Method for promoting conversion of crystal form II in isotactic poly-1-butene composite into crystal form I by using high-energy electron irradiation

A high-energy electronic and composite material technology, applied in the field of crystal form II-I transformation, can solve the problems of complex process, limited application, harsh copolymerization conditions, etc., and achieve the effects of no solvent, easy reaction control, and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

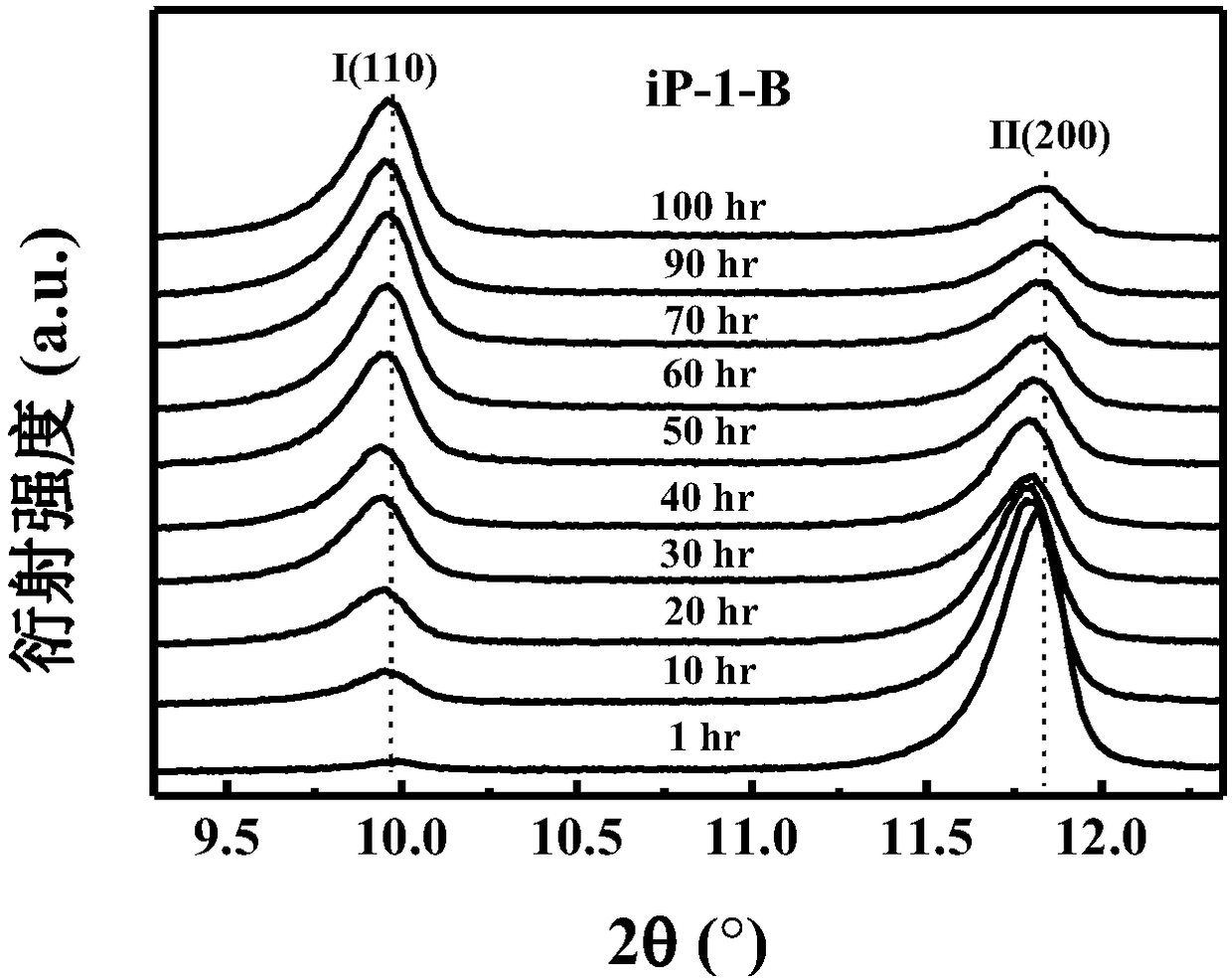

