Preparation method for purple potato puffed food

A technology of puffed food and purple potato, which is applied in food preparation, food forming, food science and other directions to achieve the effects of being rich in nutrients, delicate in structure and natural in color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A. Preparation of purple sweet potato powder: first crush the purple sweet potato into 5-10mm sized potato grains. While breaking, spray the color-protecting solution formed by mixing citric acid and disodium hydrogen phosphate for color protection. The quality of citric acid is The percentage concentration is 0.5%, and the mass percentage concentration of disodium hydrogen phosphate is 0.05%; the broken potato grains are rapidly immersed in the above-mentioned color protection solution for 15 minutes to prevent browning on the surface of the purple potato after peeling and dicing. Centrifugal drying at 4000r / min, and then blast drying at 38 degrees until the moisture content in the potato grains is 8.5%, and finally the potato grains and tea polyphenols with a concentration of 0.05% by mass are mixed evenly and pulverized, and passed through 80 Mesh sieve to obtain whole purple potato powder;

[0016] B. Powder: Take and mix evenly to make the base material, and then a...

Embodiment 2

[0020] Embodiment 2 is roughly the same as Embodiment 1, just add 20kg purple sweet potato whole powder and 80kg wheat flour, 1.1kg compound additive (acesulfame potassium 20g, monosodium glutamate 0g, baking powder 83, glyceryl monostearate 12, sodium dehydroacetate 20g and tertiary butyl hydroquinone 10g), salt 8kg, after adding water to adjust the humidity, the moisture content of the material is 11%.

Embodiment 3

[0022] Embodiment 3 is roughly the same as Example 1, just add 30kg purple sweet potato whole powder and 70kg wheat flour, 1.3kg compound additive (acesulfame potassium 15g, monosodium glutamate, baking powder, glyceryl monostearate 6, sodium dehydroacetate 30g and Tertiary butyl hydroquinone 15g), salt 9kg, after adding water and adjusting humidity, the moisture content of material is 12kg.

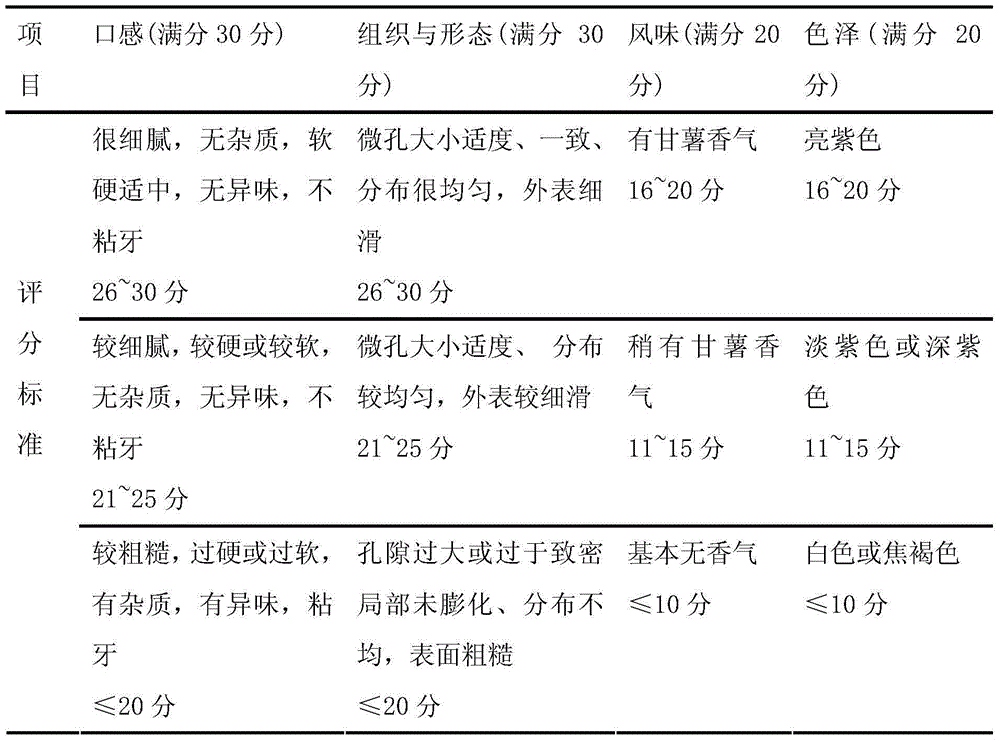

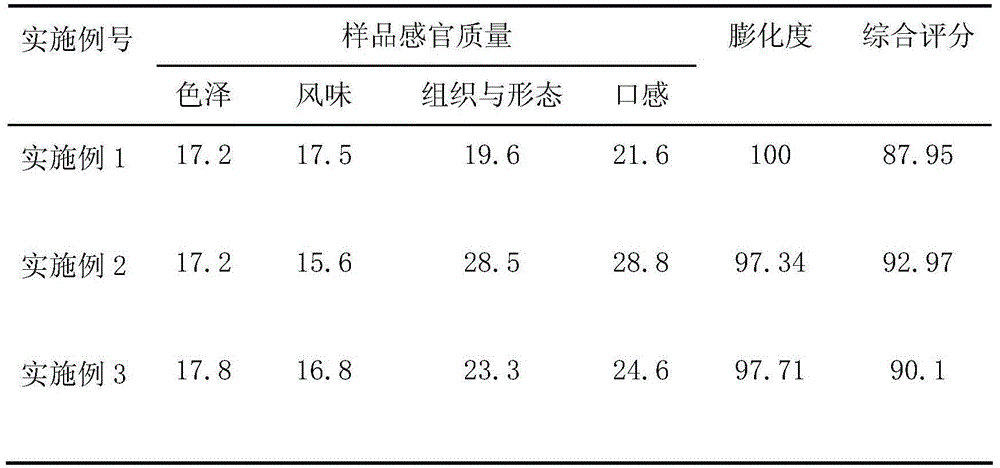

[0023] The puffed food that embodiment 1-made adopts sensory evaluation method, from local flavor, color and luster, mouthfeel, texture four aspects, and according to local flavor (20%), color and luster (20%), mouthfeel (30%), texture shape (30%) Score each sweet potato extrusion puffed product, and the total score of each experiment is 100 points. The experiment was evaluated and scored by 10 experimenters, and the average score of 10 people was taken as the final score of each experiment, and the product sensory score was obtained by adding up the scores (see Table 1).

[0024] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com