Method for making steamed buns through utilizing Lactobacillus plantarum

A technology of Lactobacillus plantarum and production method, which is applied in the field of food processing, can solve the problems of large quality differences and poor stability of product batches, and achieve the effects of inhibiting growth, accelerating the rate of acid production, and increasing the amount of dough inoculum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

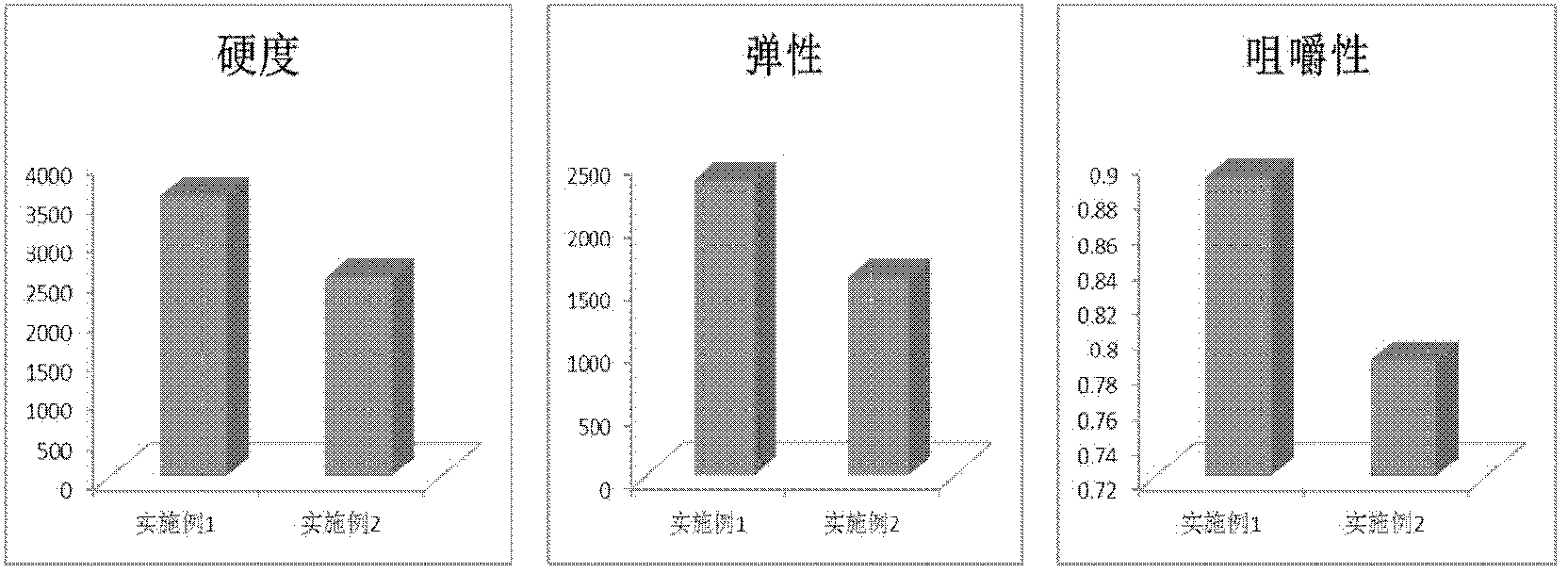

[0091] Example 1: Using commercially available Angel high-activity dry yeast (golden pack) starter to make steamed buns

[0092] The implementation steps of this embodiment are as follows:

[0093] A. Use the commercially available Angel high-activity dry yeast (gold) starter to prepare steamed bun dough

[0094] Weigh 948 parts by weight of medium-gluten flour wheat flour, 9 parts by weight of Angel high-activity dry yeast (gold) starter and 282 parts by weight of water in a mixing tank, stir at a stirring rate of 96rpm for 1.1min, and then stir at a stirring rate of 210rpm for 4.3 min, get the dough for making steamed buns;

[0095] B. Proofing and steaming of steamed bun dough

[0096] Divide the dough for making steamed buns obtained in step A into 80g / piece, then round and shape, and then place in a proofing box sold by Xinmai Machinery Co., Ltd. under the trade name SM-32S at a temperature of 32°C and a relative humidity of 85%. Proof for 42 minutes under certain cond...

