Blocky fat simulant based on long-chain fatty acid lipidosome and preparation method thereof

A fat simulant and long-chain fatty acid technology, applied in edible oil/fat, food science, application, etc., can solve problems such as poor sensory acceptance, incompatibility of texture and geochemical properties, increase water retention and thermal stability of the system, etc. Achieve the effects of reducing intake, maintaining human health, and preventing cardiovascular diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

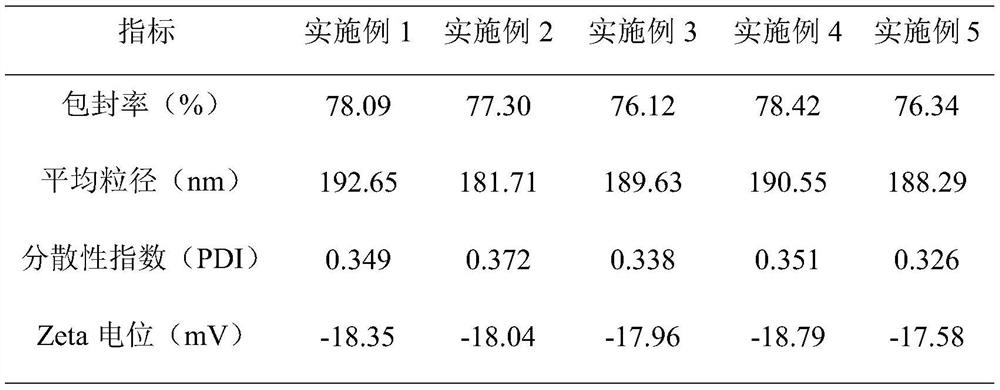

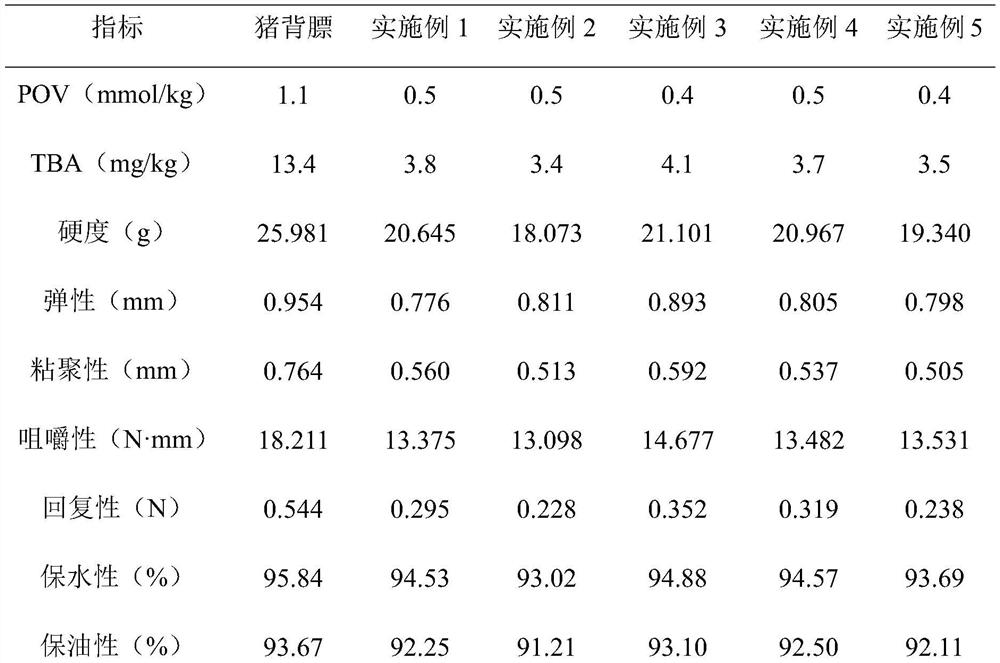

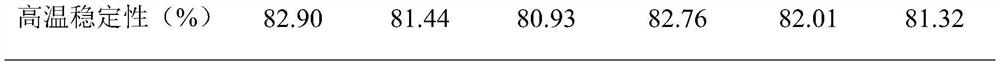

Examples

Embodiment 1

[0042] Preparation of bulk fat mimics based on long-chain fatty acid liposomes

[0043] (1) Ethanol injected into ultrasonic method to prepare long-chain fatty acid liposomes:

[0044] Take by weighing 100mg soybean lecithin, 25mg stigmasterol, 20mg Tween-80 and 60mg long-chain fatty acid mixture (the mass proportions of palmitic acid, stearic acid, oleic acid, linoleic acid and linolenic acid are respectively 20%, 13 %, 34%, 23% and 10%), dissolved in 10mL of absolute ethanol, and used a high-speed homogenizer to shear and disperse at a speed of 6000r / min for 10min to obtain a highly uniform mixture; Inject evenly into 10 mL of phosphate buffer (pH 6.8), stir at 50°C for 15 min, remove ethanol by rotary evaporation, and homogenize the mixed emulsion at high speed for 20 min to obtain a long-chain fatty acid liposome suspension;

[0045] (2) Preparation of block fat mimics based on long-chain fatty acid liposomes:

[0046] Fully dissolve 50mg of konjac powder and 60mg of sod...

Embodiment 2

[0048] Preparation of bulk fat mimics based on long-chain fatty acid liposomes

[0049] (1) Ethanol injected into ultrasonic method to prepare long-chain fatty acid liposomes:

[0050] Weigh 100mg soybean lecithin, 20mg stigmasterol, 20mg Tween-80 and 60mg long-chain fatty acid mixture (the mass proportions of palmitic acid, stearic acid, oleic acid, linoleic acid and linolenic acid are respectively 20%, 13 %, 34%, 23% and 10%), dissolved in 10mL of absolute ethanol, and used a high-speed homogenizer to shear and disperse at a speed of 6000r / min for 10min to obtain a highly uniform mixture; Inject evenly into 10 mL of phosphate buffer (pH 6.8), stir at 50°C for 15 min, remove ethanol by rotary evaporation, and homogenize the mixed emulsion at high speed for 20 min to obtain a long-chain fatty acid liposome suspension;

[0051] (2) Preparation of block fat mimics based on long-chain fatty acid liposomes:

[0052] Fully dissolve 80mg of konjac powder and 100mg of sodium algina...

Embodiment 3

[0054] Preparation of bulk fat mimics based on long-chain fatty acid liposomes

[0055] (1) Ethanol injected into ultrasonic method to prepare long-chain fatty acid liposomes:

[0056] Weigh 100mg soybean lecithin, 25mg stigmasterol, 20mg Tween-80 and 50mg long-chain fatty acid mixture (the mass proportions of palmitic acid, stearic acid, oleic acid, linoleic acid and linolenic acid are respectively 20%, 13 %, 34%, 23% and 10%), dissolved in 10mL of absolute ethanol, and used a high-speed homogenizer to shear and disperse at a speed of 6000r / min for 10min to obtain a highly uniform mixture; Inject evenly into 10 mL of phosphate buffer (pH 6.8), stir at 50°C for 15 min, remove ethanol by rotary evaporation, and homogenize the mixed emulsion at high speed for 20 min to obtain a long-chain fatty acid liposome suspension;

[0057] (2) Preparation of block fat mimics based on long-chain fatty acid liposomes:

[0058] Fully dissolve 60mg of konjac powder and 80mg of sodium alginat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com