Cross-linked polyvinyl chloride structure foam material and preparation method thereof

A technology for cross-linking polyvinyl chloride and foam materials, applied in the field of foam materials, can solve the problems of nucleating agent residue, limited fusion degree, affecting material properties, etc., and achieves lower thermal stability requirements, lower overall process energy consumption, The effect of shortening the heat time at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a cross-linked polyvinyl chloride structural foam material, comprising:

[0030] Melting and mixing polyvinyl chloride resin, modified resin, isocyanate, acid anhydride, nucleating agent and heat stabilizer to obtain a blank;

[0031] immersing the blank in foaming gas for foaming to obtain a foam;

[0032] The foam is cross-linked and solidified to obtain a cross-linked polyvinyl chloride structural foam material.

[0033] In the prior art, PVC resin (polyvinyl chloride resin, also known as PVC paste resin) produced by emulsion polymerization process is generally used as one of the main raw materials to prepare cross-linked polyvinyl chloride structural foam. Compared with PVC paste resin, loose PVC resin (also known as PVC suspension resin) produced by suspension polymerization process has the advantage of low cost. The polyvinyl chloride resin used in the preparation of cross-linked polyvinyl chloride structural foam in...

Embodiment 1

[0067] Melt and mix 100g PVC resin (paste resin), 60g PMDI, 30g MHHPA, 2.0g calcined kaolin, and 2g calcium stearate at 150°C to obtain a 6mm thick blank; then put the blank into a sealed cavity at 90°C , put in carbon dioxide to raise the pressure to 10MPa, hold the pressure for 120min, discharge the carbon dioxide, and obtain a primary foam; soak the primary foam in hot water at 90°C for secondary expansion for 6 minutes, and obtain a secondary foam; The secondary foam was placed in saturated water vapor at 60° C. for 4 days for cross-linking and curing to obtain a cross-linked PVC structural foam material.

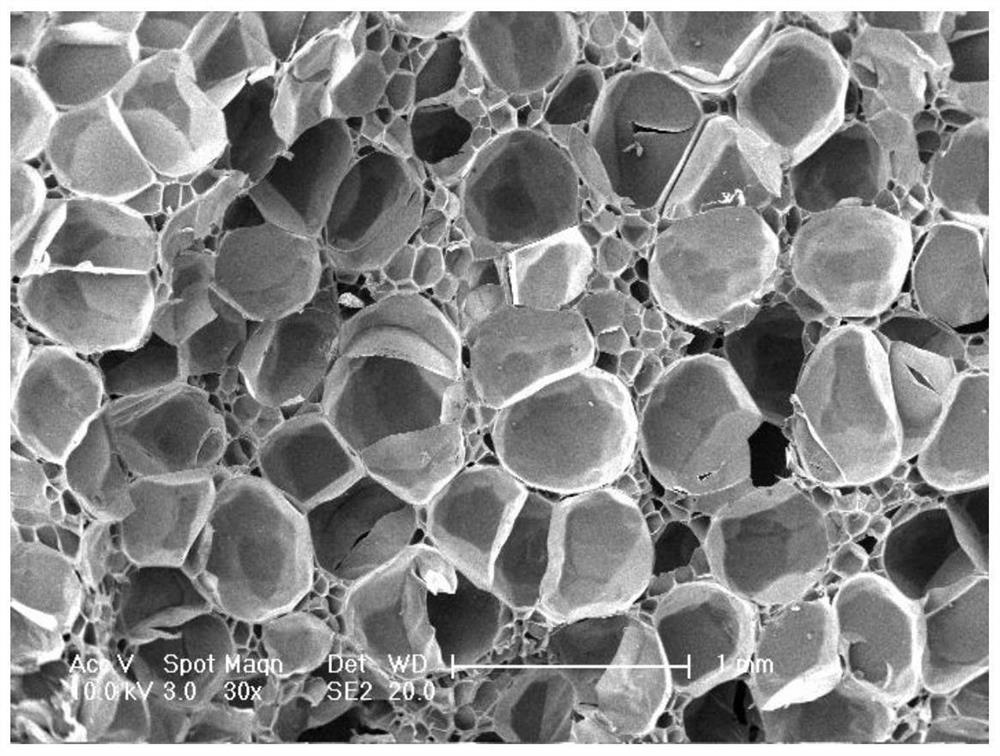

[0068] According to the method of comparative example 1, the cross-linked PVC structural foam prepared by the embodiment of the present invention 1 is detected, and the detection results are as follows: image 3 Shown, the density of the foam material that embodiment 1 prepares is 70kg / cm 3 , the average cell size is about 90 μm.

[0069] According to the method for c...

Embodiment 2

[0072] Melt 100g of PVC resin, 30g of PMMA (polymethyl methacrylate), 100g of TDI, 60g of PA, 0.6g of calcium stearate, 0.4g of zinc stearate, 1.0g of nano-silica, and 0.5g of molecular sieve at 150°C Mix to obtain a blank with a thickness of 6mm; put the blank into a sealed cavity at 125°C, introduce carbon dioxide to increase the pressure to 6MPa, keep the pressure for 120min, and discharge the carbon dioxide to obtain a PVC primary foam; soak the primary foam Perform secondary expansion in hot water at 95°C for 30 minutes to obtain a secondary foam; place the secondary foam in hot water at 40°C for cross-linking and curing for 6 days to obtain a cross-linked PVC structural foam material.

