Method for processing noodles, and noodles

A processing method and noodle technology, applied in pasta, noodle processing methods and noodle fields, can solve the problems of high cooking loss rate, easy to mix soup, blunt taste, etc., to reduce cooking loss rate, prevent surface deformation, and enhance chewiness taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

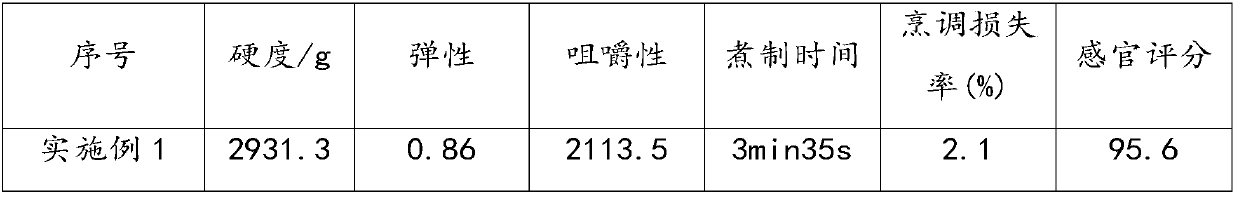

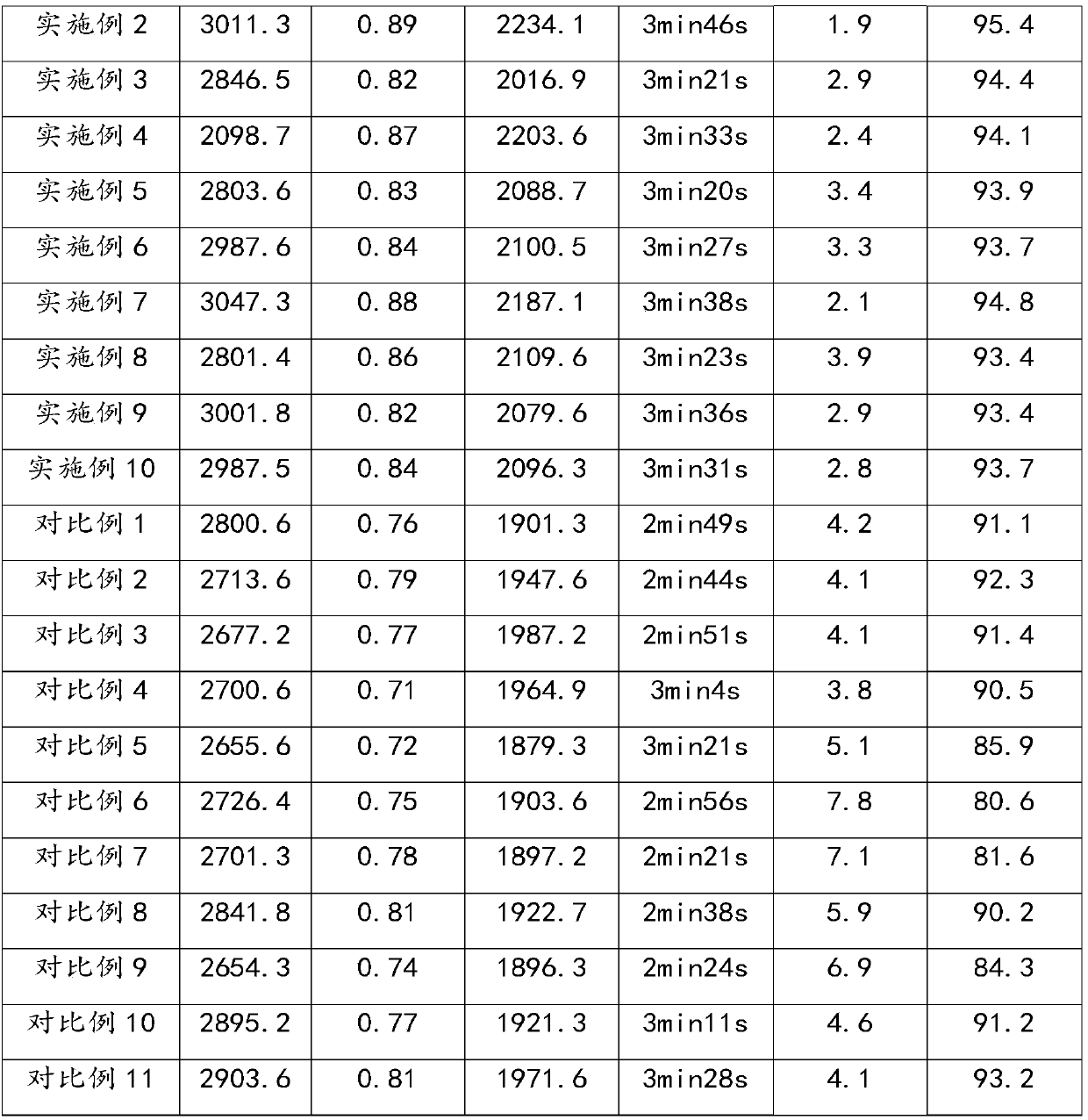

Examples

Embodiment 1

[0100] A processing method for noodles, comprising the following steps:

[0101] (a) Mix rice starch and waxy corn starch with a mass ratio of 1:1 to obtain mixed starch, add pectin with a mass fraction of 2% to the mixed starch to obtain a starch mixture, and put the starch mixture at a temperature of 120 ° C Carry out pretreatment 1h under condition, cool down;

[0102] (b) adding water to dissolve the pretreated starch mixture to obtain a mixture solution, the mass concentration of the mixture solution is 40%, and subjecting the mixture solution to a high static pressure treatment for 300s under a pressure of 300 MPa to obtain a starch mixture solution;

[0103] (c) Adding mass fraction to the flour is 20% starch mixed solution, then adding drinking water, adding water until the water content accounts for 32% of the flour mass fraction, and carrying out vacuum mixing; the vacuum degree of vacuum mixing is 0.08MPa, and The face time is 7 minutes;

[0104] (d) Refresh the n...

Embodiment 2

[0110] A kind of processing method of noodles, the difference with embodiment 1 is:

[0111] (a) Mix rice starch and waxy corn starch with a mass ratio of 3:1 to obtain mixed starch, add pectin with a mass fraction of 4% to the mixed starch to obtain a starch mixture, and put the starch mixture at a temperature of 130° C. Carry out pretreatment 2h under condition, cool down;

[0112] (b) adding water to dissolve the pretreated starch mixture to obtain a mixture solution, the mass concentration of the mixture solution is 60%, and subjecting the mixture solution to a high static pressure treatment for 100 s under a pressure of 500 MPa to obtain a starch mixture solution;

[0113] All the other are identical with embodiment 1.

Embodiment 3

[0115] A kind of processing method of noodles, the difference with embodiment 1 is:

[0116] (a) Mix rice starch and waxy corn starch with a mass ratio of 0.5:1 to obtain mixed starch, add pectin with a mass fraction of 1% to the mixed starch to obtain a starch mixture, and put the starch mixture at a temperature of 105 ° C Under the condition of pretreatment for 1.5h, cooling;

[0117] (b) adding water to dissolve the pretreated starch mixture to obtain a mixture solution, the mass concentration of the mixture solution is 30%, and subjecting the mixture solution to a high static pressure treatment for 600s under a pressure of 250 MPa to obtain a starch mixture solution;

[0118] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com