Egg sausage with high elasticity and brittleness and preparation method thereof

A technology of egg sausage and high elasticity, which is applied to the functions of food ingredients, food ingredients as taste improvers, and food ingredients as thickeners. Elasticity and brittleness, the effect of improving product elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

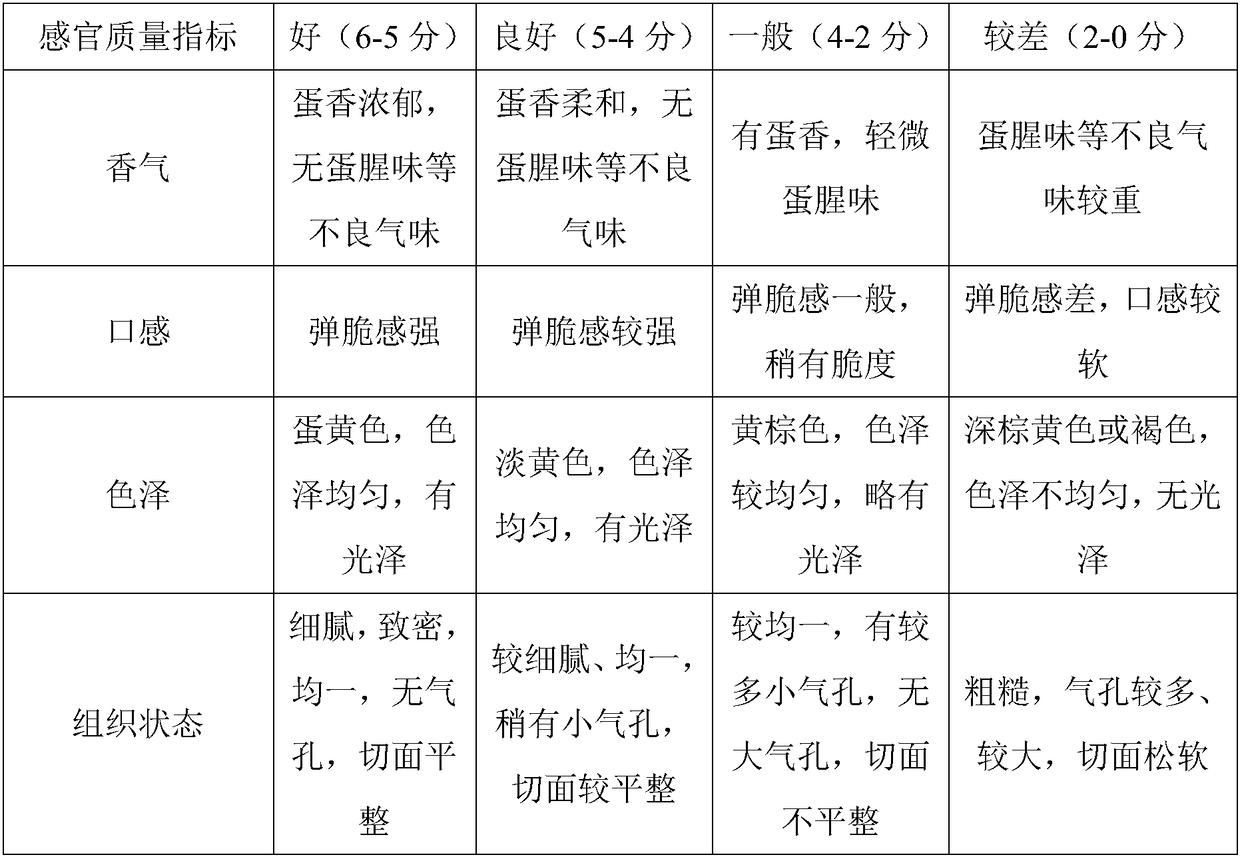

Image

Examples

Embodiment 1

[0034] An egg sausage with high elasticity and brittleness, the composition and parts by weight are as follows:

[0035] 70 parts of fermented egg liquid, 40 parts of emulsified pig skin, 1 part of salt, 3 parts of white sugar, 0.3 parts of monosodium glutamate, 2 parts of ginger juice, 2 parts of soy sauce, 3 parts of pregelatinized starch.

[0036] Preferably, the pregelatinized starch is a mixture of pregelatinized potato starch, pregelatinized tapioca starch and pregelatinized cornstarch in a mass ratio of 2:1:1.

[0037] Preferably, the preparation method of the fermented egg liquid is as follows:

[0038] ⑴ Egg pretreatment: immerse the washed eggs in 800ppm disinfectant water for 3-5 minutes, take out and rinse with tap water for 1 minute, remove the disinfectant water on the surface, drain and set aside;

[0039] ⑵ Beating eggs: break the eggshell, let the egg liquid flow down completely, do not mix broken eggshells and rotten eggs into the egg liquid when beating the...

Embodiment 2

[0052] An egg sausage with high elasticity and brittleness, the composition and parts by weight are as follows:

[0053] 80 parts of fermented egg liquid, 50 parts of emulsified pigskin, 2 parts of salt, 5 parts of white sugar, 0.5 parts of monosodium glutamate, 3 parts of ginger juice, 3 parts of soy sauce, and 5 parts of pregelatinized starch.

[0054] Moreover, the pregelatinized starch is a mixture of pregelatinized potato starch, pregelatinized tapioca starch and pregelatinized cornstarch in a mass ratio of 2:1:1.

[0055] Wherein, the preparation method of described fermented egg liquid is as follows:

[0056] ⑴ Egg pretreatment: immerse the washed eggs in 800ppm disinfectant water for 3-5 minutes, take out and rinse with tap water for 1 minute, remove the disinfectant water on the surface, drain and set aside;

[0057] ⑵ Beating eggs: break the eggshell, let the egg liquid flow down completely, do not mix broken eggshells and rotten eggs into the egg liquid when beatin...

Embodiment 3

[0071] An egg sausage with high elasticity and brittleness, the composition and parts by weight are as follows:

[0072] 50 parts of fermented egg liquid, 30 parts of emulsified pig skin, 0.5 parts of salt, 2 parts of white sugar, 0.1 part of monosodium glutamate, 0.5 parts of ginger juice, 1 part of soy sauce, 5 parts of pregelatinized starch.

[0073] Moreover, the pregelatinized starch is a mixture of pregelatinized potato starch, pregelatinized tapioca starch and pregelatinized cornstarch in a mass ratio of 2:1:1.

[0074] Wherein, the preparation method of the fermented egg liquid is as follows

[0075] (1) Egg pretreatment: After immersing the washed eggs in 800ppm disinfected water for 3 minutes, take them out and rinse them with tap water for 1 minute to remove the disinfected water on the surface, and drain them for later use.

[0076] (2) Beating eggs: Break the egg shells and let the egg liquid flow down completely. When beating eggs, do not mix broken egg shells a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com