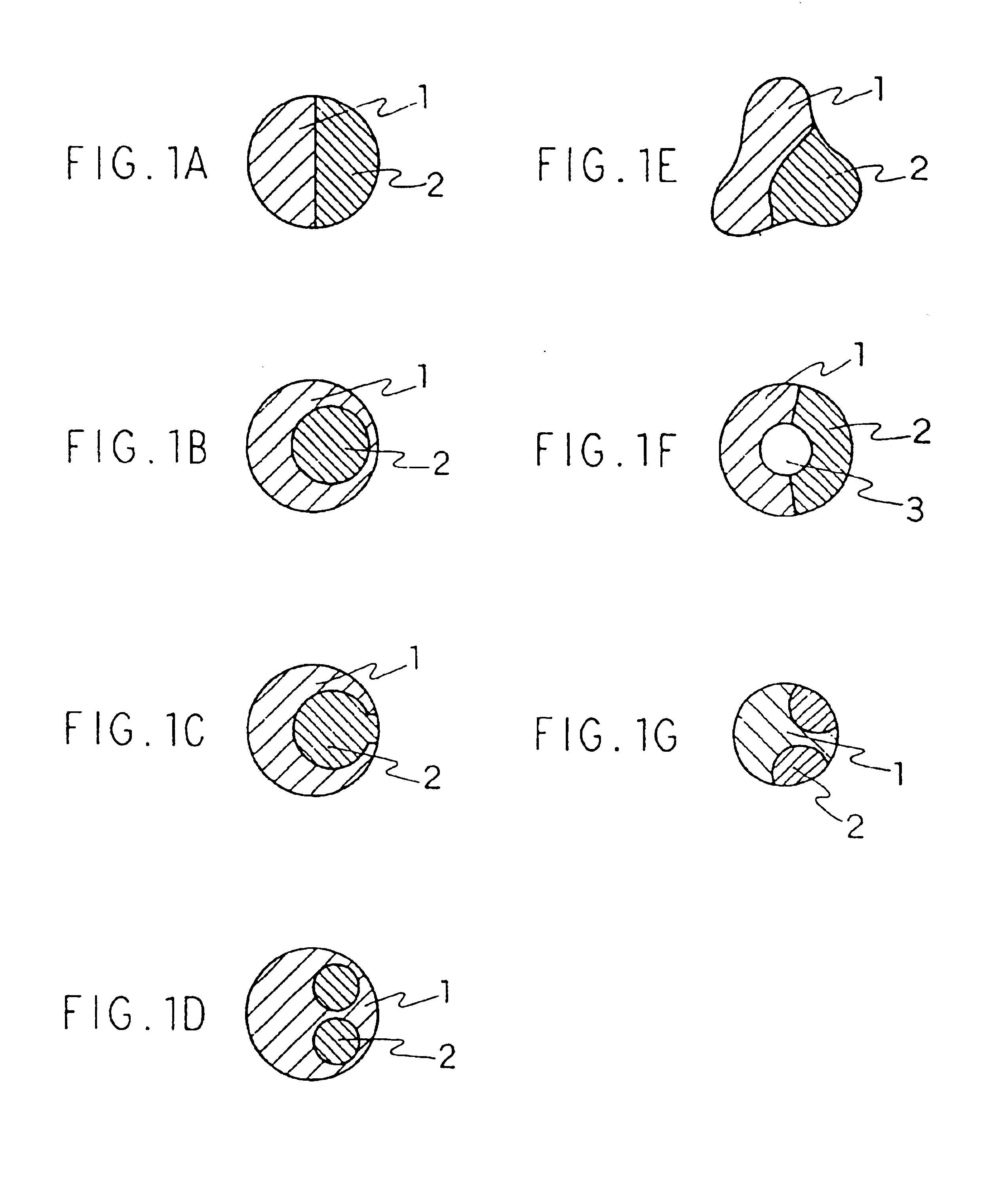

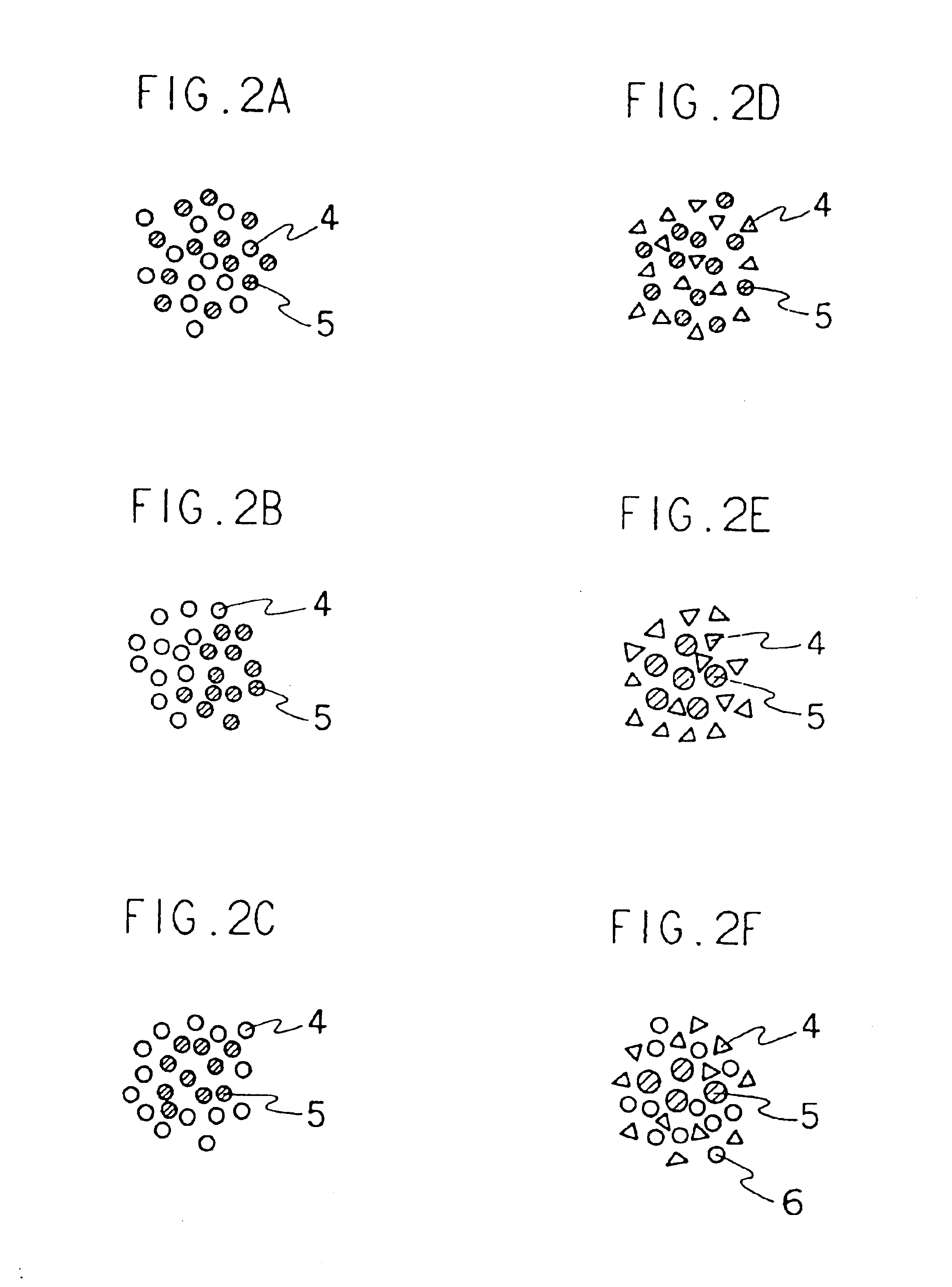

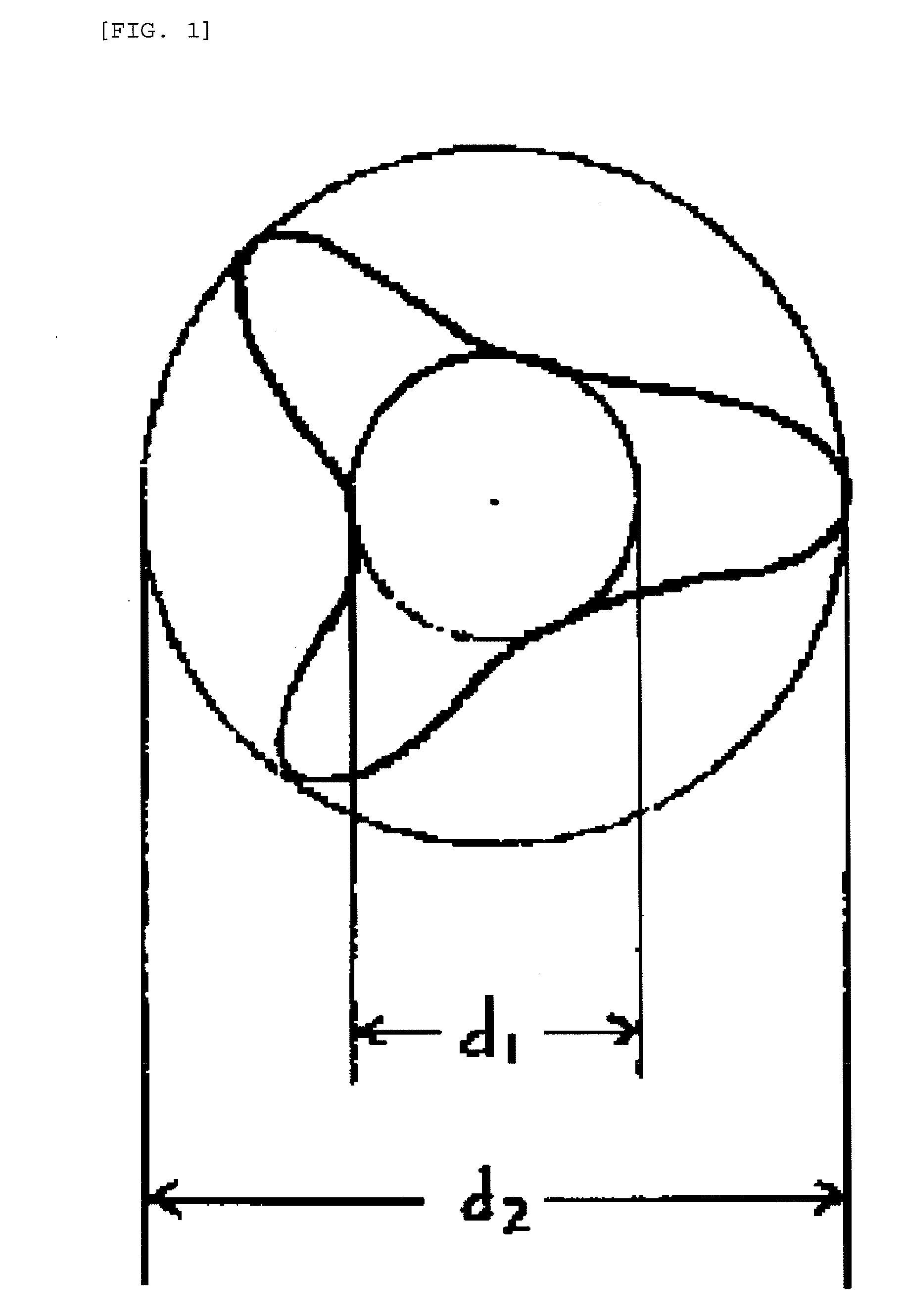

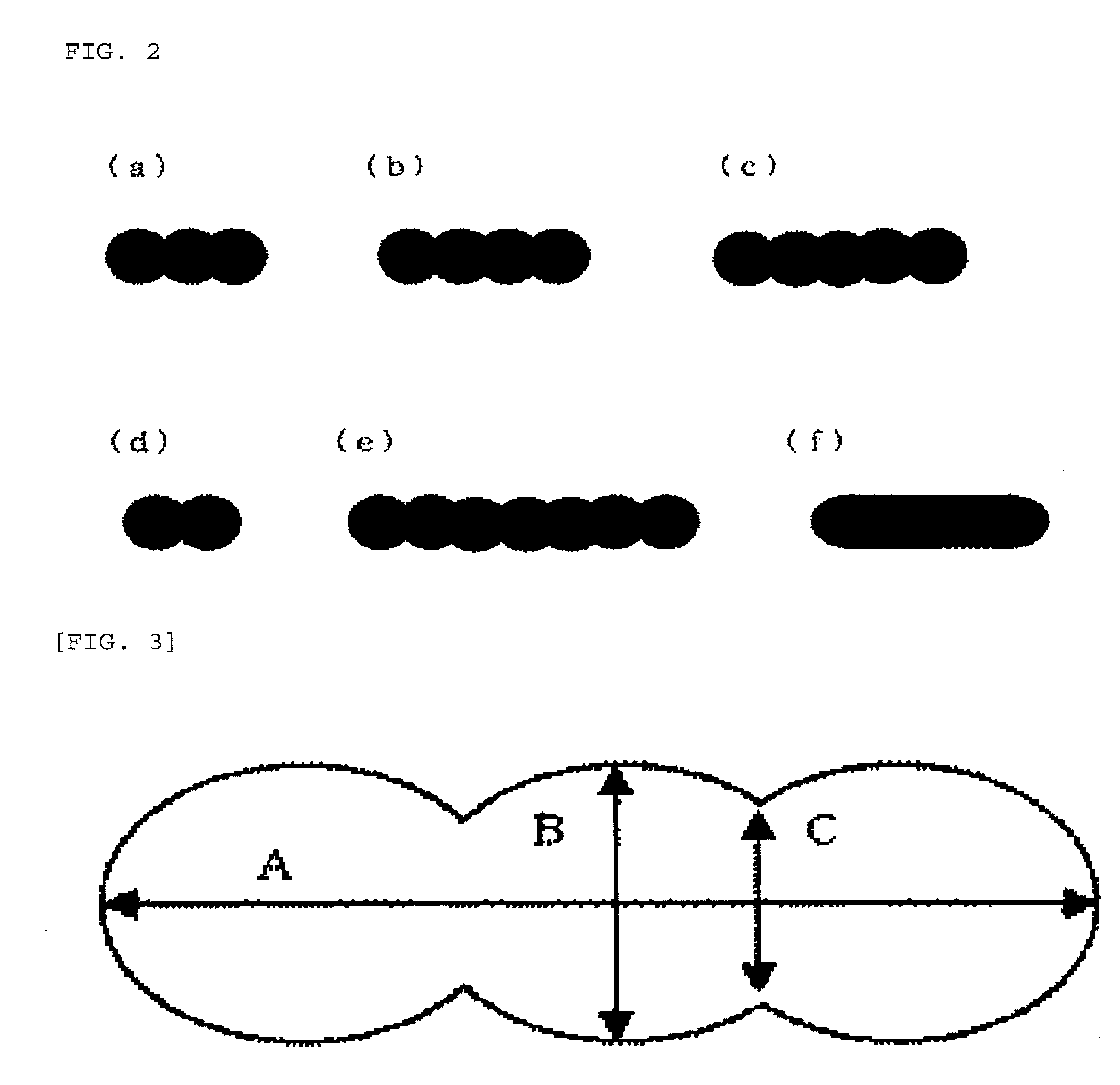

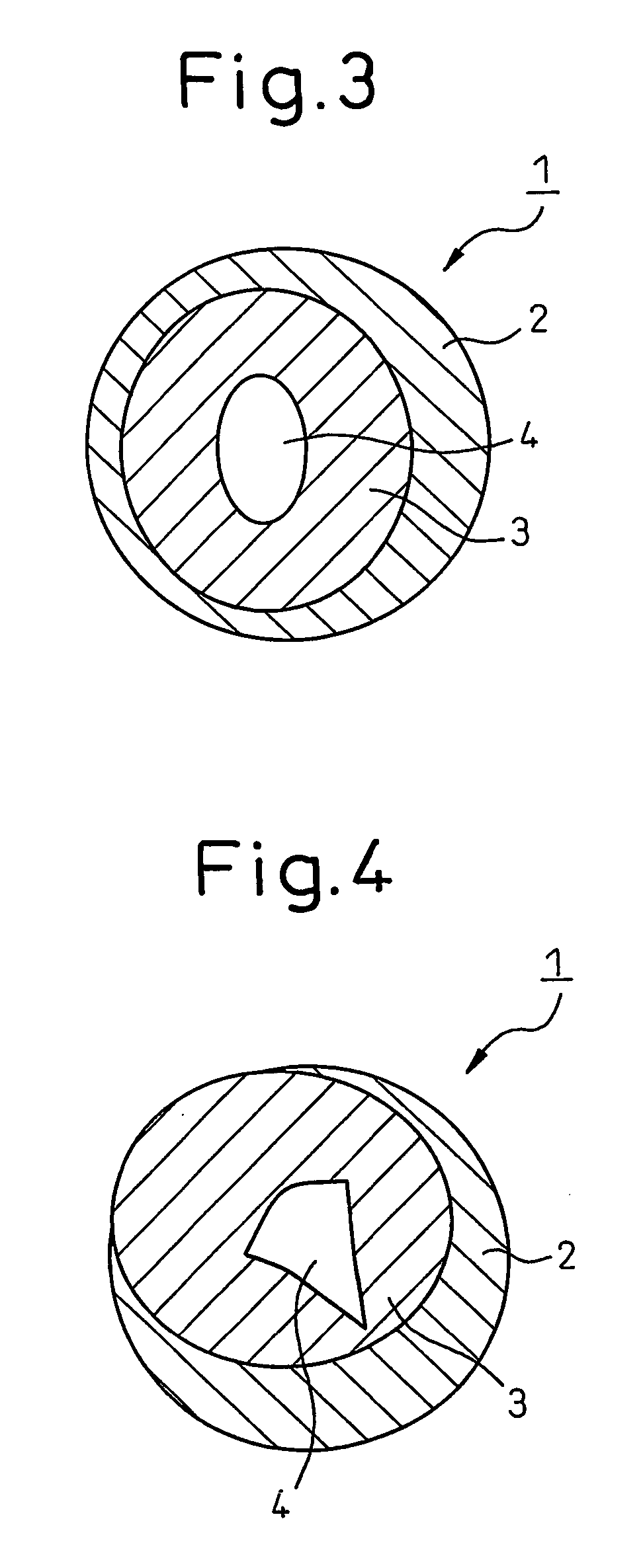

A spontaneously degradable fiber excellent in bulkiness, softness, stretchability and feeling, which comprises (A) a low heat-shrinkable fiber component comprising a high crystalline aliphatic polyester and (B) a high heat-shrinkable fiber component comprising an aliphatic polyester, e.g., a low crystalline or non-crystalline aliphatic polyester, and a block copolymer or a mixture the main component of which is an aliphatic polyester and which comprises a high-melting component and a low-melting component. Further, fibers excellent in self-crimpability or self-adhesion property and dividable fibers are obtained by suitably combining the fiber components (A) and (B) to form conjugated fibers or composite yarns.

