Horizontal reaction kettle delayed coking equipment and process thereof

A horizontal reactor and delayed coking technology, which is applied in coking carbonaceous materials, cracking, coking ovens, etc., can solve the problems of increasing construction costs and operating costs, narrow source of raw materials, high construction costs, etc., to achieve The effect of saving supporting equipment, reducing economic burden, and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

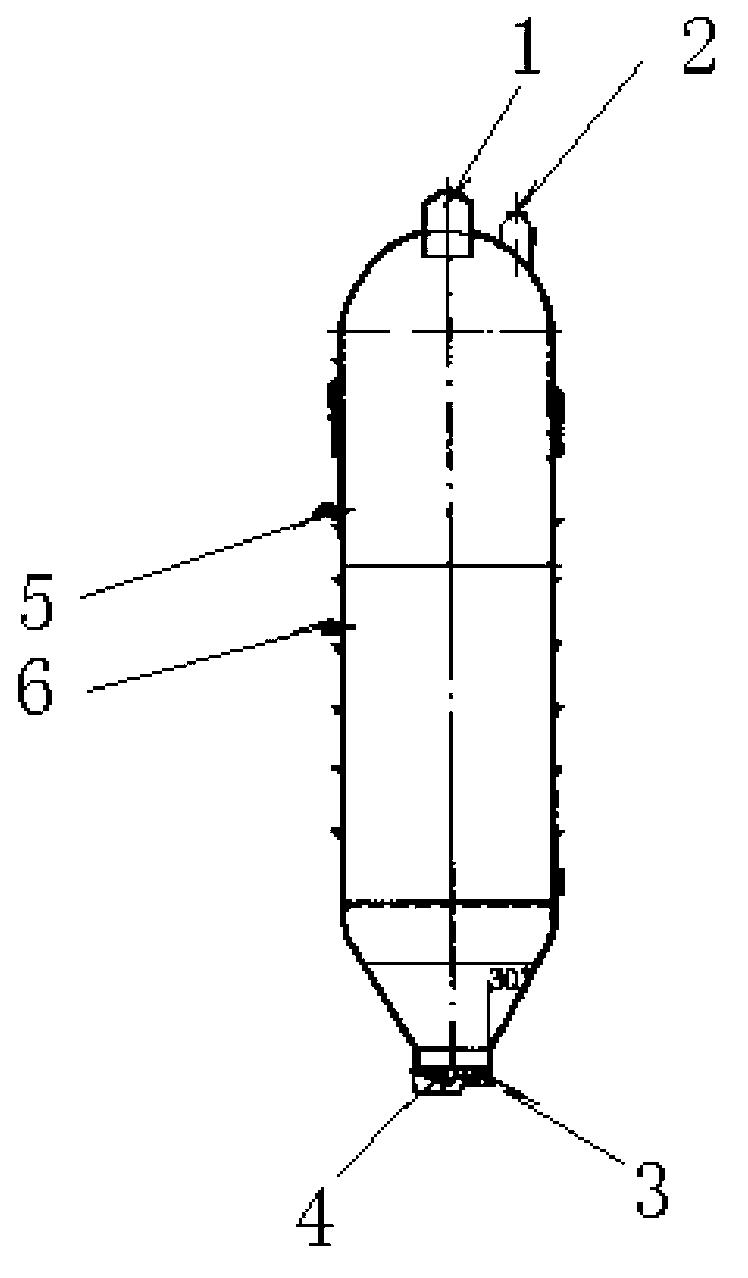

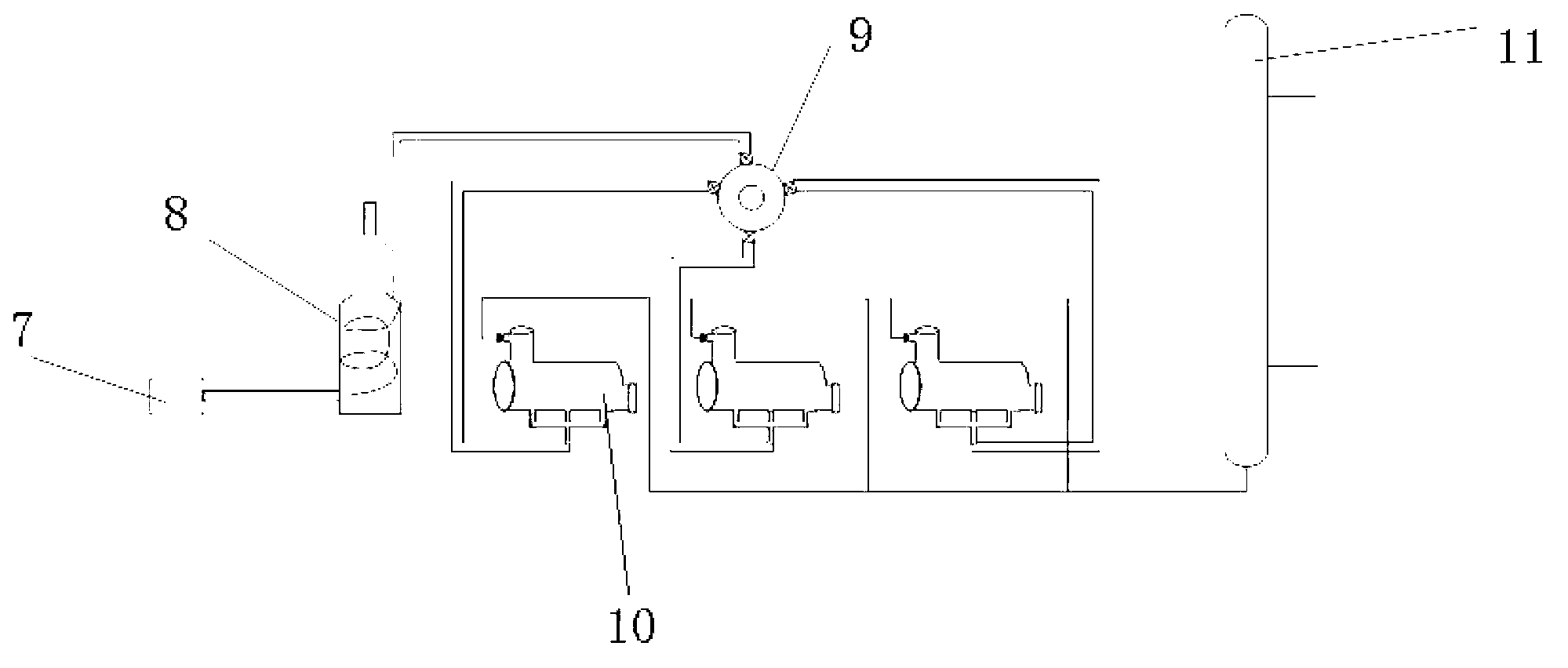

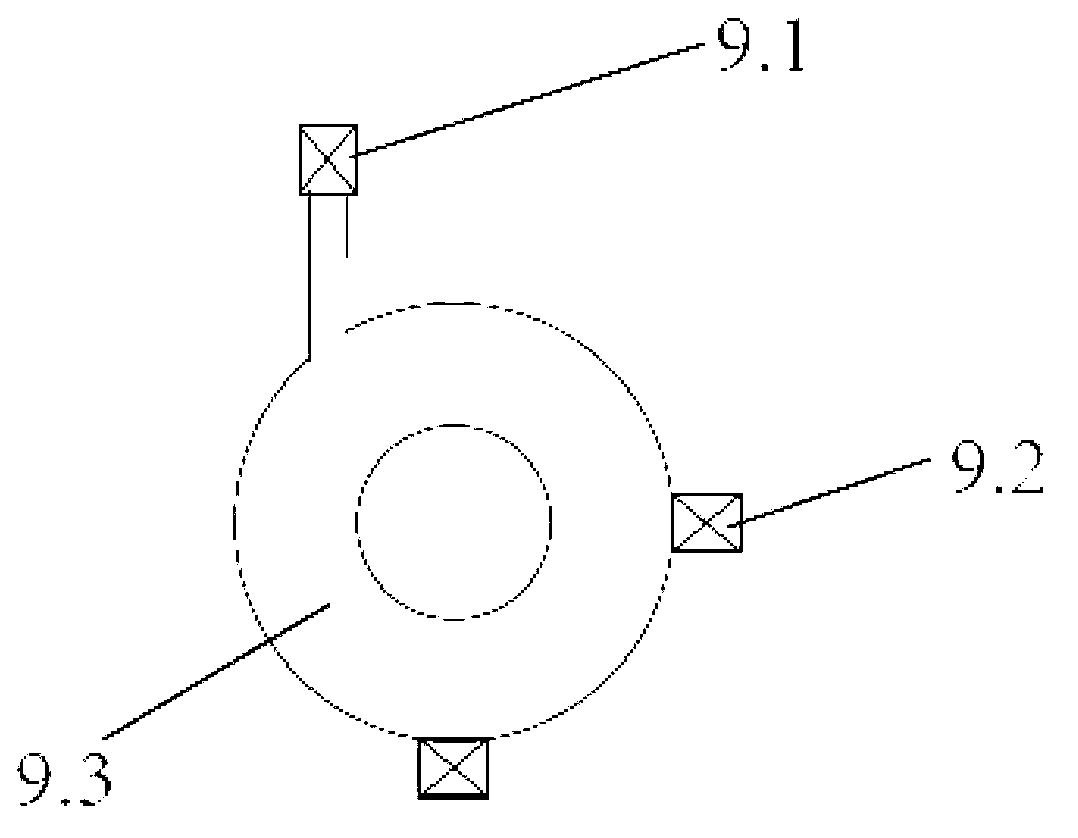

[0033] like figure 2As shown, the horizontal reactor delayed coking equipment includes a heating furnace 8, a coke tower and a fractionation tower 11. The heating furnace 8 is connected to the coke tower through a raw material distribution valve 9, and the raw material distribution valve 9 is provided with an annular inner cavity 9.3 , the annular inner cavity 9.3 is provided with a feed valve 9.1 and a plurality of discharge valves 9.2, the feed valve 9.1 of the raw material distribution valve 9 is connected to the outlet of the heating furnace 8, that is, the raw material pump 7 pumps the raw material into the heating furnace 8. After heating to the required temperature, enter the raw material distribution valve 9 through the feed valve 9.1. The discharge valve 9.2 of the raw material distribution valve 9 is connected to the coke tower; the coke tower is a horizontal reactor 10, and the bottom end of the horizontal reactor 10 is provided with a feed port 10.1, and the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com