Anion far infrared post finishing method for silk wadding quilt

An anion far-infrared and post-finishing technology, which is applied in fiber treatment, textiles, papermaking, animal fibers, etc., can solve the problems of silk floss quilt softness, reduced bulkiness, and affecting the performance of silk floss quilts, so as to achieve good bulkiness, Improve the effect of Qi and blood circulation, good health care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

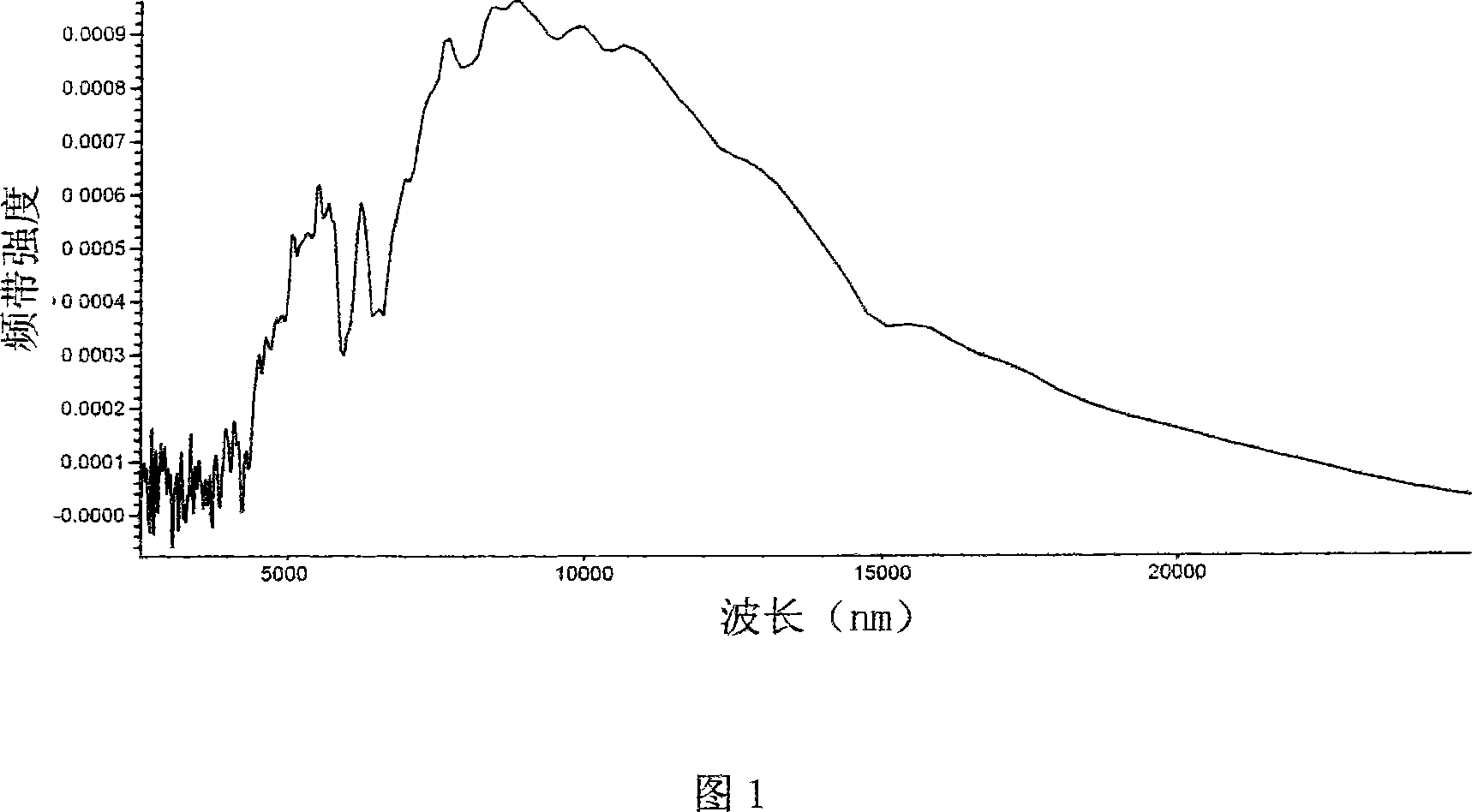

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of negative ion far-infrared post-finishing method of silk cotton quilt

[0021] (1) preparation and finishing impregnating liquid A, described finishing impregnating liquid A comprises the nano anion far-infrared radiation body with active group that is 2-6% by weight, the dispersant of 0.3-1%, surplus is water, The dispersant is selected from polyoxyethylene alcohol alkyl ethers;

[0022] (2) Prepare finishing impregnating solution B, which includes 2-6% low-temperature adhesive and 2-5% silk floss softener by weight percentage;

[0023] (3) Heat the finishing impregnating solution A to 60-80°C, put in dry silk floss, the bath ratio of the solution is 1:15-25, after all the silk floss is immersed in the finishing impregnating solution A, adjust the dipping temperature to 65-75°C , the soaking time is at least 40 minutes, and then, the soaked silk floss is dehydrated and dried to a moisture content of 8-12%;

[0024] (4) Dipping the dried silk fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com