Method for processing impregnated cord fabric fiber or cord thread based on ultraviolet light and high-energy electrons

A technology of impregnated cord fabric and high-energy electronics, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of low solid content of impregnated glue, high energy consumption, and large pollution, and achieve cost control and maintenance, and increase production efficiency. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

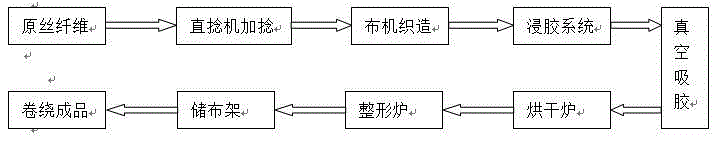

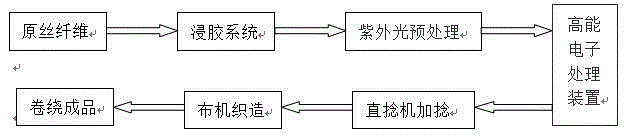

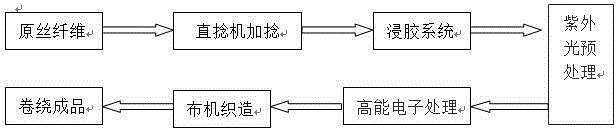

Image

Examples

Embodiment 1

[0029] In this embodiment, the cord fabric fibers or cords are cured by means of ultraviolet light and high-energy electron irradiation. The selection range of the voltage is between 200~600KV, and the selection range of the radiation absorbed dose is between 10~100KGy. In this embodiment, the electron beam irradiation voltage is adjusted to 200KV, the radiation absorption dose is 20KGy, and the impregnating glue is cured.

[0030] The radiation-curable impregnating glue of this embodiment is composed of 100 parts of polyisocyanate, 70 parts of acrylate, 10 parts of vinyl ether monomer and 0.2 part of photoinitiator in parts by weight. Among them, the polyisocyanate can be selected between 100~300 parts, the acrylate can be selected between 70~240 parts, the vinyl ether monomer can be selected between 10~40 parts, and the photoinitiator can be selected between 0.2~200 parts. Choose between 30 servings.

Embodiment 2

[0032] Regarding the above-mentioned embodiment 1, in this embodiment, the voltage of electron beam irradiation is adjusted to 600KV, the radiation absorption dose is 100KGy, and the impregnating glue is cured. The radiation-curable impregnating glue of this embodiment is composed of 200 parts of polyisocyanate, 240 parts of acrylate, 20 parts of vinyl ether monomer and 8 parts of photoinitiator in parts by weight.

Embodiment 3

[0034] Regarding the above-mentioned embodiment 1, in this embodiment, the voltage of electron beam irradiation is adjusted to 200KV, the radiation absorption dose is 10KGy, and the impregnating glue is cured. The radiation-curable impregnating glue of this embodiment is composed of 300 parts of polyisocyanate, 180 parts of acrylate, 40 parts of vinyl ether monomer and 20 parts of photoinitiator in parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com