Antibacterial composite wadding sheet and preparation method thereof

A technology of flakes and mixing ratio, applied in textiles and papermaking, non-woven fabrics, chemical characteristics of fibers, etc., can solve the problems of inability to warm, no antibacterial, anti-mite, flame retardant, poor skin-friendly, etc., and achieve bulky The effect of good performance and far-infrared efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

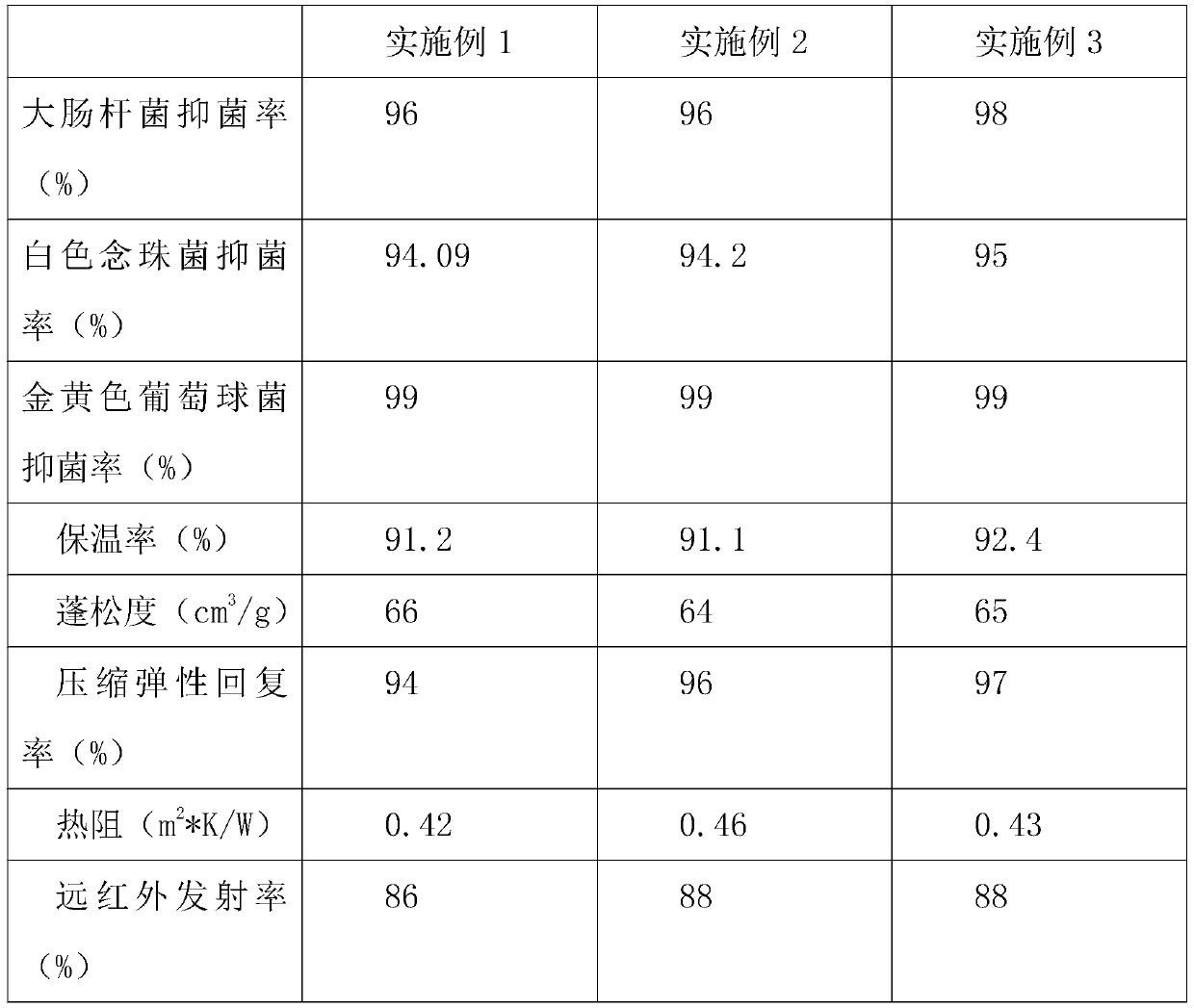

[0022] An antibacterial composite floc is formed by mixing temperature-regulating fibers and zinc oxide nanofibers, and the mixing ratio of the temperature-regulating fibers and zinc oxide nanofibers is 20%:80%.

