Polytrimethylene terephthalate hollow composite staple fibers and process for producing same

a technology of polytrimethylene terephthalate which is applied in the direction of filament/thread forming, transportation and packaging, yarn, etc., can solve the problems of composite filamentary streams that adhere to adjacent streams or to spinnerets, the melt-spinning procedure cannot be stably carried out, and the degree of bending of composite filamentary streams significantly increases with increasing the difference in intrinsic viscosity between the two polyester components. , to achieve the a polytrimethylene terephthalate and polytrimethylene terephthalate terephthalate terephthalate terephthalate terephthalate terephthalate terephthalate terephthalate terephthalate a polytrimethylene terephthalate and polytrimethylene terephthalate and composite staple fibers and a technology of polytrimethylene terephthalate and a process of production process, which is applied in filament/thrase three thr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0062] The present invention will be further explained by the following examples.

[0063] In the examples and comparative examples, the following measurements were carried out.

(1) Intrinsic Viscosity [η]

[0064] The intrinsic viscosity of polyester resin was determined in a solution of the polyester resin in a solvent consisting of orthochlorophenol at a temperature of 35° C. by using an Ubbelohde viscometer.

(2) Velocity of Cooling Air Blast

[0065] A velocity of cooling air blast having a temperature of 25° C. and a humidity of 65% applied to filamentary streams of extruded polyester resin melt in the melt-spinning apparatus at right angles to the travelling direction of the filamentary streams, to cool and solidify the filamentary streams, was measured by a wind velocity meter.

