High performance polymer base composite material for support roller and preparation method

A high-performance polymer and composite material technology, applied in the field of new materials, can solve the problems of low noise in high-speed operation, temperature resistance, weather resistance and wear resistance of plastic rollers that are inferior to ceramics, and difficult to form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

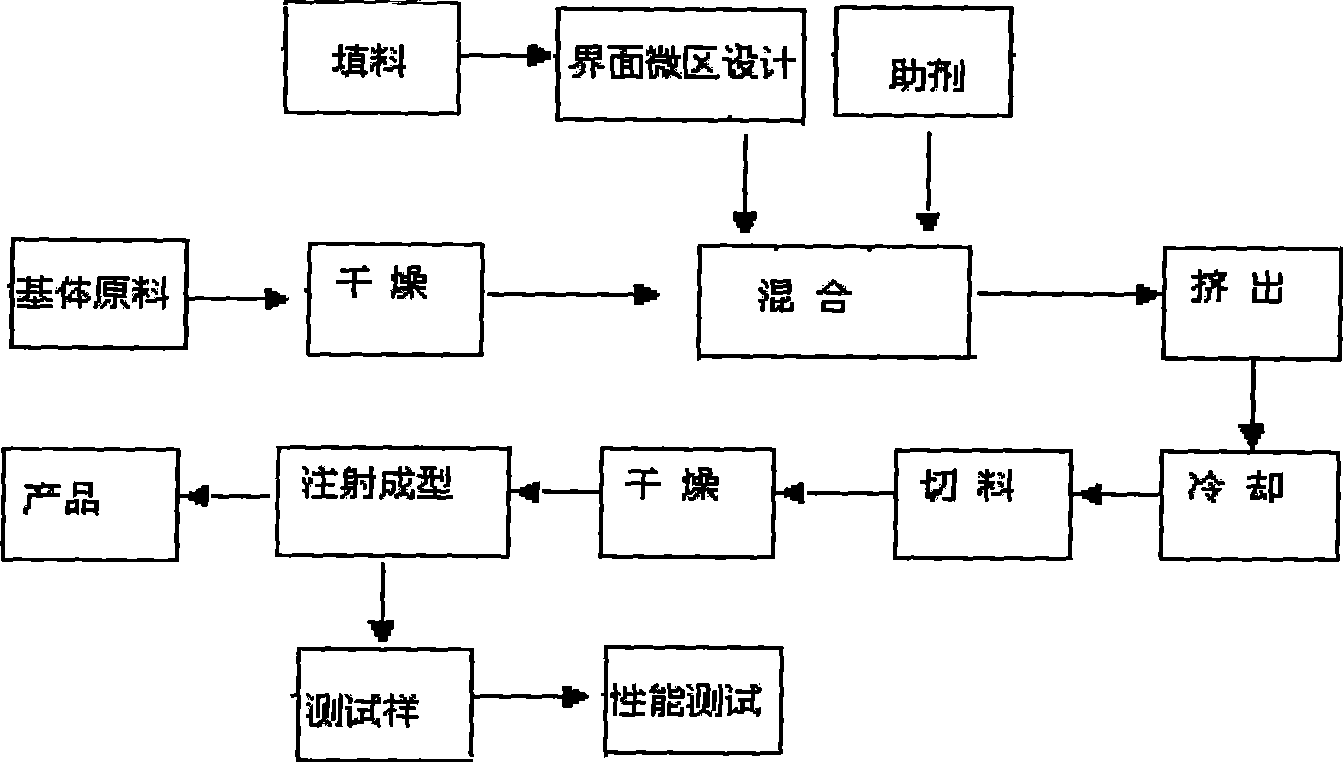

Method used

Image

Examples

example 1

[0033] The weight percentage is 51% nylon 6, 30% glass fiber, 10% ceramic powder, 5% composite solid lubricant, 3.7% flame retardant, 0.1% antistatic agent, 0.2% antiaging agent and The other additives are fully mixed evenly, and the mixed material is extruded and granulated in a twin-screw extruder, and the granular composite material is obtained after drying. The material can be used to prepare roller shells used in severe conditions.

example 2

[0035] The weight percentage is 51% nylon 6, 20% glass fiber, 20% ceramic powder, 5% composite solid lubricant and appropriately changing the composite ratio, 3.7% flame retardant, 0.1% antistatic agent, 0.2 % anti-aging agent and other additives are fully mixed, the mixed material is extruded and granulated in a twin-screw extruder, and the granular composite material is obtained after drying. The material can meet the requirements for preparing idler cylinders of belt conveyors used for conveying cement and the like.

example 3

[0037] The weight percentage is 54% of nylon 6, 15% of glass fiber, 10% of ceramic powder, 5% of composite solid lubricant and appropriately change the composite ratio, 14.9% of flame retardant, 1% of antistatic agent, 0.1 % anti-aging agent and other additives are fully mixed, the mixed material is extruded and granulated in a twin-screw extruder, and the granular composite material is obtained after drying. The flame retardant performance of the material reaches V-0 level, has good antistatic performance and good friction and wear performance, and can be used to prepare the idler cylinder for coal transportation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com