Polyethylene terephthalate, poly(ethylene naphthalene-2,6-dicarboxylate) and preparation thereof

A technology of polyethylene terephthalate and polyethylene naphthalate, applied in fiber processing, spinning solution preparation, conjugated synthetic polymer artificial filament, etc., to achieve good bulkiness and broad development effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

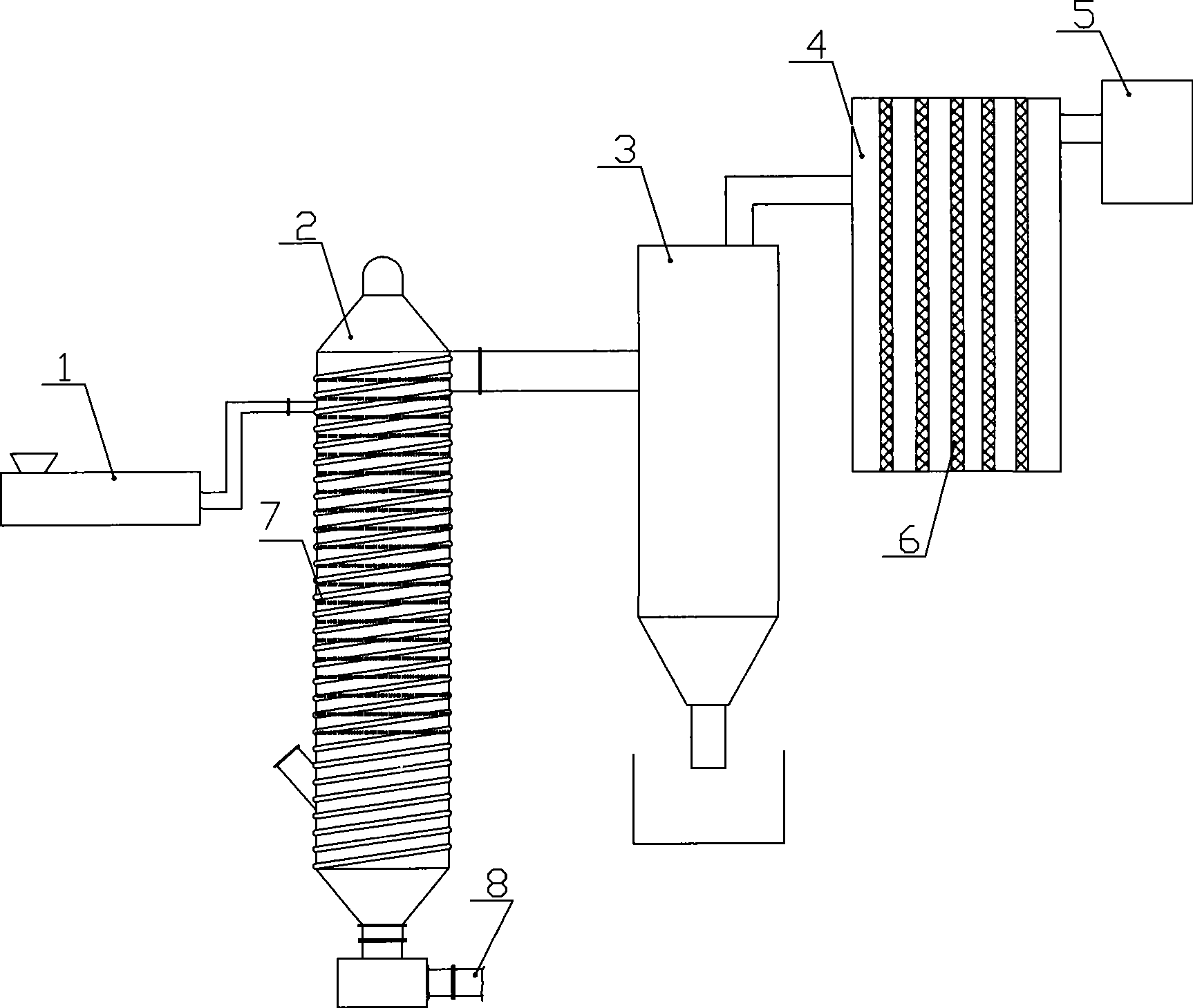

[0028] The preparation method of the alloy fiber of polyethylene terephthalate and polyethylene naphthalate, the method comprises the following steps (as figure 1 shown):

[0029] ① Take polyethylene terephthalate and polyethylene naphthalate waste and melt them in the screw extruder 1, wherein polyethylene naphthalate accounts for 10% of the weight of the alloy fiber.

