Patents

Literature

33results about How to "Product environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

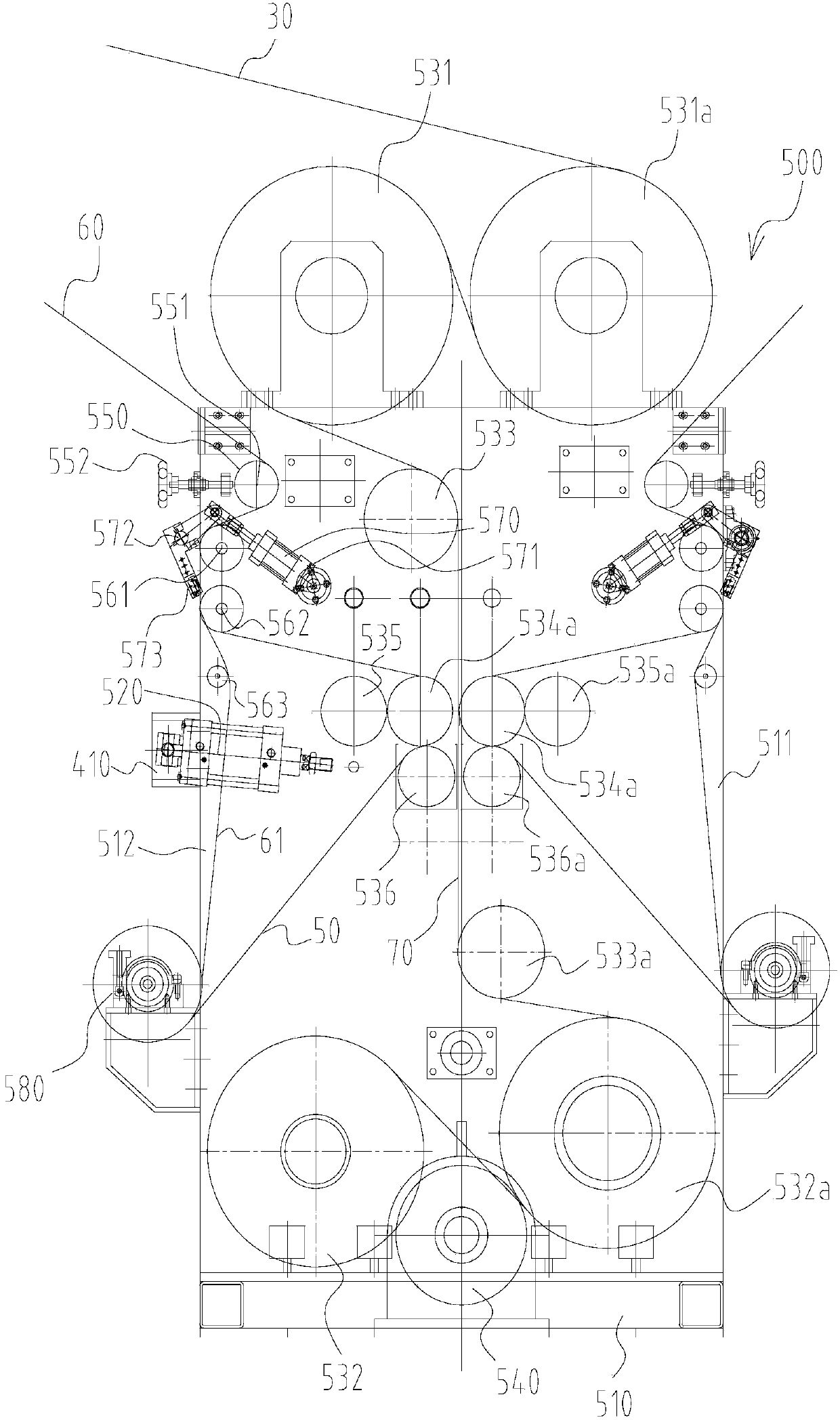

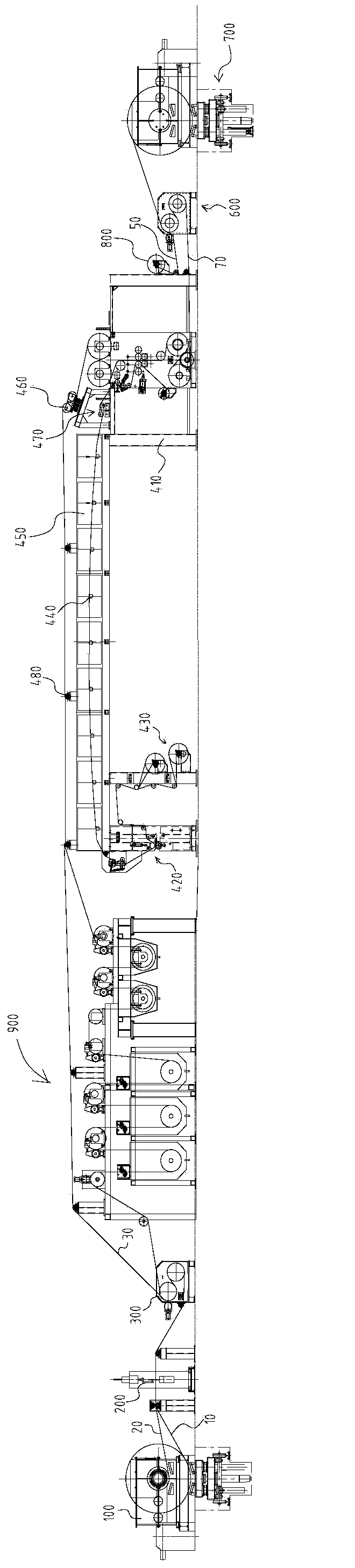

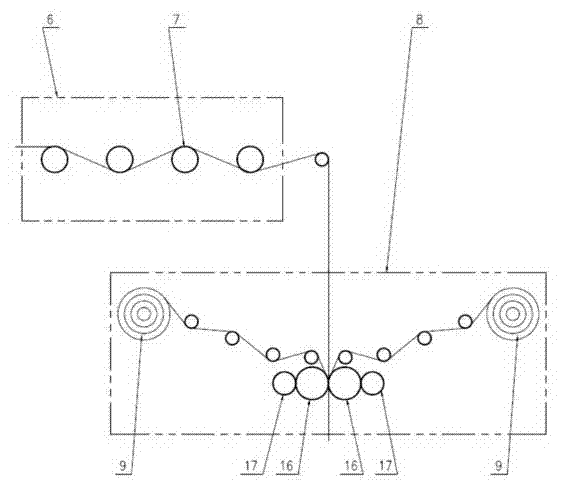

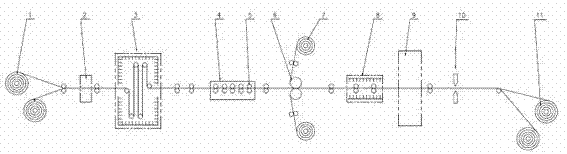

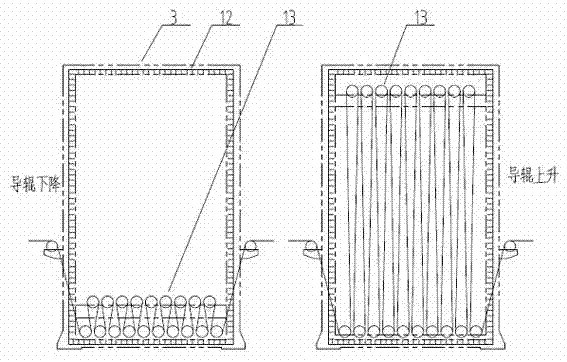

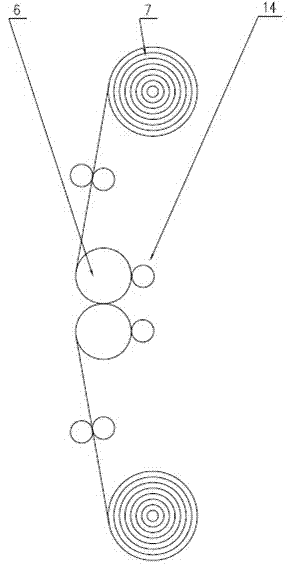

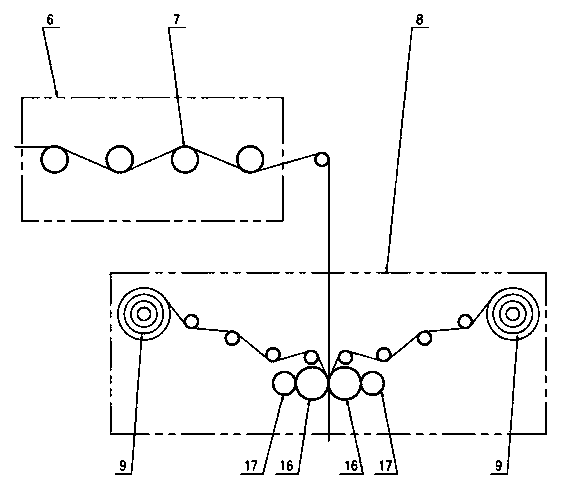

Multi-functional laminated iron production line

ActiveCN103640315AExcellent anti-rustImprove the decorative effectLamination ancillary operationsLaminationWinding machineProduction line

