Multi-functional laminated iron production line

A technology of coated iron and production line, which is applied in the direction of layered products, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems of inability to produce low-temperature bonded coated iron and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The multi-functional coated iron production line of this embodiment is used to produce high-temperature molten coated iron coated on one side.

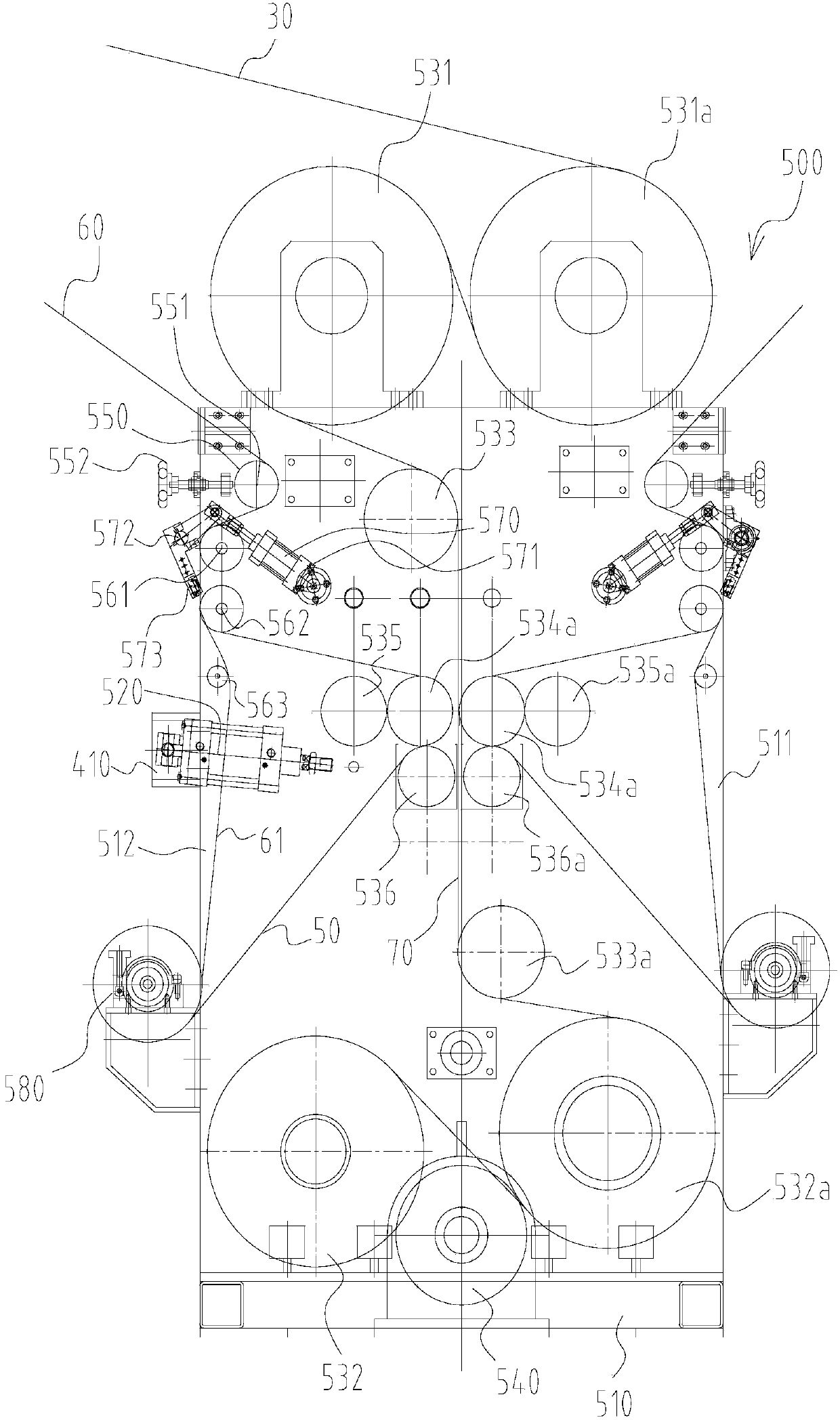

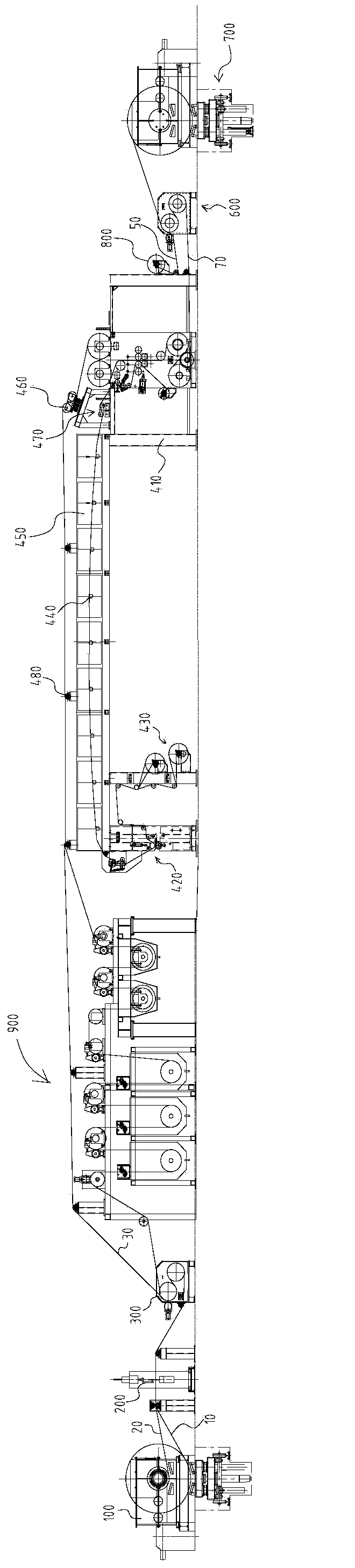

[0070] see figure 1 , a multi-functional film-coated iron production line shown in the figure includes a cold-rolled substrate unwinding device 100, a seam welder 200, an S-rotation roller group 300, an upper film releasing device 400, and an iron sheet in sequence according to the metal substrate conveying direction. Laminating device 500, S-torque roller set 600, laminating iron winder 700, finished protective film unwinding mechanism 800.

[0071] After the cold-rolled thin rolled substrate 10 and the threading belt 20 are unrolled and unrolled by the cold-rolled substrate unwinding device 100 , the metal substrate 30 formed after being welded and connected by the seam welding machine 200 enters the S-rotation roller group 300 for tensioning.