Owner:TORAY IND INC

Spontaneously degradable fibers and goods made thereof

InactiveUS6844063B2Easy to splitGood bulkinessSynthetic resin layered productsFilament/thread formingPolyesterYarn

A spontaneously degradable fiber excellent in bulkiness, softness, stretchability and feeling, which comprises (A) a low heat-shrinkable fiber component comprising a high crystalline aliphatic polyester and (B) a high heat-shrinkable fiber component comprising an aliphatic polyester, e.g., a low crystalline or non-crystalline aliphatic polyester, and a block copolymer or a mixture the main component of which is an aliphatic polyester and which comprises a high-melting component and a low-melting component. Further, fibers excellent in self-crimpability or self-adhesion property and dividable fibers are obtained by suitably combining the fiber components (A) and (B) to form conjugated fibers or composite yarns.

Owner:TORAY IND INC

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS7481843B2Good bulkinessEasy crimpingBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

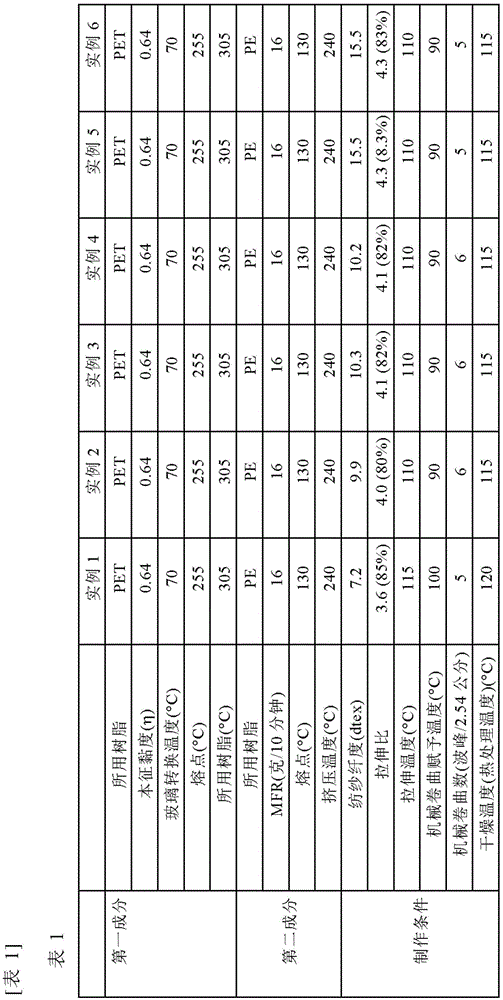

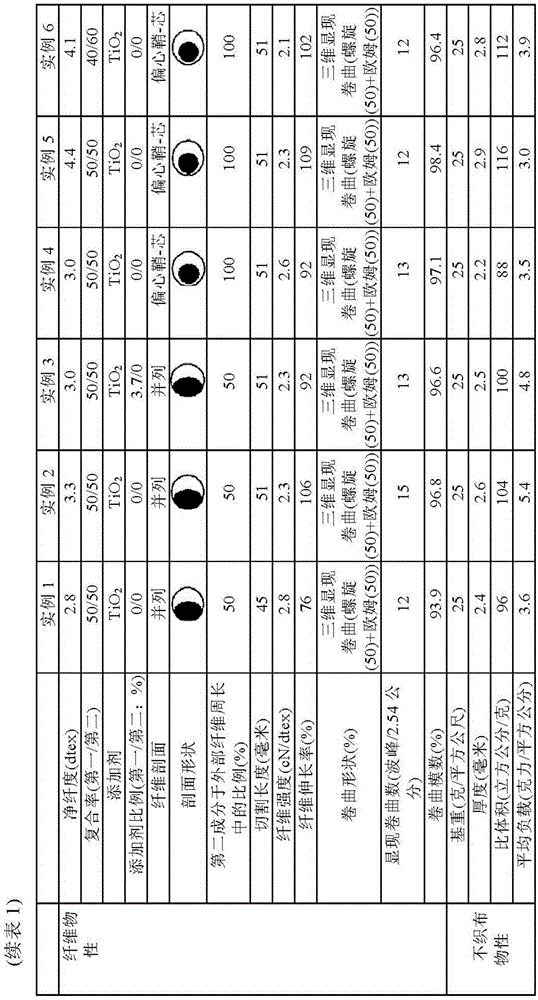

Crimped polyester fiber and fibrous structure comprising the same

InactiveCN1343271AHas curl numberHas curl rateFilament/thread formingNon-woven fabricsFiber structurePolyethylene terephtalate

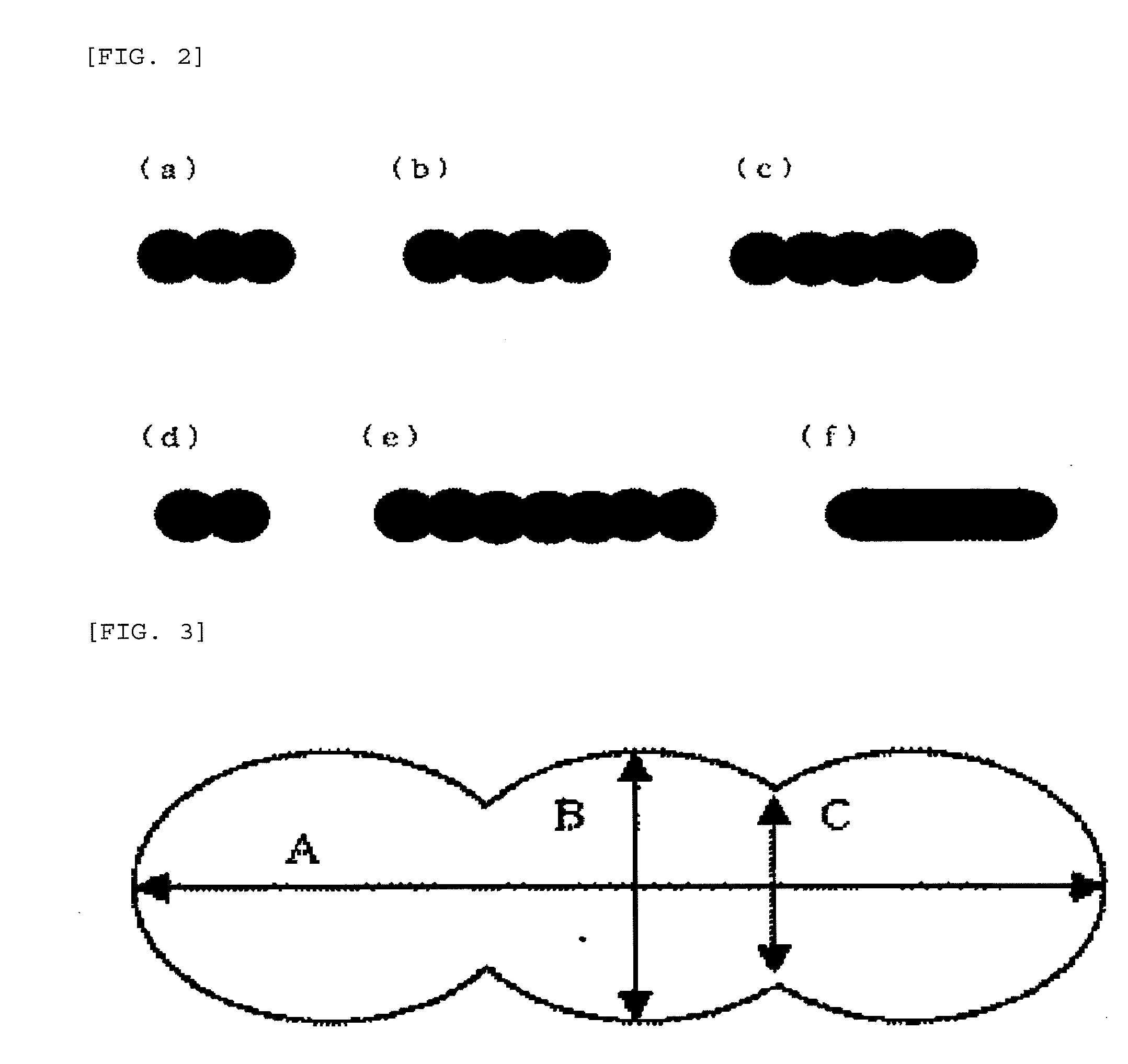

A crimped polyester fiber which is made of a polytrimethylene terephthalate polyester, is three-dimensionally crimped so as to have a number of crimps of 9 to 30 per 25 mm and a percentage crimp of 20 to 50%, and has a crimp elasticity of 80% or higher; and a fibrous structure which comprises short fibers of the crimped polyester fiber and short heat-bondable composite fibers in a weight ratio of from 30 / 70 to 95 / 5 and in which at least part of the points where the two kinds of short fibers are in contact with each other and / or the points where the short heat-bondable composite fibers are in contact with each other have been thermally fixed.

Owner:TEIJIN FRONTIER CO LTD

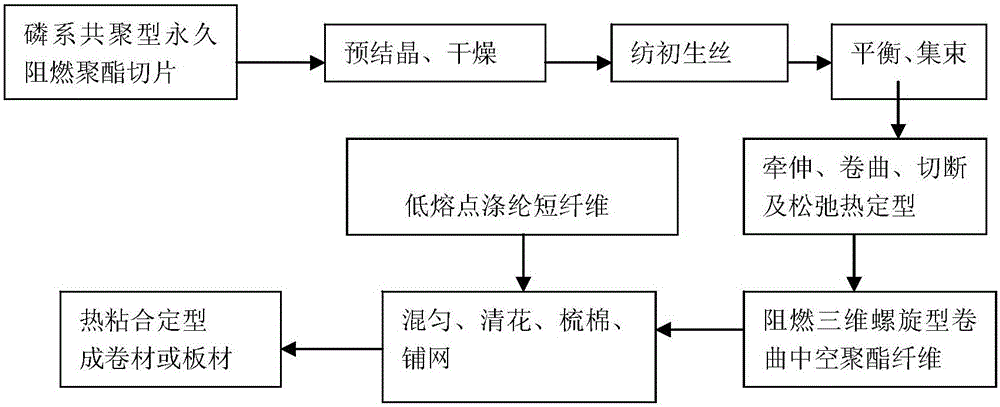

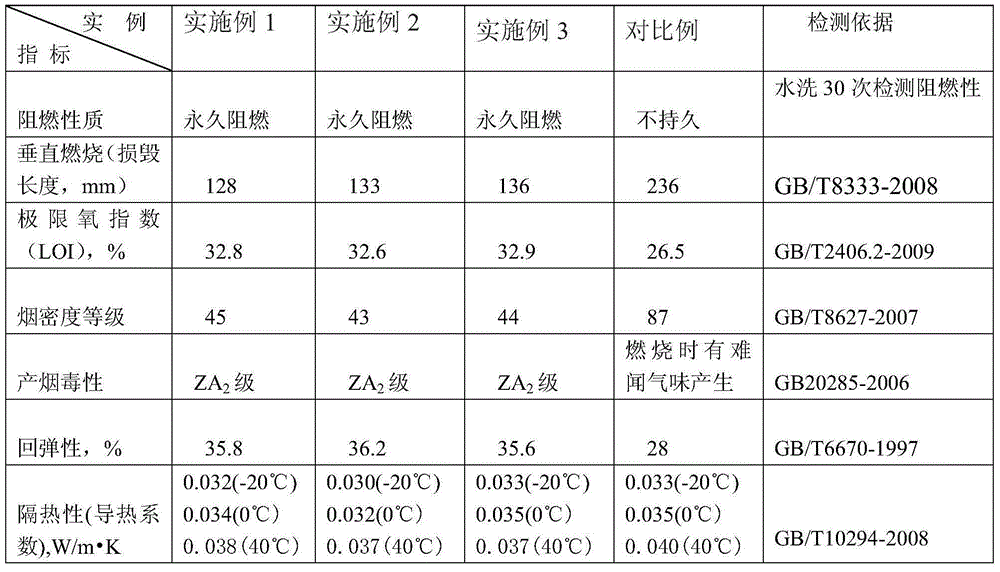

Novel flame-retardant heat-insulation elastic polyester material and preparing method and application thereof

ActiveCN105088535AStrong bondProduct environmental protectionFilament/thread formingMonocomponent copolyesters artificial filamentWater contentChemistry

The invention discloses a preparing method of a novel flame-retardant heat-insulation elastic polyester material. The preparing method includes the steps that phosphorus co-polymerized permanent flame-retardant polyester chips are pre-crystalized and dried, and then the water content is smaller than or equal to 30 ppm; spun filaments are obtained through spinning, and after the spun filaments are balanced and bundled, 2-10 D flame-retardant three-dimensional spiral crimped hollow polyester fibers are obtained through drafting, crimping, cutting-off and relaxation heat setting; 85-95wt% of flame-retardant three-dimensional spiral crimped hollow polyester fibers and 15-5wt% of low-melting-point polyester staple fibers are mixed evenly, treated in the mode of blowing, carding and lapping and then thermally bonded through a hot mill or a hot air dryer. The material is superior in performance and can replace polyurethane foaming plastic to be used as a furniture pad material, a vehicle seat pad material and various soft pad laminated composite materials.