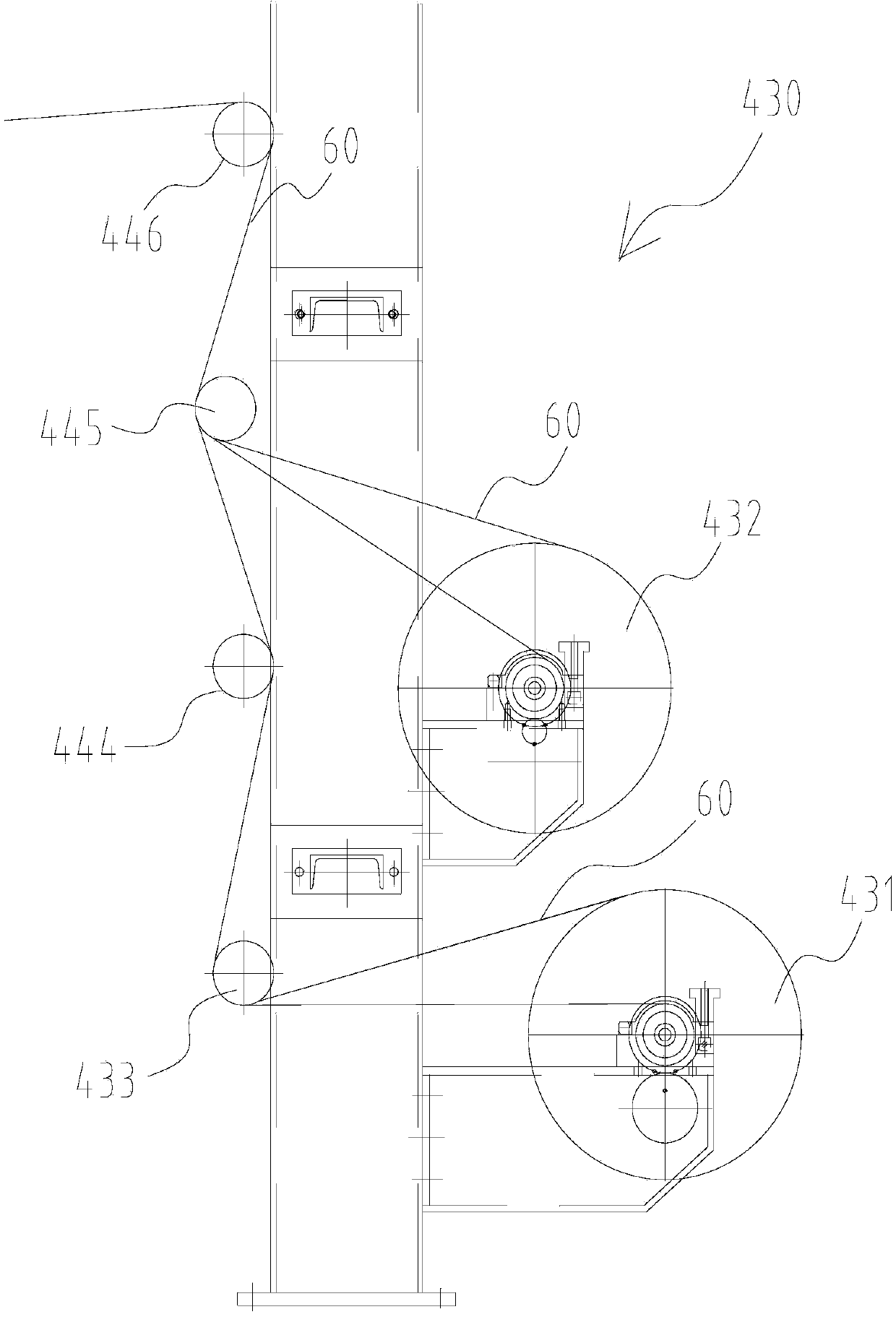

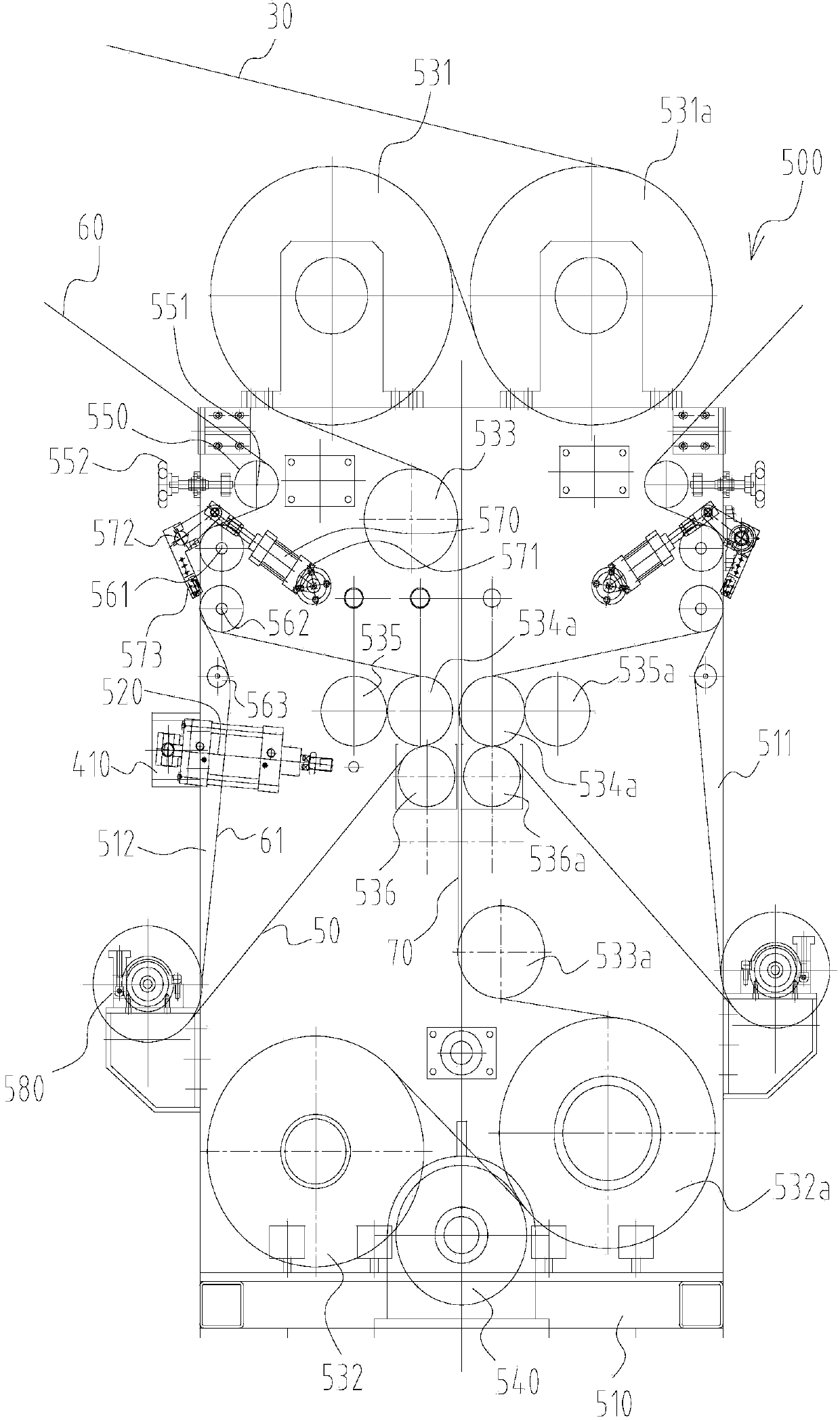

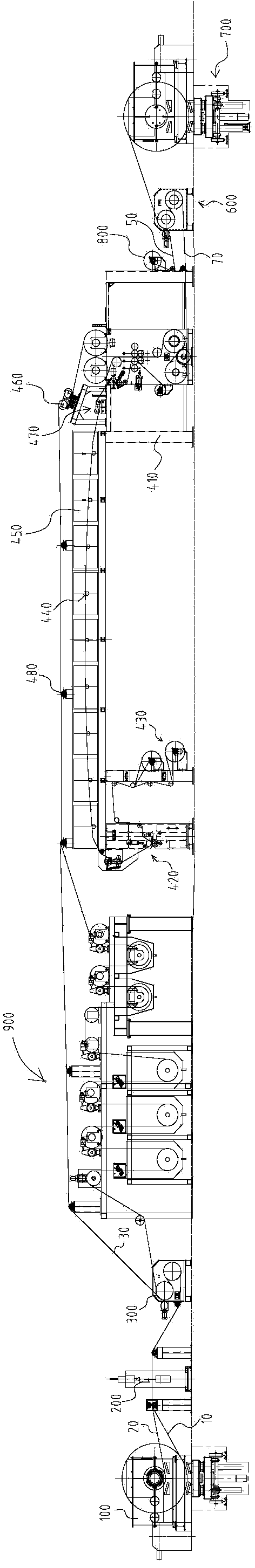

The invention discloses a multi-functional laminated iron production line. The multi-functional laminated steel production line comprises a cold rolled base plate unwinding device, a seam welder, two S turning roller sets, a first or / and second thin film release device, an iron sheet laminating device and a laminated iron winding machine, which are sequentially arranged in a conveying direction of metal base plates; the metal base plate from the seam welder enters the iron sheet laminating device after being tensioned and rectified, and a first thin film or / and second thin film is / are fed into an iron sheet laminating machine after rectification, so that the iron sheet laminating machine covers one surface or two surfaces of the metal base plate with the first thin film or / and the second thin film to form single-sided or double-sided laminated iron, the single-sided or double-sided laminated iron is fed into the other S turning roller set by the iron sheet laminating machine to be tensioned, and the tensioned single-sided laminated iron is wound by the laminated iron winding machine. The multi-functional laminated iron production line can produce both low-temperature bonded laminated iron and high-temperate melted laminated iron, is advanced iron laminating equipment capable of realizing efficient and continuous production, and can be well adaptive to the change of market requirement.

Owner:SUZHOU DONGHONGRUI PACKAGE TECH

Preparation method of superabsorbent resin used for high-molecular gel extinguishing agent, and extinguishing agent using superabsorbent resin

ActiveCN103483752APreparation Process GreenThe preparation process is environmentally friendlyFire extinguisherPolymer scienceCross linker

The invention provides a preparation method of a superabsorbent resin used for a high-molecular gel extinguishing agent. The preparation method comprises: mixing acrylic acid and a sodium carbonate aqueous solution to prepare a neutralization solution; successively adding a cross-linking agent, an initiator and an adhesion promoter into the neutralization solution to prepare a polymerization solution; performing polymerization to prepare the superabsorbent resin; and cutting into particles with a diameter of 10-20 mm to further prepare superabsorbent resin particles with a particle size of 40-150 meshes. The preparation method is simple, and the superabsorbent resin prepared by the method is convenient to used and excellent in fire extinguishing effect.

Owner:LANGFANG ZHONGAN FIRE PROTECTION TECH CO LTD

Method for preparing core-shell soap-free surface sizing agent

InactiveCN101205696AUniform particle size distributionImprove sizing effectWater-repelling agents additionPolymer scienceRoom temperature

The invention discloses a preparation method of nucleocapsid soap free surface sizing agent and comprises the following procedures that: (1) firstly, water, macromolecule polymers and monomers are mixed according to the mass ratio of 8.5:1.5 to 6.5:3.5, then proper molecular weight regulator are added and uniformly stirred; the monomers comprise a function monomer, an acrylate kind soft monomer, a hard monomer and an ion monomer; (2) in a stirring state, a part of mixture which accounts for 10 percent to 60 percent of the total mixture mass of the acrylate kind soft monomer, the hard monomer and the ion monomer is added and heated to 73 to 75 DEG C; evocating agent solution which accounts for 20 percent to 50 percent of the total evocating agent mass is then added; after 20 to 60 minutes, the mixture is heated to 76 to 82 DEG C; (3) then the residual mixture of the acrylate kind soft monomer, the hard monomer and the ion monomer and the residual evocating agent solution are respectively added; (4) the mixture is heated to 80 to 82 DEG C for heat preservation, has reaction for 2h to 3h, cooled to the room temperature and filtered, thereby achieving the nucleocapsid soap free surface sizing agent.

Owner:SOUTH CHINA UNIV OF TECH

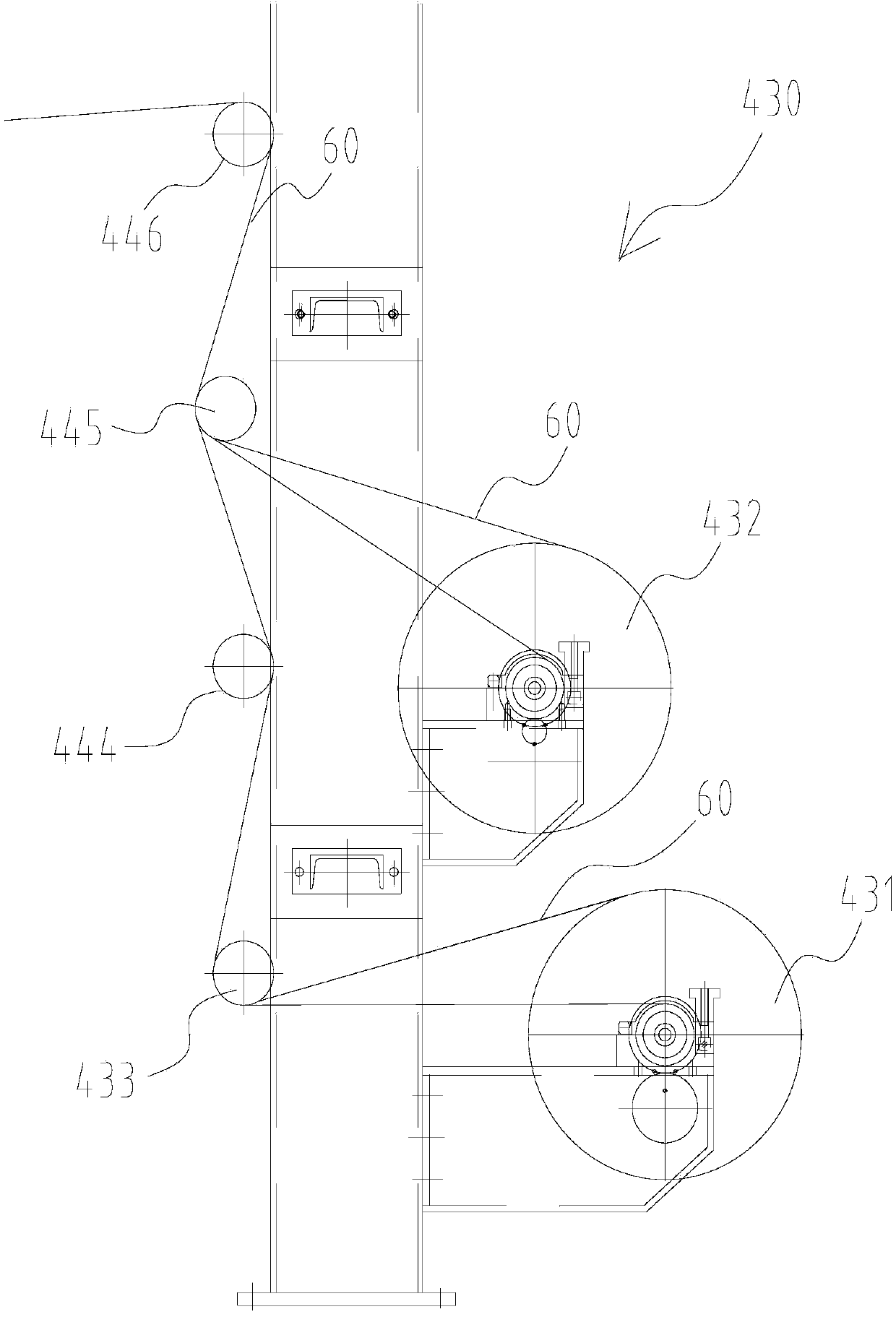

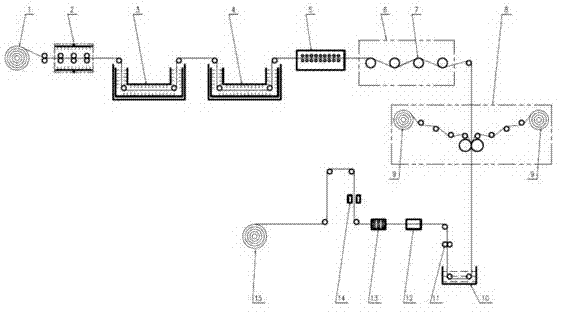

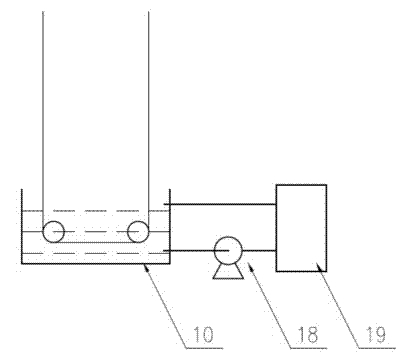

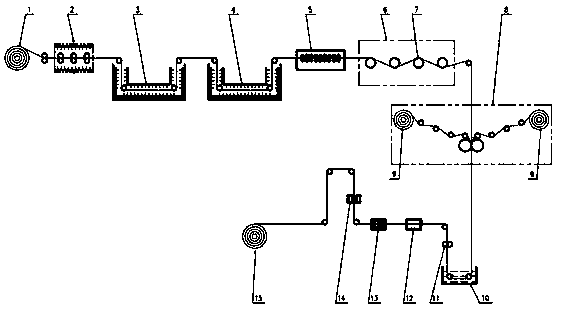

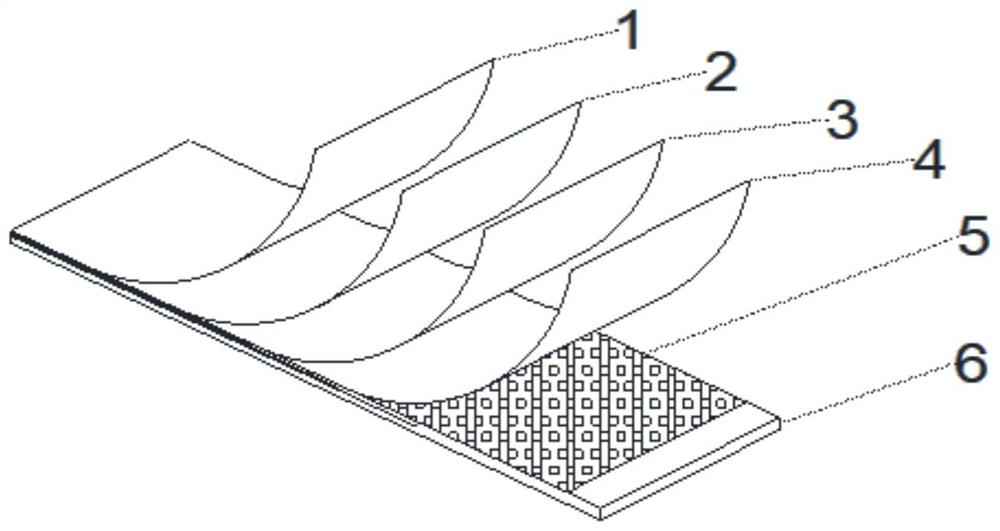

Technology and device for processing film-coated iron

ActiveCN102431269ALess surface pinholesHigh tensile strengthLamination ancillary operationsLaminationSteel platesSheet steel

The invention provides a technology for processing film-coated iron. The technology for processing film-coated iron comprises the following steps that a cold-rolled thin collared steel plate (chrome-coated iron) subjected to surface chrome coating treatment is unreeled by an unreeling machine, then is cleaned up, is dried and is put into a preheating device for preheating; and the preheated steel plate is treated by a film pressing device so that the preheated steel plate and a plastic film are compounded by heating. The invention also provides a device for processing film-coated iron. The technology and the device for processing film-coated iron have the advantages that high efficiency, environmentally friendly and low-cost steel plate surface coating is realized; a production process is environmentally friendly; a product has good impact resistance and corrosion resistance; toxic low-molecular residues are not produced; and the technology and the device accord with a modern industrial large-scale production idea of low carbon and environmental protection.