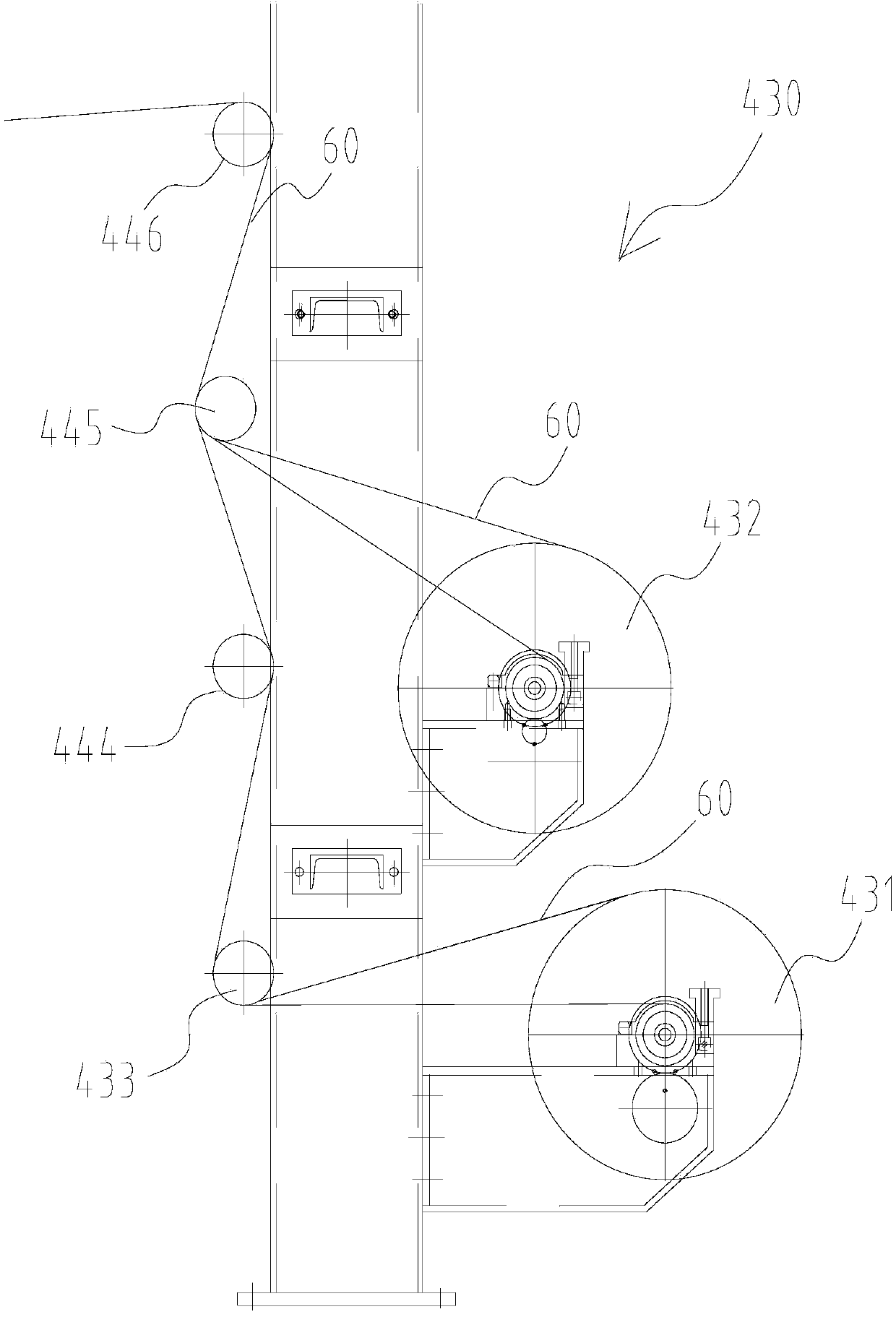

[0072] The upper film release device 400 of this embodiment includes a frame 410...

Embodiment 2

[0096] The multifunctional coated iron production line of this embodiment is also used to produce single-sided coated high-temperature molten coated iron.

[0097] see Figure 4 , the multifunctional coated iron production line of this embodiment provided in the figure is to increase a metal substrate cleaning machine 900 on the basis of the multifunctional coated iron production line of embodiment 1, and the metal substrate cleaning machine 900 is arranged on the S rotation force roller Between the group 300 and the upper film release device 400, the metal substrate 30 is cleaned, degreased, and oiled with a metal substrate cleaning agent, and then sent to the iron sheet conveying guide roller set 480 in the upper film release device 400 and is conveyed by the iron sheet guide roller set 480 Sent to iron sheet deviation correcting machine 460, all the other parts are the same as embodiment 1. The metal substrate cleaning machine 900 is a prior art, and will not be described ...

Embodiment 3

[0099] The multifunctional coated iron production line of this embodiment is also used to produce double-sided coated high-temperature molten coated iron.

[0100] see Figure 5 , the multifunctional coated iron production line of this embodiment provided in the figure is to add a lower film releasing device 400a on the basis of the multifunctional coated iron production line of embodiment 1, and carry out partial improvement to the iron sheet coating device 500, specifically as follows:

[0101] see Figure 5 , the lower film release device 400a of this embodiment includes a frame 410a and a lower film gluing part 420a installed at the feed end of the frame 410a, a double-station lower film unwinding mechanism 430a, and several lower film delivery devices on the top of the frame 410a. The guide roller set 440a and the lower film oven 450a are equipped with a lower film deviation correction device 470a at the discharge end of the frame 410a, and several lower film conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com