Preparation method of seasoned ready-to-eat lentinus edodes

A technology for shiitake mushrooms and fresh shiitake mushrooms, which is applied in the directions of food preparation, food science, application, etc., can solve the problems of seasoning shiitake mushrooms that have not been seen in patents and literature reports, and achieve the effect of very good taste and crunchy taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

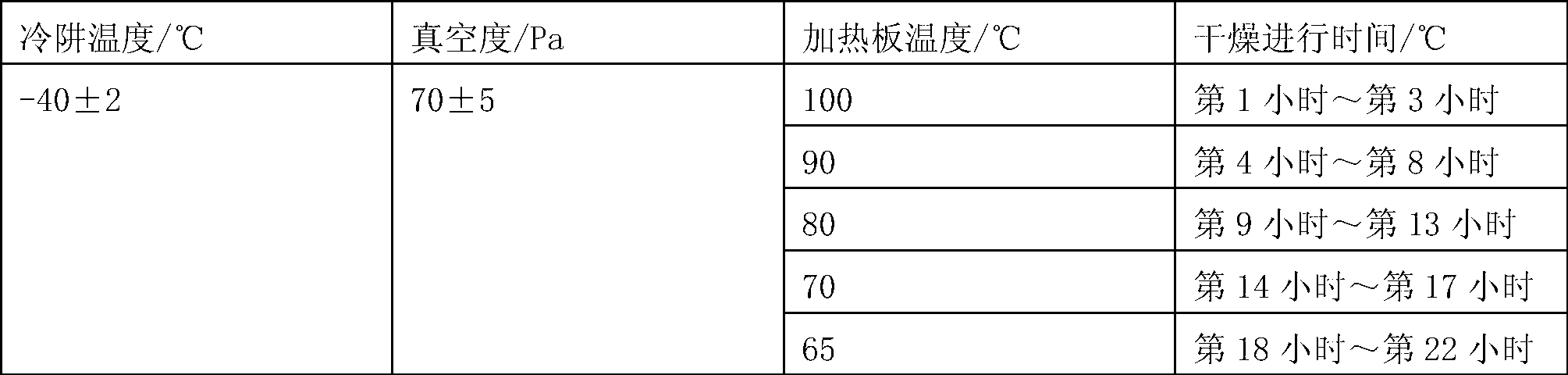

[0011] Take 3000kg of fresh shiitake mushrooms, sort, wash, slice, steam precook, centrifugal dehydration until the weight is reduced by 1 / 4, then mix in 300kg of soy sauce, 60kg of white sugar and 30kg of glucose, spread on a plate, freeze to -20°C for 2 hours; the frozen shiitake mushrooms are put into a vacuum freeze dryer for processing to obtain instant seasoning shiitake mushrooms. The parameter control in the vacuum freeze dryer is shown in Table 1.

[0012] Parameter control in table 1 vacuum freeze dryer

[0013]

Embodiment 2

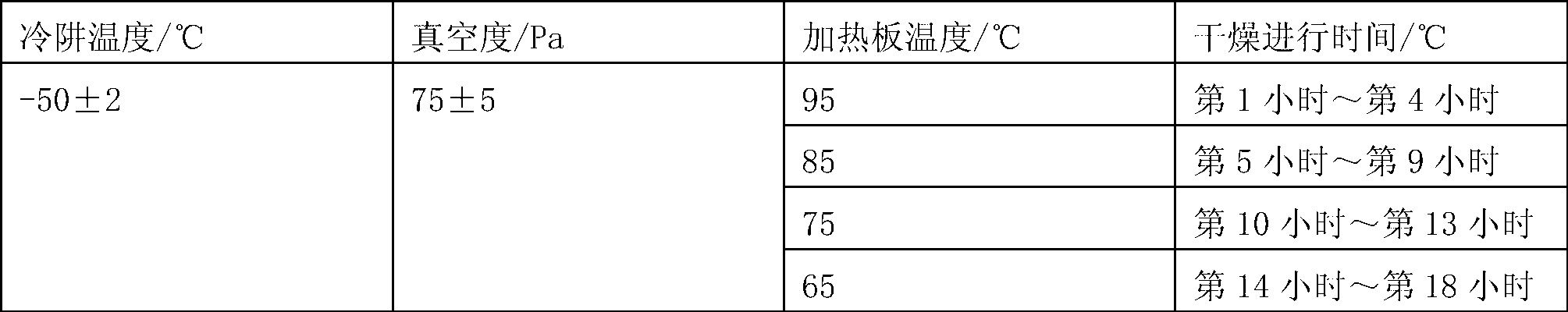

[0015] Take 3000kg of fresh shiitake mushrooms, sort, wash, dice, blanch until cooked, centrifugal dehydration until the weight is reduced by 1 / 4, then mix in 300kg of soy sauce, 120kg of white sugar, and 60kg of glucose, spread on a plate, and freeze to -25°C. 3 hours; put the frozen shiitake mushrooms into a vacuum freeze dryer for processing to obtain instant seasoning shiitake mushrooms. The parameter control in the vacuum freeze dryer is shown in Table 2.

[0016] Parameter control in table 2 vacuum freeze dryer

[0017]

Embodiment 3

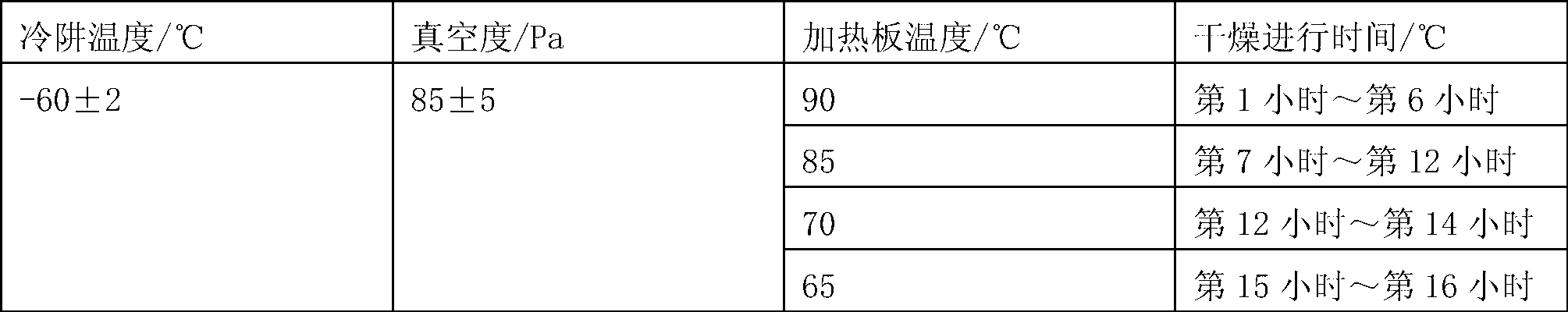

[0019] Take 3000kg of fresh shiitake mushrooms, sort, wash, dice, steam precooked, centrifugal dehydration until the weight is reduced by 1 / 4, then mix in 300kg of soy sauce, 120kg of white sugar, and 60kg of glucose, spread on a plate, freeze to -30°C, and the time is 4 hours; put the frozen shiitake mushrooms into a vacuum freeze dryer for processing to obtain instant seasoning shiitake mushrooms. The parameter control in the vacuum freeze dryer is shown in Table 3.

[0020] Parameter control in table 3 vacuum freeze dryer

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com