Embodiment 2

[0097] Embodiment 2: Adopt the method of the present invention to make steamed bread

[0098] The implementation steps of this embodiment are as follows:

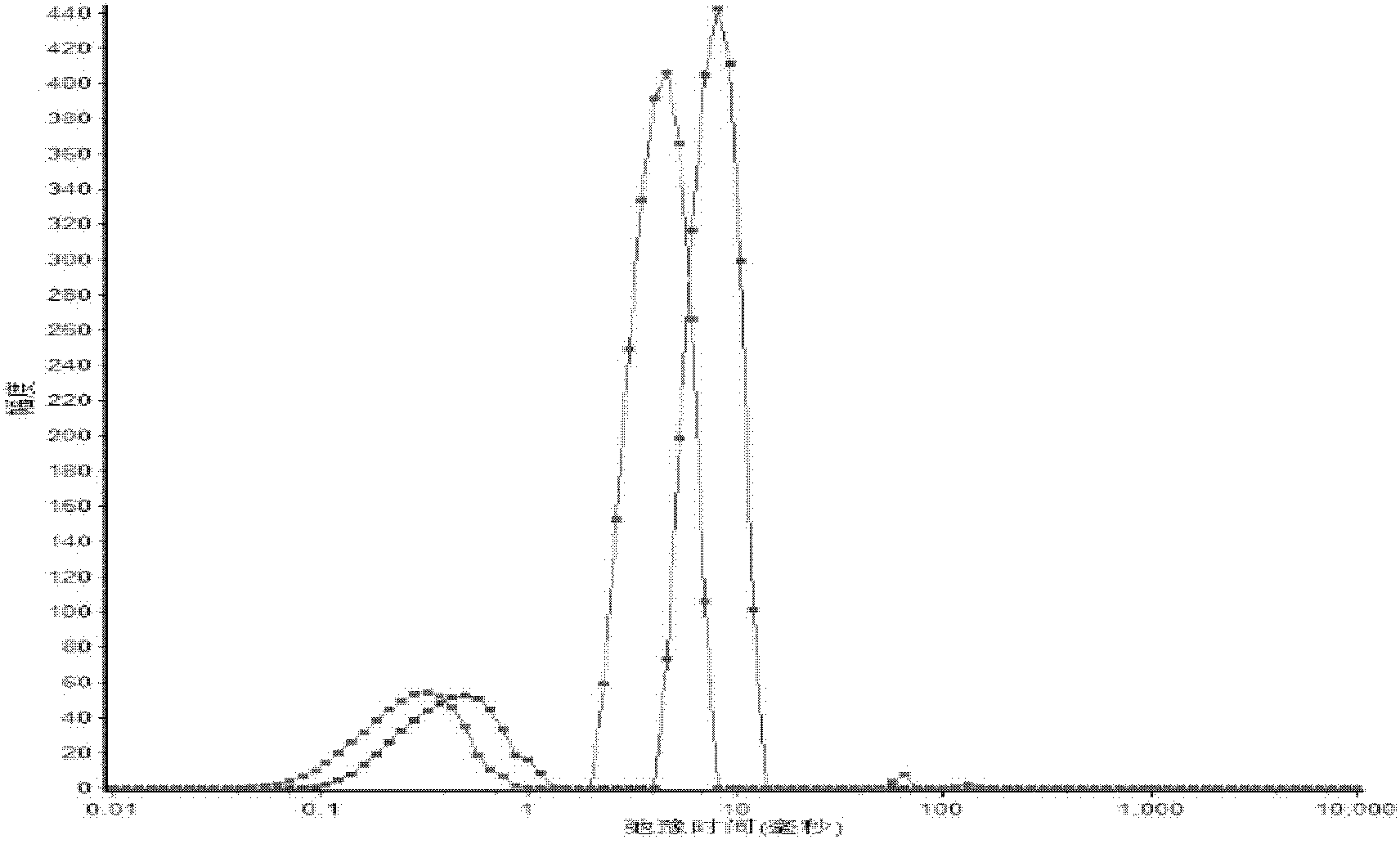

[0099] A. Activation of Lactobacillus plantarum

[0100] Draw 200 μl of Lactobacillus plantarum CCFM8661 bacteria liquid from the glycerol bacteria preservation tube, inoculate it into 900ml MRS broth medium, then carry out activation culture at 37°C for 20 hours, repeat the above activation operation 3 times, and obtain an activated Lactobacillus plantarum CCFM8661 bacterial liquid; the composition of the MRS broth medium is as follows: 500ml distilled water, 5g peptone, 5g beef extract, 2.5g yeast extract, 2.5g sodium acetate, 10g glucose, 0.05g MgSO 4 .7H 2 0.0.025g MnSO 4 .H 2 0, 1g diammonium citrate, 1g K 2 HP0 4 With 0.5ml Tween, pH6.2.

[0101] B. Preparation of sourdough containing Lactobacillus plantarum

[0102] Using a high-speed centrifuge sold under the trade name universal32R by the German Hettich com...