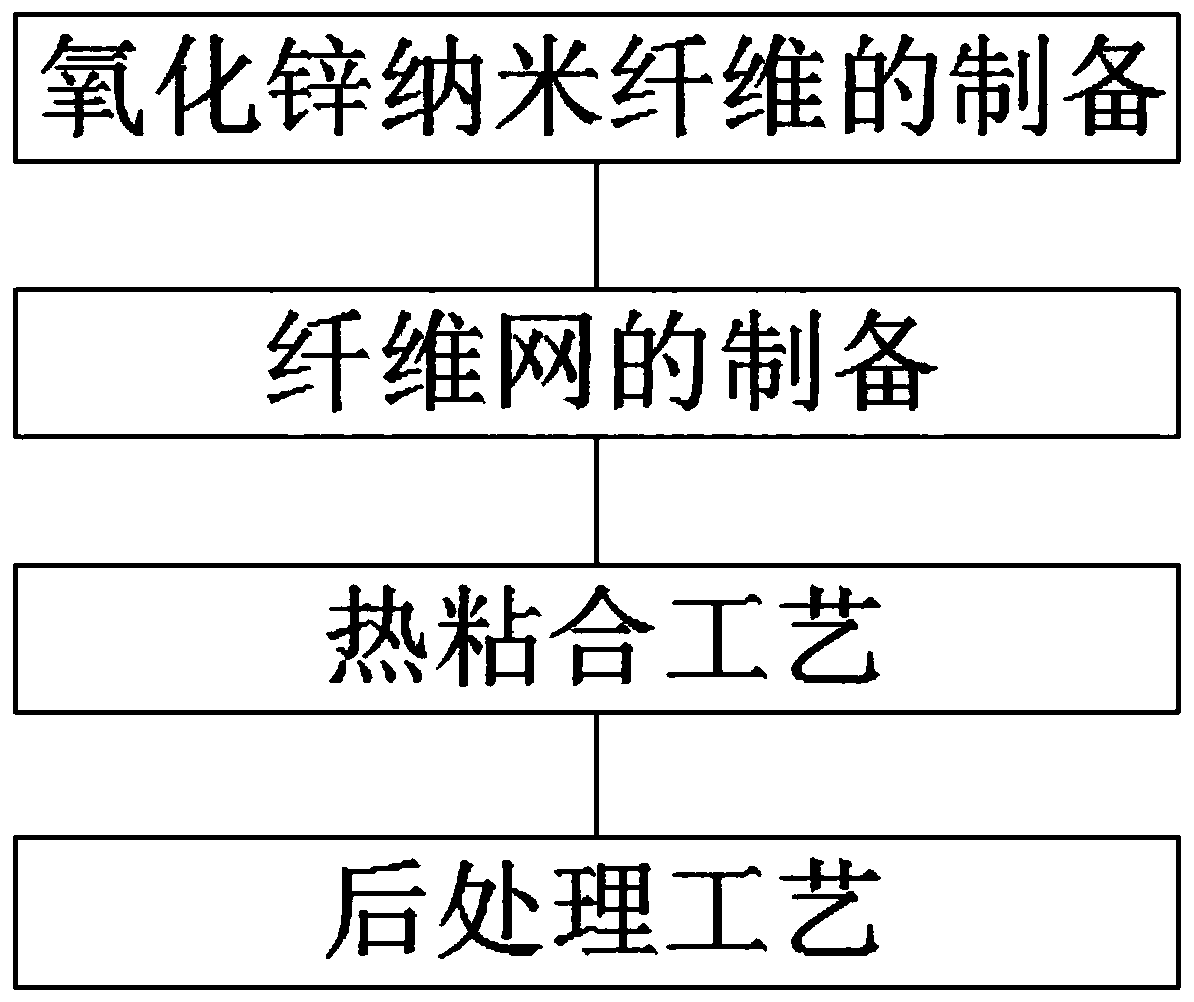

[0023] A method for preparing antibacterial composite flakes, through the steps of preparation of zinc oxide nanofibers, preparation of fiber webs, thermal bonding process and post-treatment process, the preparation method of environment-friendly composite flakes is completed, and the specific steps are as follows:

[0024] (1) Preparation of zinc oxide nanofibers: Ultrasonic degrease the matrix in acetone, absolute ethanol and deionized water for 10 minutes, mix PVA, zinc acetate and glacial acetic acid, and stir at 40°C for 2 hours to obtain a spun fiber Silk solution, the spinning solution is collected on the substrate by electrospinning, and the collected fibers are calcined in an oxygen atmosphere to complete the preparation of zinc oxide nanofibers; the mass rat...

Embodiment 2

[0029] An antibacterial composite floc is formed by mixing temperature-regulating fibers and zinc oxide nanofibers, and the mixing ratio of the temperature-regulating fibers and zinc oxide nanofibers is 50%:50%.

[0030] A method for preparing antibacterial composite flakes, through the steps of preparation of zinc oxide nanofibers, preparation of fiber webs, thermal bonding process and post-treatment process, the preparation method of environment-friendly composite flakes is completed, and the specific steps are as follows:

[0031] (1) Preparation of zinc oxide nanofibers: Ultrasonic degrease the matrix in acetone, absolute ethanol and deionized water for 30 minutes, mix PVA, zinc acetate and glacial acetic acid, and stir at 60 ° C for 3 hours to obtain a spun fiber Silk solution, the spinning solution is collected on the substrate by electrospinning, and the collected fibers are calcined under an oxygen atmosphere to complete the preparation of zinc oxide nanofibers; the mas...

Embodiment 3

[0036] An antibacterial composite flake is formed by mixing temperature-regulating fibers and zinc oxide nanofibers, and the mixing ratio of the temperature-regulating fibers and zinc oxide nanofibers is 45%:55%.

[0037] A method for preparing antibacterial composite flakes, through the steps of preparation of zinc oxide nanofibers, preparation of fiber webs, thermal bonding process and post-treatment process, the preparation method of environment-friendly composite flakes is completed, and the specific steps are as follows:

[0038] (1) Preparation of zinc oxide nanofibers: The substrate was ultrasonically degreased in acetone, absolute ethanol and deionized water for 20 minutes, mixed with PVA, zinc acetate and glacial acetic acid, and stirred at 50°C for 2.5 hours to obtain a spun fiber. Silk solution, the spinning solution is collected on the substrate by electrospinning, and the collected fibers are calcined under an oxygen atmosphere to complete the preparation of zinc o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com