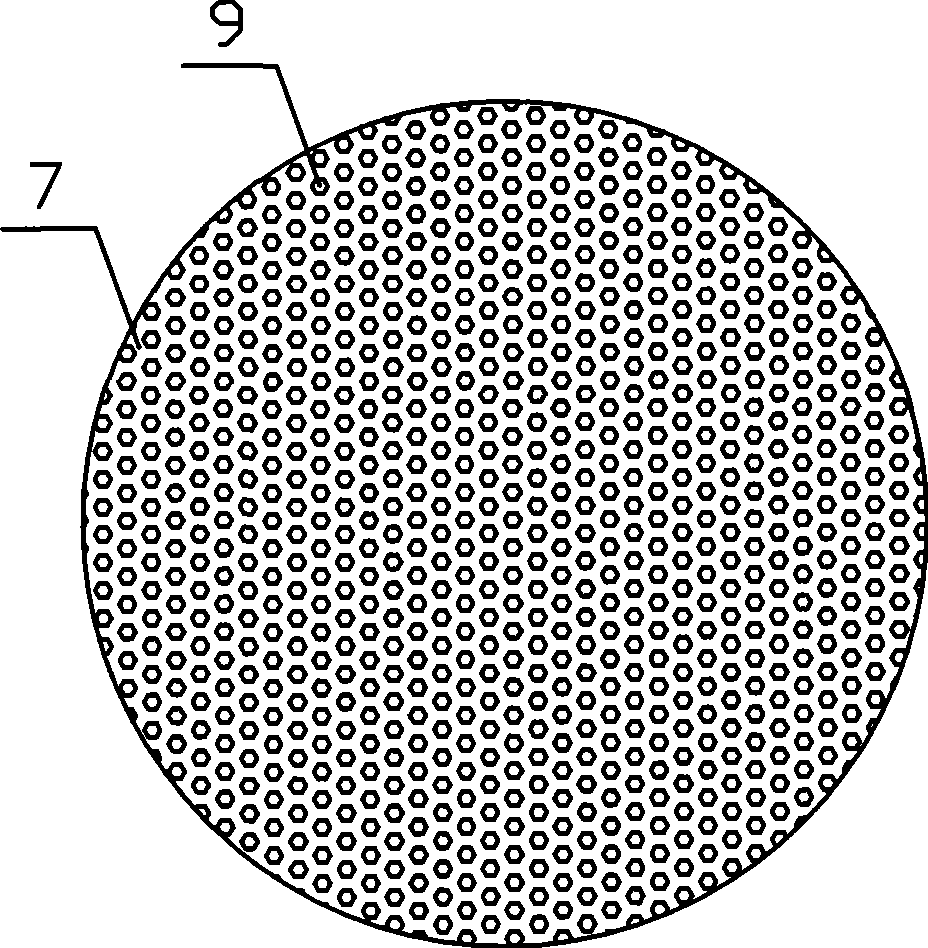

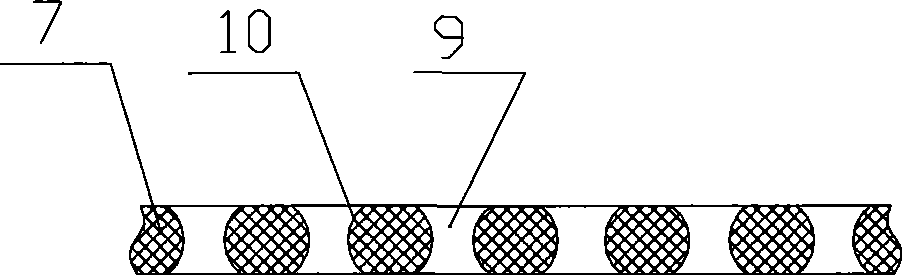

[0030] ② Then, the liquid polymer is sent into the main kettle 2, and the main kettle 2 is equipped with a multi-layer porous plate 7, and the melt is fully blended in the process of passing through the multi-layer porous plate 7 of the main kettle 1, and the surface area is increased To gasify the low-molecular substances, the temperature of the main kettle is controlled at 275°C, and the time is 40 minutes; then the melt is discharged from the bottom 8 of the main kettle 1; the top of the main kettle 1 is connected to the cyclone separator 3, and the cyclone separator 3 is connected to the filter 4 , the fi...

Embodiment 2

[0036] The preparation method of the alloy fiber of polyethylene terephthalate and polyethylene naphthalate, the method comprises the following steps:

[0037] ① Take polyethylene terephthalate and polyethylene naphthalate and melt them in a screw extruder, wherein polyethylene naphthalate accounts for 5% of the weight of the alloy fiber.

[0038] ② Then the melt is sent into the main kettle, which is equipped with a multi-layer porous plate, and the melt is blended through the multi-layer porous plate of the main kettle. The temperature of the main kettle is controlled at 275 ° C, and the time is 40 minutes; The material is discharged from the bottom of the main kettle.

[0039] ③The blended melt enters the conventional spinning equipment to produce raw silk.

[0040] ④ Three times of drawing are carried out on the raw silk, and the drawing temperature is 85-90° C. to obtain the alloy fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com