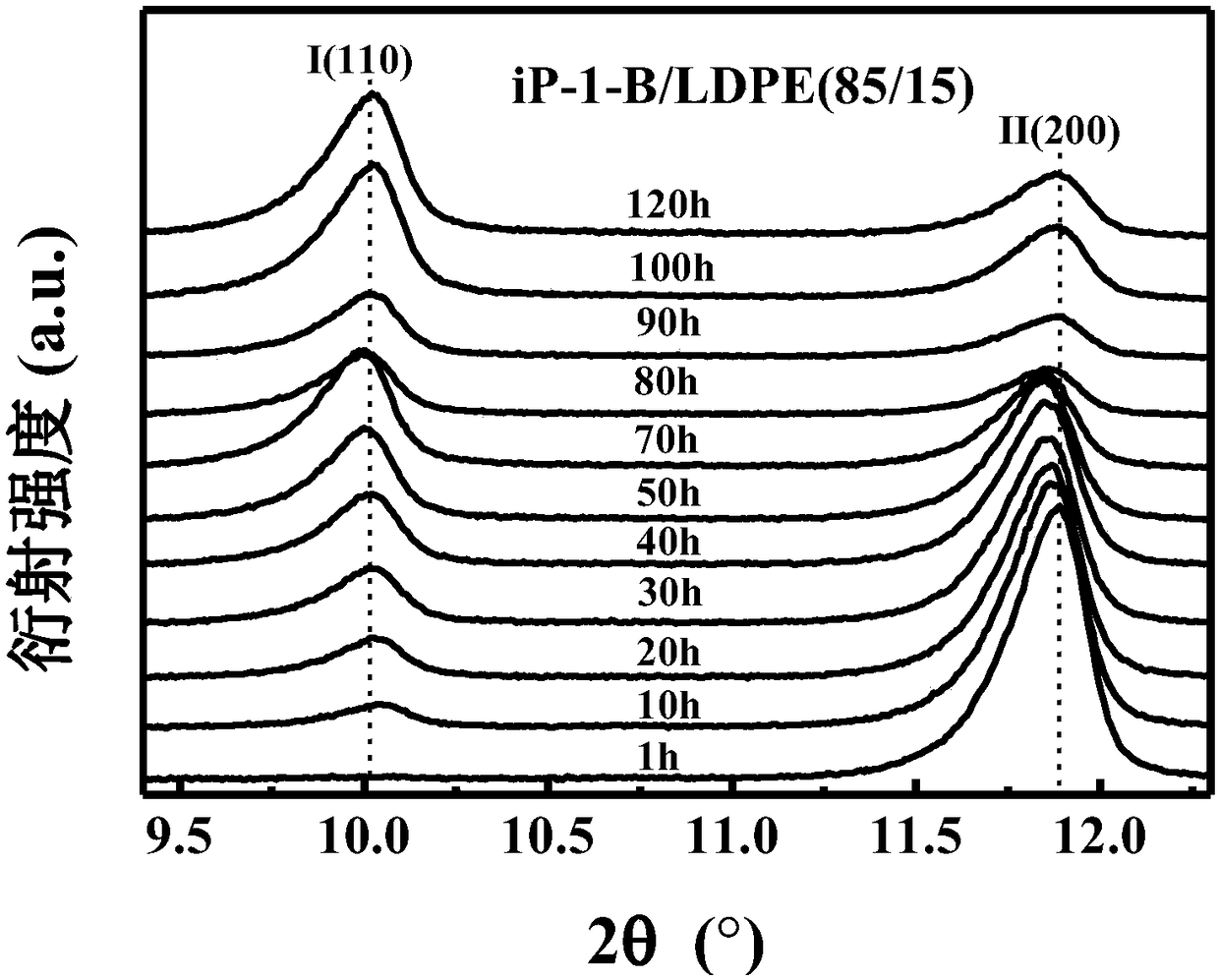

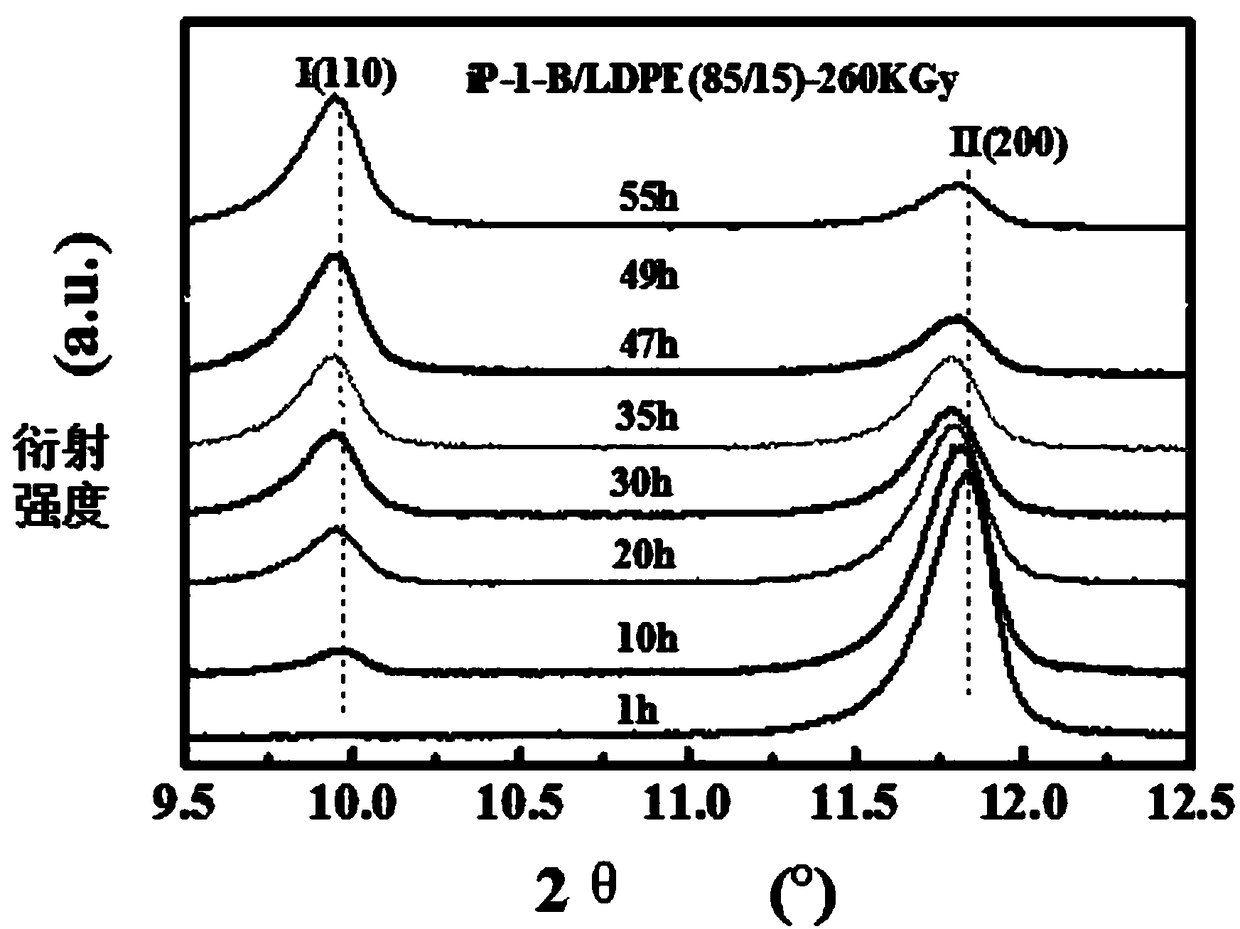

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. Isotactic poly-1-butene (iP-1-B), BASELL (BASELL Polyolefins GmbH, Frankfurt, Germany) homopolymer, the grade is PB 0110M, M w =711000g / mol, T m =117°C, T g =-20°C, ρ=0.914g·cm -3 , the melt flow rate is 0.4g / 10min (190°C / 2.16kg). Low-density polyethylene (LDPE), Sinopec Beijing Yanshan Petrochemical Branch, brand name is 112A-1, MFR=2.0g / min, density is 0.918g / cm 3 .

[0018] Weigh 7g of iP-1-B 0110M, preheat it with a flat vulcanizer at 180°C for 10 minutes, then gradually increase the pressure to 25MPa by gradually increasing the pressure, keep it at the highest pressure for 3 minutes, and then cold press it at 25MPa for 8 minutes. Press a 0.5mm-thick sheet sample, take it out, and place it at room temperature 20-25 degrees Celsius for 30 days (24×30 hours), so that the II crystal is basically transformed into I crystal. Cut the samples int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com