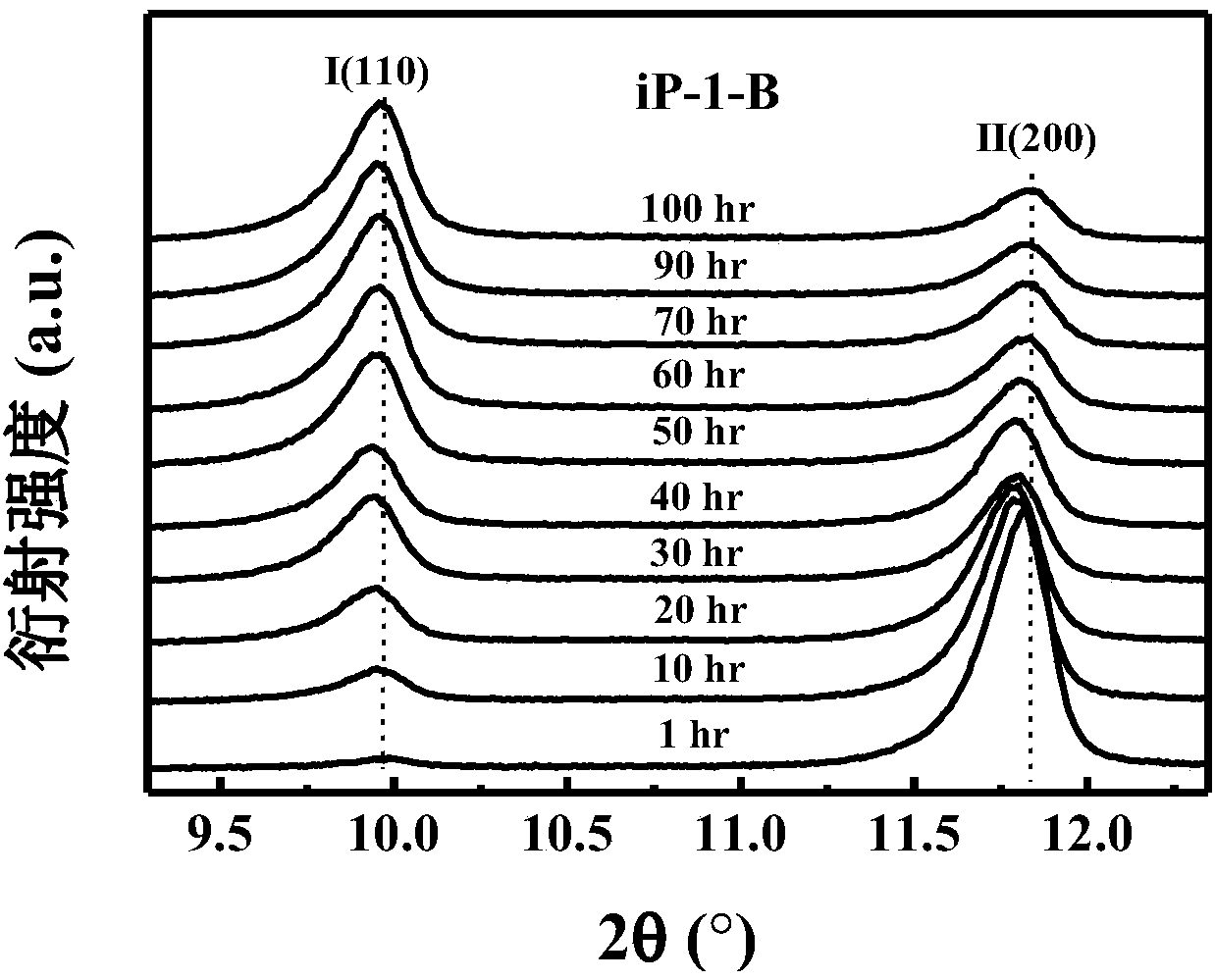

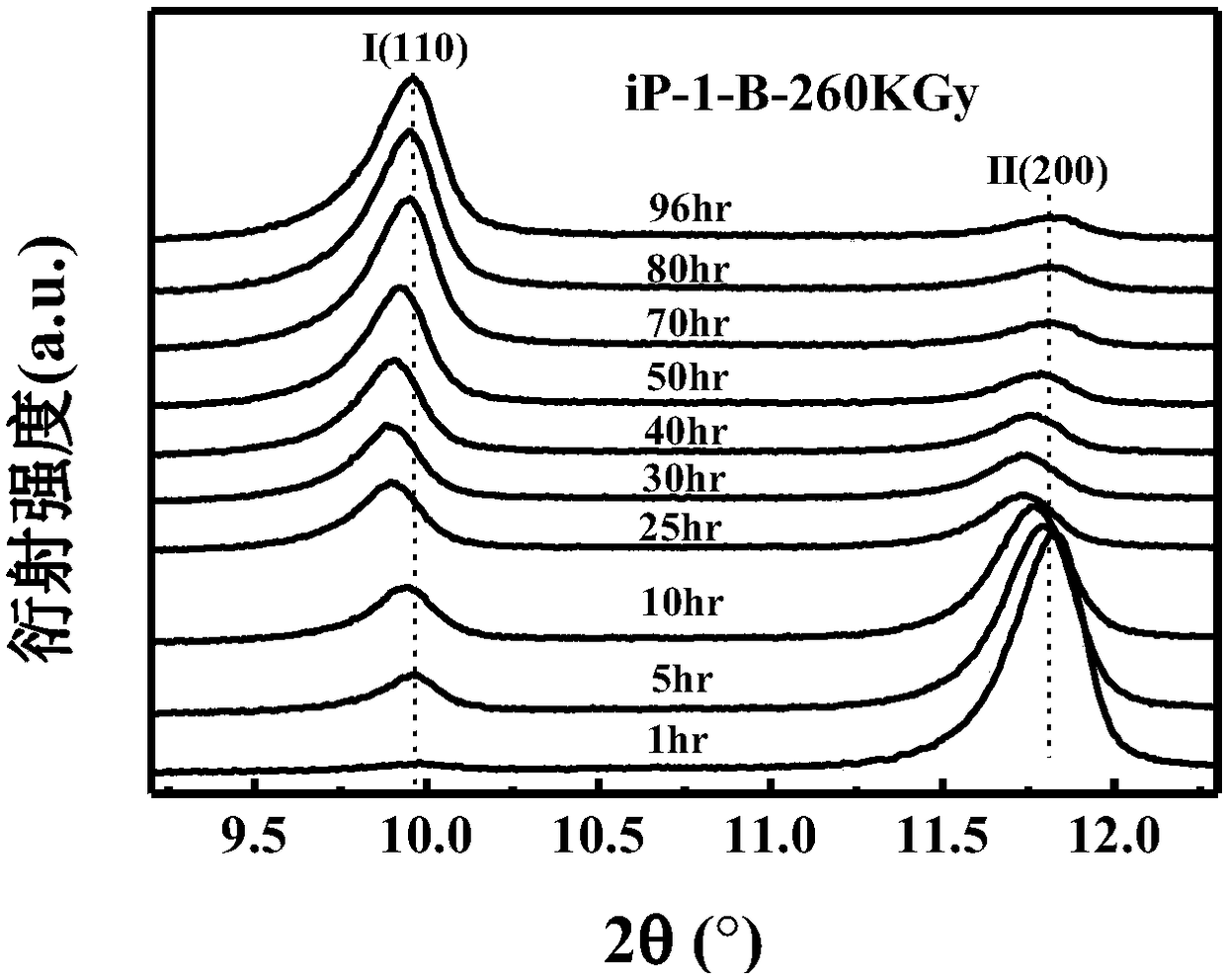

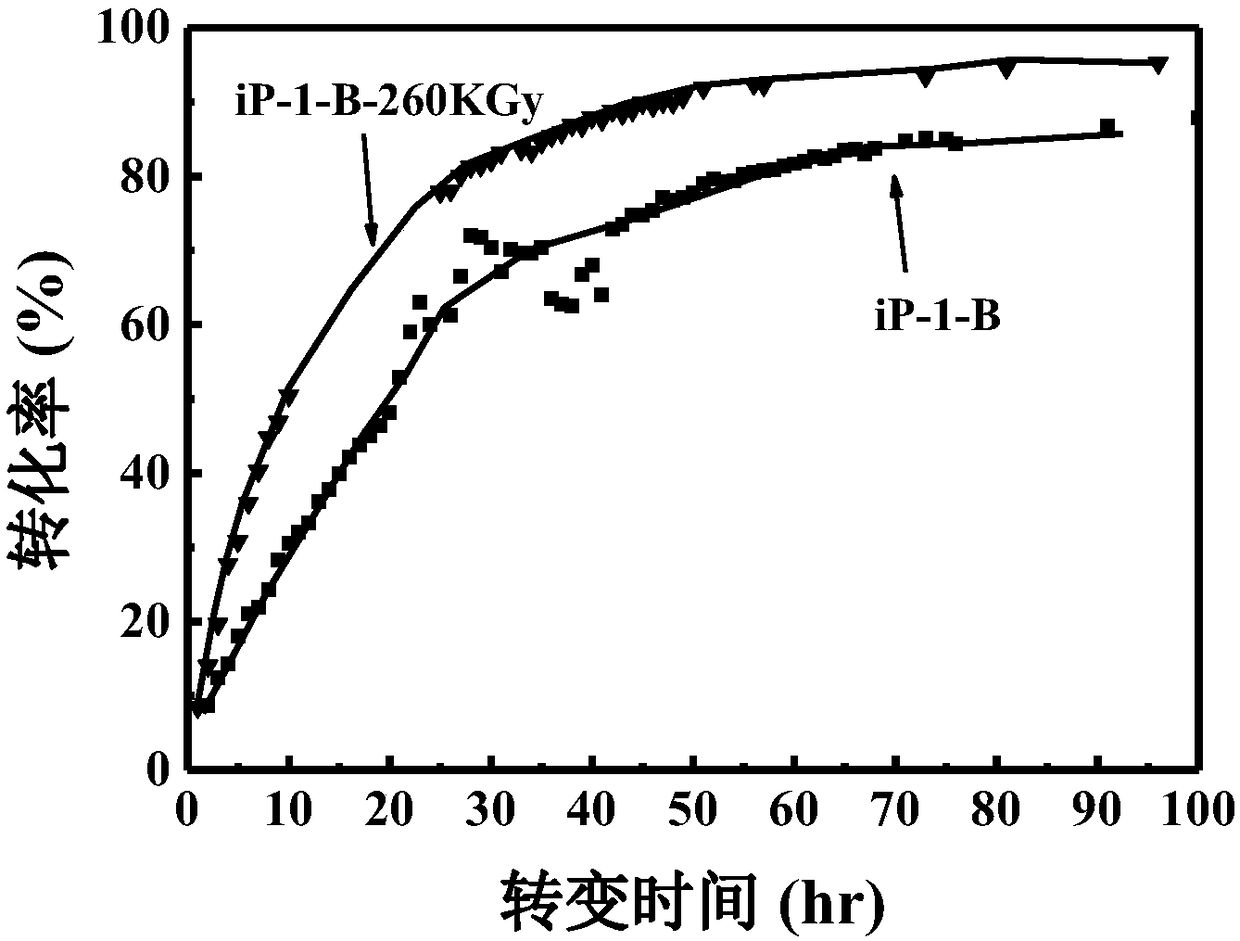

Method for promoting crystal form II-I transformation of isotactic poly-1-butylene through high energy electronic irradiation

A high-energy electron, II-I technology, applied in the field of regular poly-1-butene crystal form II-I transformation, can solve the problems of harsh copolymerization conditions, reduced isotacticity, and complicated process, and achieves easy control of the reaction and high conversion. The effect of efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0014] Weigh 7g of iP-1-B 0110M (Basell company, homopoly iP-1-B, trade mark is PB 0110M, M w =711000g / mol, T m =117°C, T g =-20°C, ρ=0.914g·cm -3 , melt flow rate is 0.4g / 10min, 190°C / 2.16kg), preheated with a flat vulcanizing machine at 180°C for 10min, and then gradually increased the pressure to 25MPa by gradually increasing the pressure, keeping the temperature at the highest pressure for 3min, and then Cold press at 25MPa for 8 minutes to form a 0.5mm-thick sheet sample. After taking it out, place it at room temperature at 20-25 degrees Celsius for 30 days (24×30 hours), so that the II crystal is basically transformed into I crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com