Arbitrarily-polarized anechoic chamber wave-absorbing material and preparation method thereof

A microwave absorbing material and microwave anechoic chamber technology, which is used in measurement devices, instruments, electrical components, etc., can solve the problems of inability to accurately grasp the performance of the antenna and the decline in measurement accuracy, so as to improve the measurement accuracy, reduce the measurement error, and reduce the effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a method for preparing a microwave anechoic chamber absorbing material with arbitrary polarization, including the following steps S1-S8:

[0038] S1. Using electromagnetic simulation software to select the base material and honeycomb structure characteristics of the arbitrary polarization microwave anechoic chamber absorbing material by optimizing the design and material selection of the special-shaped honeycomb structure;

[0039] S2. Production of conductive coatings;

[0040] S3. Spraying or dipping a conductive coating on the substrate, and drying and curing the conductive coating, so that the surface of the substrate is covered with a conductive coating;

[0041] S4. Spraying or dipping a protective coating on the conductive coating, and drying and curing the protective coating, so that the surface of the substrate is covered with a protective coating;

[0042] S5. Cutting the substrate coated with the conductive...

Embodiment 1

[0096] Example 1: 350mm high 3GHz arbitrary polarization inter-embedded wave-absorbing honeycomb

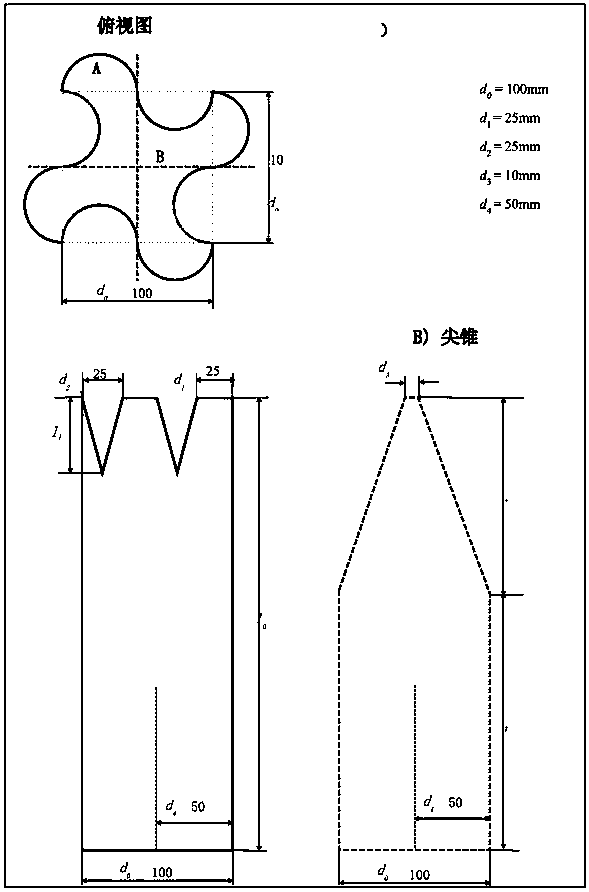

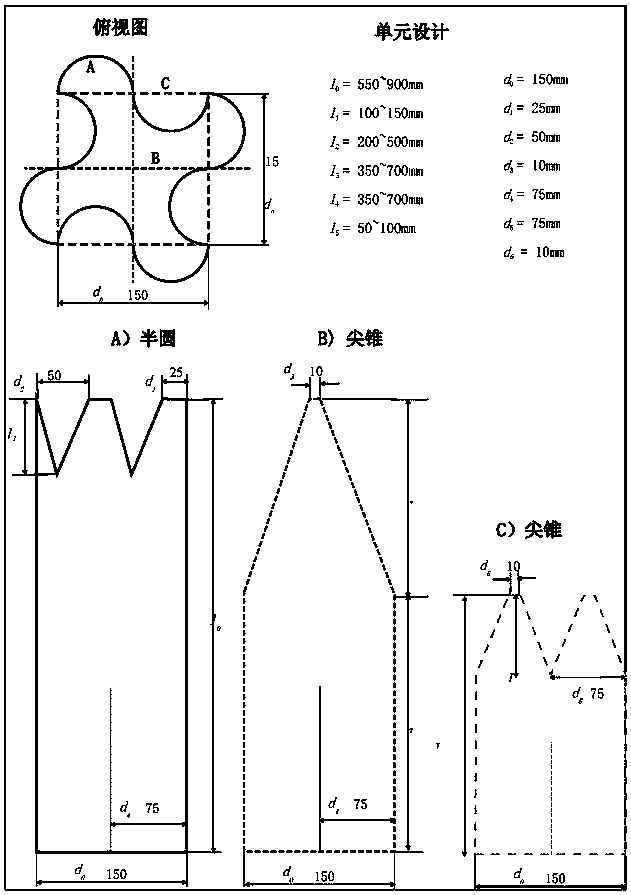

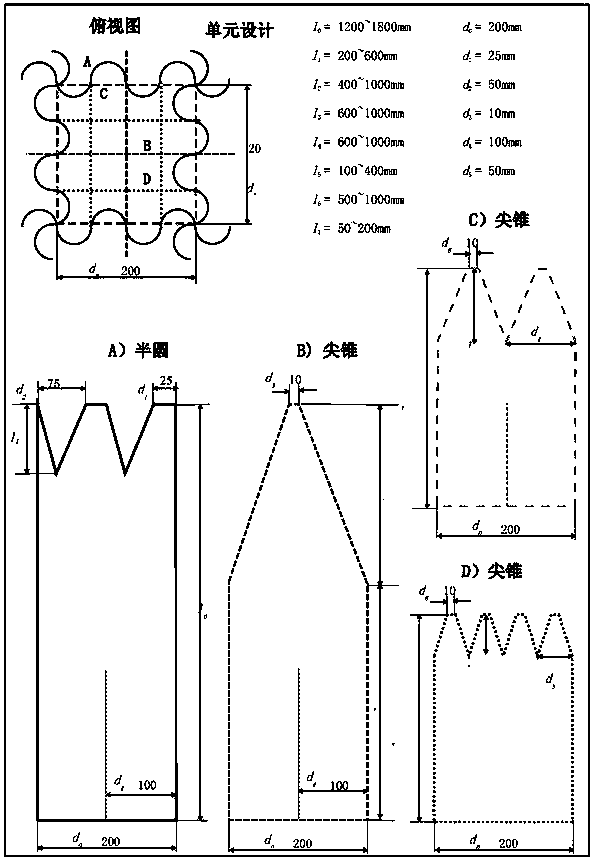