Owner:上海联净复合材料技术有限公司

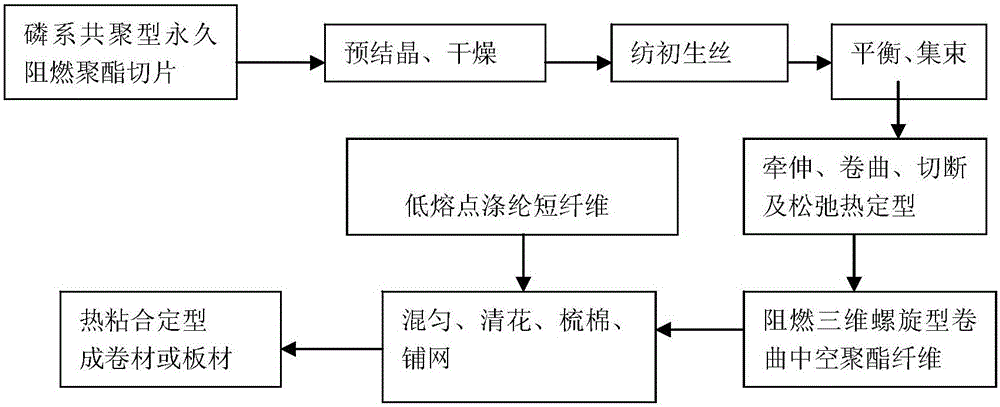

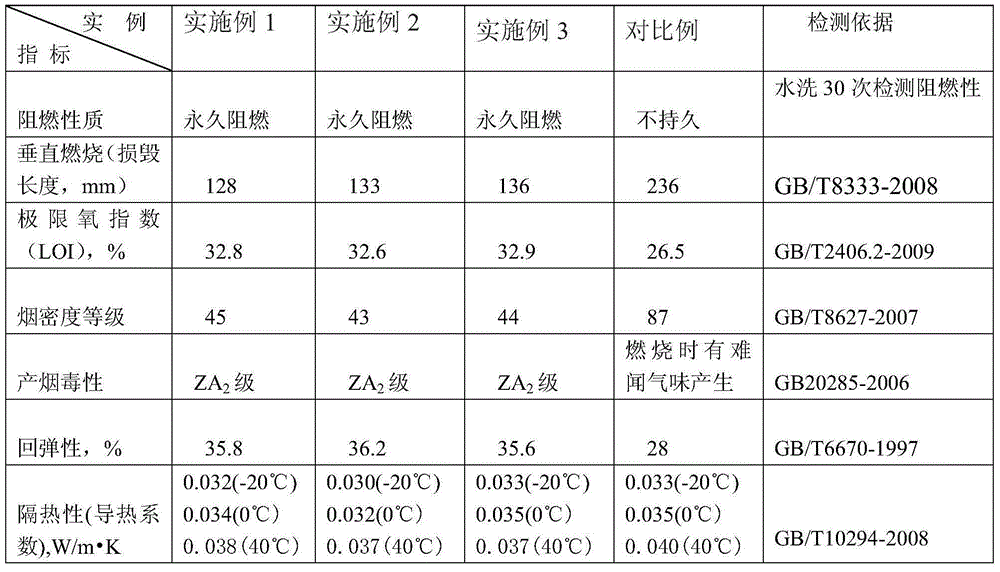

Novel flame-retardant heat-insulation elastic polyester material and preparing method and application thereof

ActiveCN105088535AStrong bondProduct environmental protectionFilament/thread formingMonocomponent copolyesters artificial filamentWater contentChemistry

The invention discloses a preparing method of a novel flame-retardant heat-insulation elastic polyester material. The preparing method includes the steps that phosphorus co-polymerized permanent flame-retardant polyester chips are pre-crystalized and dried, and then the water content is smaller than or equal to 30 ppm; spun filaments are obtained through spinning, and after the spun filaments are balanced and bundled, 2-10 D flame-retardant three-dimensional spiral crimped hollow polyester fibers are obtained through drafting, crimping, cutting-off and relaxation heat setting; 85-95wt% of flame-retardant three-dimensional spiral crimped hollow polyester fibers and 15-5wt% of low-melting-point polyester staple fibers are mixed evenly, treated in the mode of blowing, carding and lapping and then thermally bonded through a hot mill or a hot air dryer. The material is superior in performance and can replace polyurethane foaming plastic to be used as a furniture pad material, a vehicle seat pad material and various soft pad laminated composite materials.

Owner:HIGHTEX CO LTD ZHEJIANG

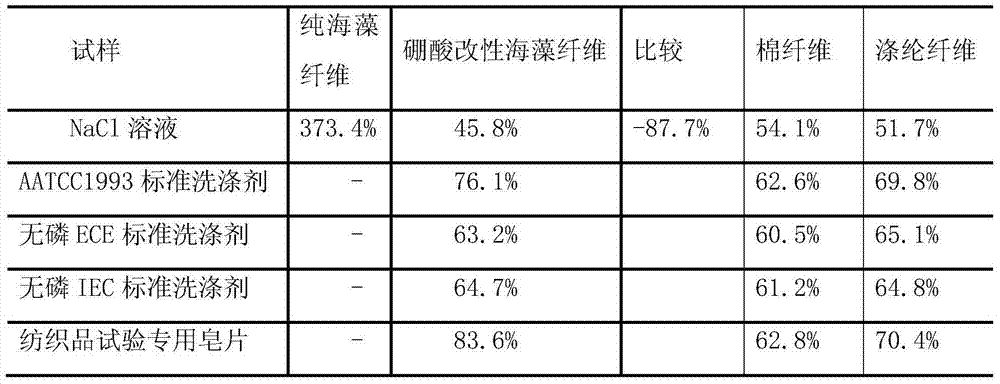

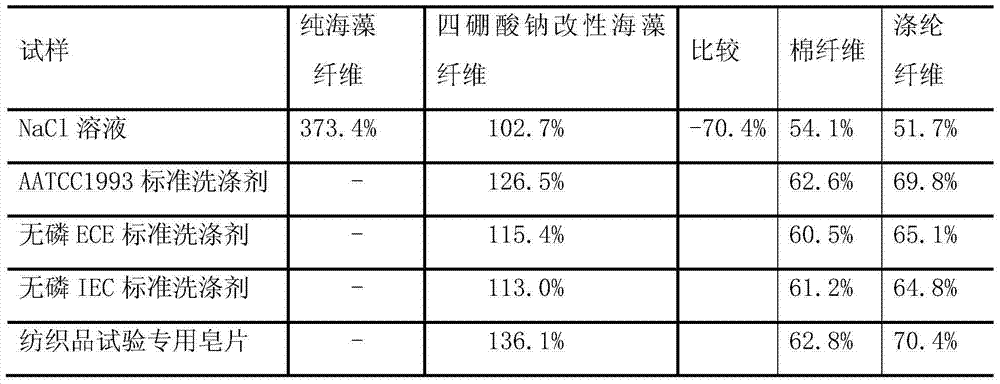

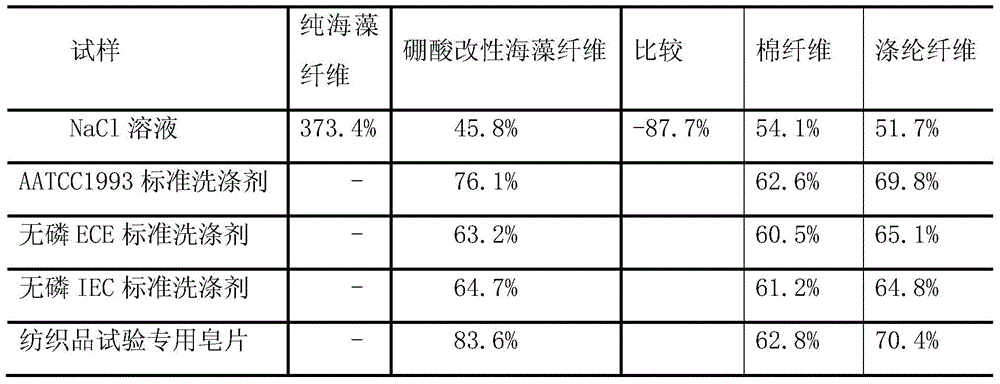

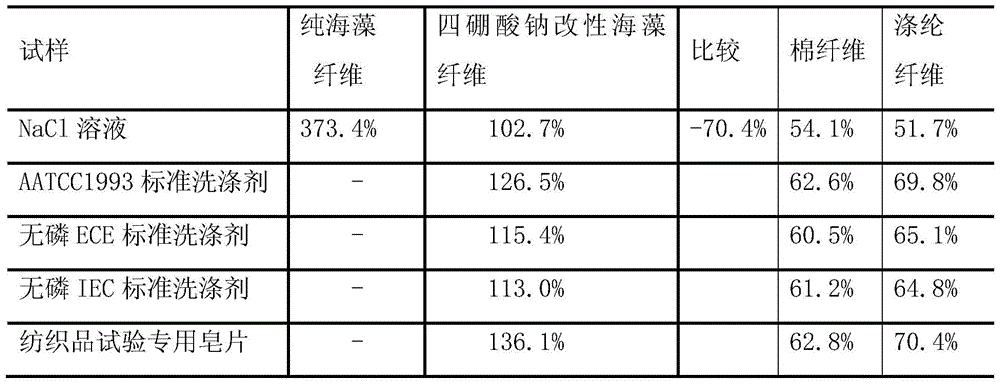

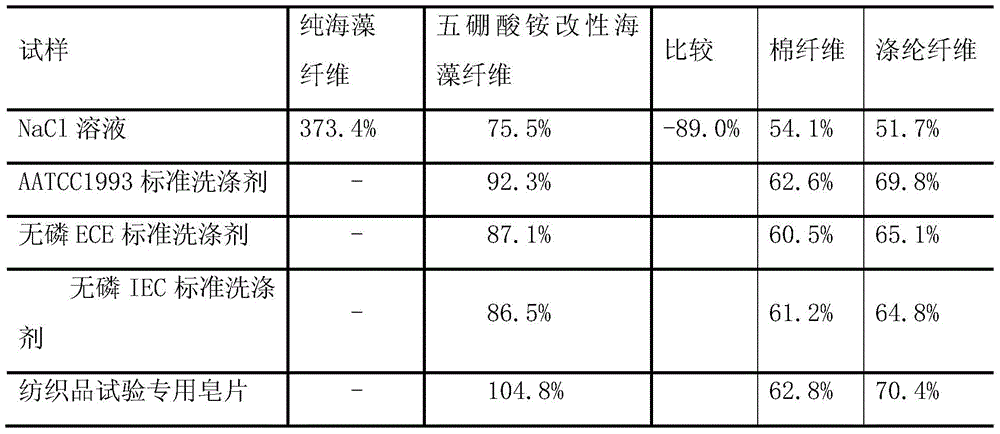

Preparation method of salt-resistant and detergent-resistant seaweed fiber

ActiveCN104846625AEasy to solveReduce swellingAlginate artificial filamentsVegetal fibresFiberSalt resistance

The invention discloses a preparation method of a salt-resistant and detergent-resistant seaweed fiber; by introducing an auxiliary agent containing a borate radical, a finished product seaweed fiber is contacted and infiltrated with an auxiliary agent solution, appropriate raw materials, proportion and reaction conditions are selected, and thus the salt-resistant and detergent-resistant seaweed fiber is prepared. The preparation method solves the problems that the seaweed fiber and textiles thereof are not resistant to salts and detergents; the seaweed fiber after being modified by the borate radical and textiles thereof have good salt resistance and can withstand washing of alkaline detergents; the seaweed fiber modified by the auxiliary agent solution enables the swelling degree to be reduced to 39.8% after being soaked for 72 h in 30 DEG C normal saline, and enables the swelling degree to be reduced to 55.3% after being soaked for 24 h in a standard detergent; and the original appearance of the fiber is maintained, no obvious dissolution phenomenon generates, and at the same time, the self flame retardant performance of the seaweed fiber can be maintained.

Owner:青岛源海新材料科技有限公司

Organic-inorganic compound fertilizer for high-yield paddy rice

InactiveCN105384527AIncrease productionProduct environmental protectionFertilizer mixturesSeabirdPesticide residue

The invention discloses an organic-inorganic compound fertilizer for high-yield paddy rice. The organic-inorganic compound fertilizer is prepared from the following raw materials in parts by weight: 20 to 50 parts of urea, 5 to 20 parts of monoammonium phosphate, 30 to 50 parts of potassium polyphosphate, 30 to 50 parts of seabird droppings, 15 to 35 parts of fermented paddy rice straws, 5 to 18 parts of fermented cow dung, 15 to 30 parts of bone dregs, 5 to 15 parts of humic acid, 2 to 8 parts of modified turf, 1 to 7 parts of paddy rice straws, 15 to 19 parts of coal ash, 5 to 12 parts of attapulgite, 1 to 6 parts of kaolin, 1 to 3 parts of manganese sulfate, 1 to 2 parts of ferrous sulfate, 1 to 4 parts of carbonic lime, 0.01 to 0.07 part of compound enzyme and 0.01 to 0.05 part of compound bacteria. A product of the organic-inorganic compound fertilizer is environment-friendly, less in pesticide residue, balanced in nutrition and high in yield of paddy rice.

Owner:高青山

Wormwood fiber composite textile material and preparing method thereof

InactiveCN105780230AKeep bacteriostasisMaintain the unique antibacterial effect of wormwoodBlanketBed linenYarnNatural fiber

The invention discloses a wormwood fiber composite textile material.The wormwood fiber composite textile material is formed by blending spun yarn made of wormwood fibers and other natural fibers, and the characteristics that the wormwood fibers are rich in resource and high in healthcare value are fully used.The invention further provides a preparing method of the wormwood fiber composite textile material.The preparing method includes the following steps that the wormwood fibers are extracted; long and flexible wormwood fibers are screened through wormwood fiber processing; the screened wormwood fibers are made into textile threads or blended with other natural fibers to be spun into textile threads; in the spinning process, a natural textile material and the textile threads formed by drawing the wormwood fibers are blended by a ratio to manufacture wormwood fiber composite textile threads; the wormwood fiber composite textile material (cloth, a blanket and a towel) can be manufactured by weaving the manufactured wormwood fiber composite textile threads, and then put into actual product production.The wormwood fiber composite textile material is healthy and environmentally friendly and keeps the unique bacteriostasis, deodorization and yang-qi strengthening advantages of wormwood better.

