A kind of waterproof material for aluminum alloy door and preparation method thereof

A waterproof material and aluminum alloy technology, applied in the direction of antifouling/underwater coatings, polyester coatings, biocide-containing paints, etc., can solve the problems of not being environmentally friendly, poor mechanical properties of waterproof coatings, weak waterproof durability, etc., to achieve Good waterproof performance, high airtightness, and improved mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

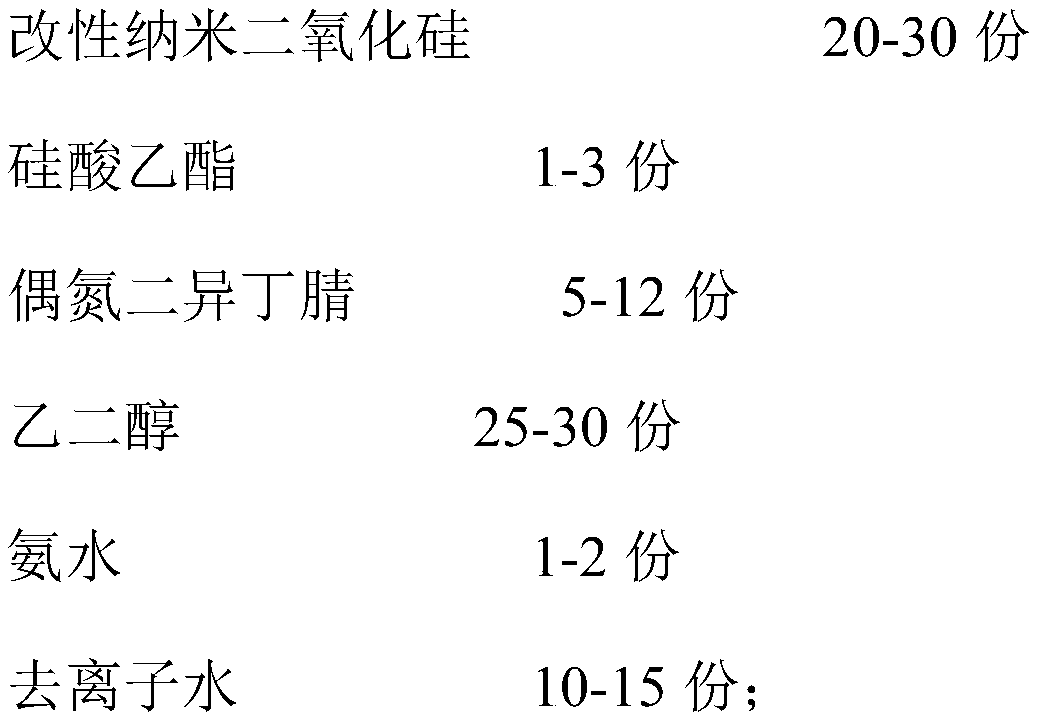

[0046] The waterproof material of this embodiment includes component one and component two. Wherein, the first component includes the following ingredients by weight: 20 parts of modified nano silica, 1 part of ethyl silicate, 5 parts of azobisisobutyronitrile, 25 parts of ethylene glycol, 1 part of ammonia, and 10 parts of ionized water.

