Novel flame-retardant heat-insulation elastic polyester material and preparing method and application thereof

A technology of elastic polyester and flame-retardant polyester, which is applied in the field of polyester materials, can solve the problems of toxic smoke, flammability, and secondary damage to the human body, and achieve the effects of environmental protection, safe use, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

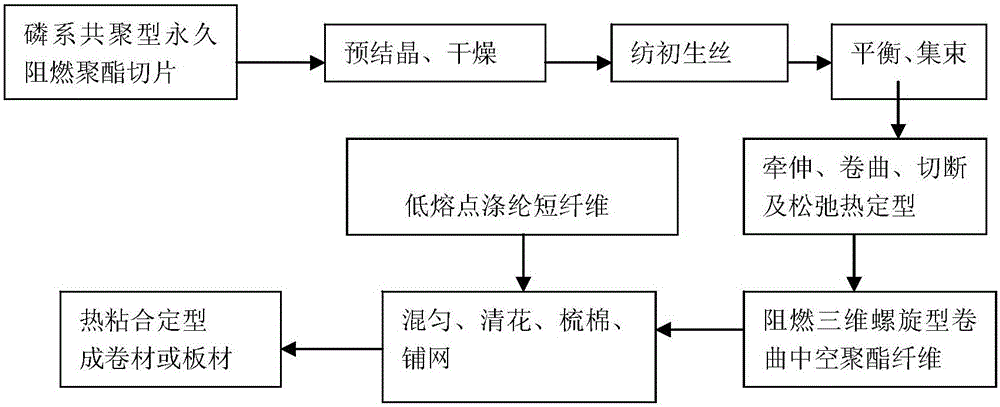

[0021] A preparation method of a novel flame-retardant and heat-insulating elastic polyester material, comprising the steps of:

[0022] Step 1. Phosphorus-based copolymerized permanent flame-retardant polyester chips with a phosphorus content of 7500-8500ppm, an intrinsic viscosity of 0.65-0.80dl / g, a melting point ≥ 240°C, diethylene glycol ≤ 3%, and a terminal carboxyl group ≤ 30mol / t Put it into the vacuum drum drying equipment, slowly heat up to 110-145°C under vacuum conditions, carry out pre-crystallization for 2-6 hours, then transfer to the packed drying tower, heat up to 140-165°C for 3-8 hours, and reach water Part content ≤ 30ppm; spinning temperature is 255 ~ 282 ℃, melted by screw extruder, statically mixed, filtered, enter the box metering pump for metering, extrude through "C" type hollow spinneret, and the temperature is 15 ~25℃, the speed is 1.5~4.5m / s asymmetrical ring blowing strong wind quenching to produce as-spun silk; after balancing and bunching the as...

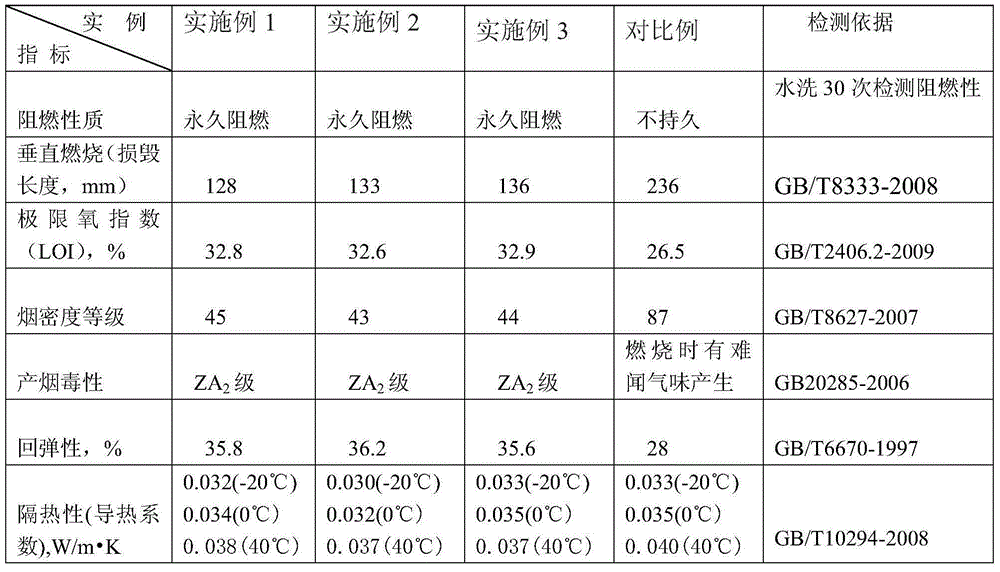

Embodiment 1

[0028] 1. Put phosphorus-based copolymerized permanent flame-retardant polyester chips (phosphorus content is 8500ppm) into vacuum drum drying equipment, slowly heat up to 110°C under vacuum conditions, perform pre-crystallization for 2 hours, and then transfer to filling drying In the tower, the temperature is raised to 140°C and dried for 3 hours to reach a moisture content of ≤30ppm; the spinning temperature is 255°C, and after being melted, statically mixed, and filtered by a screw extruder, it enters the metering pump of the box for metering, and passes through the "C" type hollow spray Slab extruded, quenched by an asymmetrical ring blowing strong wind at a temperature of 15°C and a speed of 1.5m / s to obtain as-spun silk; Flame-retardant three-dimensional spiral crimped hollow polyester fiber of 2-10D obtained by relaxation heat setting;

[0029] 2. Mix 85wt% of 2-10D flame-retardant three-dimensional spiral crimped hollow polyester fiber and 15wt% of low-melting point p...

Embodiment 2

[0031]Step 1. Put phosphorus-based copolymerized permanent flame-retardant polyester chips (phosphorus content of 8000ppm) into vacuum drum drying equipment, and slowly heat up to 130°C under vacuum conditions for 4 hours of pre-crystallization, and then transfer to the filling type In the drying tower, the temperature is raised to 155°C and dried for 5 hours to reach a moisture content of ≤30ppm; the spinning temperature is 265°C, and after being melted, statically mixed, and filtered by a screw extruder, it enters the box for metering by a metering pump, and passes through a "C" type hollow The spinneret is extruded, and the as-spun yarn is obtained by quenching with asymmetrical ring blowing and strong wind at a temperature of 20°C and a speed of 3m / s; Flame-retardant three-dimensional spiral crimped hollow polyester fiber of 2-10D obtained by relaxation heat setting;

[0032] Step 2. Mix 90wt% of 2-10D flame-retardant three-dimensional spiral crimped hollow polyester fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com