Paper-faced rice and wheat straw board and its production device and production method

A wheat straw and straw board technology, which is applied to other household appliances, pretreatment of molding materials, household appliances, etc., can solve the problems that the quality of paper rice and wheat straw boards cannot meet the requirements of building apartment buildings, and achieves improvement of laying direction, The effect of solving the problem of returning grass and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Rice and wheat straw boards on paper

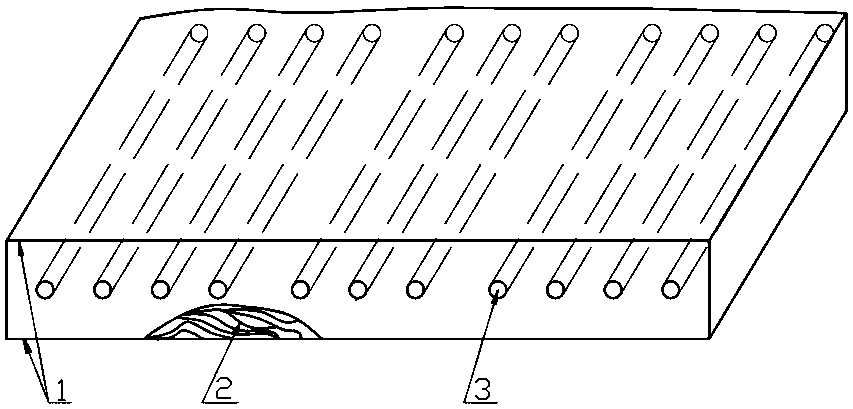

[0052] refer to figure 1 , the paper-faced rice and wheat straw boards of the present invention include: the main body 2 of the rice and wheat straw boards extruded from the rice (wheat) straw curtains after repeated punching, compacting, and heating; face-protecting paper 1; the reinforced weight-reducing through-hole 3 vertically arranged in the main body 2 of the rice and wheat straw board, the number of the reinforced weight-reducing through-hole 3 is 11, and the diameter of each reinforced weight-reducing through-hole is 20mm.

Embodiment 2

[0053] Embodiment 2 Production device for making straw boards using straw curtains

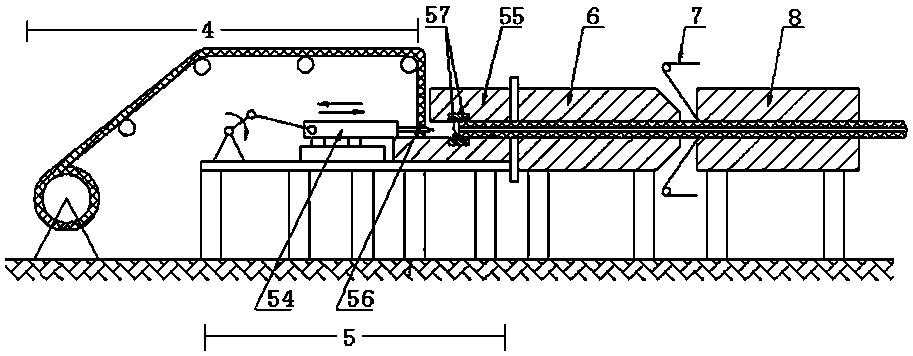

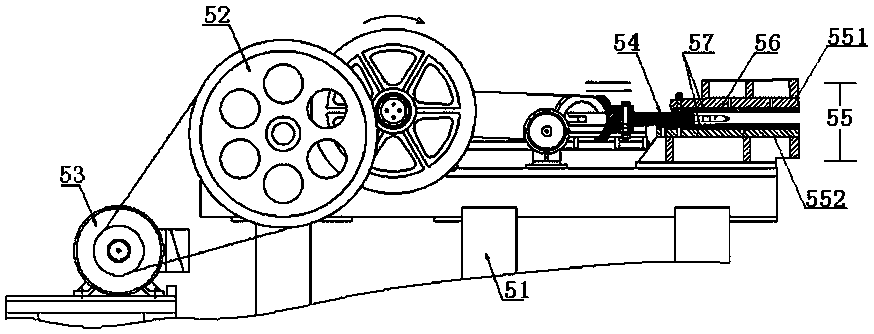

[0054] refer to figure 2 , the production device of the present invention that is specially directed at making grass boards using straw curtains includes a straw curtain tractor 4, a stamping molding machine 5, a first heating bed 6, a glue coating machine 7, and a second heating bed 8; wherein, the Described straw curtain tractor 4 is arranged on the place ahead of described stamping forming machine 5, and effect is that straw curtain is sent into the punching chamber punching entrance of stamping forming machine 5 at a constant speed; Described stamping forming machine 5 is arranged on the first The front of the heating bed 6 is used to punch and stamp straws one by one, gradually compact them, and then send them into the first heating bed 6; the first heating bed 6 is arranged on the glue coating machine 7, the effect is to heat the straw pushed from the stamping chamber, the straw is hea...

Embodiment 3

[0057] Example 3 A production device for making straw boards using bundled rice and wheat straw as raw materials

[0058] refer to Figure 5 , the use of bundled rice and wheat straw according to the present invention is a production device for making straw boards as raw materials, the device includes a horizontal conveyor 10, an inclined conveyor 20, a bundler 30, a loose grass homogenizer 40, machine 50, belt conveyor 60, stamping machine 70, the first heating bed, the glue coating mechanism, the second heating bed; wherein, the horizontal conveyor 10 is connected with the inclined conveyor 20, and the effect is to bundle the rice, The wheat is transported to the inclined conveyor 20 at a uniform speed; the inclined conveyor 20 is connected with the beam unbundling machine 30, and its effect is to transport the bundled rice and wheat straw to the unbundling machine 30 at a uniform speed for unbundling treatment, and simultaneously the rice 1. The wheat straw is softened, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com