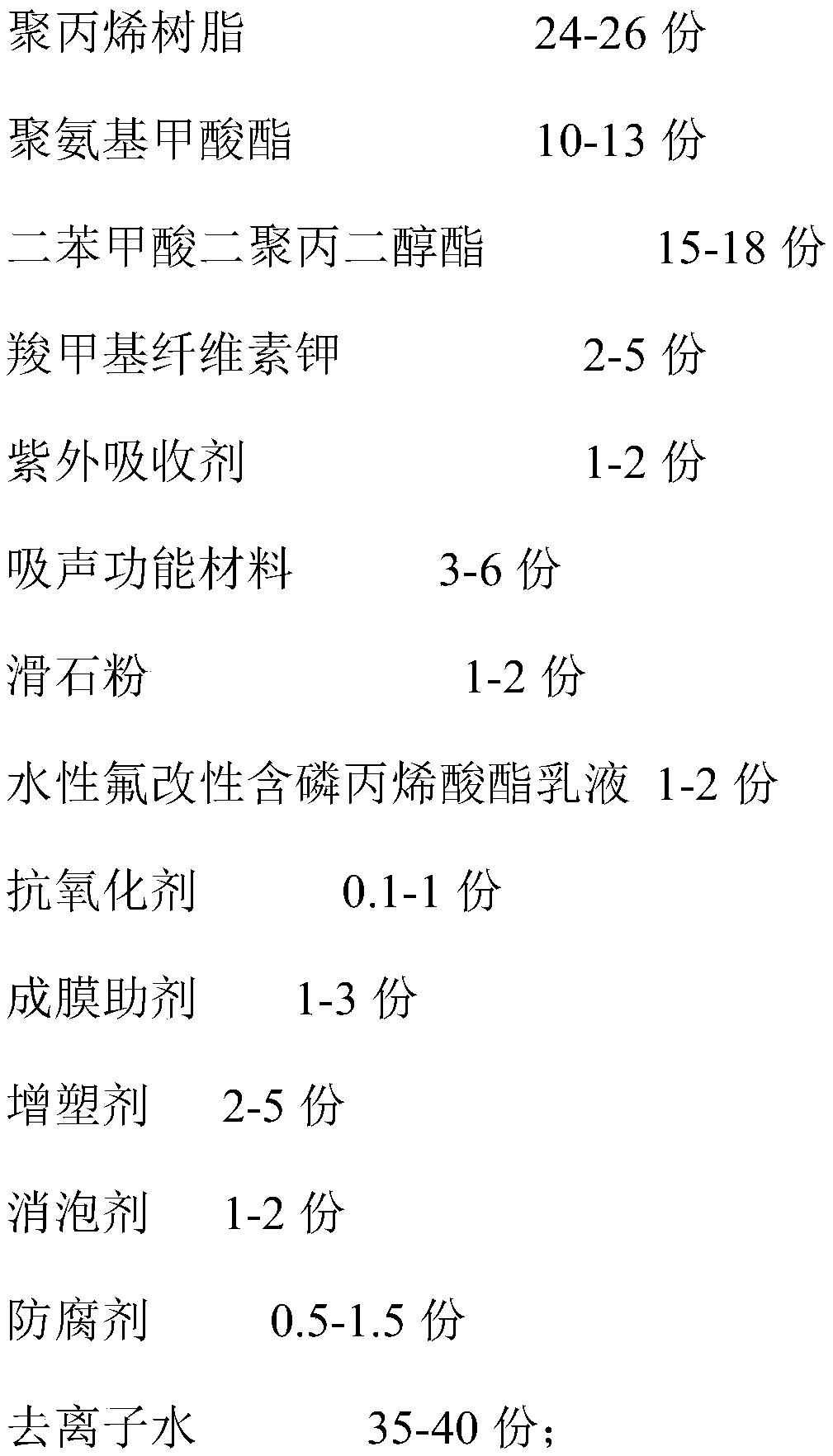

[0047] The second component includes the following ingredients in parts by weight: 24 parts of polypropylene resin, 10 parts of polyurethane, 15 parts of dipropylene glycol dibenzoate, 2 parts of potassium carboxymethyl cellulose, 2 parts of ultraviolet absorber, 2'-Dihydroxy-4,4'-dimethoxybenzophenone-5,5'-disulfonic acid 1 part, sound-absorbing functional material slag fiber and mineral fiber 3 parts, talcum powder 1 part, water-based fluorine 1 part of modified phosphorus-containing acrylate emulsion, 0.1 part of antioxidant 245, 1 part of film-forming assistant, 2 parts of plasticizer, 1 part of defoamer, 0.5 part of preservative, and 35 ...

Embodiment 2

[0055] The waterproof material of this embodiment includes component one and component two. Wherein, the first component includes the following ingredients by weight: 25 parts of modified nano silica, 2 parts of ethyl silicate, 8 parts of azobisisobutyronitrile, 27 parts of ethylene glycol, 1.6 parts of ammonia, and 13 parts of ionized water. The second component includes the following ingredients in parts by weight: 25 parts of polypropylene resin, 12 parts of polyurethane, 16 parts of dipropylene glycol dibenzoate, 4 parts of potassium carboxymethyl cellulose, and ultraviolet absorber 2- 1.5 parts of hydroxy-4-methoxy-5-sulfonic acid benzophenone, 4 parts of sound-absorbing functional materials mineral fiber and glass fiber, 1.2 parts of talc, 1.5 parts of water-based fluorine-modified phosphorus-containing acrylate emulsion, antioxidant 0.5 parts of 1010, 2 parts of film-forming auxiliary, 4 parts of plasticizer, 1.2 parts of defoamer, 1 part of preservative, 36 parts of de...

Embodiment 3

[0063] The waterproof material of this embodiment includes component one and component two. Wherein, the first component includes the following ingredients by weight: 30 parts of modified nano silica, 3 parts of ethyl silicate, 12 parts of azobisisobutyronitrile, 30 parts of ethylene glycol, 2 parts of ammonia, and 15 parts of ionized water. The second component includes the following ingredients in parts by weight: 26 parts of polypropylene resin, 13 parts of polyurethane, 18 parts of dipropylene glycol dibenzoate, 5 parts of potassium carboxymethyl cellulose, and ultraviolet absorber 4- 2 parts of methoxy-2-hydroxy benzophenone, 6 parts of sound-absorbing functional material glass fiber and wood fiber, 2 parts of talc, 2 parts of water-based fluorine-modified phosphorus-containing acrylate emulsion, 1 part of antioxidant 1098, into 3 parts of membrane aid, 5 parts of plasticizer, 2 parts of defoamer, 1.5 parts of preservative, and 40 parts of deionized water.

[0064] Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com