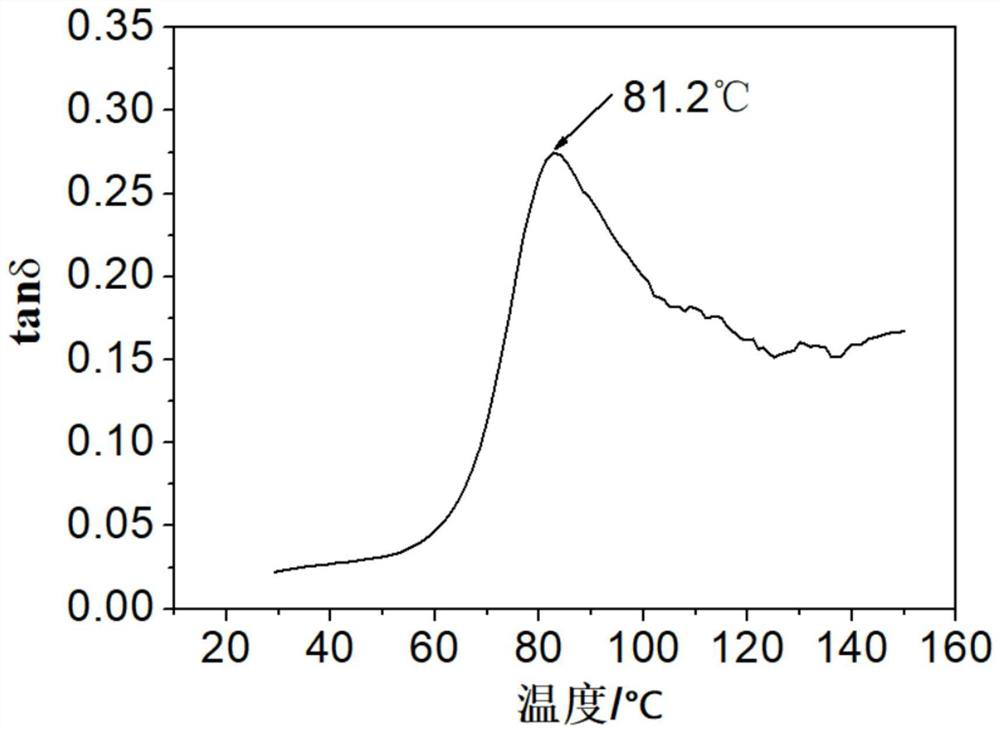

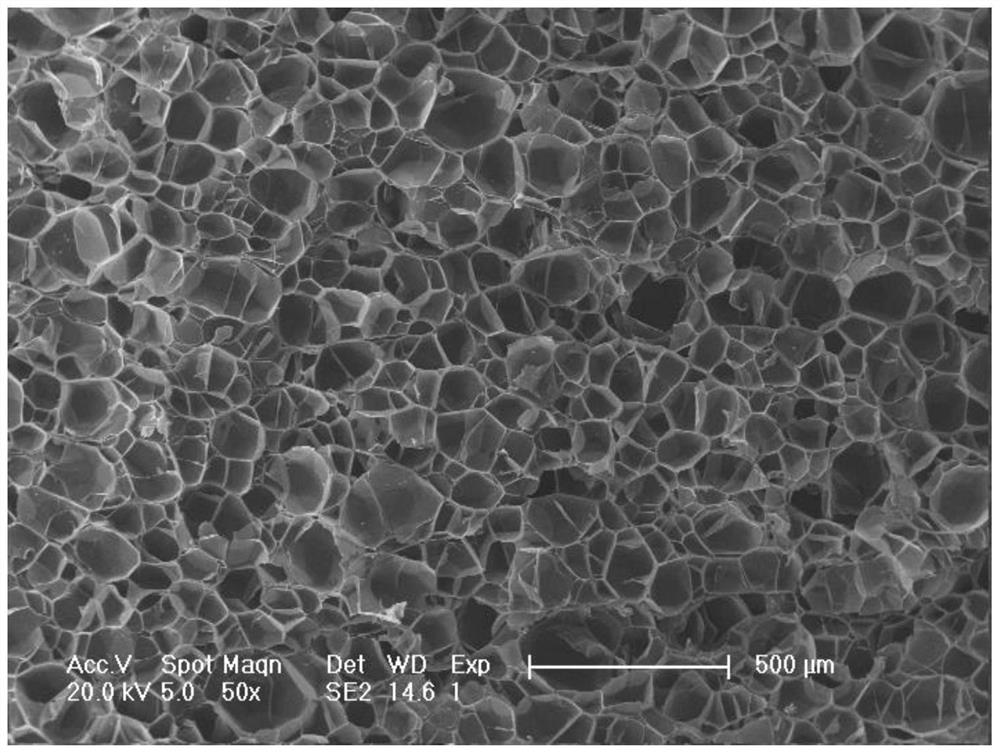

[0073] According to the method of comparative example 1, the cross-linked PVC structural foam prepared by the embodiment of the present invention 2 is detected, and the density of the foam material is 50kg / cm 3 , the average cell size is about 95 μm, and the glass transition temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com