Owner:HIGHTEX CO LTD ZHEJIANG

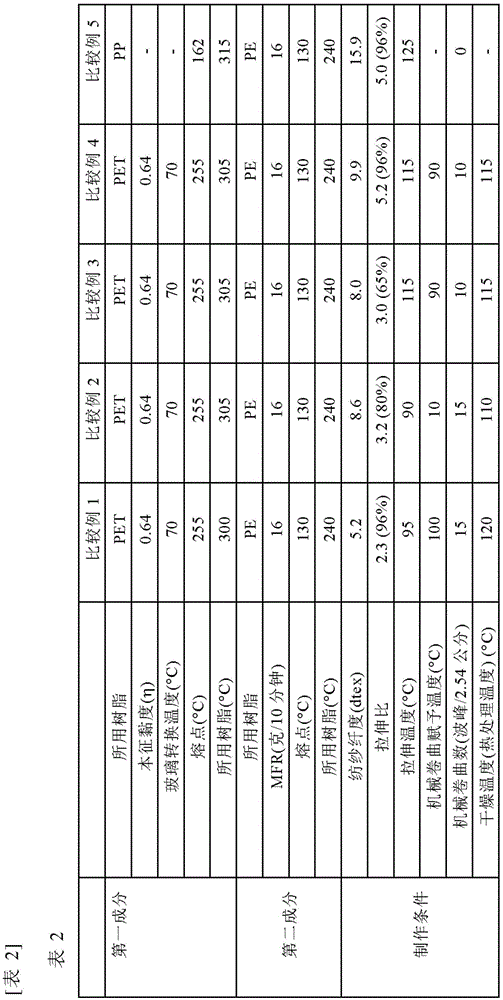

Heat-bondable conjugate fiber with excellent softness and nonwoven fabric using the same

ActiveCN105283589AGood specific fiber elongationGood flexibilityFilament/thread formingAbsorbent padsPolyesterPolyolefin

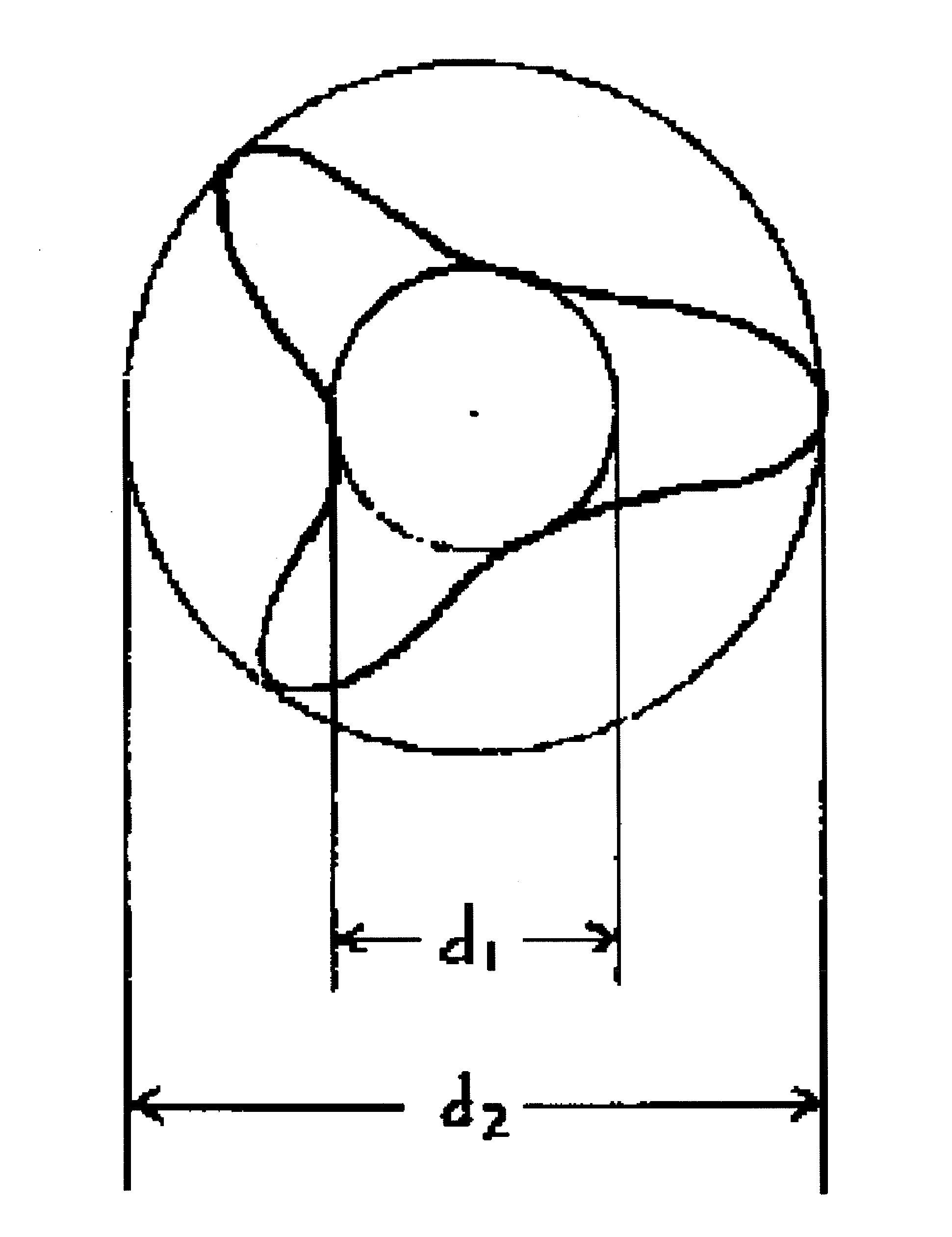

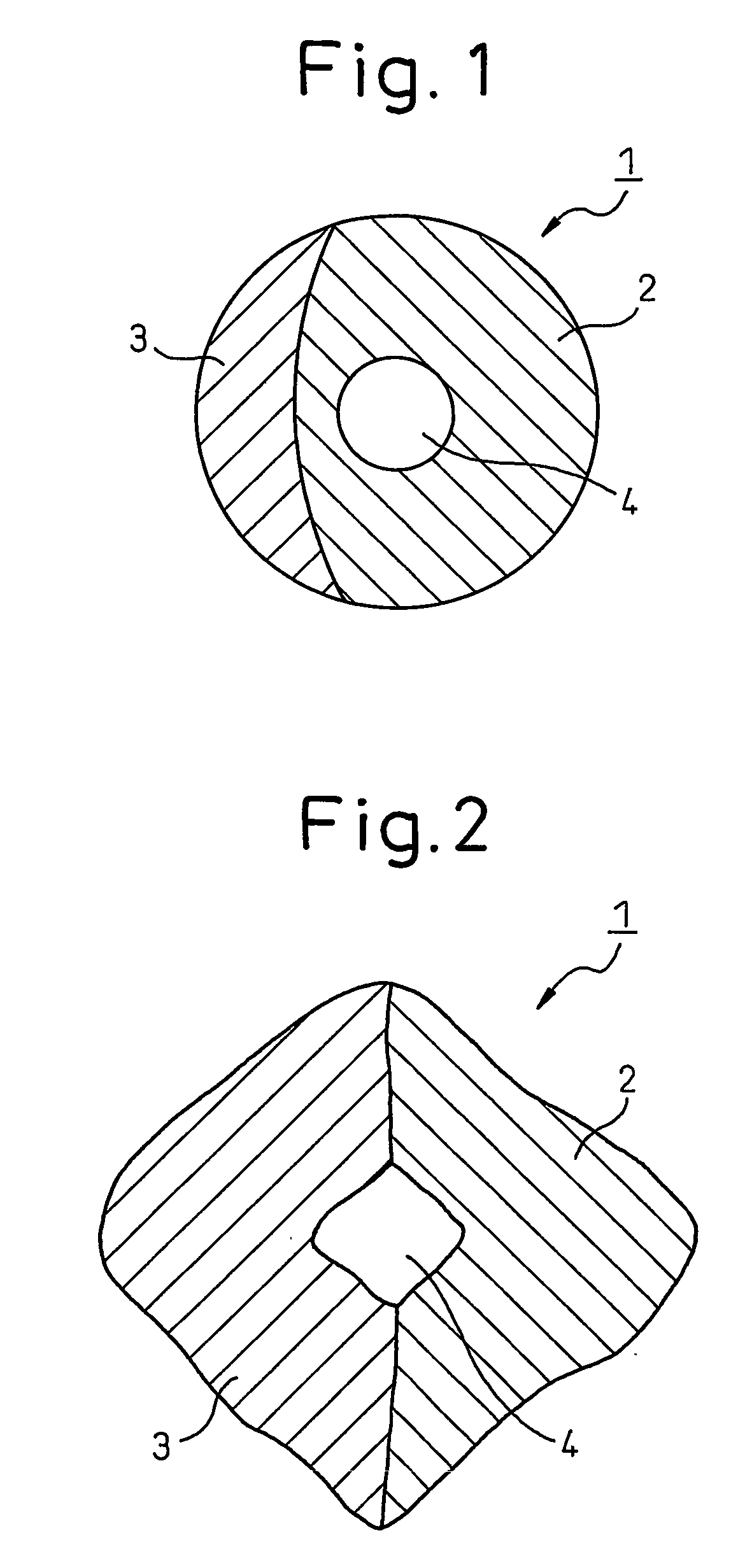

An object of the present invention is to provide a heat-bondable conjugate fiber ensuring that the crimp configuration stability can be maintained even in the state of leaving elongation of the fiber and bulkiness and softness are imparted to the nonwoven fabric, and a nonwoven fabric using the same. The present invention provides a heat-bondable conjugate fiber comprising a first component containing a polyester-based resin and a second component containing a polyolefin-based resin having a melting point lower than the melting point of said polyester-based resin, wherein said second component is a heat-bondable conjugate fiber accounting for a specific range of the outer fiber circumference and having a side-by-side or eccentric sheath-core structure and the fiber has a specific elongation, a specific range of a three-dimensional actualized crimp and a specific range of a crimp modulus.

Owner:FIBERVISIONS LP +1

Thermal bonding conjugate fiber with excellent bulkiness and softness, and fiber formed article using the same

ActiveUS8075994B2Maintains crimped form stabilityGood flexibilityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyolefin

A thermal bonding conjugate fiber constituted from a first component comprising a polyester resin and a second component comprising a polyolefin resin with a melting point lower than that of the polyester resin by not less than 20° C., characterized in that a post-heat treatment bulk retention rate thereof is 20% or more when calculated by the following measurement method: Bulk retention rate=(H1 (mm) / H0 (mm))×100(%) (wherein H0 is the web height when a 0.1 g / cm2 load is applied to a web with a mass per unit area of 200 g / m2; and H1 is the web height after a heat treatment for 5 min at 145° C. when a 0.1 g / cm2 load is applied to that web).

Owner:FIBERVISIONS LP +2

Normal pressure cationic dyeable polyester and fiber

InactiveUS20100275568A1Improve dyeing effectHigh strengthFilament/thread formingMonocomponent copolyesters artificial filamentPolyesterPhosphonium salt

It is a problem of the present invention to provide a normal pressure cationic dyeable polyester being cationic dyeable under normal pressure, and having high strength. The problem can be solved by a normal pressure cationic dyeable polyester, characterized by being a copolymerized polyester having a main repeating unit including ethylene terephthalate, and including, in an acid component forming the copolymerized polyester, a metal salt of sulfoisophthalic acid (A) and a compound (B) which is a phosphonium salt of sulfoisophthalic acid or the like in such a state as to simultaneously satisfy the two mathematical expressions. Preferably, the glass transition temperature of the copolymerized polyester is within the range of 70 to 85° C., and the intrinsic viscosity of the copolymerized polyester is within the range of 0.55 to 1.00 dL / g. Further, by melt spinning the copolymerized polyester, it is possible to provide a polyester fiber.

Owner:TEJIN FIBERS LTD

Grilled fish leavening agent, its preparation method and application

The invention relates to the technical field of food additive production, and aims to provide a grilled fish leavening agent special for grilled fish products. The leavening agent has reasonable formula, good leavening effect, and low production cost, and can maintain the good mouthfeel of grilled fish products. The grilled fish leavening agent of the invention is mixed by the following components by weight: 20-40% of sodium bicarbonate, 5-10% of citric acid, 10-15% of tartrate, 10-15% of diglyceride, 15-25% of calcium dihydrogen phosphate and 10-15% of sodium hexametaphosphate.

Owner:ZHEJIANG MARINE DEV RES INST

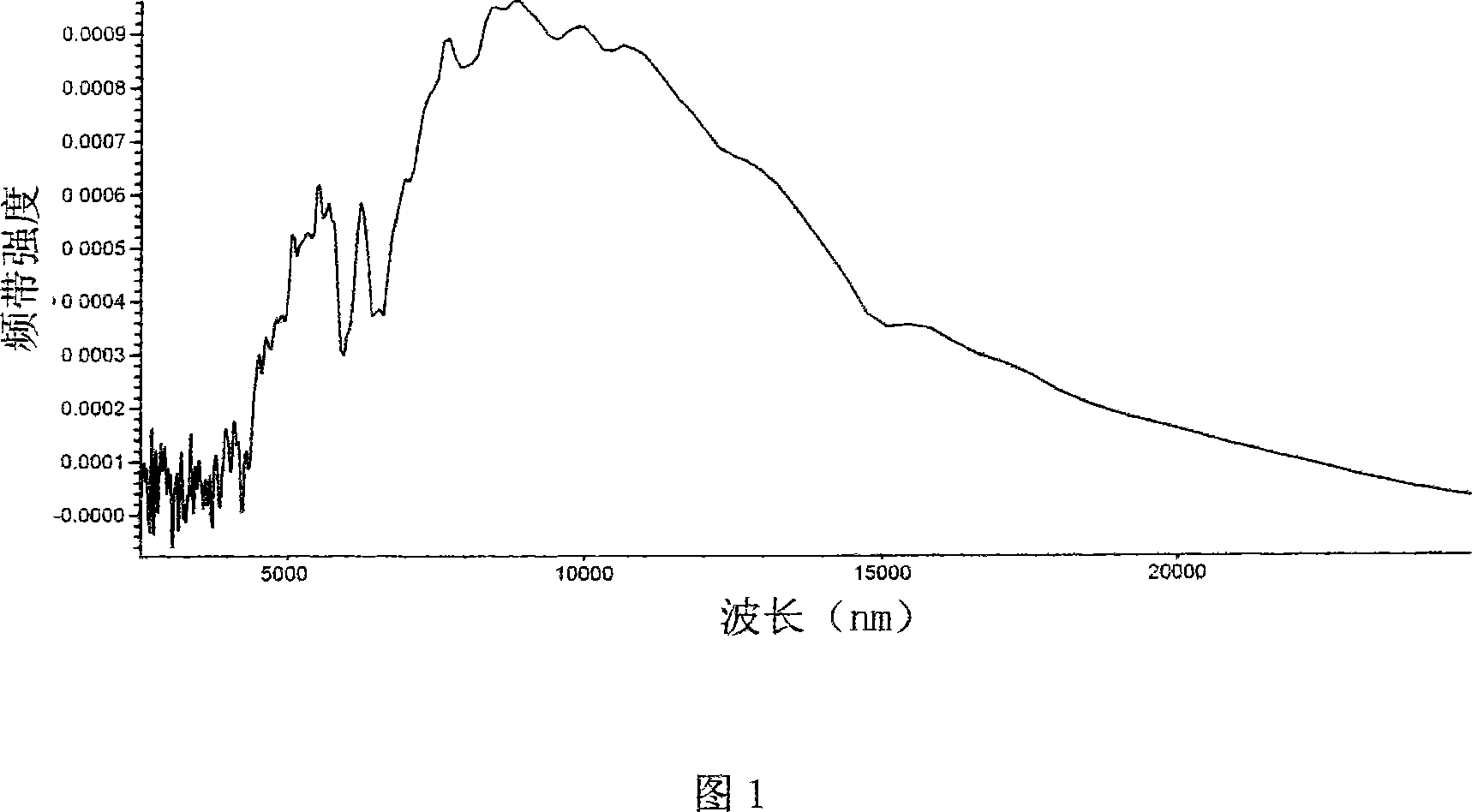

Anion far infrared post finishing method for silk wadding quilt

The invention discloses a far infrared finishing method of negative ions of silk floss quilts, which is characterized in that the method comprises respectively preparing finishing maceration extract A and B, and finishing maceration extract A comprises nanometer negative-ions far-infrared radiating body and dispersing agent and water, and finishing maceration extract B comprises low temperature cementing compound and silk cotton softening agent, placing finishing maceration extract A in dry silk cotton after heating, dipping for at least 40 minutes, dewatering, and drying to the wet containing rate which is 8-12%, utilizing finishing maceration extract B to dip and handle for 30-40 minutes, producing a silk floss quilt with a conventional method after centrifugally dewatering and drying. The silk floss quilt of the invention can effectively release negative ions, omnidirectional emission rate of the far infrared method can reach 88%, and the invention can effectively improve qi-blood circulation of human bodies, which plays an excellent health care effect, meanwhile, the invention is soft, whose bulkiness property is excellent, and has excellent performance property.