Owner:邓华刚

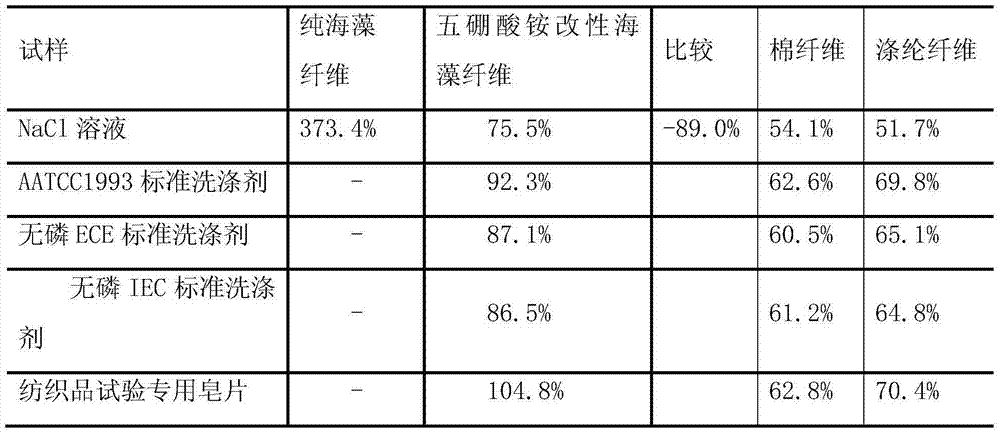

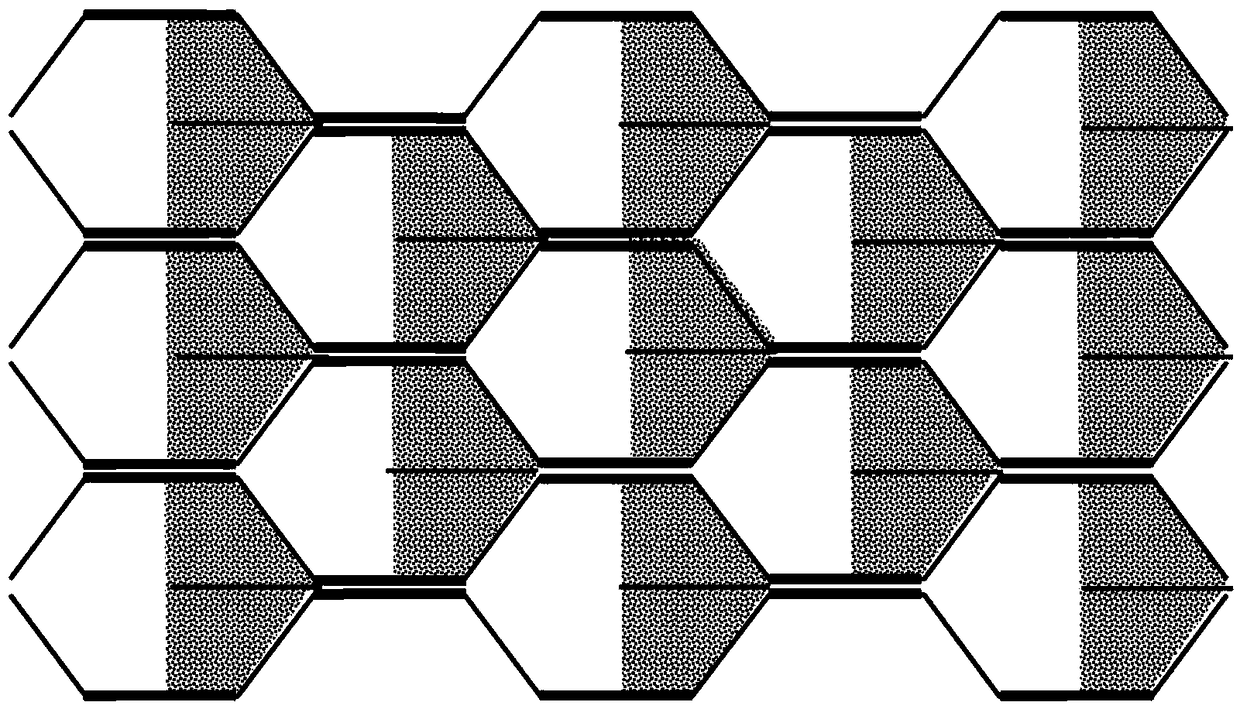

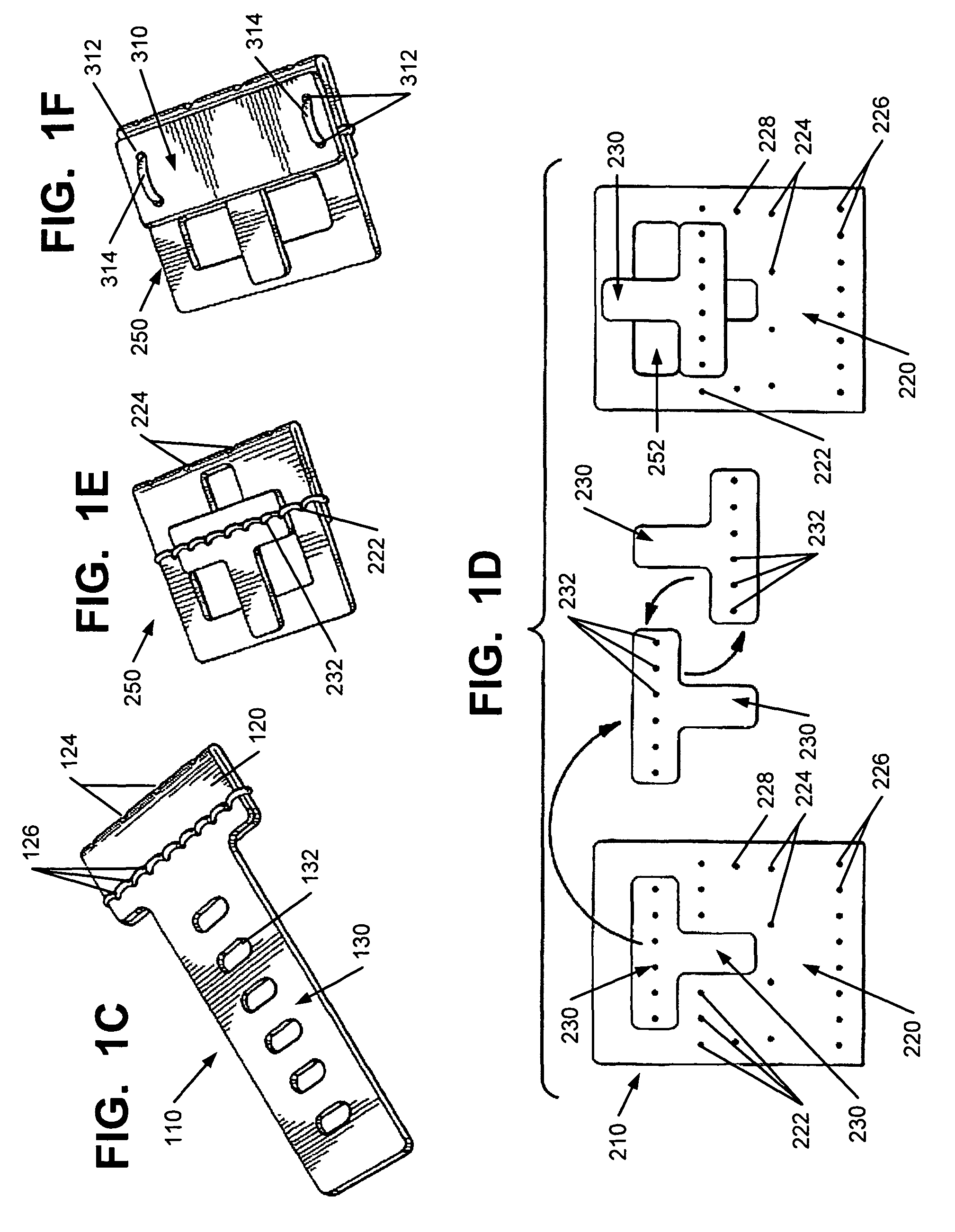

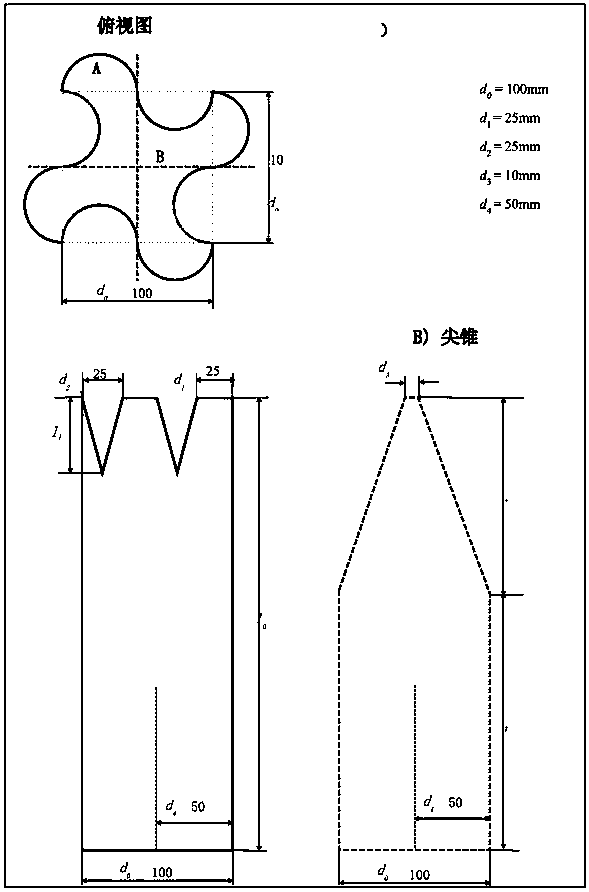

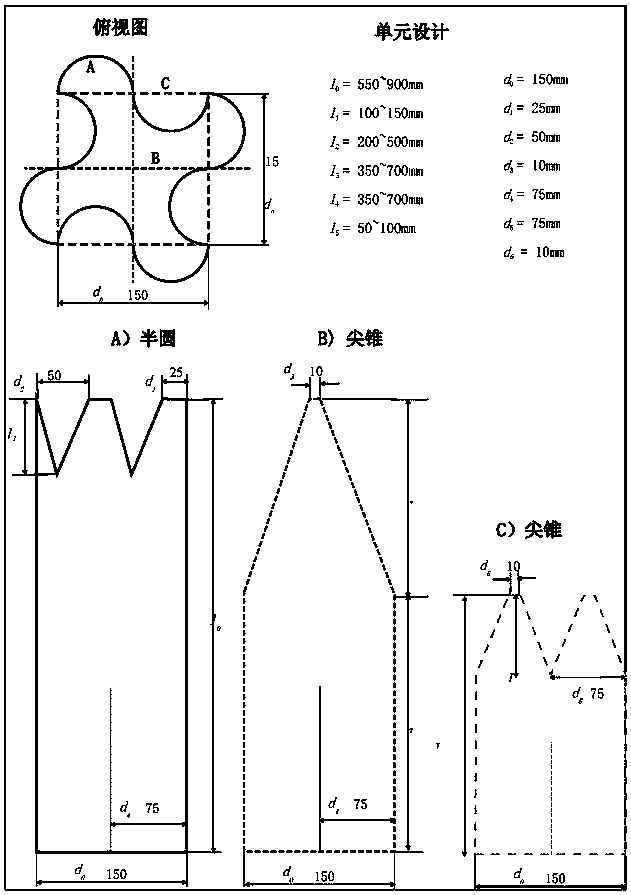

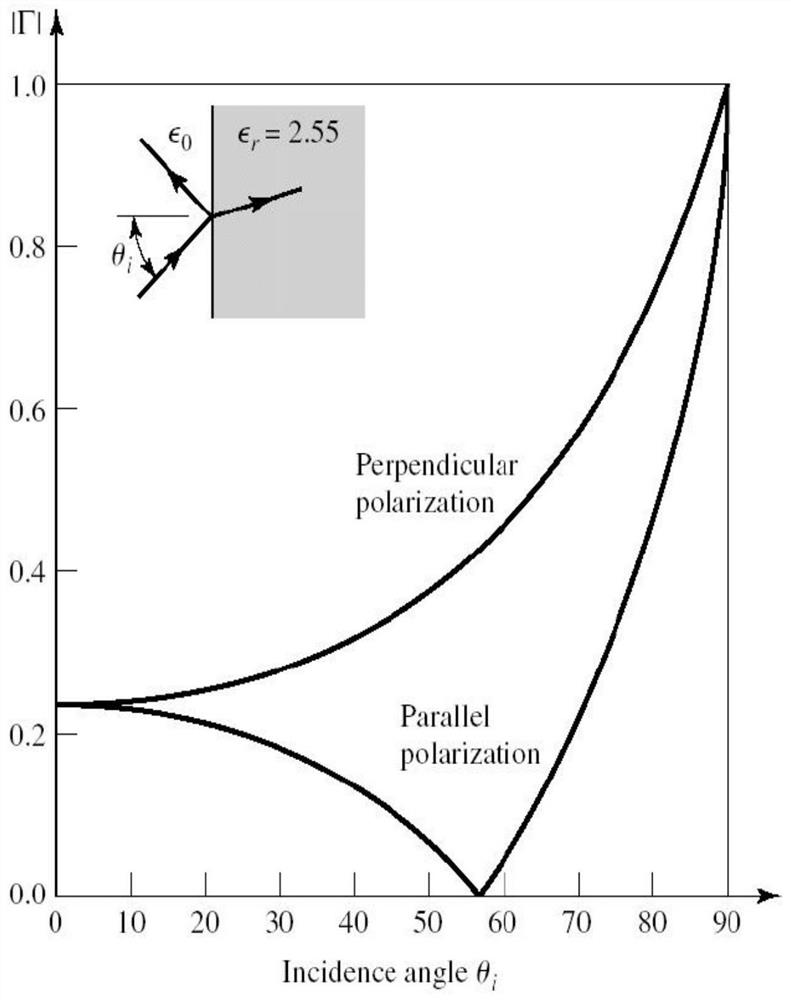

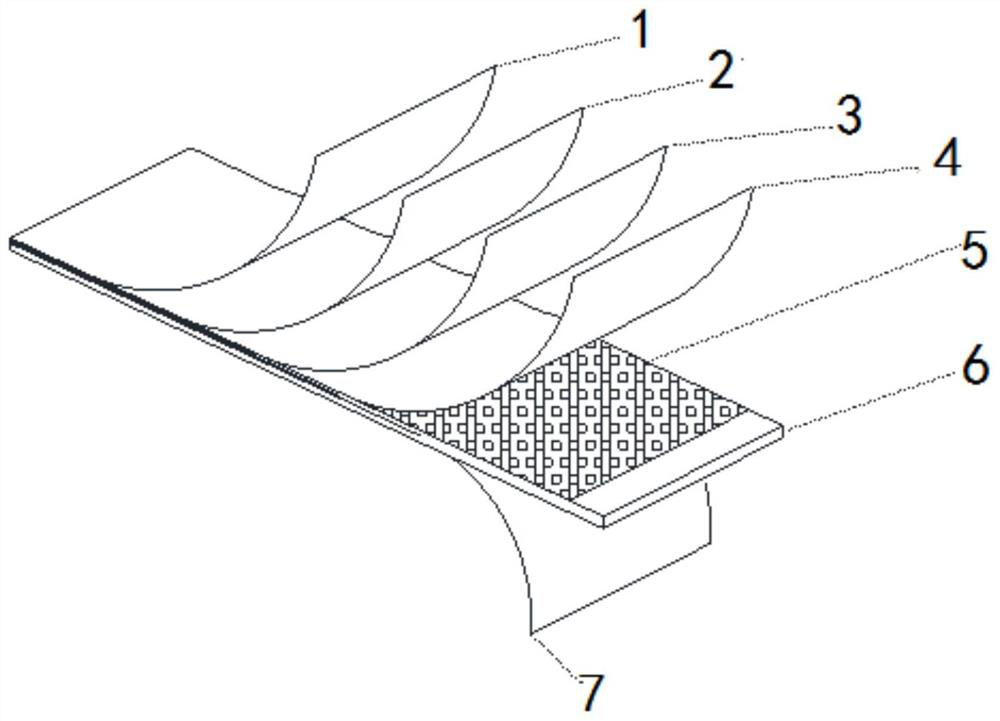

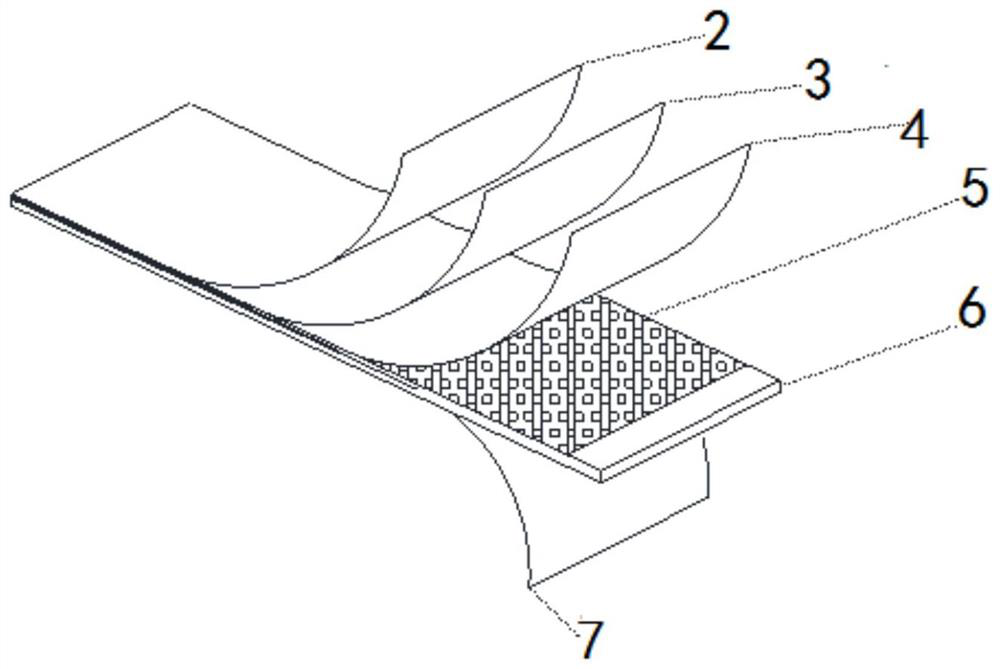

Super-wide incidence angle microwave absorbing materials and a production method thereof

InactiveCN108966622AHigh temperature resistanceFlame retardantMagnetic/electric field screeningElectrically-conductive paintsAngle of incidenceTemperature resistance

The invention belongs to the technical field of microwave absorbing materials. The invention discloses a kind of super-wide incidence angle microwave absorbing materials which are composed of a slanted irregular honeycomb structure made of a flexible substrate and a graphene conductive coating coated on the flexible substrate. The invention also discloses a production method of the super-wide incidence angle microwave absorbing materials. The method comprises the steps of the structural design of the super-wide incidence angle microwave absorbing materials, generation of surface resistance distribution through printing the graphene conductive coating on the flexible materials, manufacturing of the slanted irregular honeycomb structure, etc. The super-wide incidence angle microwave absorbing materials have the microwave absorbing frequencies ranging from millimeter wave to microwaves and incidence angles ranging from normal incidence angles to high incidence angles. Meanwhile, the material has the advantages such as low cost, a high technique, being environment-friendly, high mechanical strength, low density, a long service life, high temperature resistance and flame retardancy. Furthermore, the super-wide incidence angle microwave absorbing materials of the invention can be contracted to keep, can reduce cost for transport and collection and is in favor of construction and usage of secret test external fields.

