Non-excavation directional drilling construction method for municipal pipeline

A construction method and directional drilling technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of unsatisfactory construction period, increased investment cost, low construction efficiency, etc., and shorten the construction period , Save investment cost, improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further elaborated and illustrated below in conjunction with the embodiments.

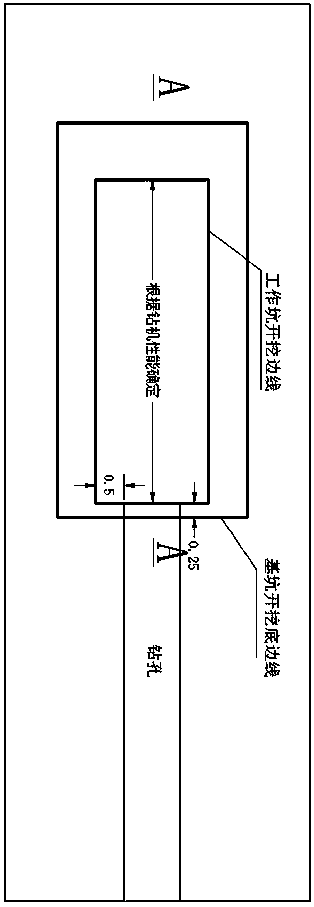

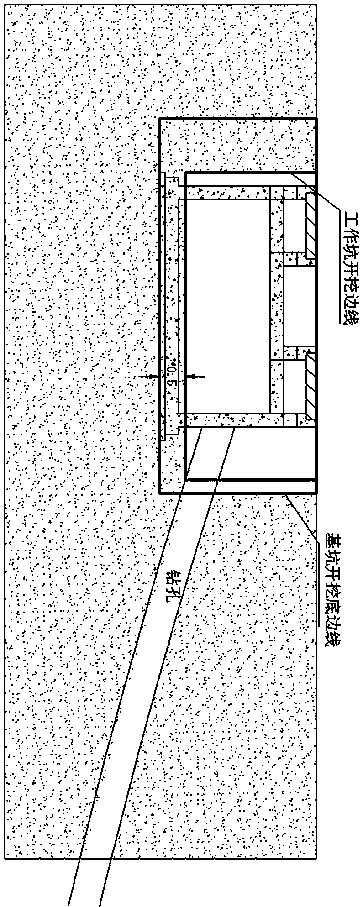

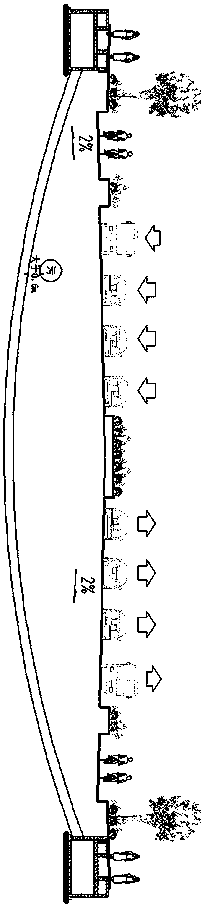

[0031] A non-excavation directional drilling construction method for municipal pipelines. This method is mainly suitable for the laying construction of various pipelines crossing rivers, roads, structures and other obstacles, and it is not suitable to adopt the form of open cut. The laying pipe diameter is 50~600mm, and the laying distance 50~200m, the pipe material is MPP pipe, HDPE pipe, steel pipe for power, communication, water supply and drainage and other buried pipeline laying construction. The construction process of this embodiment is: construction preparation→track design→measurement and setting out→work pit construction→direct drilling rig in place, commissioning→mud preparation→pilot hole drilling→step-by-step reaming→pipe welding reinforcement, pulling back the pipe→inspection Well construction → foundation pit backfilling....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com