Owner:NANTONG LOVER APPL +1

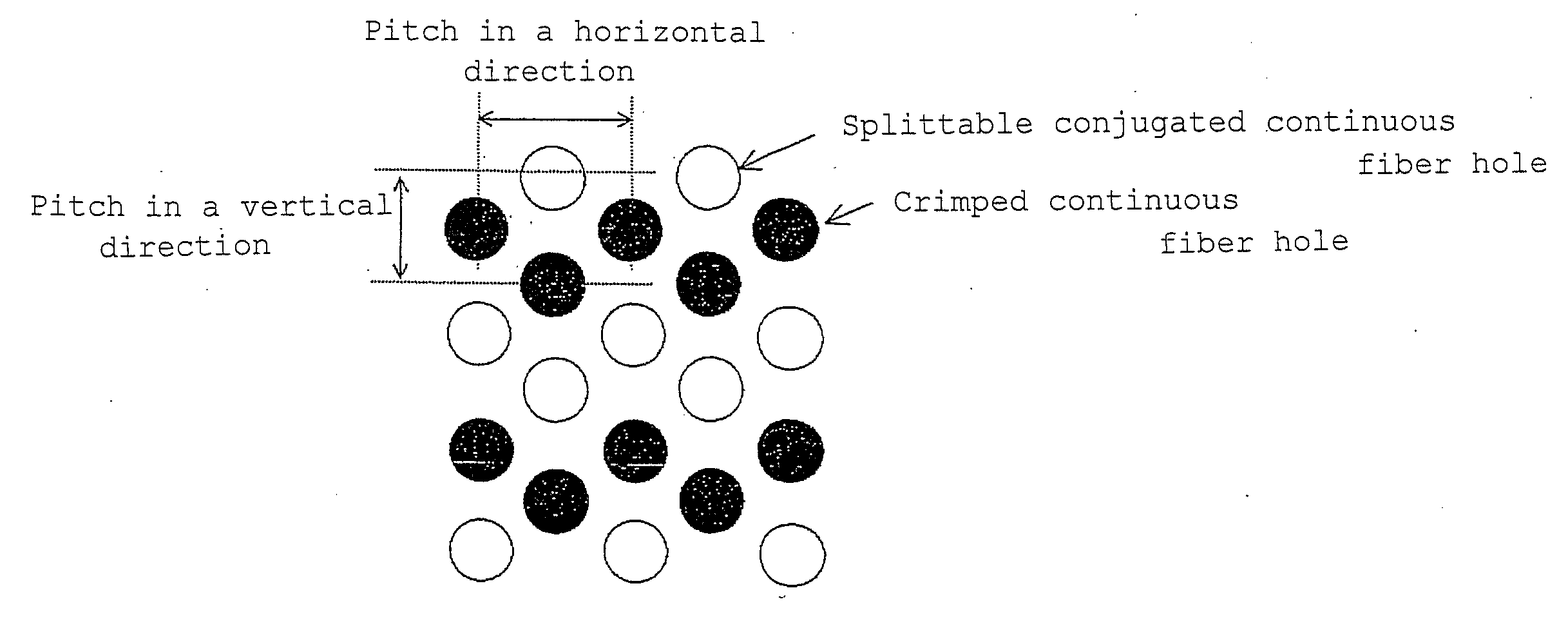

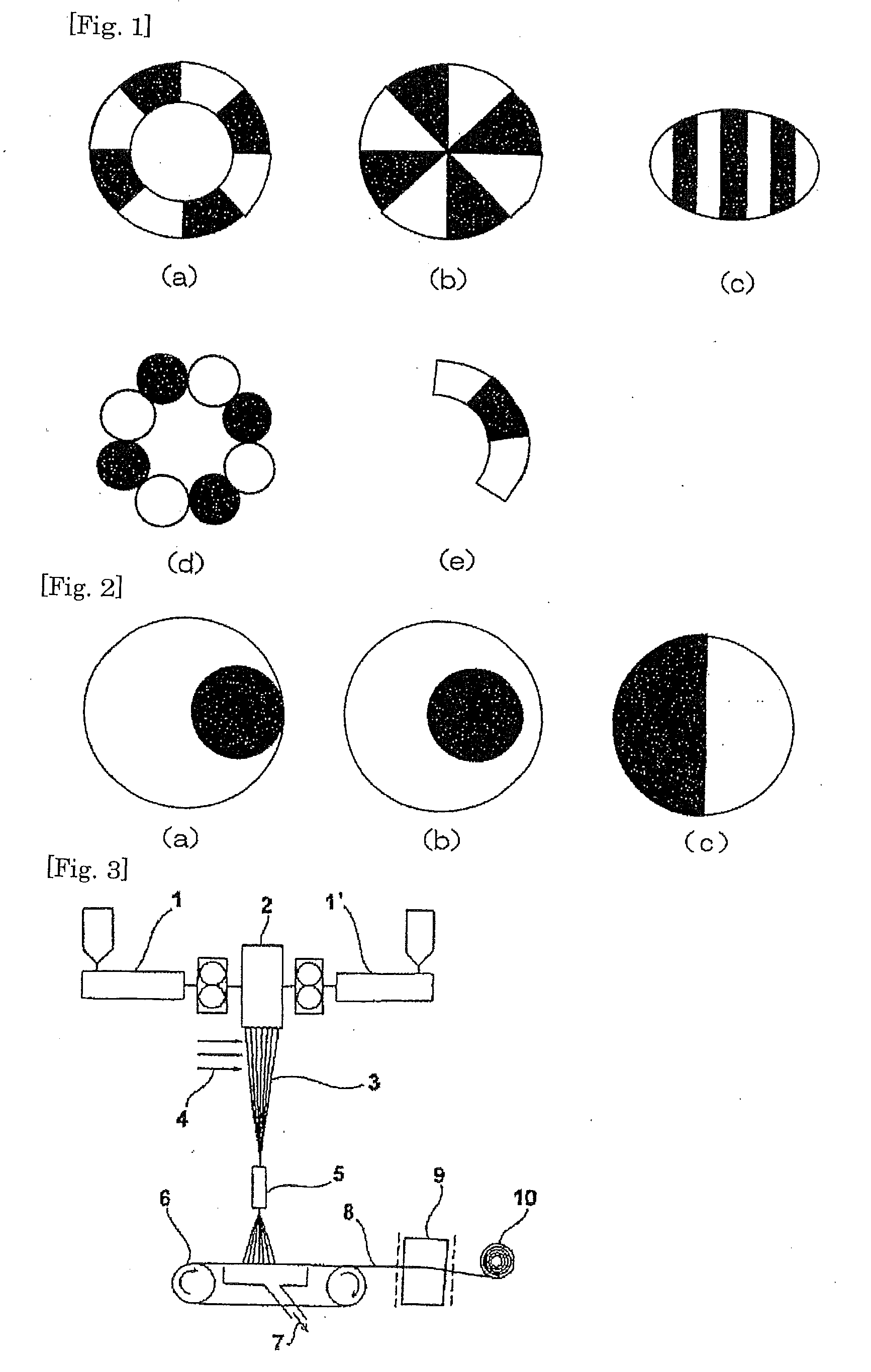

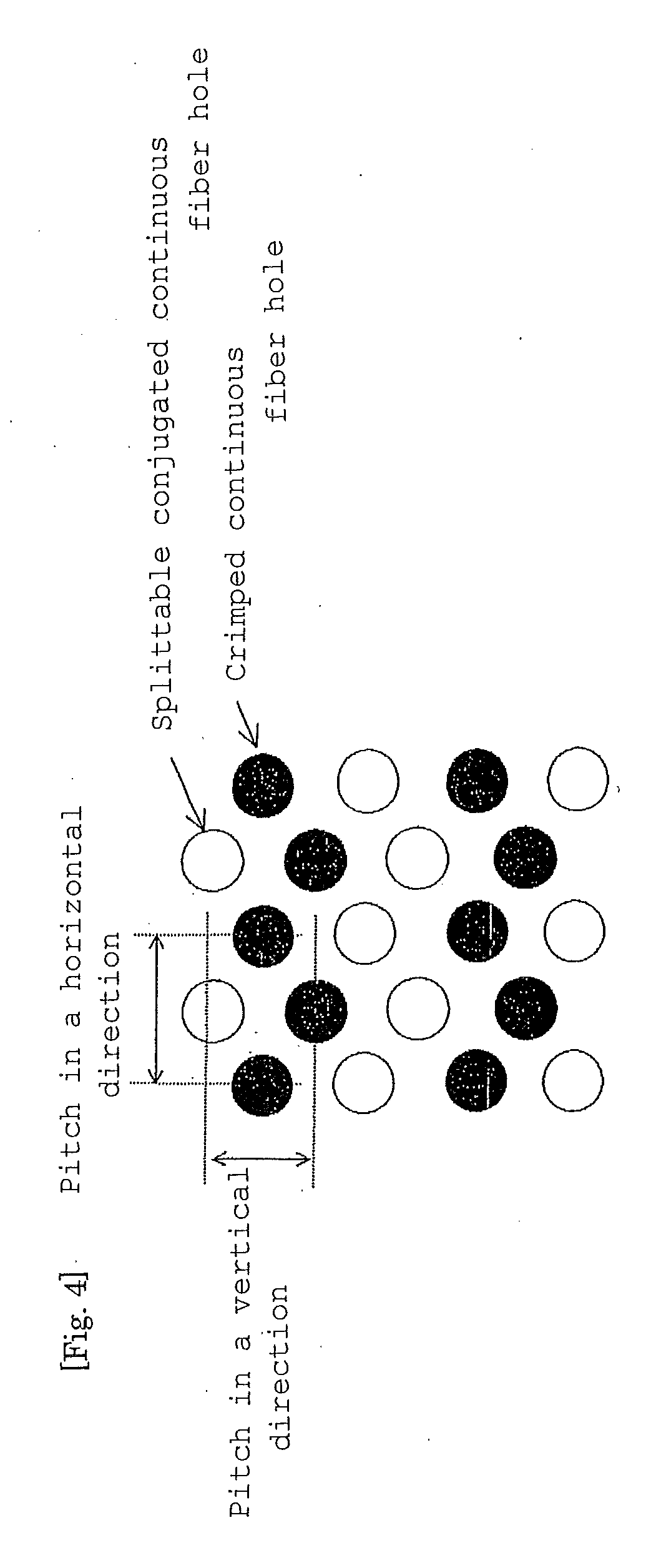

Mixed continuous fiber non-woven fabric and method for producing the same

InactiveUS20100130084A1Good bulkinessIncrease flexibilityPersonal careCarpet cleanersPliabilityEngineering

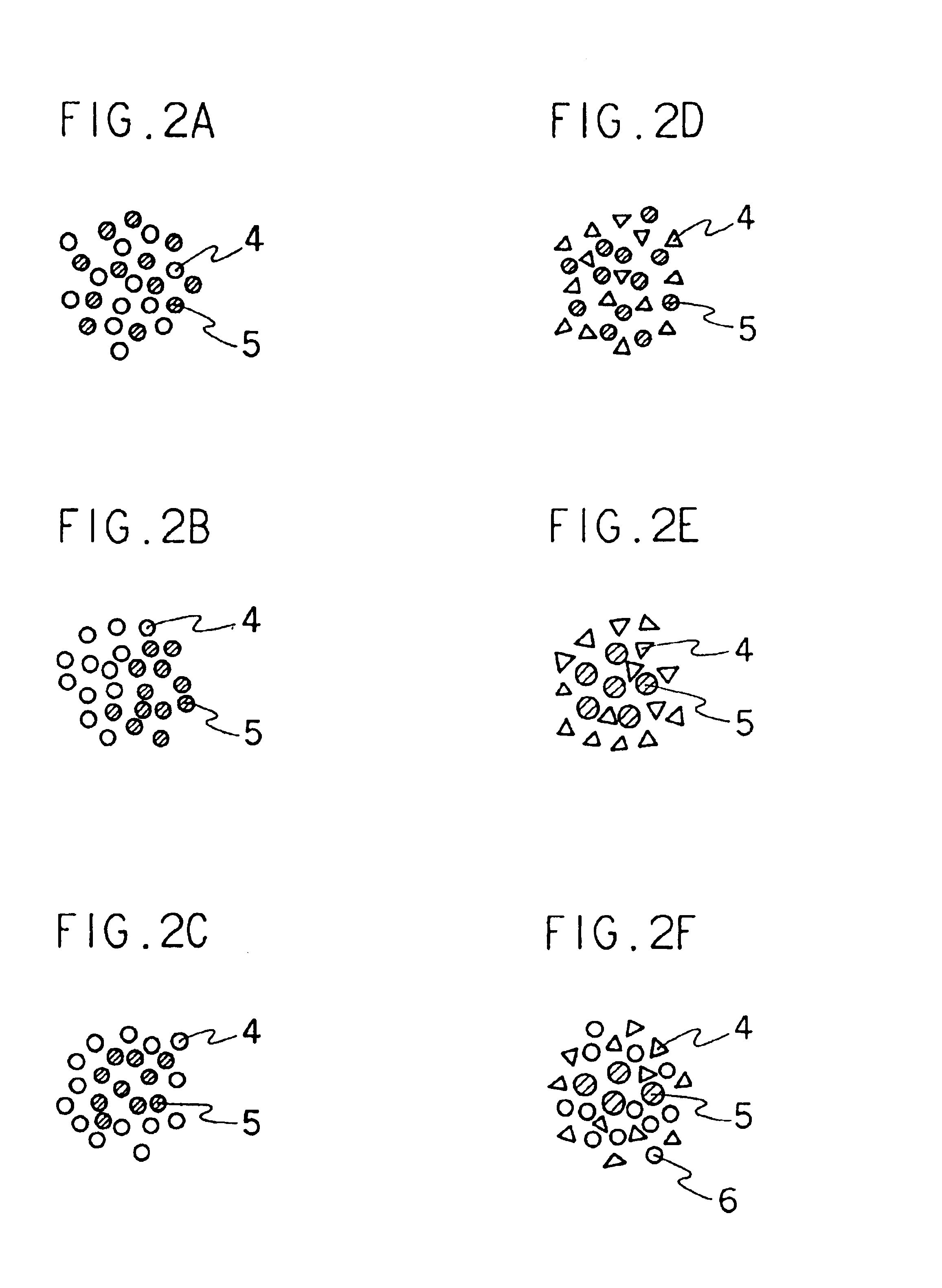

According to the present invention, it is possible to obtain a non-woven fabric that is excellent in bulkiness, flexibility, and feeling, in which less fibers drop out even in the case wherein the non-woven fabric is used for an application such as clothing items and a wiping cloth in which a surface of a non-woven fabric is rubbed, that is, excellent in a lint-free property.A mixed continuous fiber non-woven fabric in accordance with the present invention is characterized by comprising a split continuous fiber and a crimped continuous fiber, and is preferably characterized in that a total amount of the crimped continuous fiber is in the range of 10 to 90% by weight (where a total weight of a split continuous fiber and a crimped continuous fiber is 100% by weight).

Owner:MITSUI CHEM INC

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS20070094810A1Maintain good propertiesGood bulkinessBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

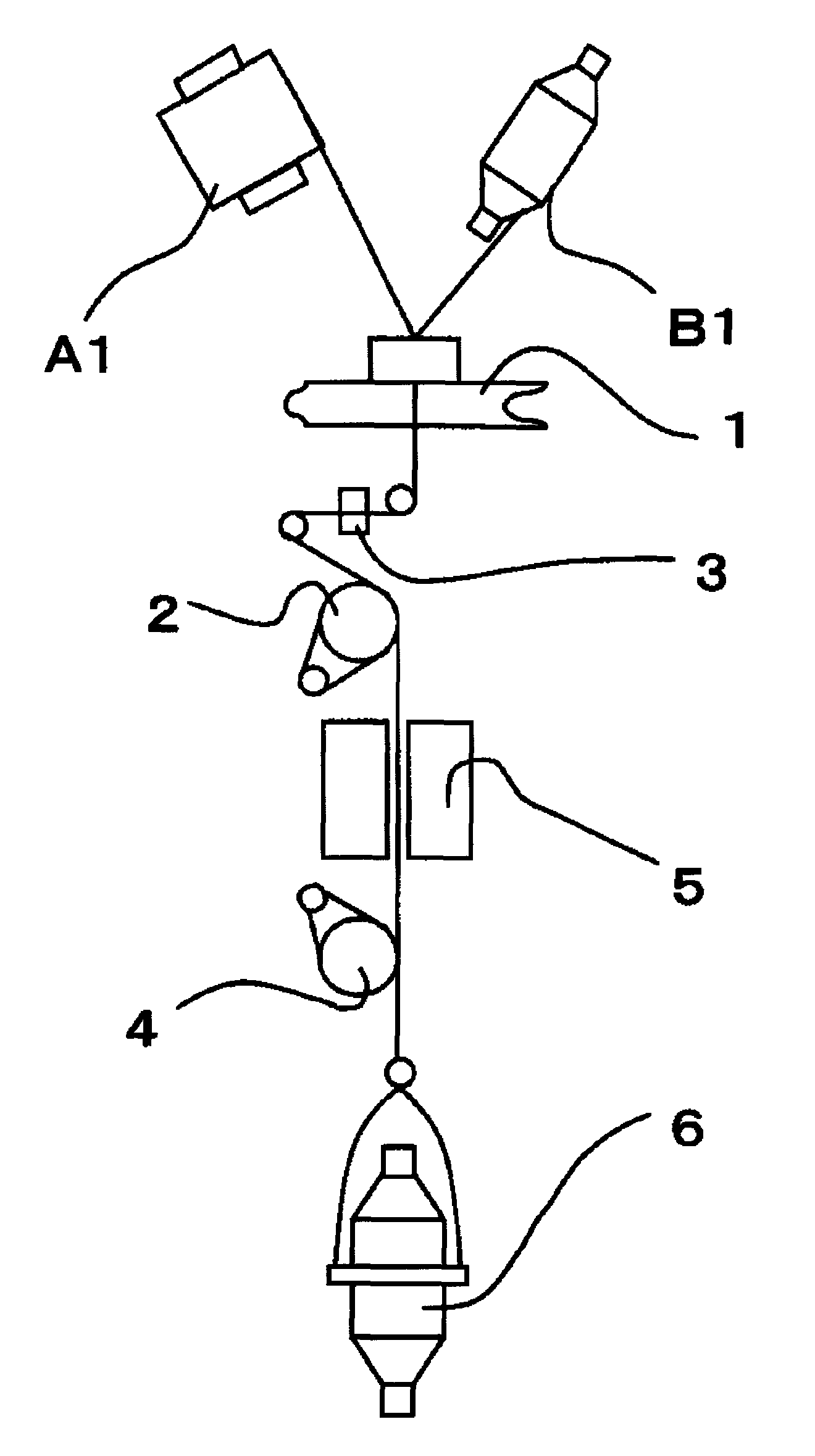

Injected melt direct-spinning production process for PET-PTT composite elastic fibers

InactiveCN105274637AReduce degradationGood qualityMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer meltElastic fiber