Owner:西安安聚德纳米科技有限公司

Heat compounding technique and apparatus of BOPET film and tin-free steel plate

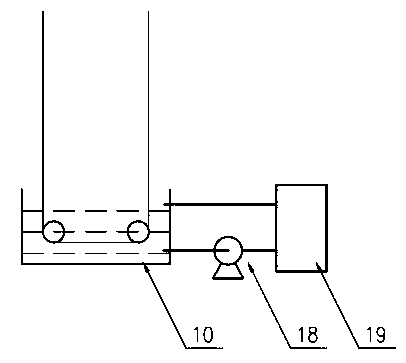

ActiveCN102514347AImprove corrosion resistanceReduce consumptionLaminationLamination apparatusBoPETThin membrane

The invention provides a heat compounding technique of a BOPET film and a tin-free steel plate,which comprises the steps of: uncoiling the steel plate by an uncoiling machine, preheating the steel plate to a set temperature by a preheating machine set, and high temperature heat compounding the preheated steel plate with the BOPET film through a hot pressing device, and coiling the heat compounded steel plate by a coiling machine. The invention also provides a heat compounding apparatus of BOPET film and tin-free steel plate, wherein the steel plate is uncoiled by the uncoiling machine and is conveyed to the preheating machine set to be preheated, and the preheated steel plate is heat compounded with the BOPET film by the hot pressing device. The heat compounding technique and apparatus of BOPET film and tin-free steel plate provided by the invention has the advantages of compounding a plastic film on the surface of the steel plate in an efficient, environmental friendly and low-cost manner, the production process is environmental friendly, the product has better erosion resistance, and no toxic low molecular compound is residual, so that the invention satisfies the low-carbon and environmental friendly conception of mass production in the modern industry.

Owner:上海联净复合材料技术有限公司

High-yield environment-friendly organic-inorganic compound fertilizer for co-cultivation of paddy rice and ducks

InactiveCN105384525AProduct environmental protectionReduce pesticide residuesFertilizer mixturesChemistryHumic acid

The invention discloses a high-yield environment-friendly organic-inorganic compound fertilizer for co-cultivation of paddy rice and ducks. The high-yield environment-friendly organic-inorganic compound fertilizer is prepared from the following raw materials in parts by weight: 5 to 20 parts of urea, 15 to 30 parts of monoammonium phosphate, 15 to 35 parts of potash magnesium sulfate fertilizer, 40 to 60 parts of seabird droppings, 5 to 18 parts of fermented paddy rice straws, 15 to 25 parts of rapeseed cakes, 12 to 20 parts of bone dregs, 5 to 15 parts of humic acid, 2 to 10 parts of modified turf, 2 to 7 parts of corn straws, 1 to 5 parts of dolomite powder, 2 to 10 parts of attapulgite clay, 2 to 7 parts of kaolin, 1 to 3 parts of ferrous sulfate, 1 to 2.5 parts of manganese sulfate, 1 to 3 parts of carbonic lime, 0.5 to 1.05 parts of compound enzyme and 0.5 to 0.88 part of compound bacteria. A product of the high-yield environment-friendly organic-inorganic compound fertilizer is environment-friendly, less in pesticide residue, balanced in nutrition and high in yield of paddy rice.

Owner:高青山

Preparation method of superabsorbent resin used for high-molecular gel extinguishing agent, and extinguishing agent using superabsorbent resin

ActiveCN103483752BPreparation Process GreenThe preparation process is environmentally friendlyFire extinguisherPolymer scienceCross linker

The invention provides a method for preparing a superabsorbent resin used in a polymer gel fire extinguishing agent, comprising: mixing acrylic acid with sodium hydroxide or sodium carbonate aqueous solution to prepare a neutralizing liquid; Crosslinking agent, initiator and adhesion promoter to prepare polymerization solution; polymerize to obtain super absorbent resin; cut into particles with a diameter of 10-20mm and further make super absorbent resin with a particle size of 40-150 mesh particles. The method has simple process, and the superabsorbent resin prepared by the method is convenient to use and has excellent fire extinguishing effect.

