Double-loop desulfurization device for ship

A desulfurization device and dual-loop technology, applied in the use of liquid separation agents, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of affecting the uniform distribution of exhaust gas, complex structure of the scrubber, and increase the difficulty of construction, so as to offset the cost of the device. , Improve the utilization rate and reduce the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

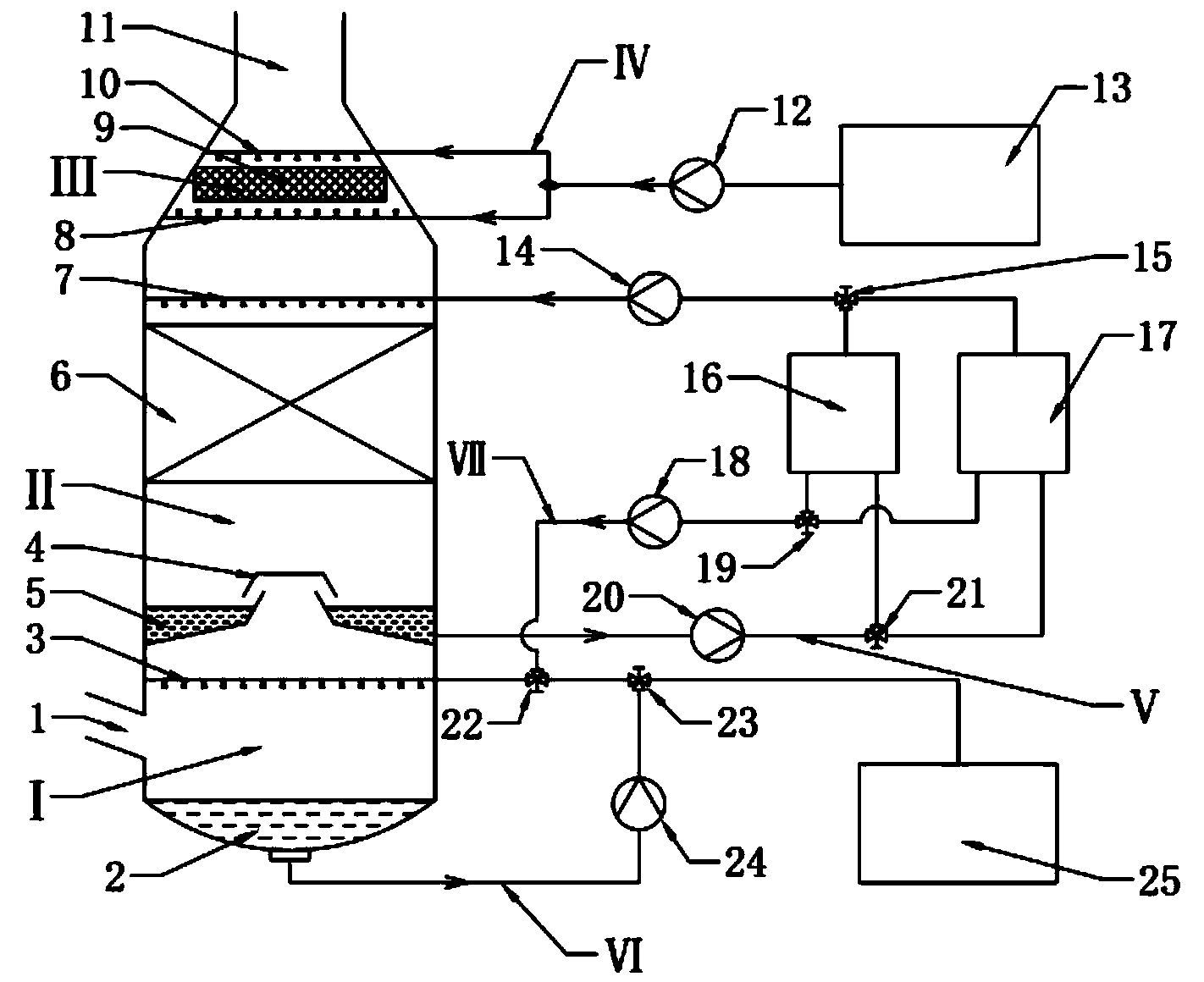

[0015] combine figure 1 , the present invention comprises low pH value lye spraying area I, high pH value lye spraying area II, defogging area III, demister cleaning pipeline IV, high pH value lye circuit V, low pH value lye Circuit Ⅵ, connecting pipeline Ⅶ, waste gas inlet 1, liquid collection tank 2, 5, low pH lye spray device 3, waste gas hood 4, packing 6, high pH lye spray device 7, mist eliminator cleaning Devices 8, 10, demister 9, waste gas outlet 11, water pump 12, 14, 18, 20, 24, fresh water tank 13, three-way valve 15, 19, 21, 22, 23, lye tank 16, 17, waste Liquid tank 25.

[0016] The washing tower in the marine desulfurization method and device of the present invention adopts countercurrent spraying operation.

[0017] The working process of the device of the present invention is: the waste gas of the ship power unit enters the low pH value lye spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com