Side drainage type directly-embedded part and construction method thereof

A construction method and side-discharge technology, which is applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., to achieve the effects of reducing chiseling through walls, improving construction efficiency, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

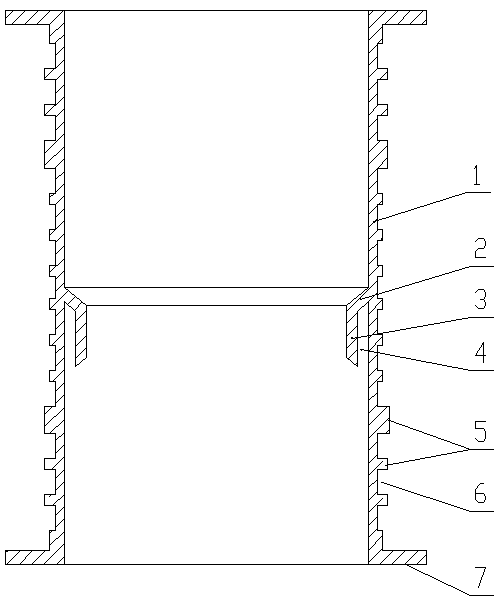

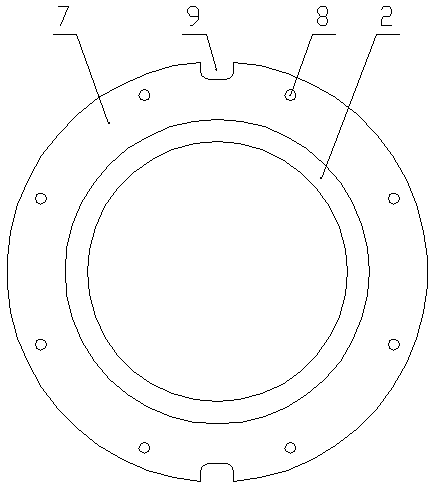

[0029] Such as figure 1 and figure 2 As shown, the side row type direct buried part of the present invention includes a straight pipe part 1 in a cylindrical structure, and the middle position in the straight pipe part 1 is coaxially fixed with a socket pipe, and the socket pipe includes a bell mouth section 2 and The straight pipe section 3, the outer ring of the thicker end of the bell mouth section 2 is fixedly connected with the inner wall of the straight pipe piece 1, one end of the straight pipe section 3 is fixedly connected with the thinner end of the bell mouth section 2, and the outer circle of the straight pipe section 3 is connected with the inner wall of the straight pipe piece 1 A socket ring groove 4 is formed between them, and the outer circumference and both ends of the straight pipe piece 1 are provided with pre-embedded positioning structures.

[0030] The pre-embedded positioning structure of the outer circumference of the straight pipe 1 includes several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com