Owner:LANGFANG ZHONGAN FIRE PROTECTION TECH CO LTD

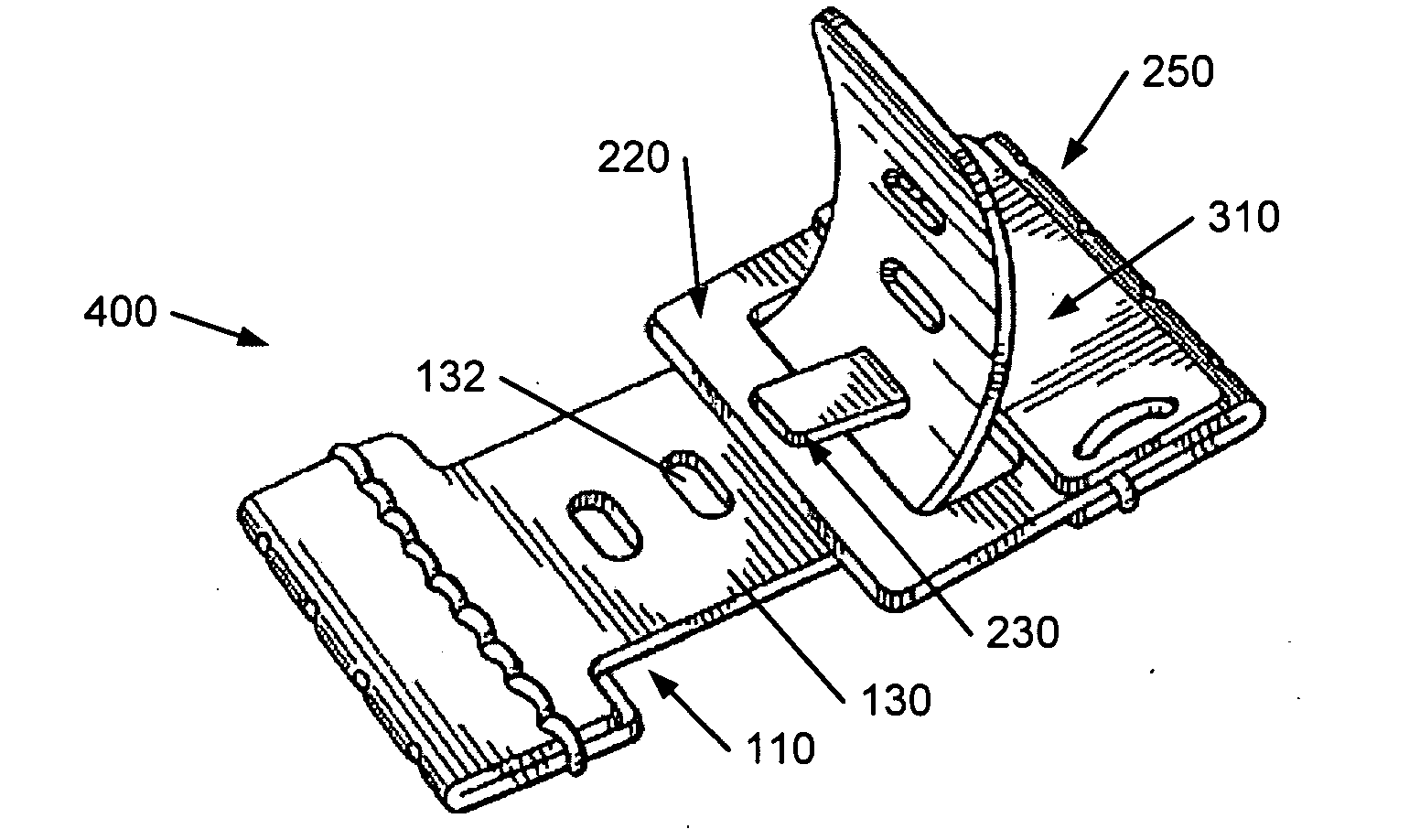

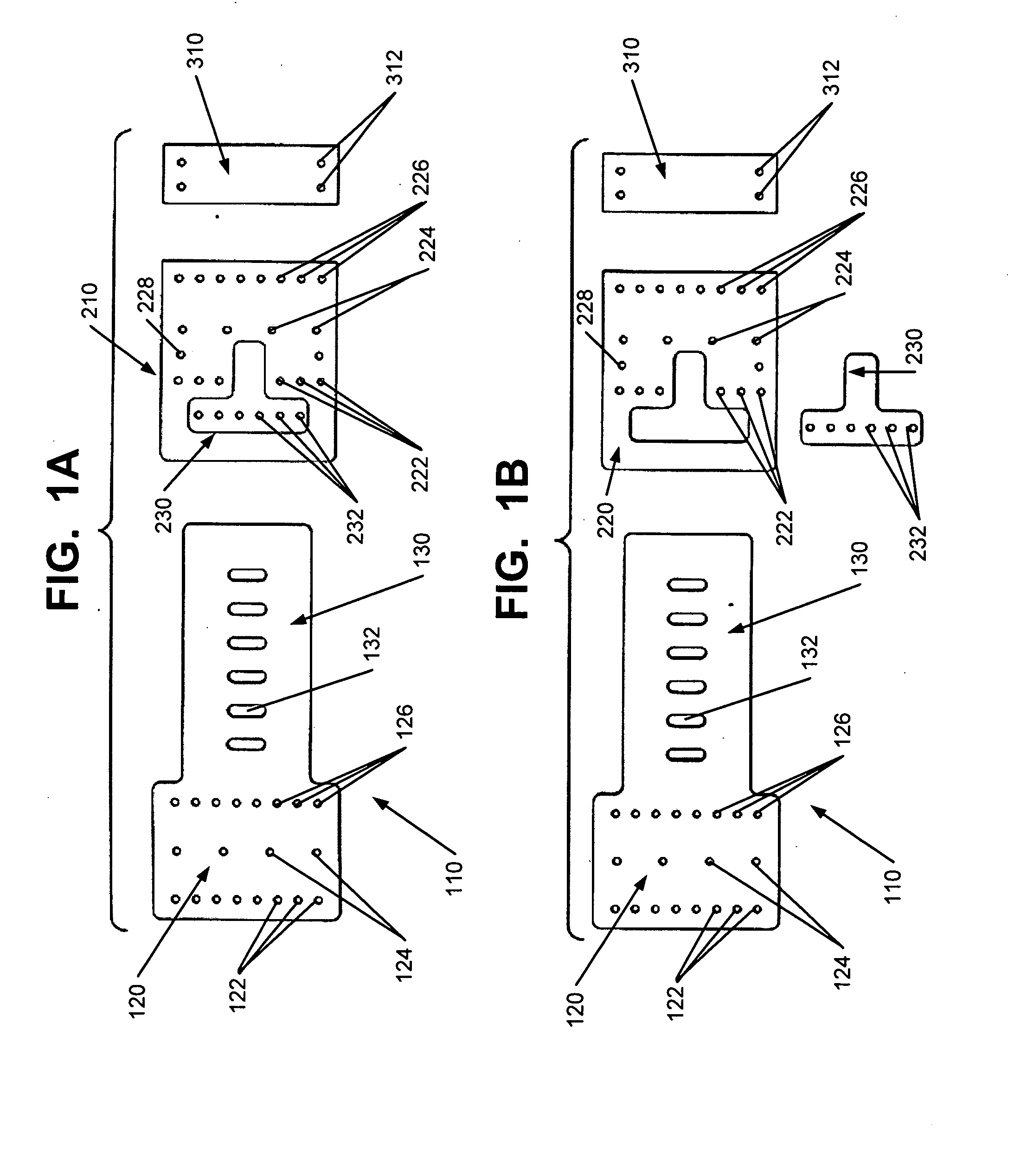

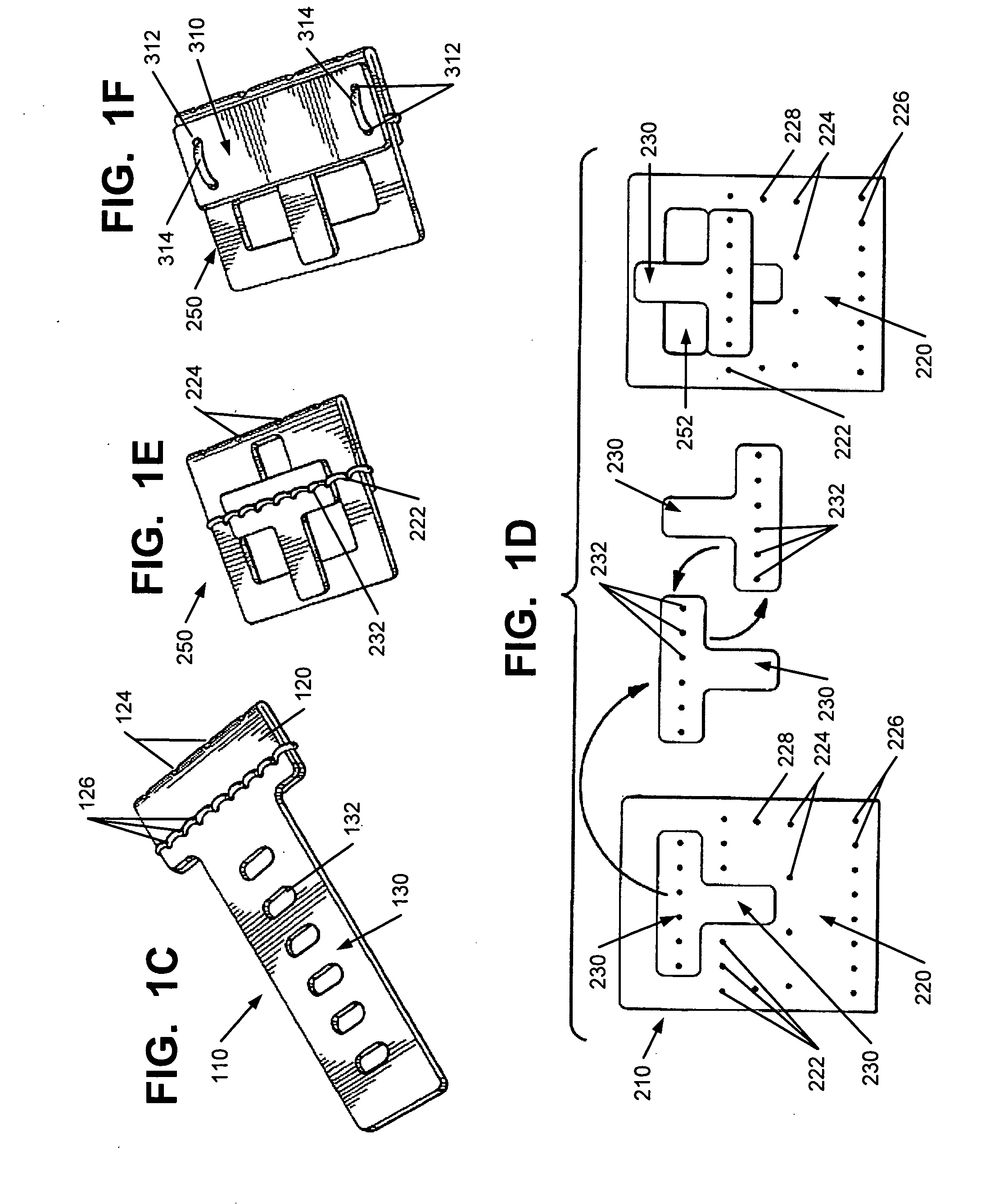

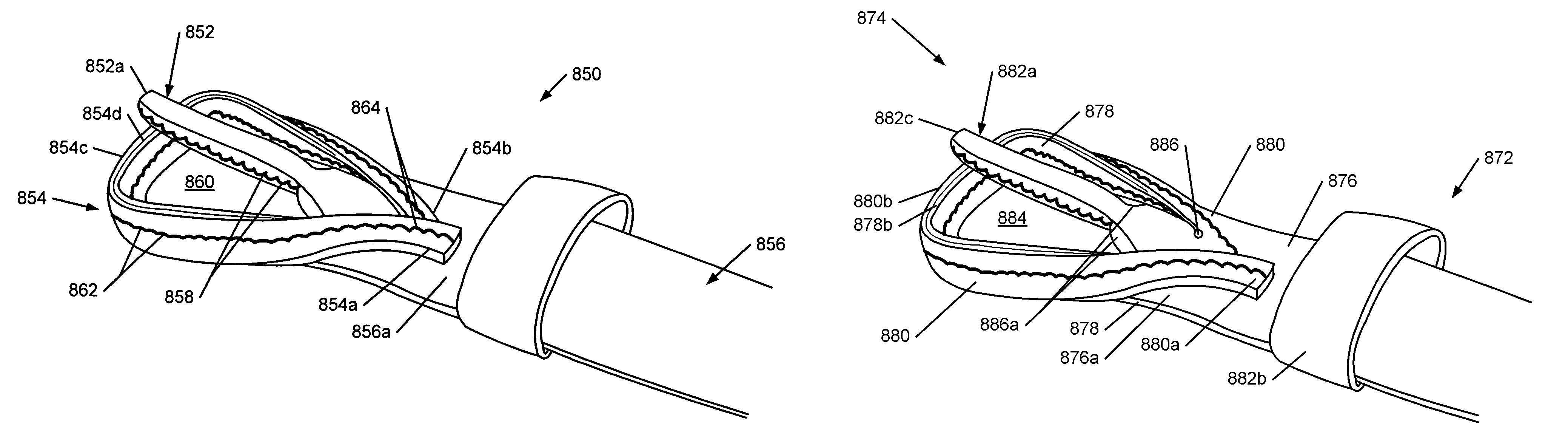

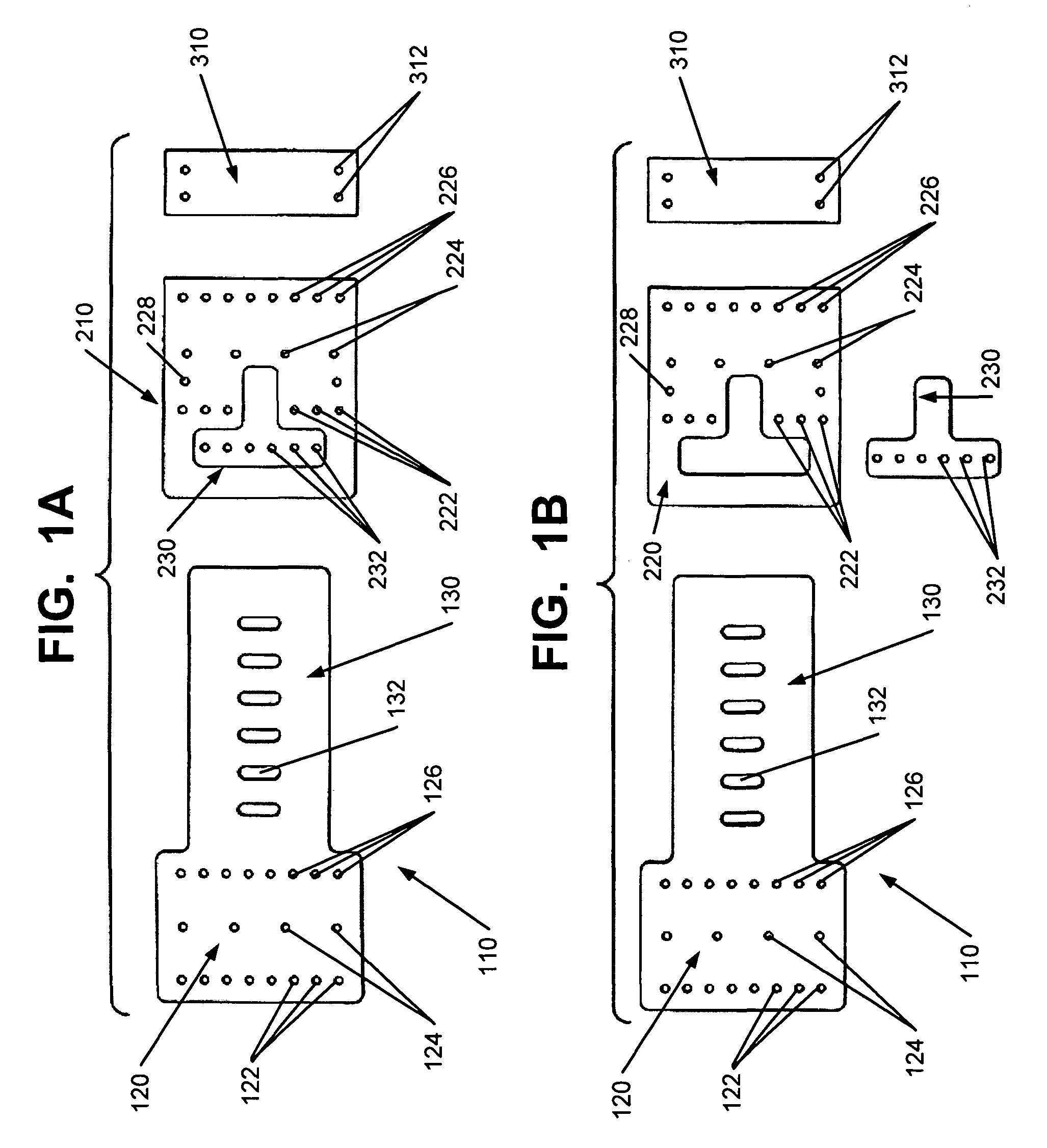

Belt and/or Buckle Assembly

ActiveUS20100058562A1Minimum of waste materialLow production costSnap fastenersFastening devicesAdhesiveBiomedical engineering

Buckle type attachment elements, such as for belts, watch bands, or the like, and / or for securing or fastening elements (e.g., for footwear, handbags, briefcases, containers, or other objects) may be produced in a manner that generates minimal waste materials, without the use of metal or mechanical hardware type connectors, from completely recyclable materials, without the need for molding, without the use of plastics, and / or without the use of adhesives or cements. Such buckle elements may include a buckle portion and a tongue portion formed from the same material. In some structures, the tongue portion may be made from a part cut out to form the buckle portion. In other structures, the tongue portion may be formed by cutting slits into a base substrate that also makes up the buckle portion. Final products and methods of making such products also are described.