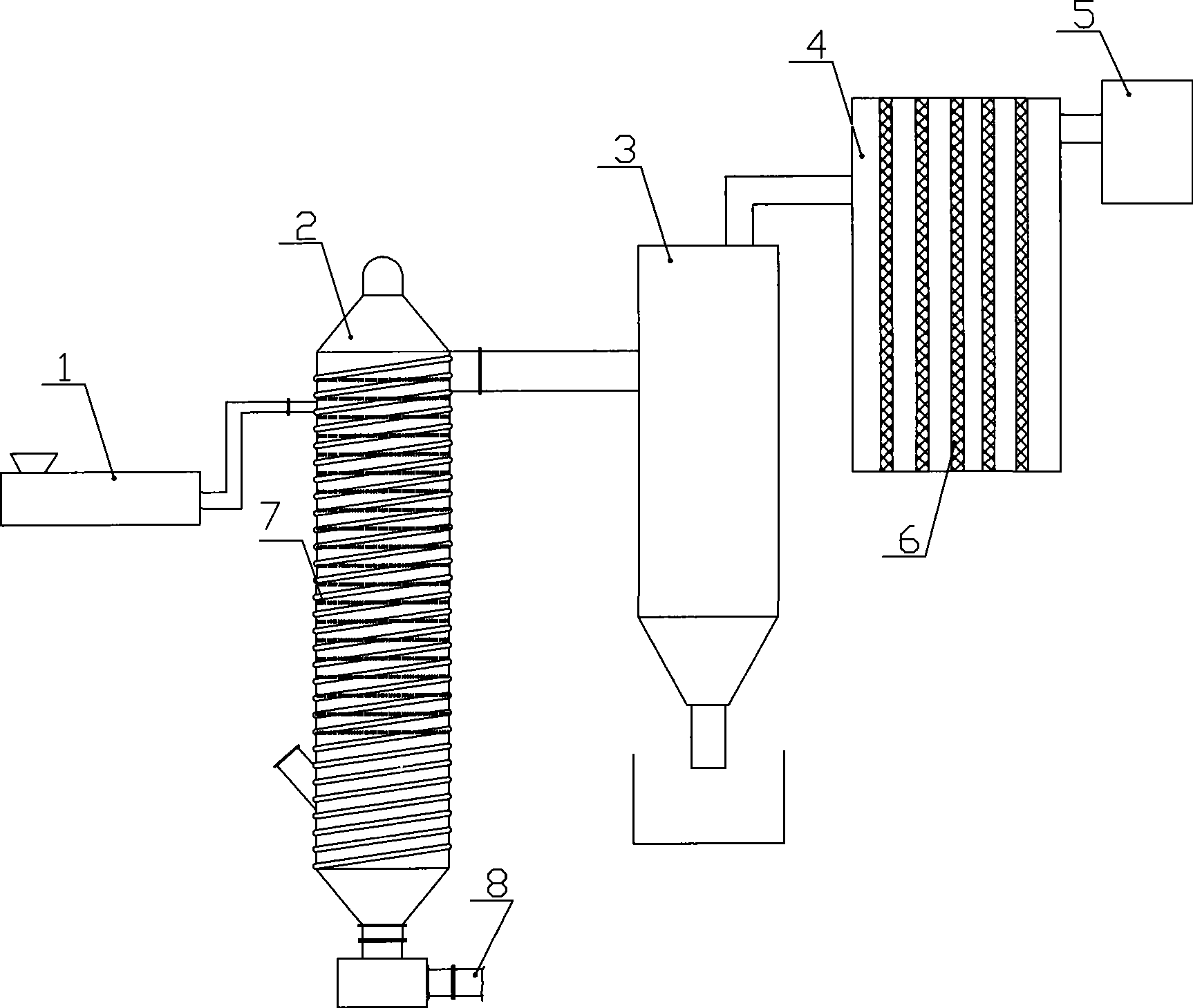

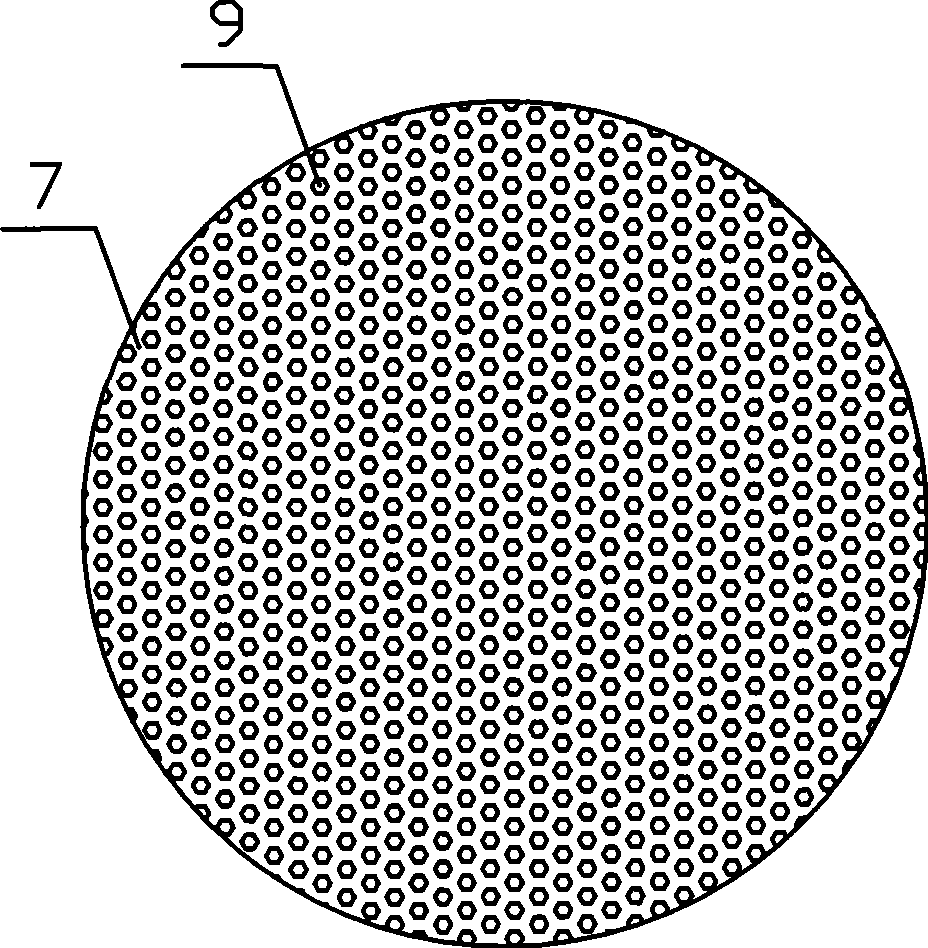

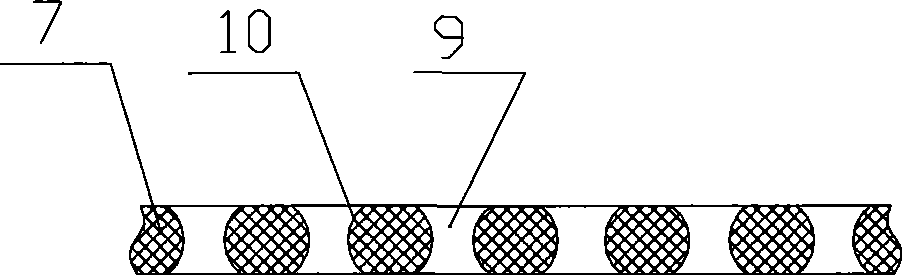

The invention provides an injected melt direct-spinning production process for PET-PTT composite elastic fibers. The process is characterized in that PET is subjected to the polymer-melt directly spinning treatment and PET is subjected to the slice screw melting treatment. After that, the melted PTT is injected into a spinning manifold and then is subjected to the jet spinning treatment at a spinneret orifice together with the PET melt side by side to form a side-by-side wire structure. Finally, composite elastic fibers are prepared and the mass ratio of PET to PTT in the eventually produced composite elastic fibers is 1:1. According to the technical scheme of the invention, the melt direct-spinning treatment of the PET is adopted, so that the special melting process is avoided. The slice screw melting treatment of the PTT is adopted, and the melted PTT is injected into the spinning manifold to be sprayed out as spun fibers together with the PET melt at the injected into a spinning manifold side by side so as to form the side-by-side wire structure. Therefore, the energy is saved, and the melt degradation is reduced. The eventually produced composite elastic fibers are good in quality and the fiber breakage strength thereof is larger than or equal to 2.5 CN / dtex. Meanwhile, the breakage elongation of the composite elastic fibers is larger than or equal to 20%, and the crimp elasticity thereof is larger than or equal to 90%. Therefore, the composite elastic fibers are good in quality.

Owner:福建经纬新纤科技实业有限公司

Method for preparing low-gel-strength eucheuma carrageenan

Owner:青岛海隆达生物科技有限公司

Grilled fish bone swelling agent, and preparation method and application of swelling agent

The invention discloses a grilled fish bone swelling agent which comprises the following components by mass percentage: 30-40% of sodium bicarbonate, 10-15% of monocalcium phosphate, 0.5-1% of xanthan gum, 40-50% of gluconic acid-delta-lactone, and 5-9% of soybean phosphatide powder. The swelling agent is reasonable in formula, and good in swelling effect and storability, and can allow a grilled fish bone to have a loose structure and a crispy taste and be easy to chew. The invention further discloses a preparation method of the grilled fish bone swelling agent. The method comprises the step of uniformly mixing sodium bicarbonate, xanthan gum, gluconic acid-delta-lactone and soybean phosphatide in proportion. The preparation method is simple in processing step, high in operability and low in cost, and is suitable for industrial production.

Owner:ZHEJIANG OCEAN UNIV

Normal pressure cationic dyeable polyester and fiber

InactiveUS8297035B2High strengthEasy to fixFilament/thread formingMonocomponent copolyesters artificial filamentPolyesterPhosphonium salt

It is a problem of the present invention to provide a normal pressure cationic dyeable polyester being cationic dyeable under normal pressure, and having high strength. The problem can be solved by a normal pressure cationic dyeable polyester, characterized by being a copolymerized polyester having a main repeating unit including ethylene terephthalate, and including, in an acid component forming the copolymerized polyester, a metal salt of sulfoisophthalic acid (A) and a compound (B) which is a phosphonium salt of sulfoisophthalic acid or the like in such a state as to simultaneously satisfy the two mathematical expressions. Preferably, the glass transition temperature of the copolymerized polyester is within the range of 70 to 85° C., and the intrinsic viscosity of the copolymerized polyester is within the range of 0.55 to 1.00 dL / g. Further, by melt spinning the copolymerized polyester, it is possible to provide a polyester fiber.

Owner:TEJIN FIBERS LTD

Polyethylene terephthalate, poly(ethylene naphthalene-2,6-dicarboxylate) and preparation thereof

InactiveCN101463507AImprove rigidityStable supportConjugated synthetic polymer artificial filamentsSpinning solutions preparationFiberPolyethylene terephthalate

The invention relates to an alloy fiber and a preparing method thereof, in particular to an alloy fiber of polyethylene terephthalate and polyethyleneglycol-2-6-naphthalene and a preparing method thereof. The alloy fiber of polyethylene terephthalate and polyethyleneglycol-2-6-naphthalene is prepared by melting, blending and spinning the polyethylene terephthalate and the polyethyleneglycol-2-6-naphthalene, and the polyethyleneglycol-2-6-naphthalene accounts for 1-15% of the weight of the alloy fiber. The invention also discloses a preparation technique of the alloy fiber. The invention well solve the problem of the blending condition of PEN and PET and provides good foundation for producing high-quality spinning melt. The alloy fiber prepared by the method has the characteristics of good rigidity (reflected by the supporting performance of the fiber) and bulkiness, and provides wider development space for the production of distinct chemical fiber.

Owner:NINGBO DAFA CHEM FIBER

Negative ion far infrared after-finishing method for silk floss quilt

InactiveCN1782169AEfficient releaseEffective combinationFibre treatmentLiquid/gas/vapor textile treatmentEmissivityAdhesive

The negative ion far infrared post-finishing process for silk floss quilt features the two kinds of compounded finishing immersion liquid, including the finishing immersion liquid A comprising negative ion far infrared radiator, dispersant and water, and the finishing immersion liquid B comprising adhesive and silk softener. The post-finishing process includes the steps of: soaking dry silk floss in heated finishing immersion liquid A for at least 40 min, dewatering and stoving to water content of 8-12 %; soaking in finishing immersion liquid B for 30-40 min, centrifugal dewatering and stoving; and convenient finishing. The silk floss quilt through the said post-finishing process can release negative ion, has far infrared emissivity up to 88 %, capacity of improving bodyí»s vital energy and blood running and excellent health functions, and is soft, puffy and excellent in wear performance.