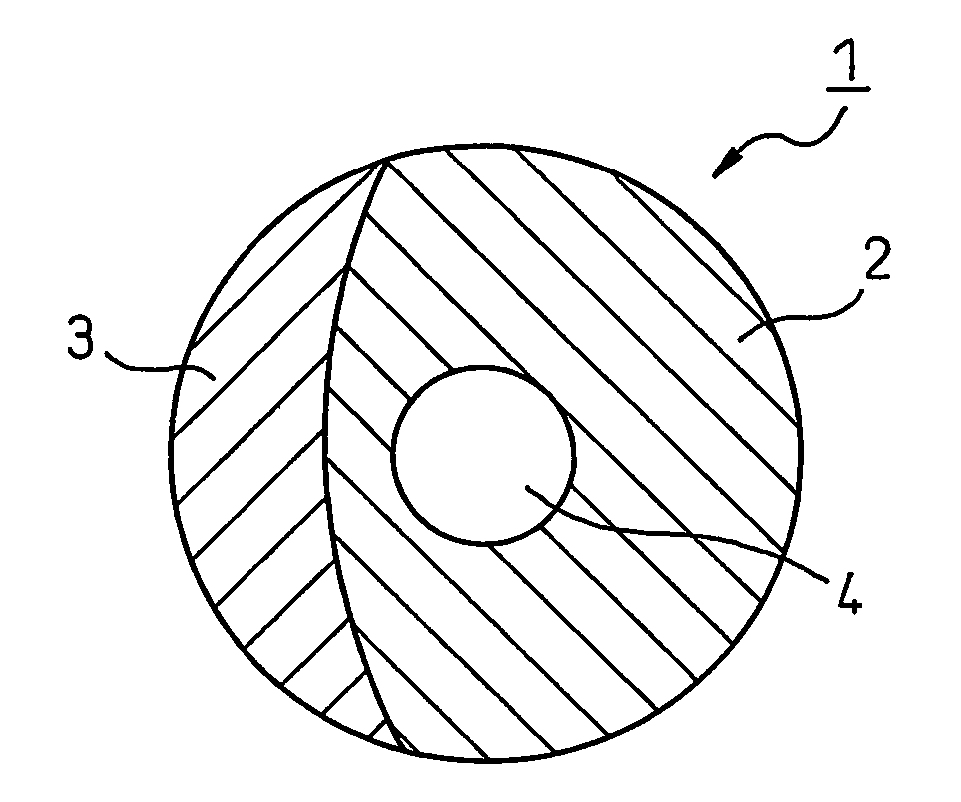

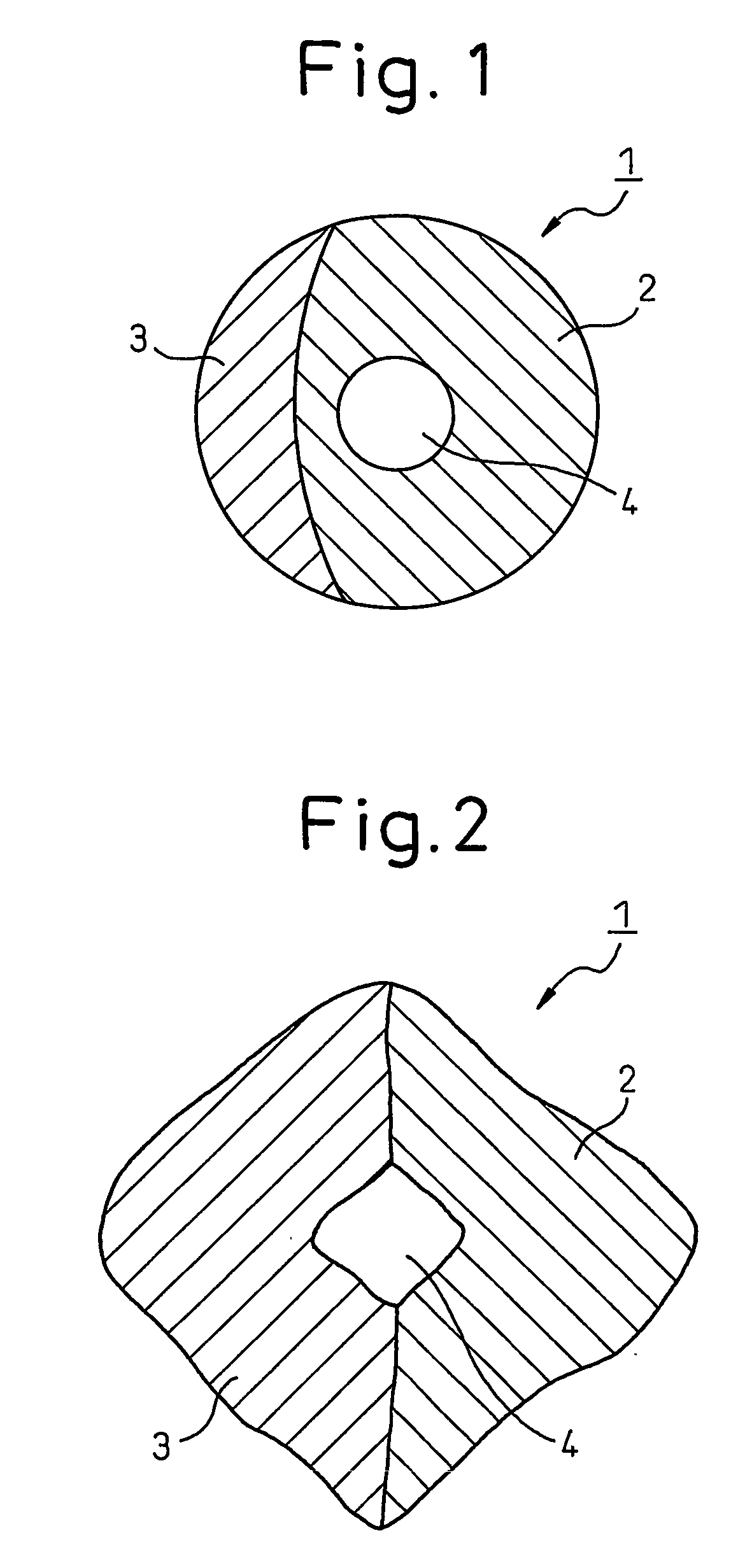

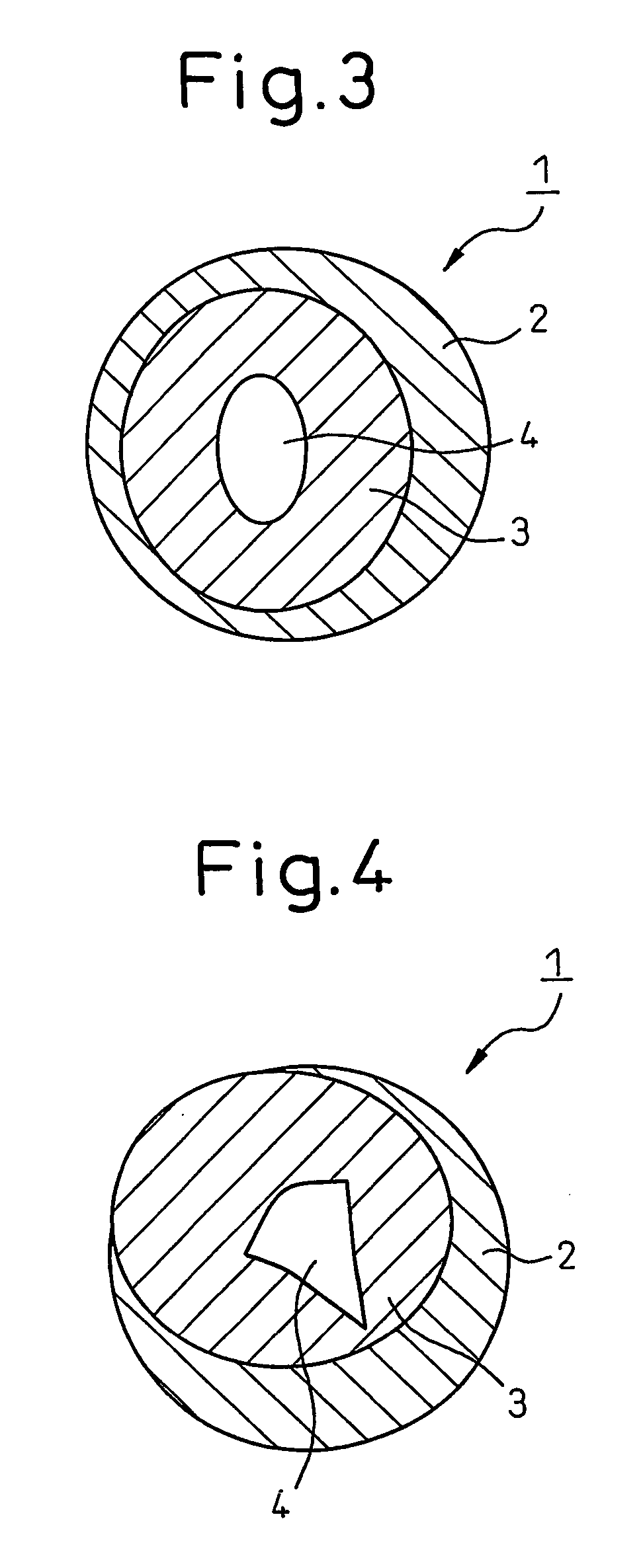

(3) Cross-Sectional Proportion of Hollow Part in Hollow Composite Fiber

[0066] In a cross-sectional profile of a hollow composite fiber, a proportion of the area of a hollow part of the hollow composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com