Owner:NIKE INC

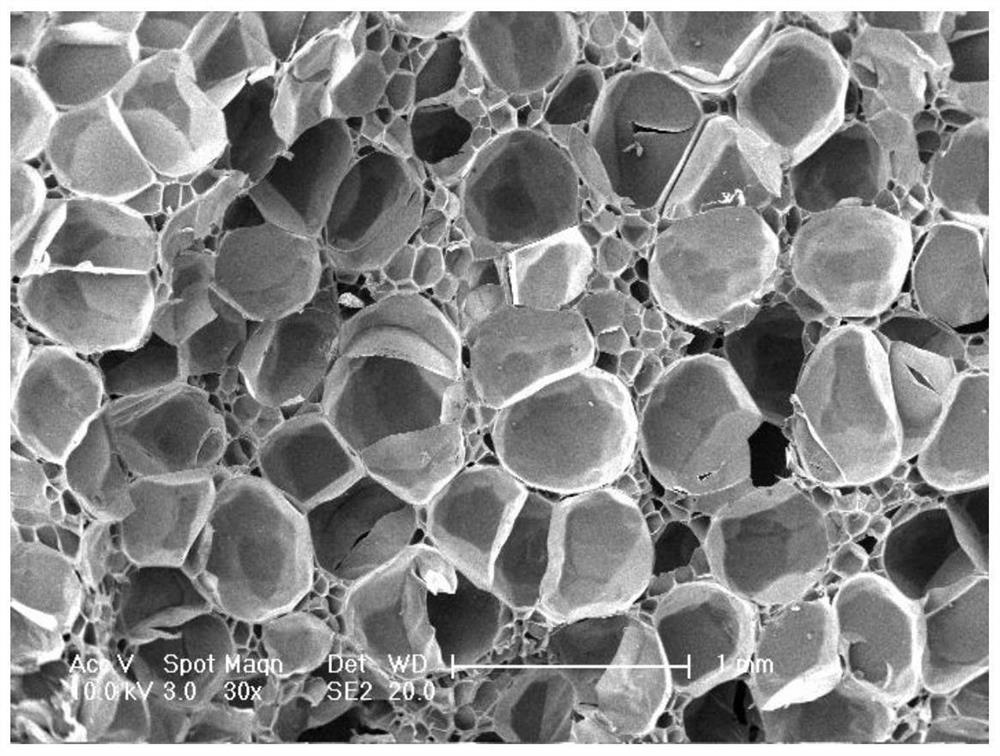

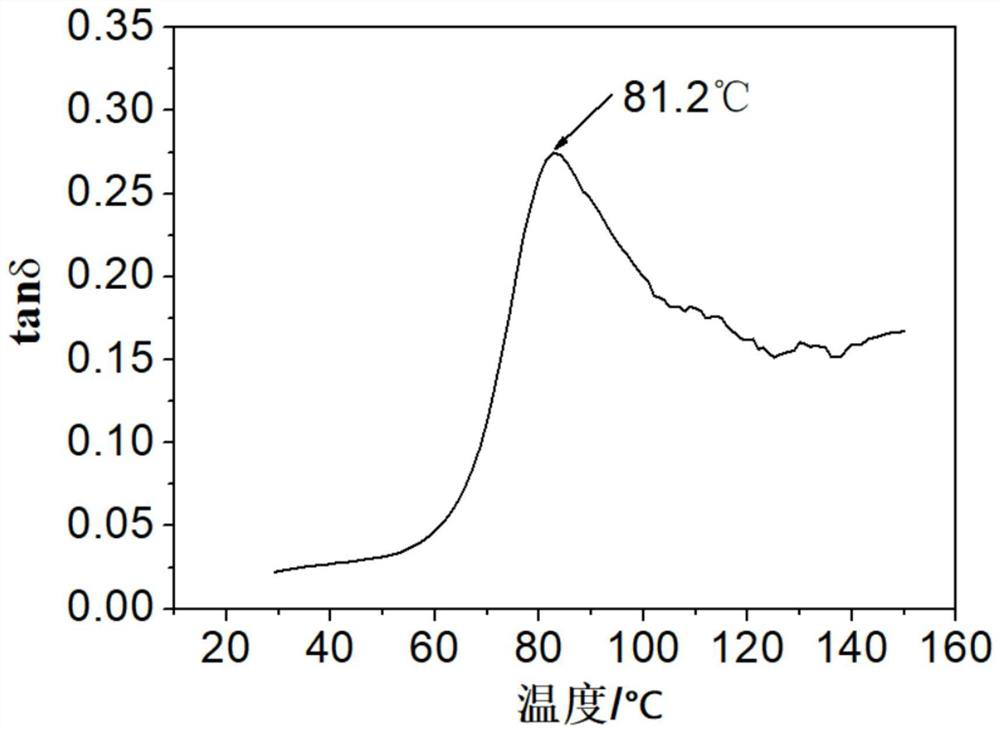

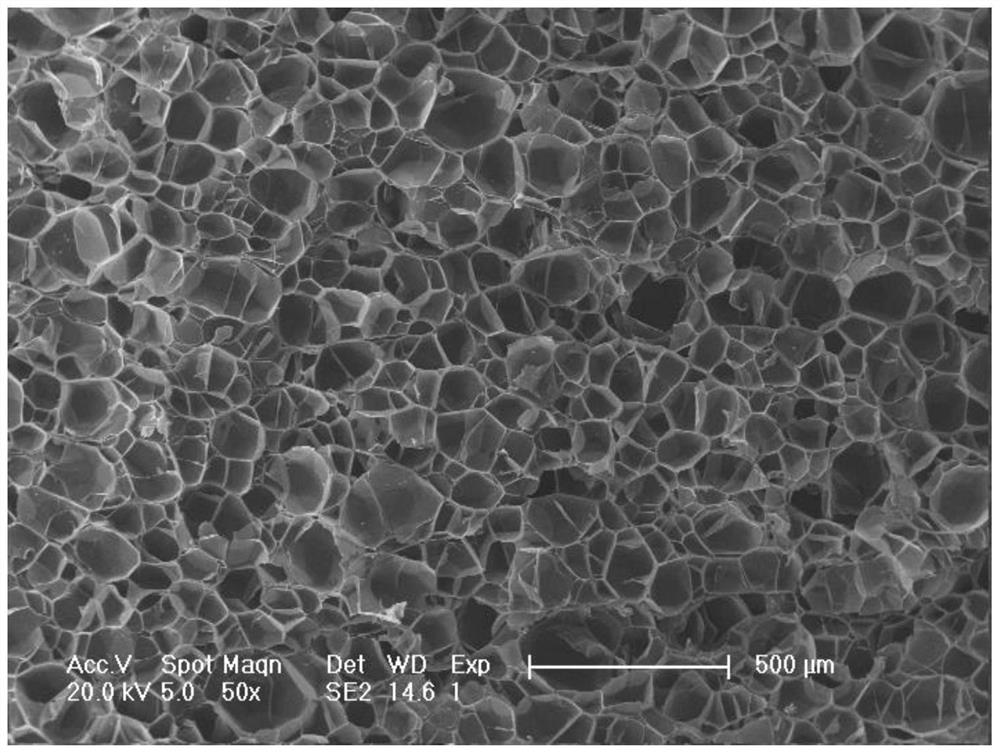

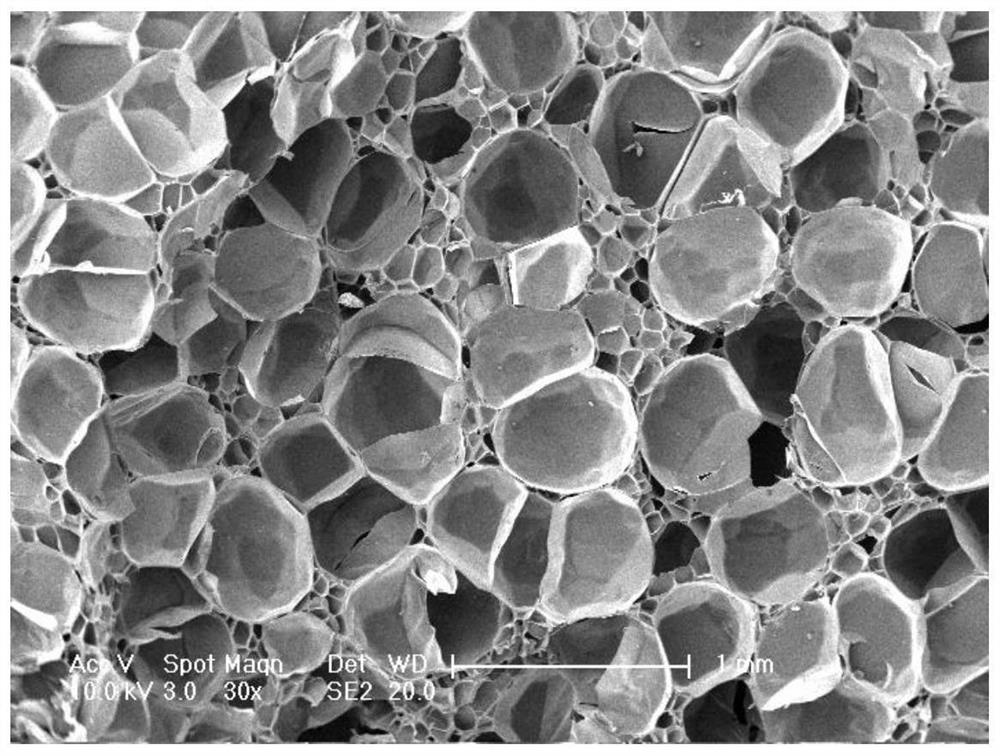

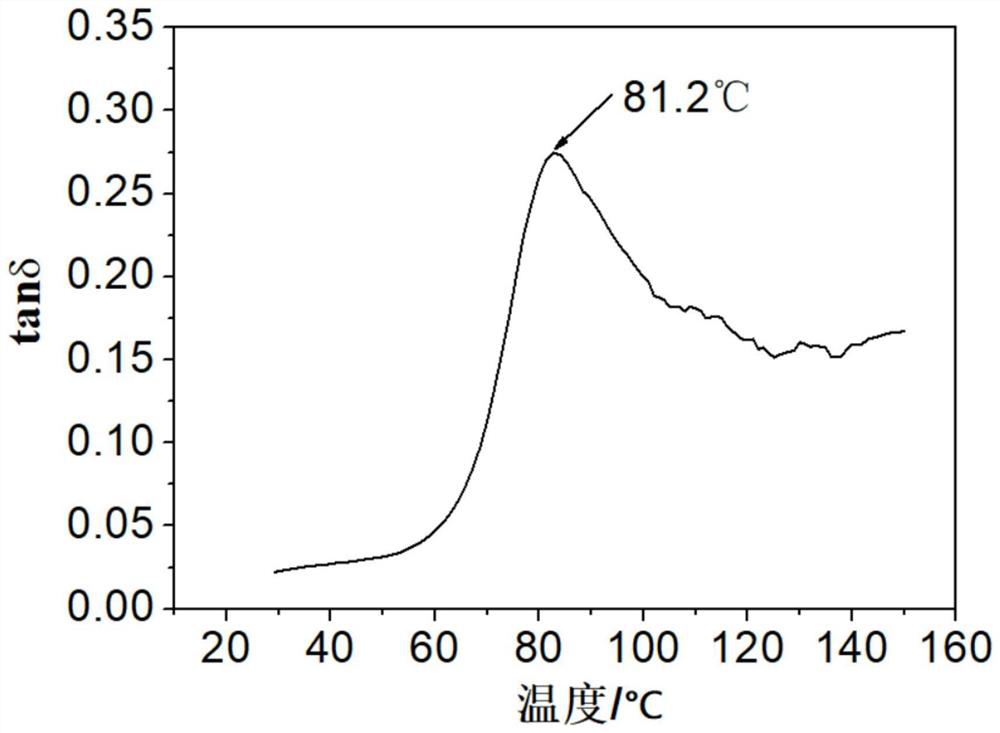

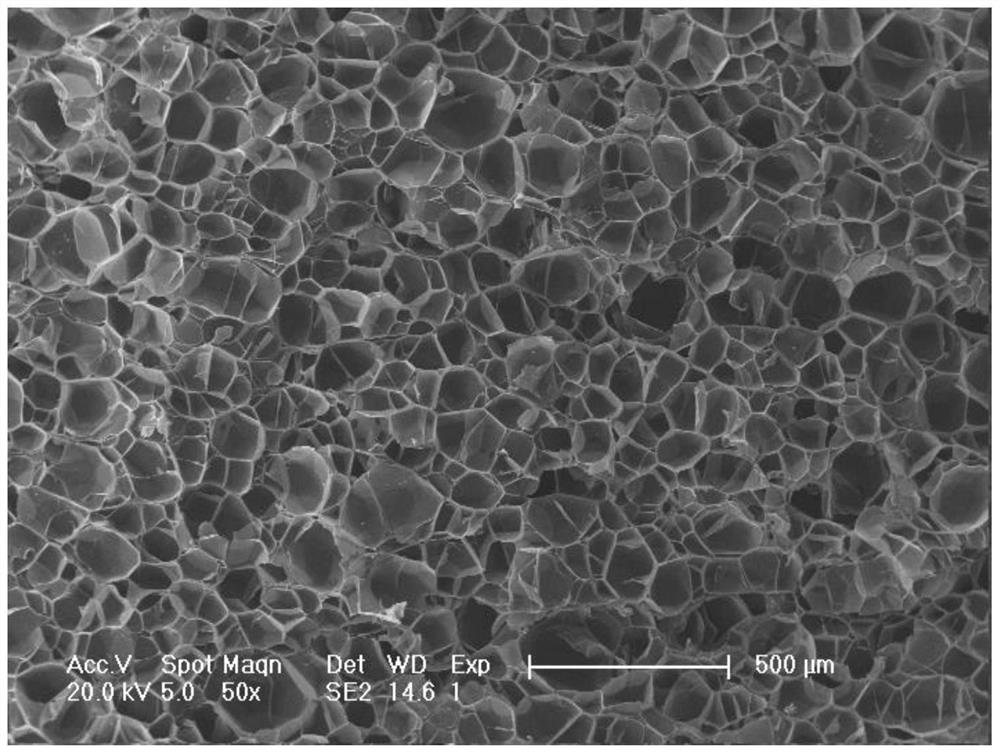

Cross-linked polyvinyl chloride structure foam material and preparation method thereof

ActiveCN113061310AImprove uniformityFine foamFinal product manufactureFoaming agentPolyvinyl chloride

The invention provides a method for preparing a cross-linked polyvinyl chloride structure foam material by using a physical foaming agent, which comprises the following steps: melting and mixing polyvinyl chloride resin, modified resin, isocyanate, anhydride, a nucleating agent and a heat stabilizer to obtain a blank; soaking the blank in foaming gas to be foamed, and obtaining a foaming body; and carrying out cross-linking curing on the foaming body to obtain the cross-linked polyvinyl chloride structure foam material. The cross-linked polyvinyl chloride structural foam material is prepared by adopting a brand new process route, and the adjustable range of the composition and proportion of the PVC resin and other raw materials is large; carbon dioxide or nitrogen is adopted for foaming, the PVC foam preparation process can be safer and more environmentally friendly, and the cost can be reduced; the foam material prepared by the invention has high glass transition temperature and good heat resistance; according to the preparation process disclosed by the invention, the compatibility or intersolubility of PVC and other raw materials is improved, and the material performance is better. The invention also provides a cross-linked polyvinyl chloride structural foam material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

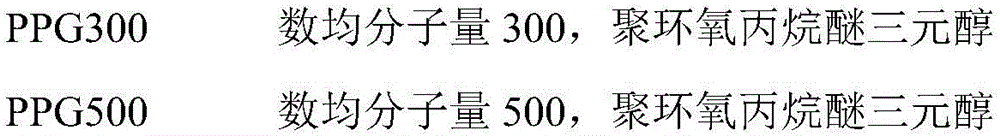

Two-component polyurethane adhesive for grinding tool and preparation method of two-component polyurethane adhesive

ActiveCN106674483AProduct environmental protectionEasy to operateAbrasion apparatusIsocyanatePolyurethane adhesive

The invention belongs to the technical field of polyurethane application, and in particular relates to a two-component polyurethane adhesive for a grinding tool and a preparation method of the two-component polyurethane adhesive. The two-component polyurethane adhesive adopts a two-component system; a polymer is prepared from polyether polyol of a functionality degree of 4 or 3, castor oil, a catalyst and a water absorbing agent in a mixed manner; an isocyanate component is prepared from 0-20% of diphenyl methane diisocyanate and 80-100% of polyisocyanates; and the two components are mixed together, thereby the polyurethane adhesive of high shore hardness D75-85 can be prepared. The two-component polyurethane adhesive is mainly applied to production and manufacturing of a polyurethane grinding material, is environmental-friendly in product, easy to operate, high in adhesiveness to minerals, smooth in grinding material surface, long in service life and economic and applicable.

Owner:SHANDONG INOV POLYURETHANE

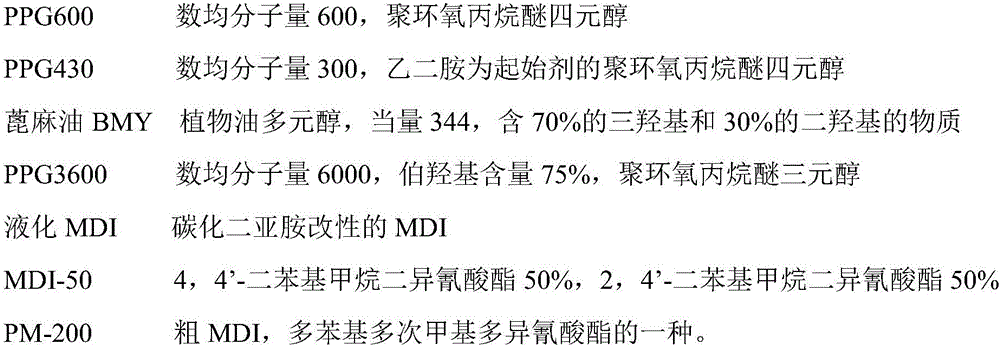

Flame-retardant PVC (polyvinyl chloride) sunlight film and preparation method thereof

InactiveCN108589320AStrong combinationNot easy to peel offConstructions elementsTextiles and paperSolventPlasticizer

The invention relates to a flame-retardant PVC (polyvinyl chloride) sunlight film and a preparation method thereof, and belongs to the technical field of chemistry and chemical products. The preparation method comprises the following steps: 1) setting amachine barrel temperature and a scraper temperature of a double-screw extruder; 2) taking an uniformly mixed mixture which comprises the followingcomponents in parts by weight: 100 parts of PVC resin, 3-10 parts of a plasticizer, 2-8 parts of a heat stabilizer, and 2-10 parts of a flame retardant, placing the mixture in a machine barrel of thedouble-screw extruder of step 1), and melting and extruding to obtain a resin melt; and blade-coating two surfaces of a base fabric layer with the resin melt by adopting a doctor blade, so as to forma base fabric coated with a resin melt layer; 3) subjecting the base fabric coated with the resin melt layer of step 2) to water-cooling solidification, trimming, and winding to prepare and obtain the flame-retardant PVC sunlight film. By adopting a method of directly impregnating a PVC resin melt with a substrate, the use of a highly toxic solvent or glue is avoided, and the flame retardance ofan obtained product can reach a limiting oxygen index of 32.4%.

Owner:WUHAN TEXTILE UNIV

Gas adsorbing material and preparation method thereof

InactiveCN109663564AGuaranteed qualityImprove adsorption capacityGas treatmentOther chemical processesBenzeneActivated carbon

The present invention provides a gas adsorbing material, which is prepared from the following materials by weight: 90-260 parts of a graphene aqueous solution and 79-81 parts of active carbon. According to the present invention, the graphene aqueous solution is mixed with active carbon, such that the adsorption capacity of the active carbon to toxic substances is enhanced, and particularly the active carbon has strong adsorption capacity to benzene and dust; by directly adopting the graphene aqueous solution as the raw material, such that the quality of the graphene can be ensured, and the production can be simplified; the graphene / active carbon gas adsorbing material for air purification has obviously-enhanced adsorption capacity compared with pure granular active carbon; and the preparedproduct and the preparation method are environmentally friendly, the process is simple, and the method is suitable for large-scale production.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Production method of flanged ball capable of being deflated for packaging and transport

InactiveCN107310208ANo creasesBeautiful and perfect packagingLamination ancillary operationsLaminationEngineeringAir pollution

The invention discloses a production method of a flanged ball capable of being deflated for packaging and transport. The production method mainly comprises the following steps of tailoring a complex into a plurality of ball skin pieces in different sizes and shapes by a special cutter, flanging the ball skin pieces, coating a binding agent on all edges of the ball skin pieces, and mutually binding the ball skin pieces which can constitute outer ball skin and are coated with the edge binding agent to form outer skin of a complete and stereoscopic spherical ball. A part about 900MM<2> at a ball nozzle of a middle tyre or a ball bladder is only bound with the outer skin of the ball by the binding agent to fix the middle tyre or the ball bladder, so that inflation and deflation are facilitated; but all other parts of the middle tyre or the ball bladder are mutually separated from the outer skin of the ball. The production method saves the cost of the binding agent, greatly reduces generation of toxic and harmful gas, and reduces air pollution; and a product can be deflated for the packaging and the transport, so that the packaging and transport cost is saved, the product is soft and plump, and perfect quality of the product is achieved.

Owner:魏彧

Technology and device for processing film-coated iron

ActiveCN102431269BAchieve high temperature thermal compoundingImprove fitLamination ancillary operationsLaminationPlastic filmCorrosion

Owner:上海联净复合材料技术有限公司

Multi-functional laminated iron production line

ActiveCN103640315BExcellent anti-rustImprove the decorative effectLamination ancillary operationsLaminationWinding machineProduction line

Owner:SUZHOU DONGHONGRUI PACKAGE TECH

Waterproof material for aluminum alloy doors and preparation method of material

InactiveCN107337968AImprove airtightnessExtended service lifeAntifouling/underwater paintsPaints with biocidesEnvironmentally friendlyAluminium alloy

The invention discloses a waterproof material for aluminum alloy doors and a preparation method of the material. The waterproof material comprises a component one and a component two, and solves the technical problems that waterproof coatings of aluminum alloy doors and windows in the prior art have poor mechanical properties and weak waterproof durability, and are not environmentally friendly enough and the like. The waterproof material is used on aluminum alloy doors and realizes technological effects such as high waterproof impermeability, long service life, safety, environmental protection, and the like on the aluminum alloy doors.

Owner:东莞市易禹门业有限公司

Formula of ethylene propylene diene monomer seal washer of plate heat exchanger

The invention provides a formula of an ethylene propylene diene monomer seal washer of a plate heat exchanger. The ethylene propylene diene monomer seal washer comprises the following materials in parts by mass: 70-110 parts of ethylene propylene diene monomer, 10-25 parts of carbon black N550, 40-70 parts of paraffin oil, 5-15 parts of zinc oxide, 1-6 parts of stearic acid, 2-4 parts of amine thermal-resisting antioxidant, 2-5 parts of peroxide, 0.5-3.5 parts of triallyl cyanurate, 3-6 parts of a blending agent and 3-8 parts of an anti-wear agent, wherein the peroxide is 2,5-dimethyl-2,5-di (tert-butylperoxy) hexane. The formula of the high heat-aging resistance ethylene propylene diene monomer seal washer of the plate heat exchanger is designed by combining the ethylene propylene diene monomer, the carbon black N550, the paraffin oil, the zinc oxide, the stearic acid, the amine thermal-resisting antioxidant, the peroxide, the triallyl cyanurate, the blending agent and the anti-wear agent; by using the Lanxess imported long-chain branched ethylene propylene diene monomer, the 2,5-dimethyl-2,5-di (tert-butylperoxy) hexane and the efficient thermal-resisting antioxidant, the heat aging resistance of a rubber material is improved, and the heat resistance reaches 175 DEG C; therefore, the ethylene propylene diene monomer seal washer can meet the use requirement of the plate heat exchanger, and the product is environmental-friendly.