Owner:NANTONG LOVER APPL +1

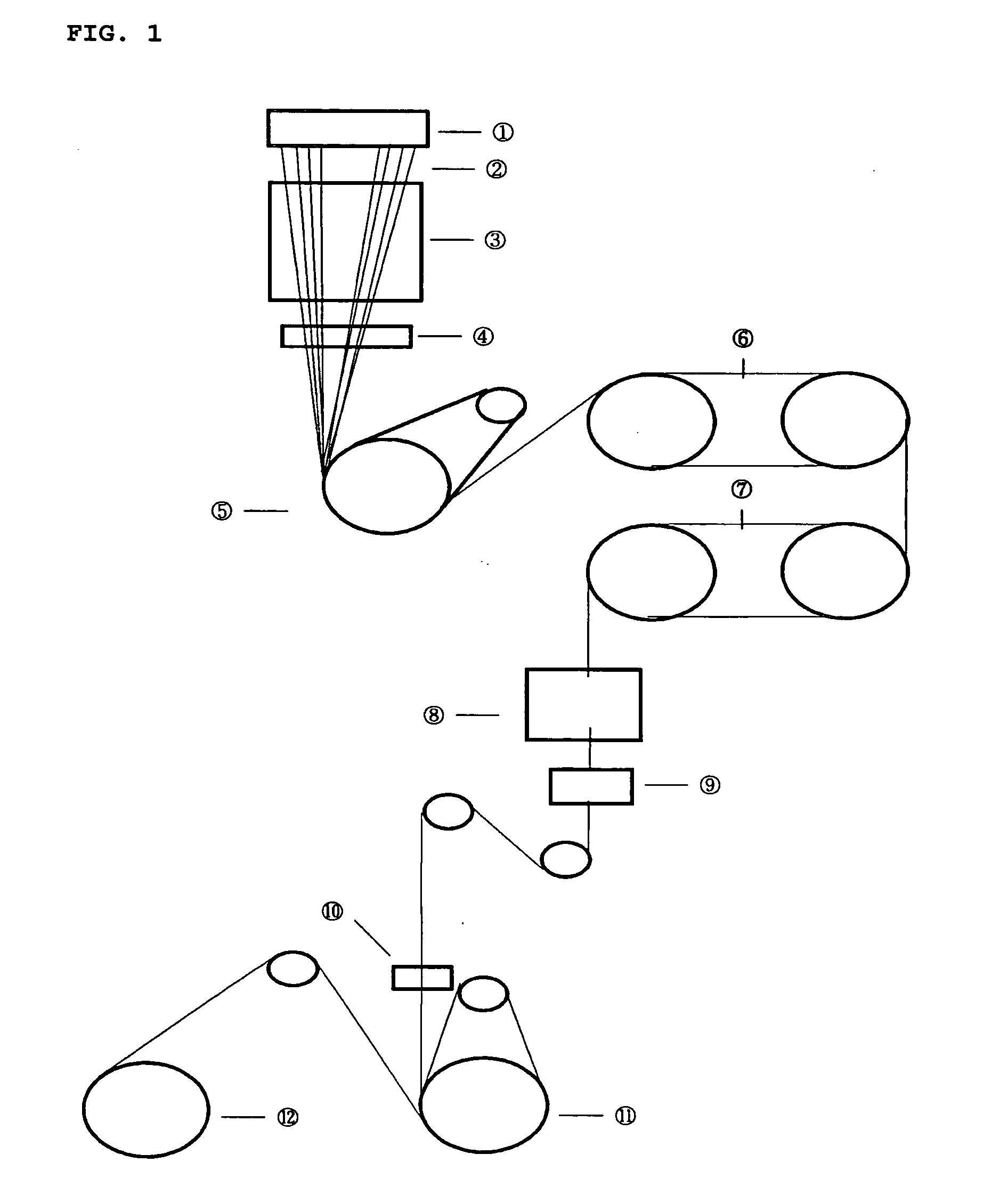

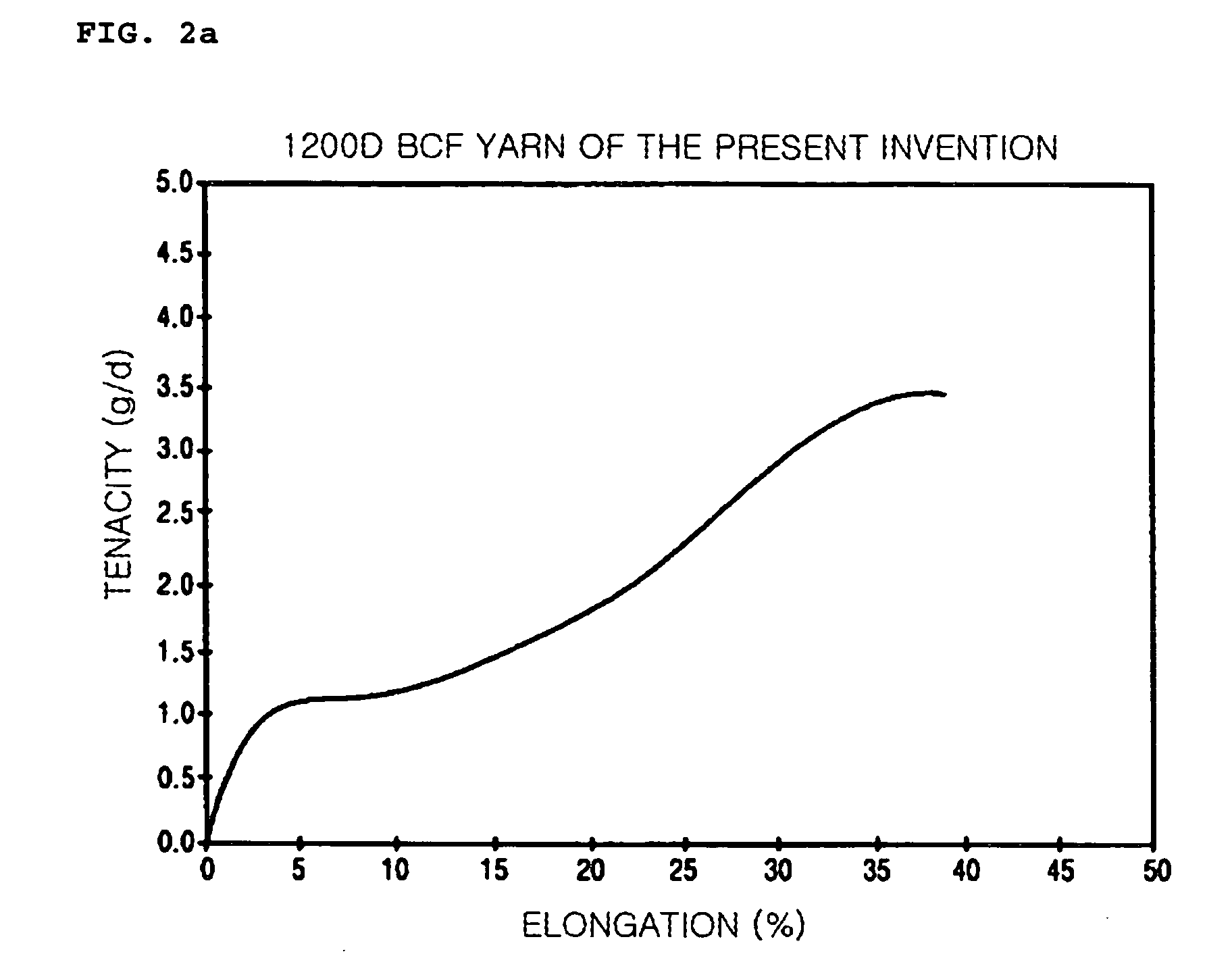

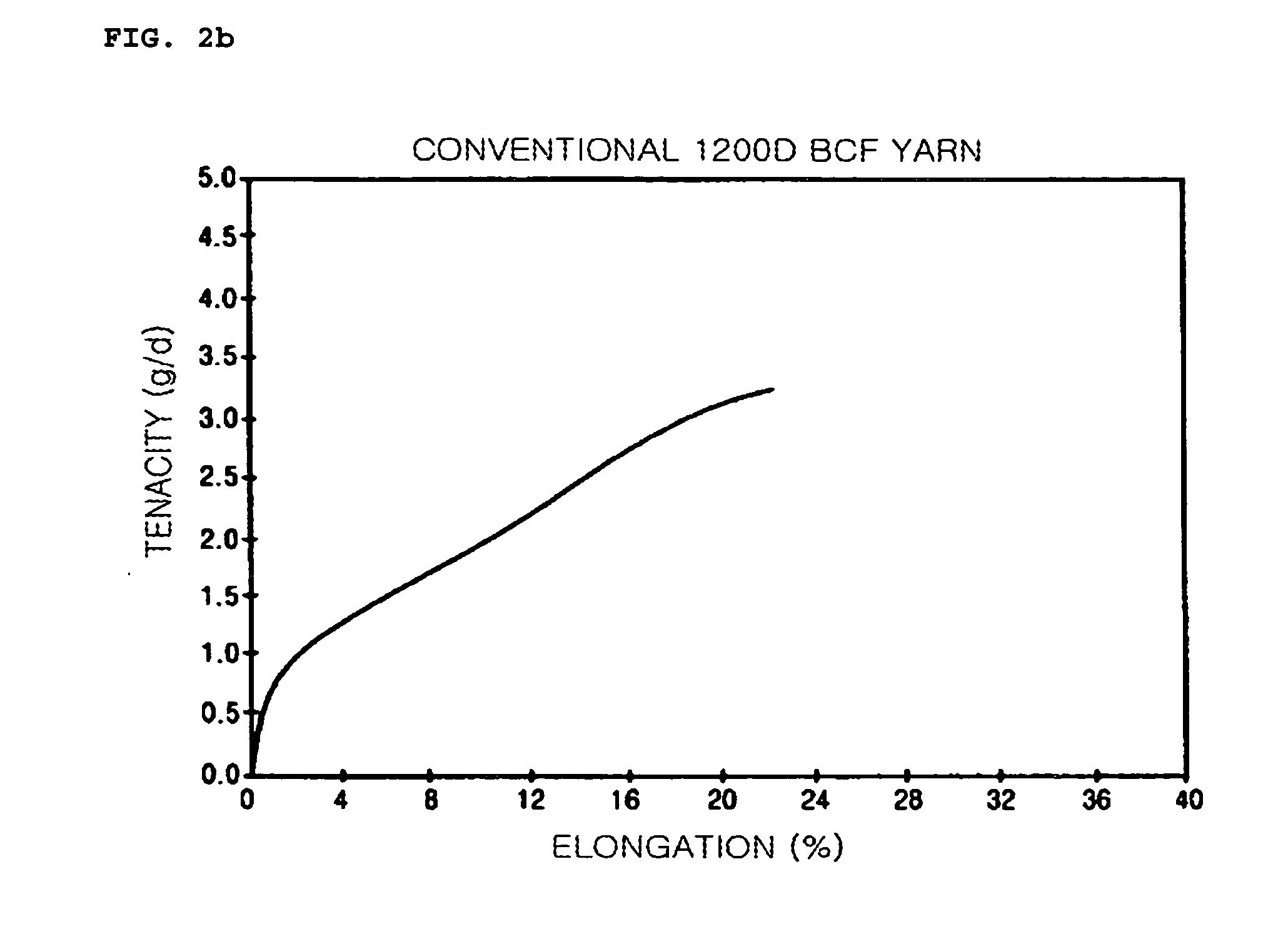

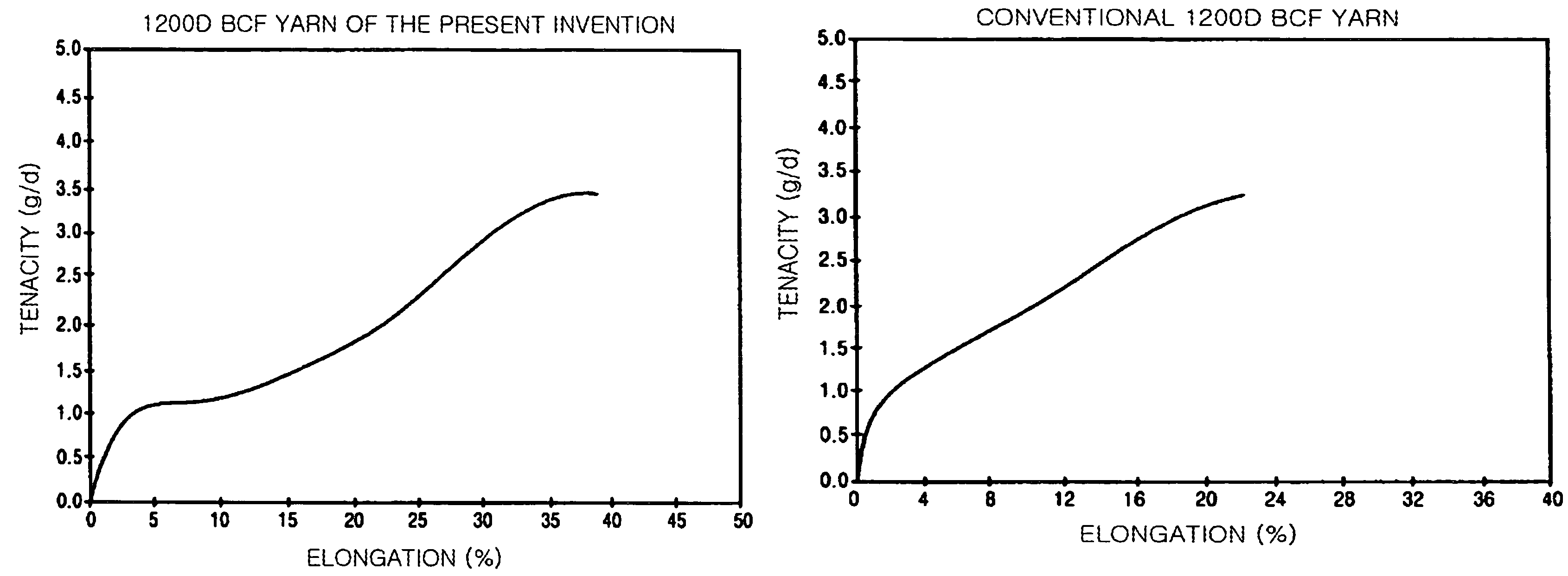

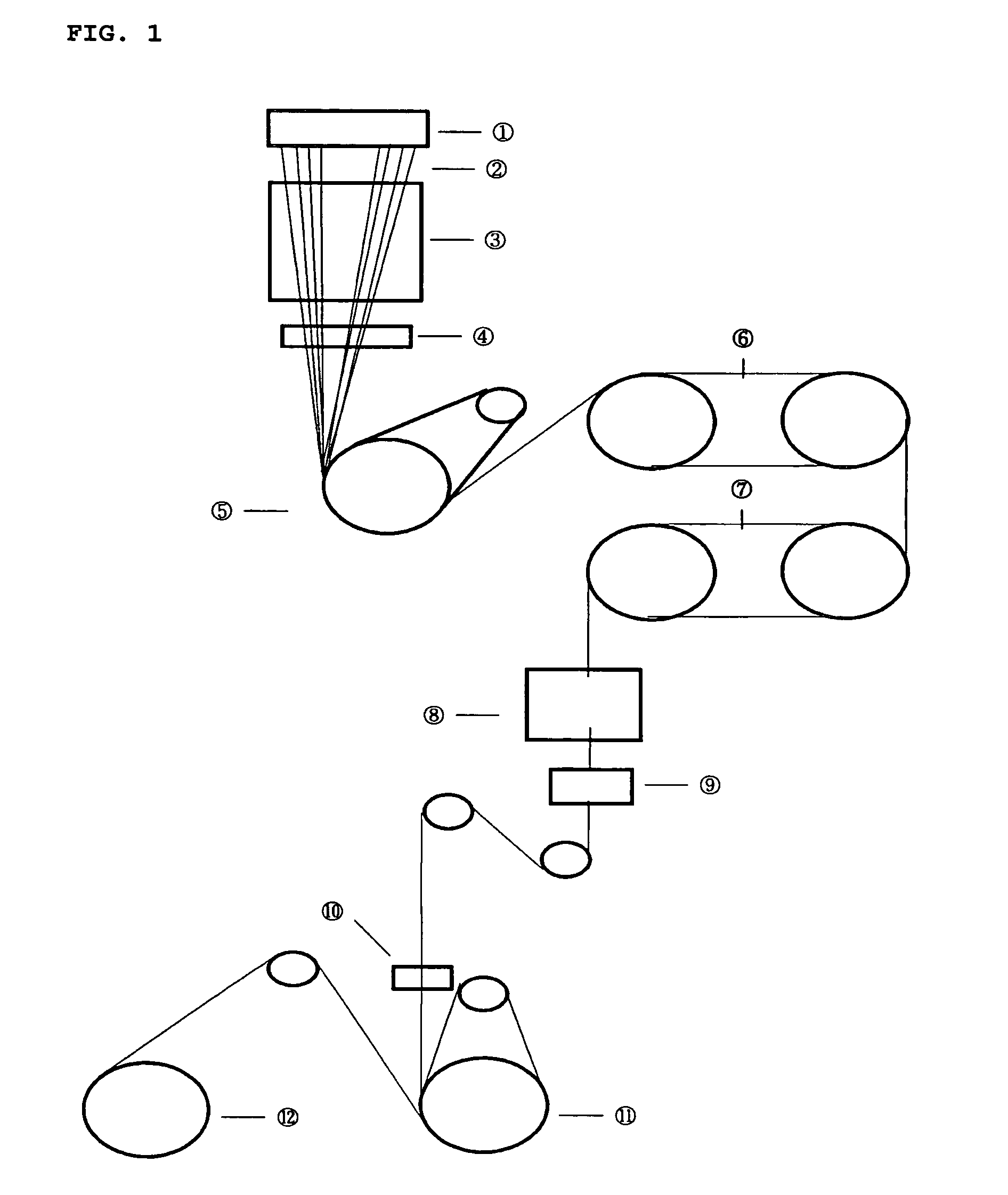

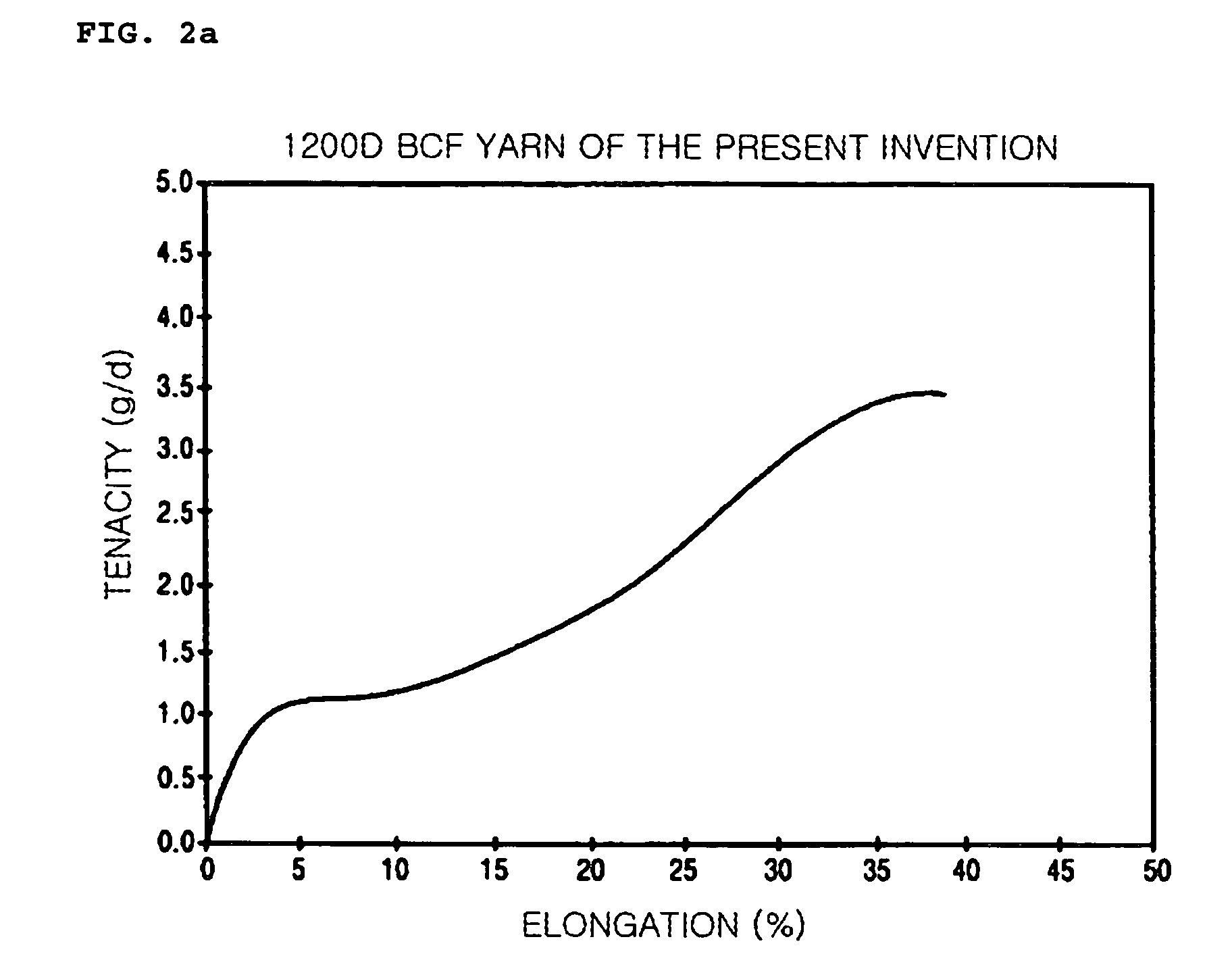

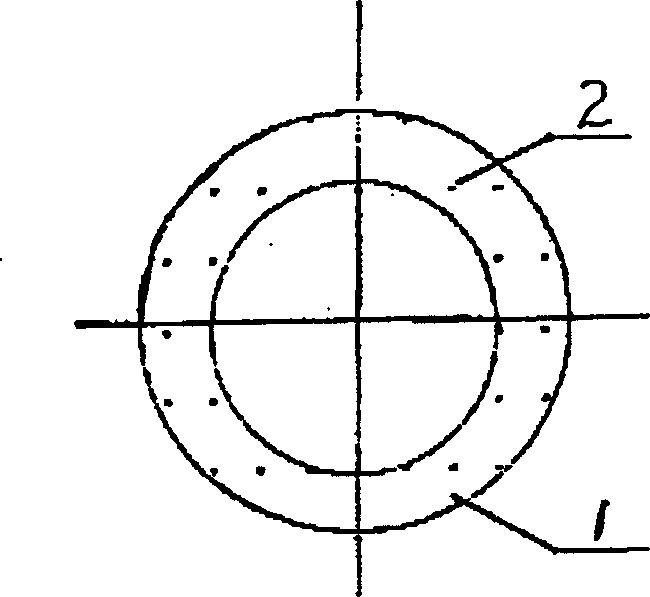

3-Dimension crimp polyethyleneterephthalate multifilament for carpet

ActiveUS20070243379A1Improve flame retardant performanceImprove toughnessFlame-proof filament manufactureSynthetic resin layered productsPolymer sciencePolyethylene terephthalate

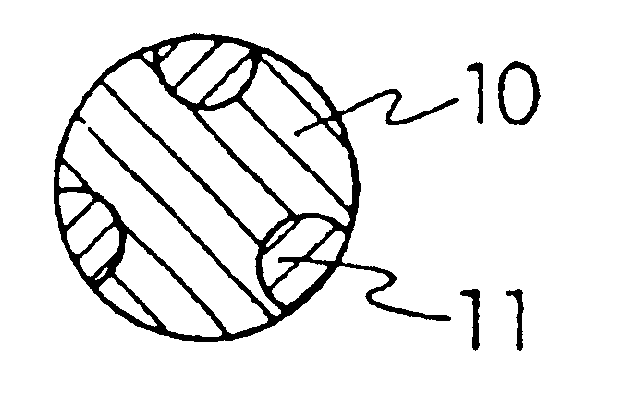

Disclosed is a 3-D crimp polyethylene terephthalate multifilament (BCF) having a stress-strain curve that (a) it elongates less than 5.0% when subjected to an initial stress of 1.0 g / d, (b) it has an initial modulus of 20 to 60 g / d, (c) it elongates at least 20% when subjected to a stress region of 1.0 to 2.5 g / d and (d) it elongates from a tensile strength of at least 3.0 g / d to the tensile strength at break. The BCF has improved physical properties such as excellent flame retardancy, high toughness, improved crimp uniformity and improved compressive elasticity modulus.

