Method for preparing original taste soft-boiled eggs by ultrasound

A soft-boiled egg and ultrasonic technology, which is applied in the field of ultrasonic preparation of original-flavored soft-boiled eggs, can solve the problem of low proportion of original-flavored soft-boiled eggs, and achieve the effects of easy control of parameter conditions, strong egg flavor, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

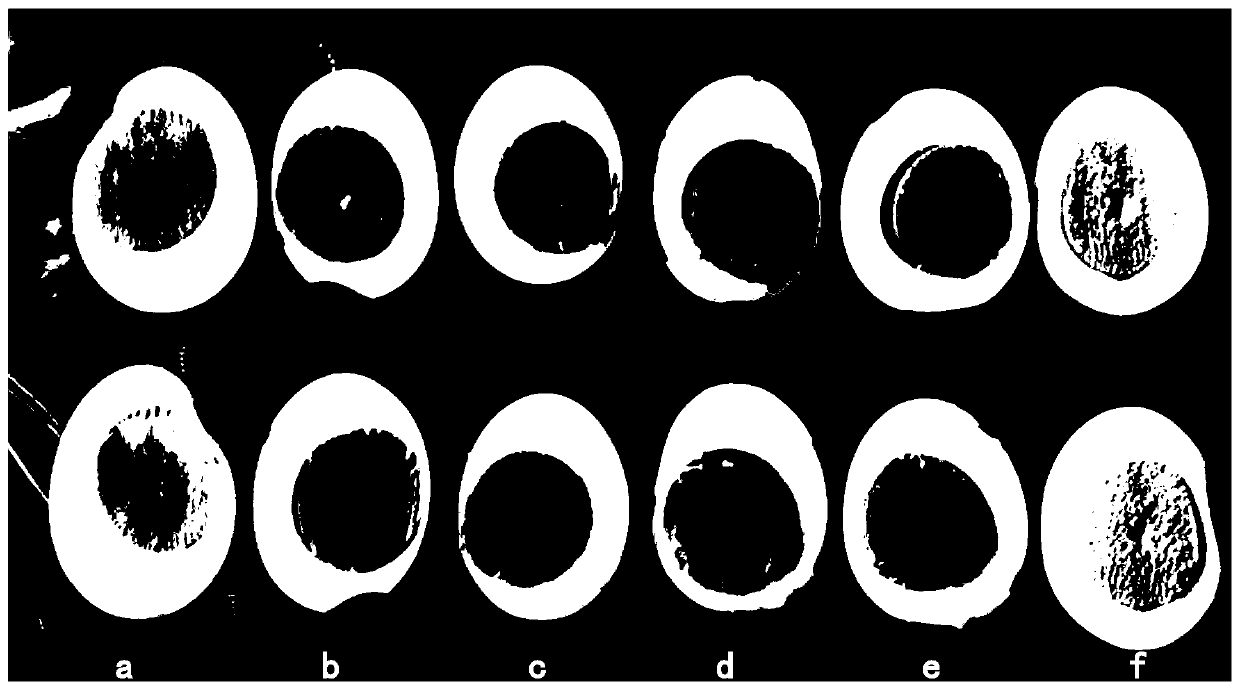

Embodiment 1

[0032] (1) Screen out 10 fresh eggs with a mass range of 53-60 g.

[0033] (2) Wash the eggs with warm water at 30°C, clean the dirt on the surface with a soft brush, and then clean the surface of the eggs again with 6% hydrogen peroxide until the residual dirt on the surface of the eggs is cleaned, and finally use Rinse the eggs with warm water at 30°C.

[0034] (3) Adjust the temperature of the 800W constant temperature ultrasonic instrument to 80°C, set the temperature of the constant temperature water bath to 95°C, add pure water, cook, and wait for preheating.

[0035] (4) Put the 10 eggs that have been screened and washed in a plastic mesh bag, put them in an 800W constant temperature ultrasonic instrument that has been heated to 80°C, heat them for 13 minutes, and then immediately place them in a constant temperature water bath adjusted to 95°C , Take it out immediately after 1min.

[0036] (5) Put the taken-out eggs in a net bag in an ice-water bath at 0°C for 20 min...

Embodiment 2

[0039] (1) Screen out 10 fresh eggs with a mass range of 53-60 g.

[0040] (2) Wash the eggs with warm water at 30°C, clean the dirt on the surface with a soft brush, and then clean the surface of the eggs again with 6% hydrogen peroxide until the residual dirt on the surface of the eggs is cleaned, and finally use Rinse the eggs with warm water at 30°C.

[0041] (3) Adjust the temperature of the 800W constant temperature ultrasonic instrument to 78°C, set the temperature of the constant temperature water bath to 91°C, add pure water, cook, and wait for preheating.

[0042] (4) Put the 10 eggs that have been screened and washed in a plastic mesh bag, and put them in an 800W constant temperature ultrasonic instrument that has been heated to 78°C, heat treatment for 13 minutes, and then immediately place them in a constant temperature water bath adjusted to 91°C , Take it out immediately after 1min.

[0043] (5) Put the taken-out eggs in a net bag in an ice-water bath at 0°C f...

Embodiment 3

[0046] (1) Screen out 10 fresh eggs with a mass range of 53-60 g.

[0047] (2) Wash the eggs with warm water at 30°C, clean the dirt on the surface with a soft brush, and then clean the surface of the eggs again with 6% hydrogen peroxide until the residual dirt on the surface of the eggs is cleaned, and finally use Rinse the eggs with warm water at 30°C.

[0048] (3) Adjust the temperature of the 800W constant temperature ultrasonic instrument to 80°C, set the temperature of the constant temperature water bath to 93°C, add pure water, cook, and wait for preheating.

[0049] (4) Put the 10 eggs that have been screened and washed in a plastic mesh bag, put them in an 800W constant temperature ultrasonic instrument that has been heated to 80°C, heat them for 15 minutes, and then immediately place them in a constant temperature water bath adjusted to 93°C , Take it out immediately after 1min.

[0050] (5) Put the taken-out eggs in a net bag in an ice-water bath at 0°C for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com