[0097] This embodiment uses a surface density of 100g / m2 Flame-retardant non-woven fabric as the base material, and 13m2 of non-woven fabric is required to produce 1m2 wave-absorbing honeycomb material, such as Figure 12 As shown, a 50mm diameter semicircle wave A is used to form a 100x100mm quadrilateral wave absorbing unit, and a sharp cone cross B is embedded in it. The upper part of the semicircle wave forms a table shape to reduce the reflection of the honeycomb surface. One of the simulation optimization schemes is that the upper side of the semicircular table is 25mm (d1), the height is 75mm (l1), the tip width of the flat cone is 5mm (d3), and the height is 150mm (l2). The square resistance of the semicircular wave surface is 200 ohms, and the surface square resistance of the tapered plate is 350 ohms.

[0098] Graphene conductive coating formula: 6% graphene (graphite ...

Embodiment 2

[0102] Example 2: 450mm high 2GHz arbitrary polarization inter-embedded wave-absorbing honeycomb

[0103] The surface density used in this embodiment is 120g / m 2 Flame-retardant non-woven fabric is used as the base material, which requires 20m 2 Production of non-woven fabrics 1m 2 Absorbing honeycomb materials, such as Figure 11 As shown, a 50mm diameter semicircle wave is used to form a 100x100mm quadrilateral wave absorbing unit, and a pointed cone cross B is embedded in it. The upper part of the semicircle wave forms a table shape to reduce the reflection of the honeycomb surface. One of the simulation optimization schemes is that the upper side of the semicircular table is 25mm (d1), the height is 100mm (l1), the tip width of the flat cone is 5mm (d3), and the height is 200mm (l2). The square resistance of the semicircular wave surface is 200 ohms, and the surface square resistance of the tapered plate is 300 ohms.

[0104] Graphene conductive coating formula: same a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com