Owner:HYOSUNG ADVANCED MATERIALS CORP

Hollow regenerated cellulose fiber and manufacturing method thereof

ActiveCN103088455ALow costIncrease productivityArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentPolymer scienceCellulose fiber

The invention relates to a manufacturing method of a hollow regenerated cellulose fiber. The manufacturing method comprises the following steps of: preparing a spinning viscose solution through working procedures of soaking, squeezing, grinding, aging, yellowing, dissolving, filtering and defoaming on cellulose pulp, then spinning, in the dissolving step out of the working procedures for the preparation of the spinning viscose solution, adding one or mixture of water-soluble vinylon, a denaturing agent and a crosslinking agent, and then spinning to prepare the hollow regenerated cellulose fiber, wherein the fineness of the hollow regenerated cellulose fiber is 2.22-3.33 dtex, the dry strength of the hollow regenerated cellulose fiber is 2.2-2.6 cN / dtex, the wet strength of the hollow regenerated cellulose fiber is 1.2-2.0 cN / dtex, the degree of hollowness of the hollow regenerated cellulose fiber is greater than or equal to 70%, and the dry elongation is 10-20%. The manufacturing method is simple to operate, does not need special processing technology or equipment, does not release gas in a spinning process, and solves the problems such as reduction of the end breakage rate in spinning. The produced hollow fiber not only has high degree of hollowness, but also cannot collapse or deform due to after finishing and machining.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

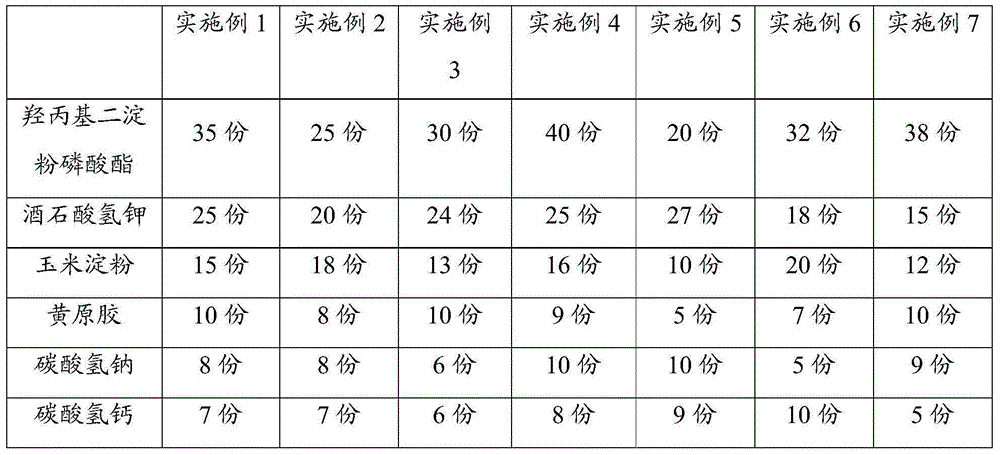

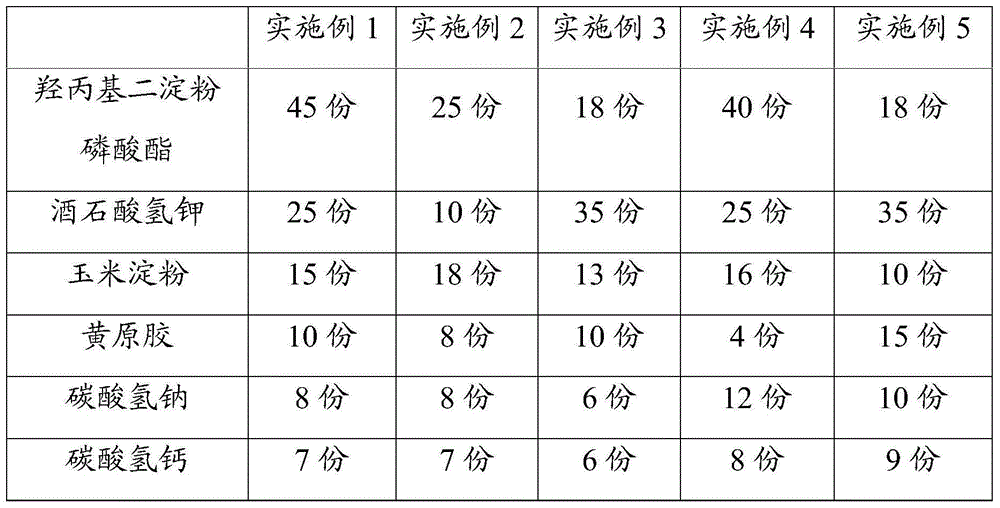

Food leavening agent and preparation method thereof

The invention relates to a food leavening agent, which consists of the following components in parts by weight: 20 to 40 parts of hydroxy propyl distarch phosphate, 15 to 30 parts of potassium hydrogen tartrate, 10 to 20 parts of corn starch, 5 to 10 parts of xanthan gum, 5 to 10 parts of sodium bicarbonate and 5 to 10 parts of calcium bicarbonate. The invention also provides a preparation method for the food leavening agent. The food leavening agent disclosed by the invention has good leavening property, moisturizing property and taste improvement property, so that baked food prepared from the food leavening agent is soft and moist in taste.

Owner:GUANGZHOU TIANHUI FOOD

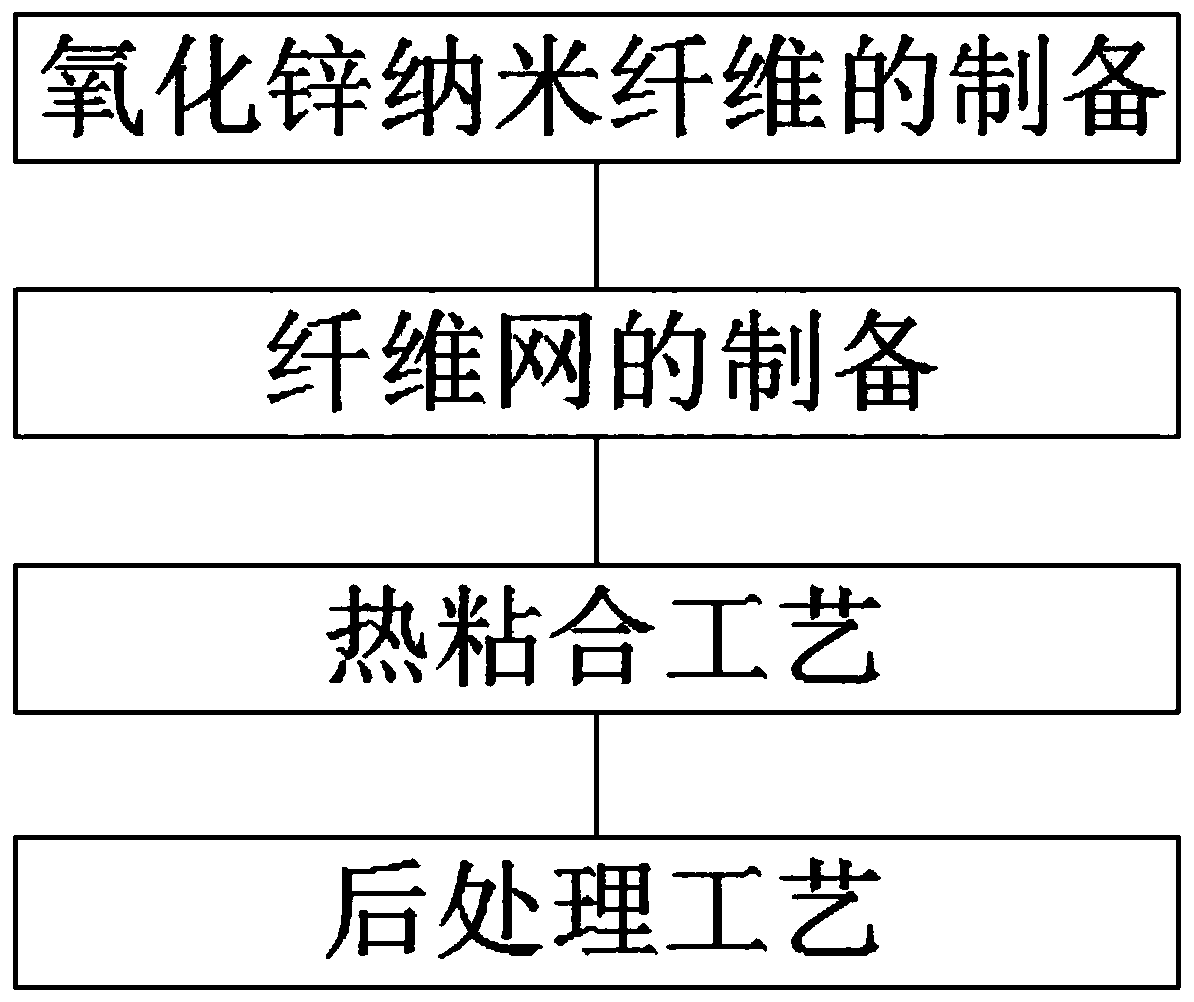

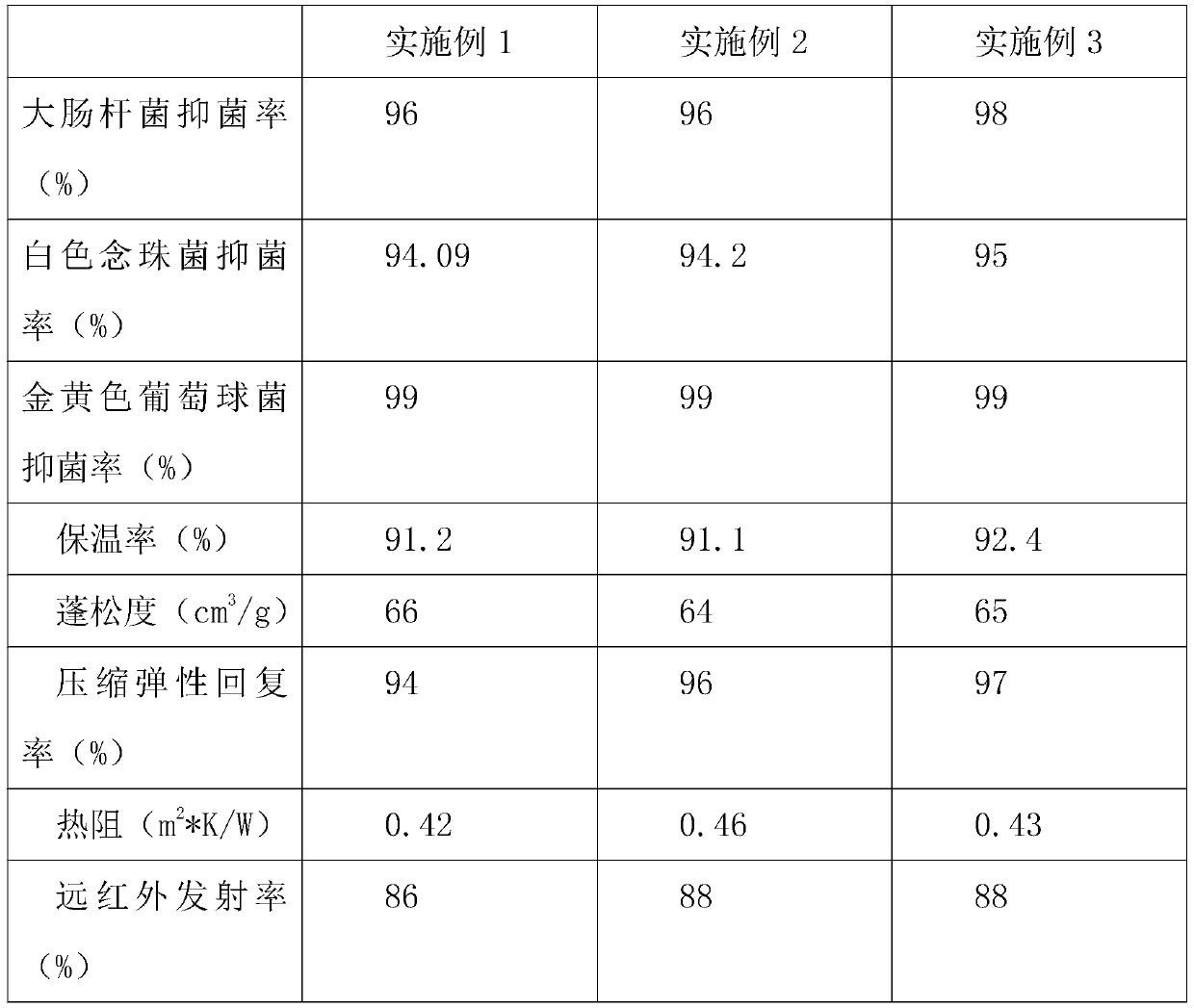

Antibacterial composite wadding sheet and preparation method thereof

InactiveCN110629400AGood bulkinessGood Far Infrared EfficacyFibre chemical featuresNon-woven fabricsFiberAfter treatment

The invention discloses an antibacterial composite wadding sheet and a preparation method thereof. The antibacterial composite wadding sheet is prepared by mixing of thermo-regulation fiber and zinc oxide nano-fiber according to the ratio of (20-50%) : (50-80%). The preparation method of the environmental-friendly composite wadding sheet includes the steps of preparation of zinc oxide nano-fiber,preparation of web, heat bonding process and after-treatment. The thermo-regulation fiber and the zinc oxide nano-fiber are mixed to prepare the composite wadding sheet, and accordingly, the compositewadding sheet has both functions of the thermo-regulation fiber and the zinc oxide nano-fiber, has excellent antibacterial property, high elasticity, good bulkiness and good far-infrared effect, andachieves effective temperature and humidity regulation through the thermo-regulation fiber. The temperature is controlled at 28-35 DEG C.

Owner:南通市同泰纺织科技有限公司

3-Dimension crimp polyethylene terephthalate multifilament for carpet

ActiveUS7566496B2Growth retardationImprove toughnessFlame-proof filament manufactureSynthetic resin layered productsPolymer sciencePolyethylene terephthalate

Owner:HYOSUNG ADVANCED MATERIALS CORP

Non-woven fabric laminate

ActiveUS8501646B2Good stretchabilityIncrease flexibilityPersonal careLayered productsFiberThermoplastic elastomer

A non-woven fabric laminate that is excellent in strechability, flexibility, and bulkiness, and that is less sticky and is suitable for a mechanical fastening female material. The non-woven fabric laminate includes a mixed fiber spunbonded non-woven fabric and a non-woven fabric comprising a crimped fiber that is laminated on at least one face of the mixed fiber spunbonded non-woven fabric, which includes a continuous fiber of a thermoplastic elastomer (A) in the range of 10 to 90% by weight and a continuous fiber of a thermoplastic resin (B) in the range of 90 to 10% by weight (where (A)+(B)=100% by weight). The non-woven fabric laminate can be suitably used for a sanitary material and other materials. More specifically, there can be mentioned for instance an absorbent article such as a disposable diaper and a menstrual sanitary product as a sanitary material.

