Technology and device for processing film-coated iron

A technology of coated iron and processing methods, applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems of being unable to use high-temperature cooking and sterilization, and can not be used, so as to achieve low production costs, energy consumption and material consumption Low, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

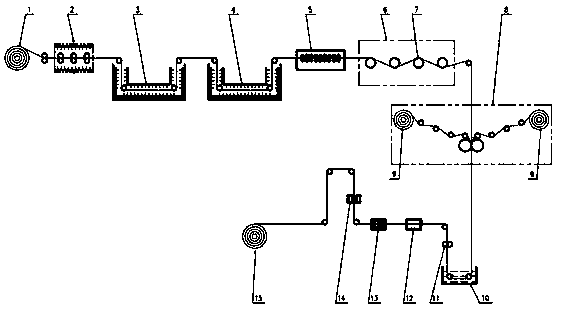

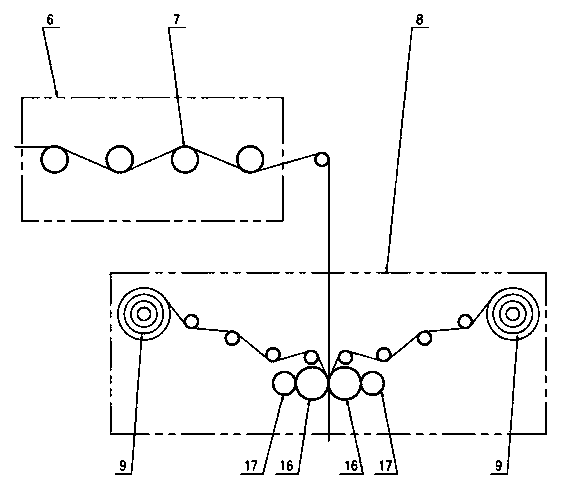

[0058] figure 1 It is a schematic diagram of a production line of an embodiment of the coated iron processing technology of the present invention.

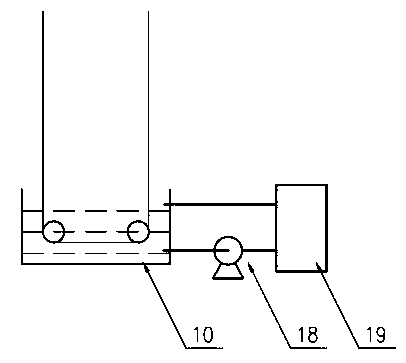

[0059] The whole process flow is divided into cleaning and drying stage, preheating stage, lamination stage, cooling stage and auxiliary stage, etc. The entire technological process and steps of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0060]The steel plate to be processed is cold-rolled thin coiled steel plate (chrome-plated iron) with chrome-plated surface, and the plastic film used for compounding can be PP plastic (polypropylene) or PET plastic (polyester).

[0061] The first is the cleaning and drying stage. Such as figure 1 Among them, the cold-rolled thin coiled steel plate (chrome-plated iron) that needs to be processed is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com