Anti-eccentricity pressing piston rod connecting device of no-guiding slider type hydraulic press

A non-guided slider type, connecting device technology, applied in the direction of manufacturing tools, other household appliances, household appliances, etc., can solve the problems of uneven force on flange threaded connections, damage to the guide sleeve of the cylinder port, and bolt cutting, etc. Achieve the effect of avoiding mechanical equipment damage, reducing equipment manufacturing costs, and difficult to repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

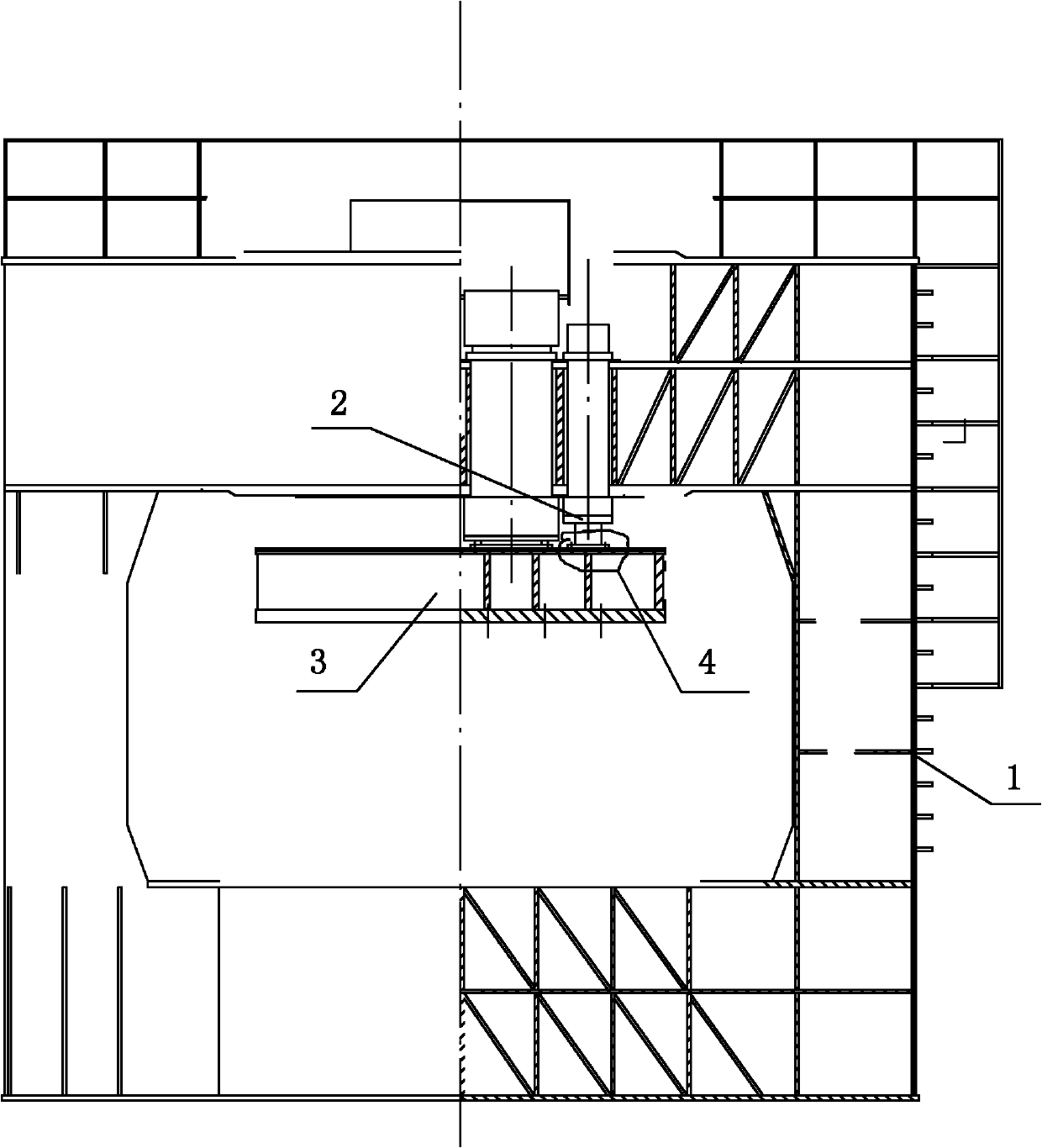

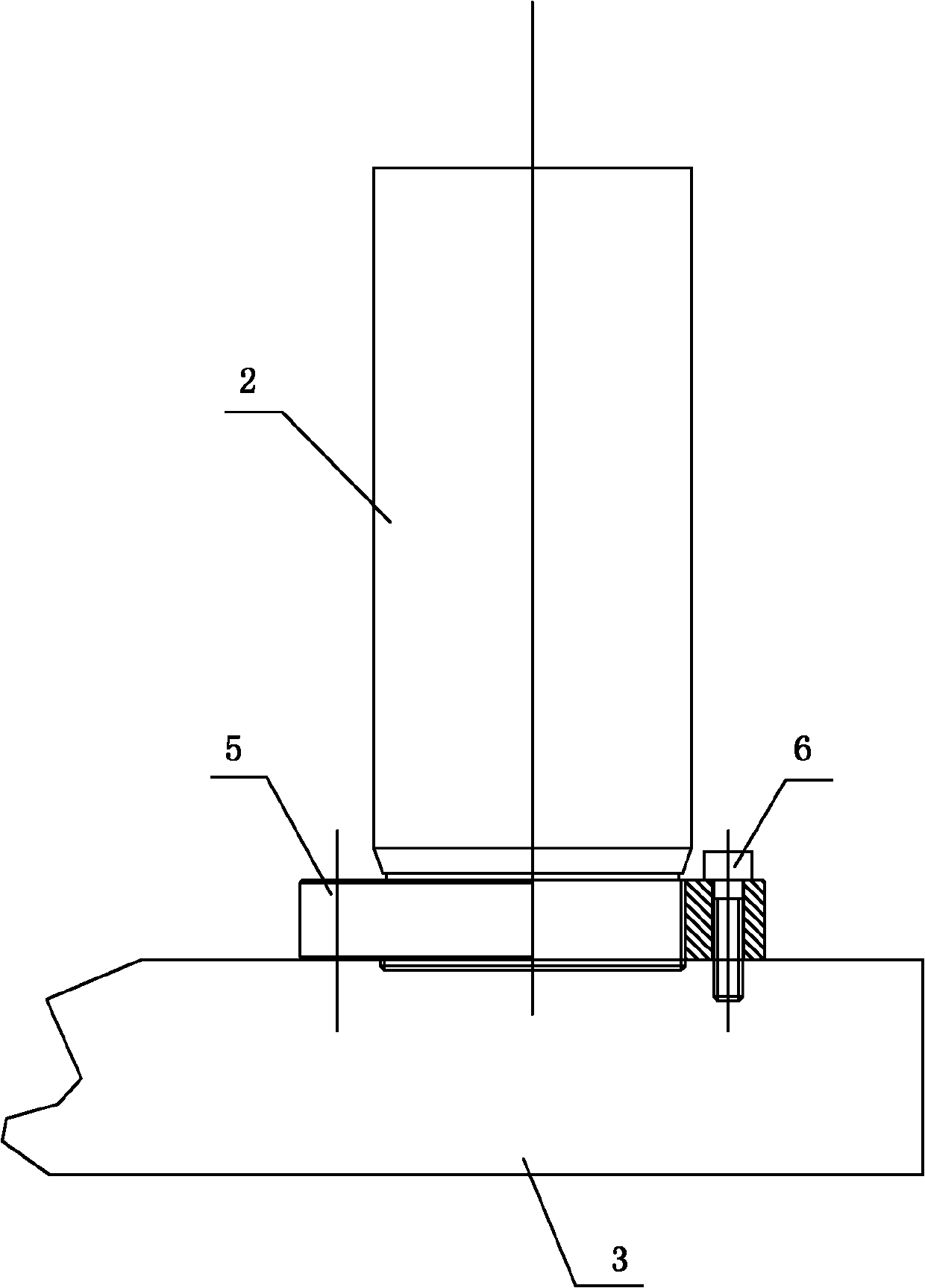

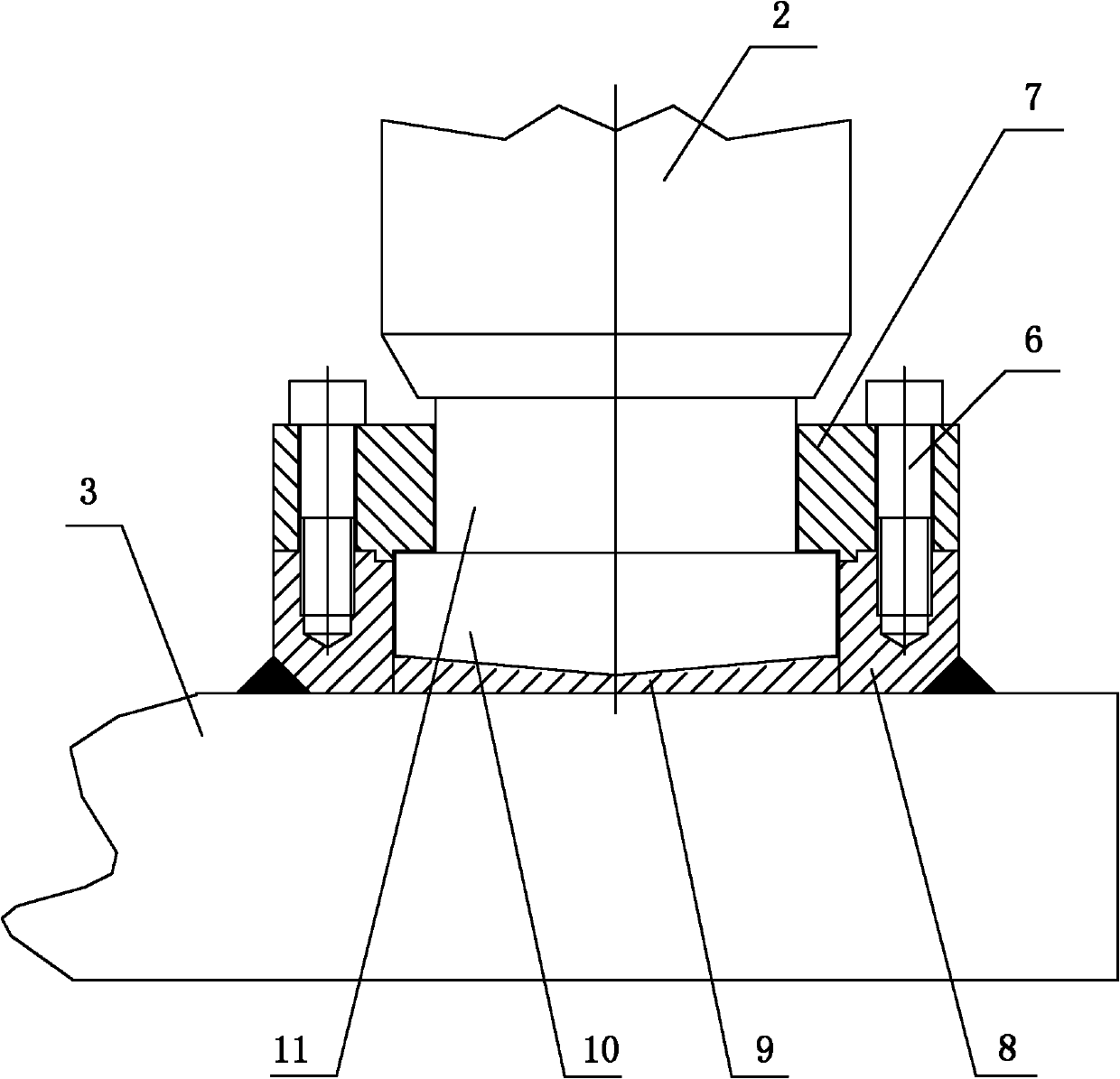

[0019] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the drawings, see figure 1 , image 3 , Figure 4 , Figure 5 :

[0020] An anti-eccentric compression piston rod connecting device for a non-guide slider type hydraulic machine, which relates to the piston rod 2 of a hydraulic cylinder 2 and a working slider 3. The connecting device includes a bolt 6, a compression flange 7, a fixed support 8, and an articulated support 9. The compression flange 7 is provided with a piston rod diameter through hole 12 in the middle. The diameter of the piston rod diameter through hole 12 is larger than the diameter of the piston rod diameter 11 by 3~5mm (and the diameter of the piston rod diameter through hole 12 Smaller than the maximum diameter of the piston rod ball head 10), the compression flange 7 is provided with a plurality of bolt through holes 13 (the plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com