Owner:WUHU JITUO RUBBER TECH

Belt and/or buckle assembly

ActiveUS8156614B2Minimum of waste materialLow production costSnap fastenersFastening devicesAdhesiveBiomedical engineering

Buckle type attachment elements, such as for belts, watch bands, or the like, and / or for securing or fastening elements (e.g., for footwear, handbags, briefcases, containers, or other objects) may be produced in a manner that generates minimal waste materials, without the use of metal or mechanical hardware type connectors, from completely recyclable materials, without the need for molding, without the use of plastics, and / or without the use of adhesives or cements. Such buckle elements may include a buckle portion and a tongue portion formed from the same material. In some structures, the tongue portion may be made from a part cut out to form the buckle portion. In other structures, the tongue portion may be formed by cutting slits into a base substrate that also makes up the buckle portion. Final products and methods of making such products also are described.

Owner:NIKE INC

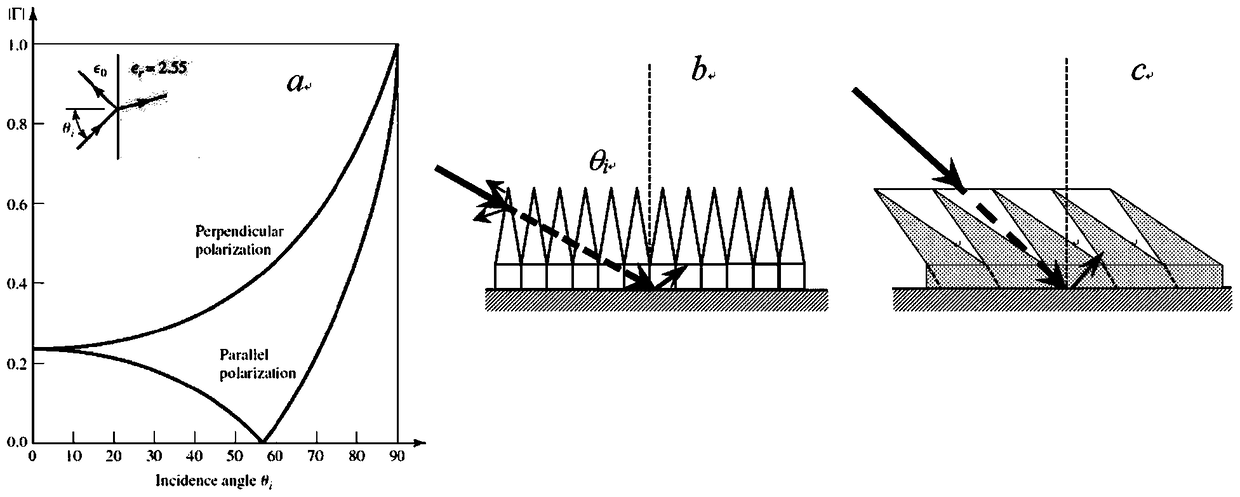

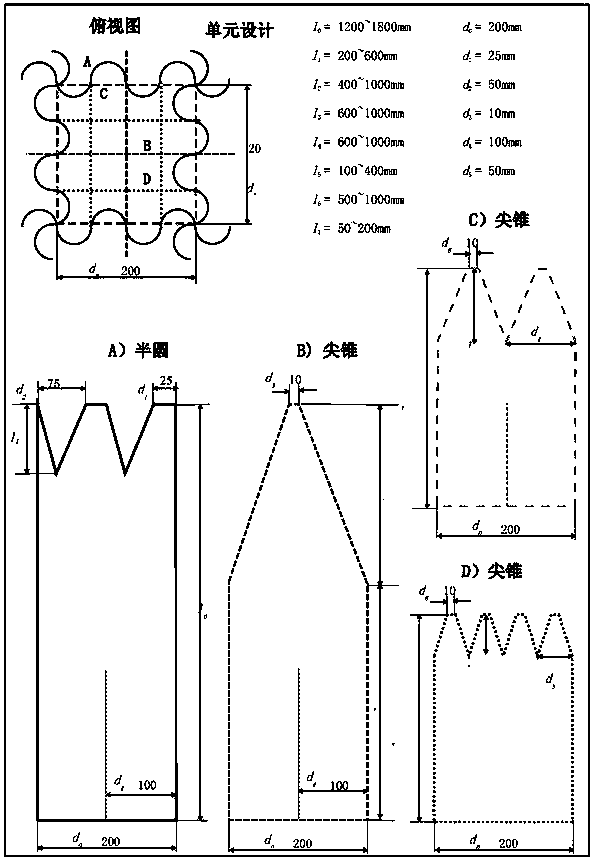

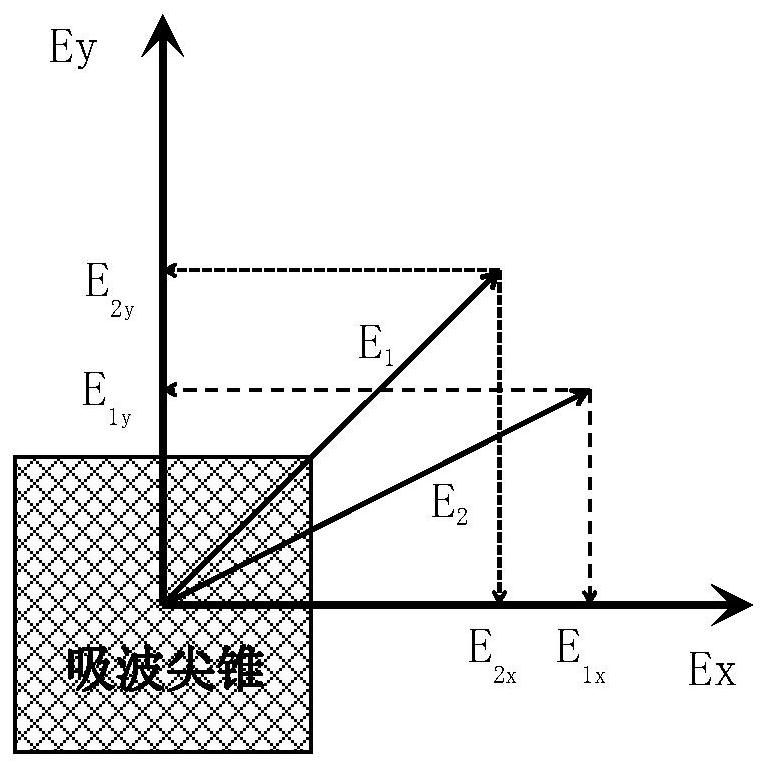

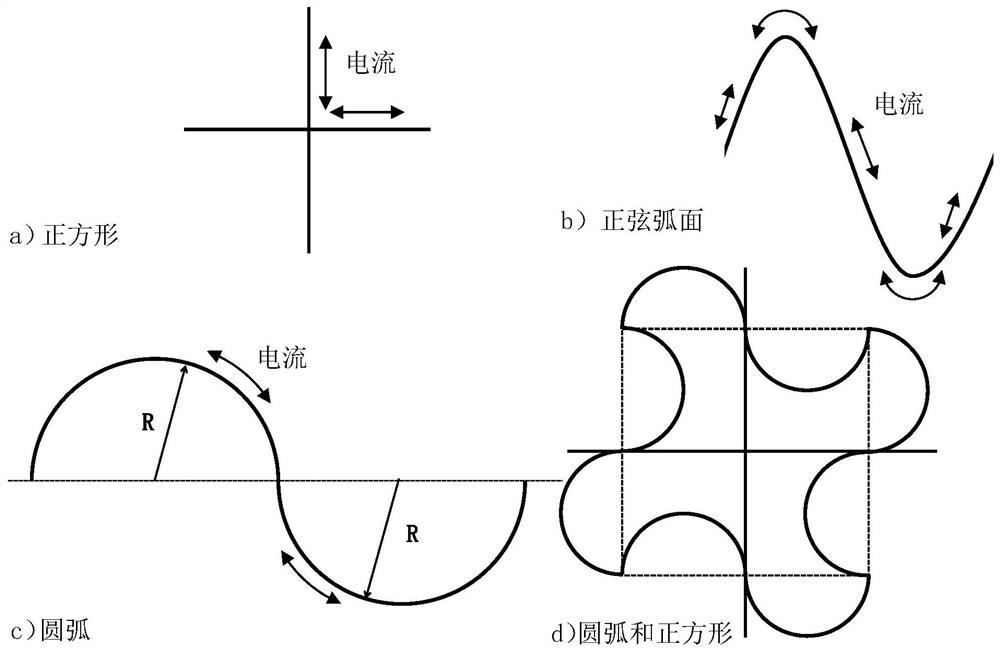

Arbitrarily-polarized anechoic chamber wave-absorbing material and preparation method thereof

ActiveCN111163624AReduce mistakesImprove test measurement accuracyMagnetic/electric field screeningElectromagentic field characteristicsMicrowaveAntenna polarization

The embodiment of the invention provides a broadband arbitrarily-polarized microwave absorbing material and a preparation method thereof. The structure of the arbitrarily-polarized anechoic chamber wave-absorbing material is characterized in that a square honeycomb periodic structure is formed by mutually embedding the wave plates which have the same wave absorbing capacity for the electromagneticwaves of any polarization; the surface of the arbitrarily-polarized anechoic chamber wave-absorbing material is coated with a conductive coating, and the wave-absorbing bandwidth range of the randomly polarized anechoic chamber wave-absorbing material is 0.1-110GHz. When the anechoic chamber wave-absorbing material provided by the embodiment of the invention is used as a wave-absorbing material for an antenna testing anechoic chamber, the testing and measuring precision can be improved, and errors during antenna polarization performance testing are reduced.

Owner:西安安聚德纳米科技有限公司

A kind of waterproof material for aluminum alloy door and preparation method thereof

InactiveCN107337968BAvoid aging speedLow toxicityAntifouling/underwater paintsPaints with biocidesMechanical engineeringEnvironmentally friendly

The invention discloses a waterproof material for aluminum alloy doors and a preparation method of the material. The waterproof material comprises a component one and a component two, and solves the technical problems that waterproof coatings of aluminum alloy doors and windows in the prior art have poor mechanical properties and weak waterproof durability, and are not environmentally friendly enough and the like. The waterproof material is used on aluminum alloy doors and realizes technological effects such as high waterproof impermeability, long service life, safety, environmental protection, and the like on the aluminum alloy doors.

Owner:东莞市易禹门业有限公司

A kind of cross-linked polyvinyl chloride structural foam material and preparation method thereof

ActiveCN113061310BImprove uniformityFine foamFinal product manufactureFoaming agentPolyvinyl chloride

The invention provides a method for preparing a cross-linked polyvinyl chloride structural foam material with a physical foaming agent, comprising: melting and mixing polyvinyl chloride resin, modified resin, isocyanate, acid anhydride, nucleating agent and heat stabilizer to obtain a blank ; soaking the blank in the foaming gas for foaming to obtain a foam; cross-linking and curing the foam to obtain a cross-linked polyvinyl chloride structural foam material. The invention adopts a new process route to prepare cross-linked polyvinyl chloride structural foam, and the composition and proportion of PVC resin and other raw materials can be adjusted in a large range; the invention uses carbon dioxide or nitrogen to foam, which can make the PVC foam preparation process safer and more environmentally friendly, and can Cost reduction; the foam material prepared by the invention has a high glass transition temperature and good heat resistance; the preparation process of the invention improves the compatibility or mutual solubility of PVC and other raw materials, and the material performance is better. The invention also provides a cross-linked polyvinyl chloride structural foam material.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of wave-absorbing material of arbitrary polarization microwave anechoic chamber and its preparation method

ActiveCN111163624BReduce mistakesImprove test measurement accuracyMagnetic/electric field screeningElectromagentic field characteristicsMicrowaveAntenna polarization

Embodiments of the present invention provide a broadband and arbitrary polarization microwave absorbing material and a preparation method, wherein the structure of the arbitrary polarization microwave anechoic chamber absorbing material is: a wave plate with the same absorbing ability for arbitrary polarized electromagnetic waves The square honeycomb periodic structure formed by inter-embedding, the surface of the microwave anechoic chamber absorbing material with any polarization is: the surface coated with conductive paint, and the absorbing frequency range of the microwave anechoic chamber absorbing material with any polarization is 0.1 ~110 GHz, when the microwave anechoic chamber absorbing material provided by the embodiment of the present invention is used as the absorbing material for the antenna test anechoic chamber, the test measurement accuracy can be improved and the error in the antenna polarization performance test can be reduced.

Owner:西安安聚德纳米科技有限公司

A kind of clean production method of tpo modified tpu superfine fiber synthetic leather

ActiveCN106811986BImprove mechanical propertiesIncrease productivityTextiles and paperProduction lineSurface layer

The invention relates to a clean production method of TPO modified TPU superfine fiber synthetic leather. The cleaning production method includes: using superfine fiber synthetic leather base cloth as the base material, and using a continuous impregnation manner to perform hydrophilic treatment to obtain hydrophilic superfine fiber synthetic base cloth; using a calendaring production line to add surface-layer materials into a kneading machine, kneading, feeding the kneaded surface-layer materials into an internal mixer, performing internal mixing, feeding the mixed materials into a plasticator, plasticating, feeding the plasticated materials into a calendaring machine, calendaring into a surface-layer thin film, allowing the surface-layer thin film to attach to the hydrophilic superfine fiber synthetic base cloth, and reeling to obtain a semi-finished product; knurling the semi-finished product to obtain the TPO modified TPU superfine fiber synthetic leather. The clean production method has the advantages that no organic solvents are used in the method, so that solvent pollution is avoided; the method is simple to operate and stable in process; the produced TPO modified TPU superfine fiber synthetic leather is excellent in mechanical performance and good in quality.

Owner:SHAANXI UNIV OF SCI & TECH

Novel environment-friendly touch decorative plate and manufacturing method thereof

PendingCN113878950AThe preparation process is environmentally friendlyProduct environmental protectionLamination ancillary operationsSynthetic resin layered productsStructural engineeringChemical corrosion

The invention discloses a novel environment-friendly touch decorative plate and a manufacturing method thereof. The novel environment-friendly touch decorative plate comprises a base material layer. A touch effect layer highlighting the 3D concave-convex shape of the base material layer is arranged on the base material layer. A surface structure layer protecting the concave-convex shape on the touch effect layer is arranged on the side, away from the base material layer, of the touch effect layer. The inner side, facing the touch effect layer, of the surface structure layer is provided with a surface color layer used for coloring the concave-convex shape on the touch effect layer. The surface structure layer and the surface color layer are tightly attached to the base material layer through a middle bonding layer. The plate is produced through embossing in the manufacturing process, chemical corrosion and electroplating are not needed, and the preparation process and the product are more environment-friendly. Meanwhile, the surface structure layer and the optional surface protection layer are arranged on the surface of the novel environment-friendly touch decorative plate and matched with each other, the flexibility of the outer side of the plate is protected, conventional machining such as bending, proper stretching, punching shearing and bending is met, and the application is wider.

Owner:佛山市呈阳新材科技有限公司

A preparation method of salt-resistant and detergent-resistant seaweed fiber

ActiveCN104846625BEasy to solveReduce swellingAlginate artificial filamentsVegetal fibresFiberSaline water

The invention discloses a preparation method of salt-resistant and detergent-resistant seaweed fiber, which is through introducing an auxiliary agent containing borate radicals, contacting and infiltrating the finished seaweed fiber with the auxiliary agent solution, and selecting suitable raw materials, ratios and reaction conditions , Prepared salt-resistant and detergent-resistant seaweed fibers. The preparation method of the present invention solves the problems of the seaweed fiber and its textiles that are not resistant to salt and detergent, and the seaweed fiber and its textiles modified by borate radicals have good salt resistance and can withstand the washing of alkaline detergents. The swelling degree of seaweed fiber modified by additive solution can be reduced to 39.8% after soaking in 30°C physiological saline for 72 hours, and the swelling degree can be reduced to 55.3% after soaking in standard detergent for 24 hours, and the fiber maintains its original shape. There is no obvious dissolution phenomenon, and at the same time, the self-flame-retardant performance of the seaweed fiber can be maintained.

Owner:青岛源海新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com