Embodiment 3

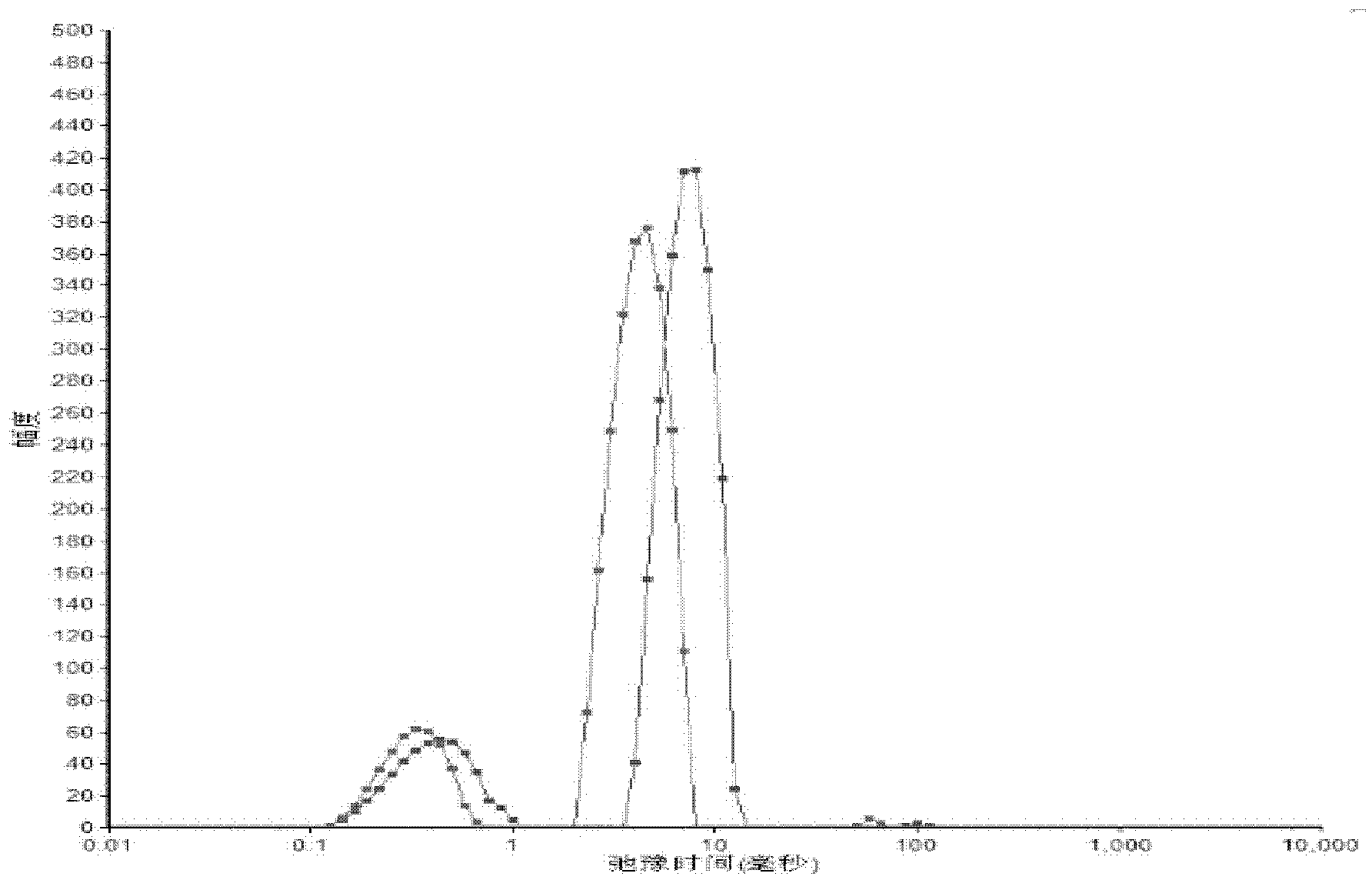

[0113] Embodiment 3: Adopt the method of the present invention to make steamed bread

[0114] The implementation steps of this embodiment are as follows:

[0115] A. Activation of Lactobacillus plantarum

[0116] Draw 200 μl of Lactobacillus plantarum CCFM8661 bacterial solution from the glycerol bacteria preservation tube, inoculate it into 1000ml MRS broth medium, and then carry out activation culture at a temperature of 36.8°C for 22 hours, repeat the above activation operation twice, and obtain an activated Lactobacillus plantarum CCFM8661 bacterial liquid; the composition of the MRS broth culture medium is the same as in Example 1, except that its pH value is adjusted to 6.4.

[0117] B. Preparation of sourdough containing Lactobacillus plantarum

[0118] Use the high-speed centrifuge sold by the German Hettich company under the trade name universal32R, under the condition of 6400g, allow the activated Lactobacillus plantarum CCFM8661 bacterium liquid that step A obtains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com