Owner:MITSUI CHEM INC

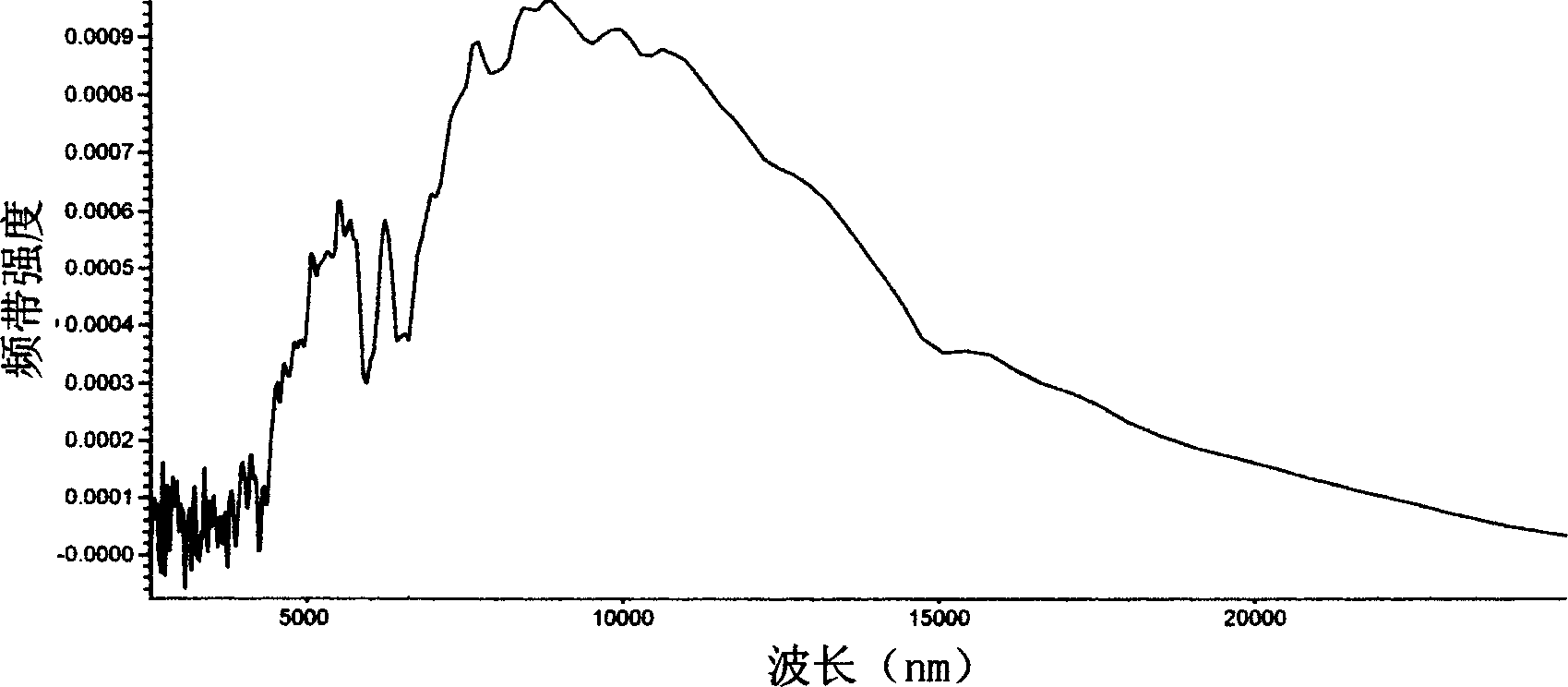

Far infrared radiating hollow 3-D crimped polyester fiber and its making process

InactiveCN1208507CGood bulkinessGood health functionHollow filament manufactureMonocomponent polyesters artificial filamentOperating temperaturePolyester

The invention relates to a far-infrared radiation hollow three-dimensional crimped polyester fiber in the fields of chemical engineering, polymer and chemical fiber manufacturing and a manufacturing method thereof, which combines 0.3-0.5 μm composite inorganic far-infrared ultrafine The coupling agent and surfactant are added into the high-speed mixer together for dry surface treatment. The superfine material powder after surface treatment is mixed with the polyester carrier in the high-speed mixer, and the mixed powder obtained is sent to the twin-screw extruder. Co-extrusion, its working temperature is 10-30°C lower than that of conventional color masterbatch. The far-infrared masterbatch and polyester chips obtained above are fed to the mixer through the metering feeder for mixing, and then sent to the production of hollow three-dimensional The crimped fiber is spun by a screw spinning machine, and the final product obtained is the far-infrared radiation hollow three-dimensional crimped polyester fiber of the present invention.

Owner:仪征化纤股份有限公司

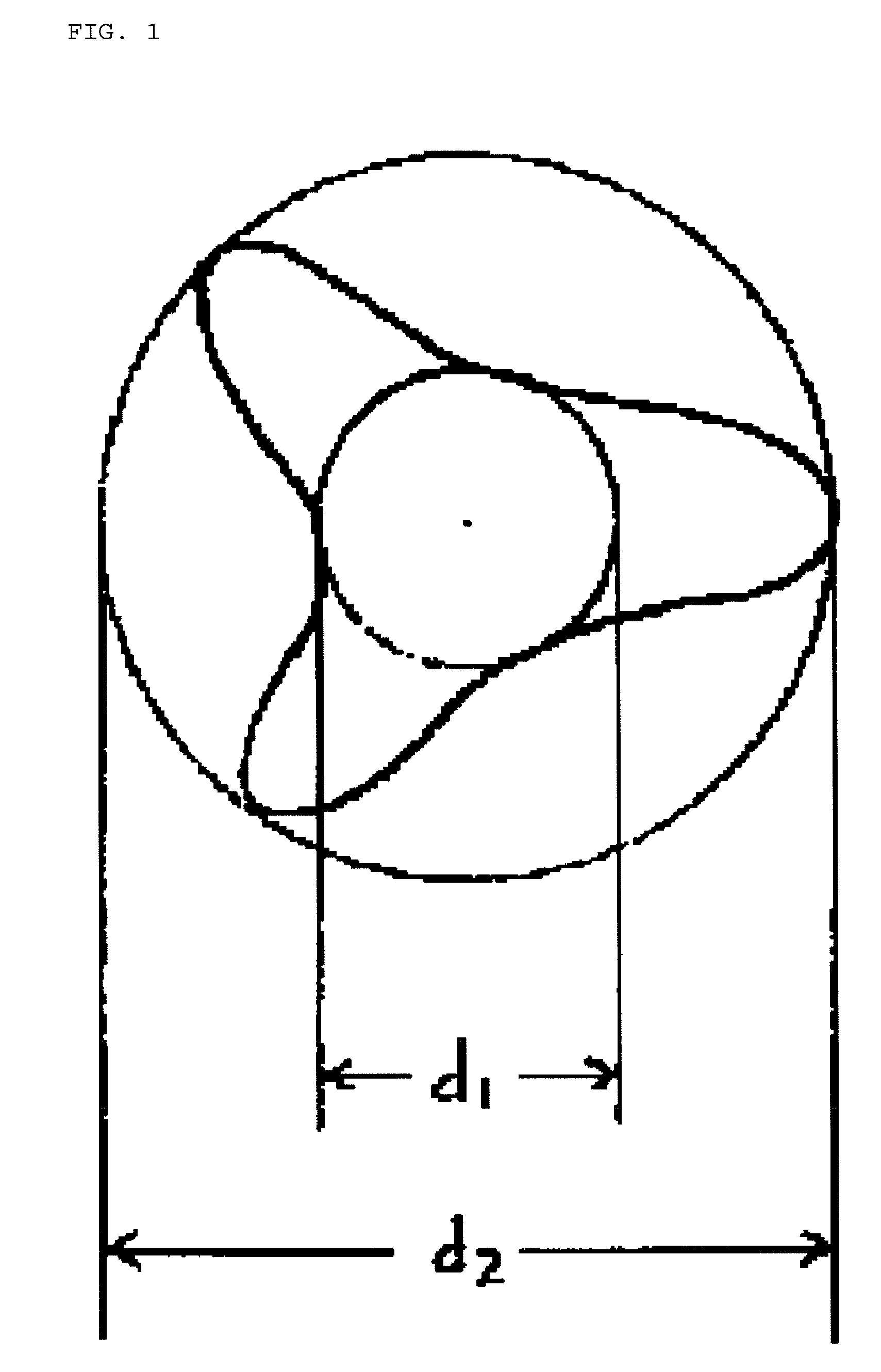

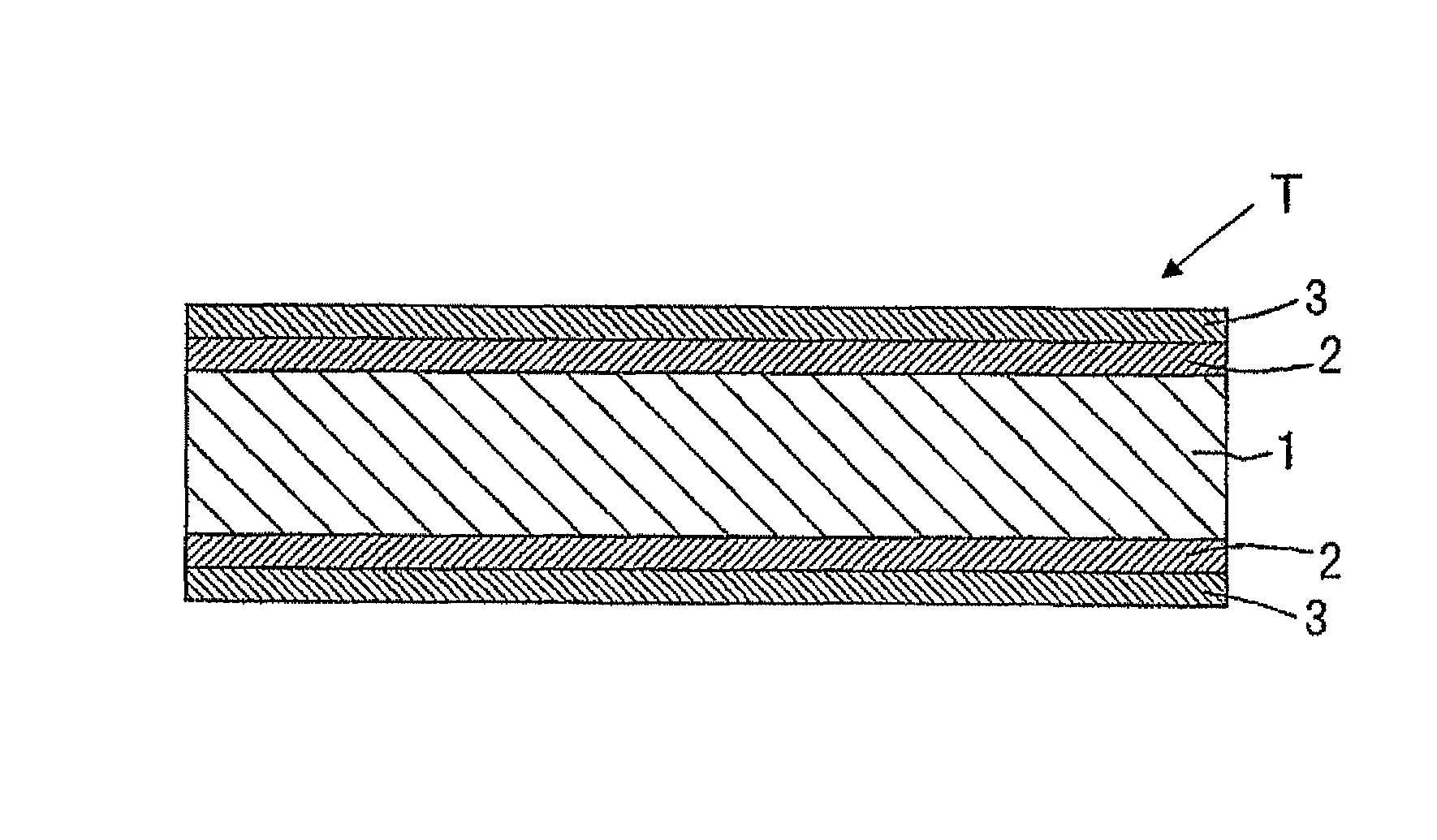

Polytrimethylene terephthalate hollow composite staple fibers and process for producing same

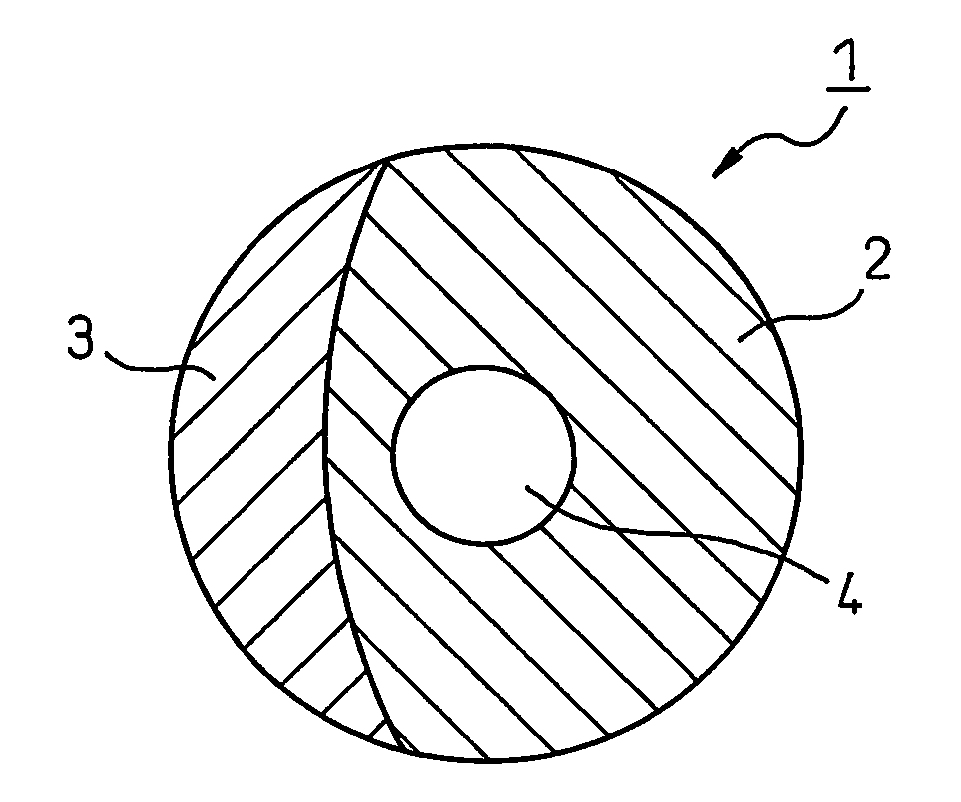

InactiveUS20060210793A1Good bulkinessPromote recoveryMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsPolymer sciencePolytrimethylene terephthalate

The polytrimethylene terephthalate hollow composite staple fibers exhibiting a latent crimping property and high bulkiness and elastic recovery and useful for nonwoen, woven and knitted fabrics and cushioning materials, have a hollow side-by-side or core-in-sheath type structure formed from two polytrimethylene terephthalate resin components one of which has an intrinsic viscosity of 0.50 to 1.40 dl / g and other one of which has an intrinsic viscosity of 0.40 to 1.30 dl / g and 0.1 to 0.5 dl / g below that of the former, and having a hollow part with a cross-sectional area of 2 to 15% of the total cross-sectional area, and exhibit, after the hollow composite staple fibers are formed into a web having a basis weight of 30 g / m2, and the web is heated at 120° C. for 10 minutes to cause the web to freely shrink, an area thermal shrinkage of 30 to 70% based on the original area of non-heated web.

Owner:SOLOTEX CORP

Method for manufacturing a regenerated particle aggregate

InactiveUS8152963B2Improve abilitiesGood bulkinessPigmenting treatmentNatural cellulose pulp/paperPulp and paper industryNewsprint

Owner:DAIO PAPER CORP

Terry product

InactiveUS20150093538A1Good bulkinessImprove stabilityWeft knittingBlanketEngineeringCellulose fiber

The invention relates to a terry product consisting of a textile base material and a pile associated with the base material, which is characterized in that the base material and / or the pile comprise(s) at least partially a cellulose fiber selected from the group consisting of viscose fibers, modal fibers, polynosic fibers and lyocell, which cellulose fiber has a titer of more than

Owner:LENZING AG

Ready-to-eat fried dough twists with Flos Sophorae and method for making ready-to-eat fried dough twists with Flos Sophorae

InactiveCN105494538AIncrease the fragranceStrong umamiDough treatmentBakery productsReady to eatPetal

The invention discloses ready-to-eat fried dough twists with Flos Sophorae and method for making the ready-to-eat fried dough twists with Flos Sophorae. The fried dough twists are prepared from, by weight, 500 parts of wheat flour, 100-120 parts of petals of Flos Sophorae, 50-60 parts of eggs, 1-3 parts of salt, 60-80 parts of white sugar, 3-5 parts of honey and 3-5 parts of active yeast. The method includes: (1) pouring hot water to the petals of Flos Sophorae, soaking in cold water, draining, roasting to a brown yellow color, adding the white sugar and the honey, soaking in alkaline ionized water, and mashing into Flos Sophoraee mash; (2) evenly dividing the wheat flour into three parts, adding boiling water to a first part of the wheat flour to obtain scalded dough, adding the Flos Sophoraee mash and the active yeast into a second part of the wheat flour to obtain fermented dough by kneading, and adding the eggs, the salt and clear water into a third part of the wheat flour to obtain egg elastic dough by kneading; (3) mixing the three types of dough, kneading uniformly, dividing into small pieces, rubbing and twisting the small pieces into dough twists, and frying until the dough twists are faint yellow. The ready-to-eat fried dough twists with Flos Sophorae has the advantages of nutrition, healthiness, instantaneity and convenience in eating and crispiness in taste.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com