High-speed warp knitting machine with double-sided fixed needle bed mechanism

A high-speed warp knitting machine and needle bed technology, which is applied in the field of warp knitting machines, can solve the problems of substandard quality of knitted fabrics, uneven stress on the needle bed, waste of production materials, etc., to reduce the time for taking needles, save space, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

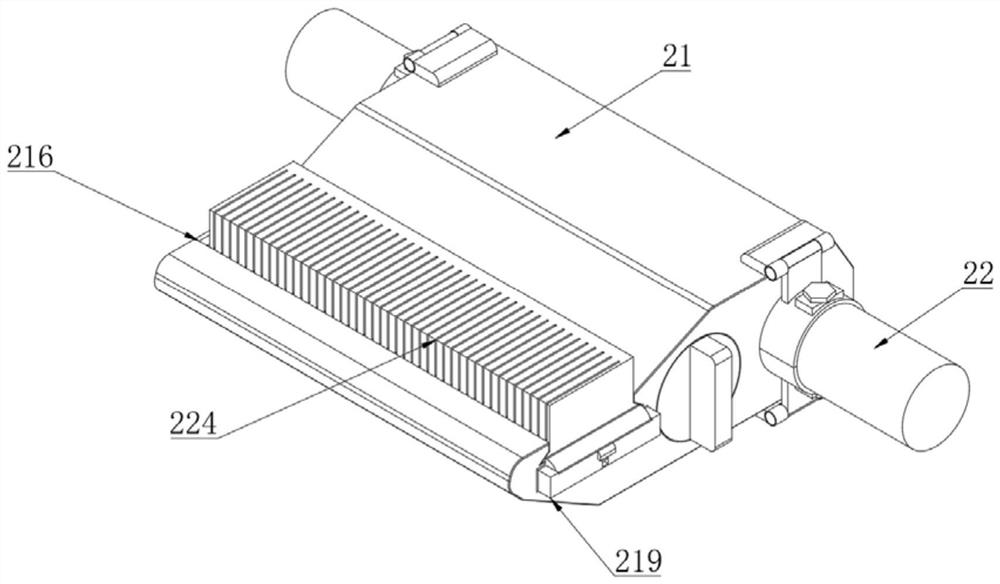

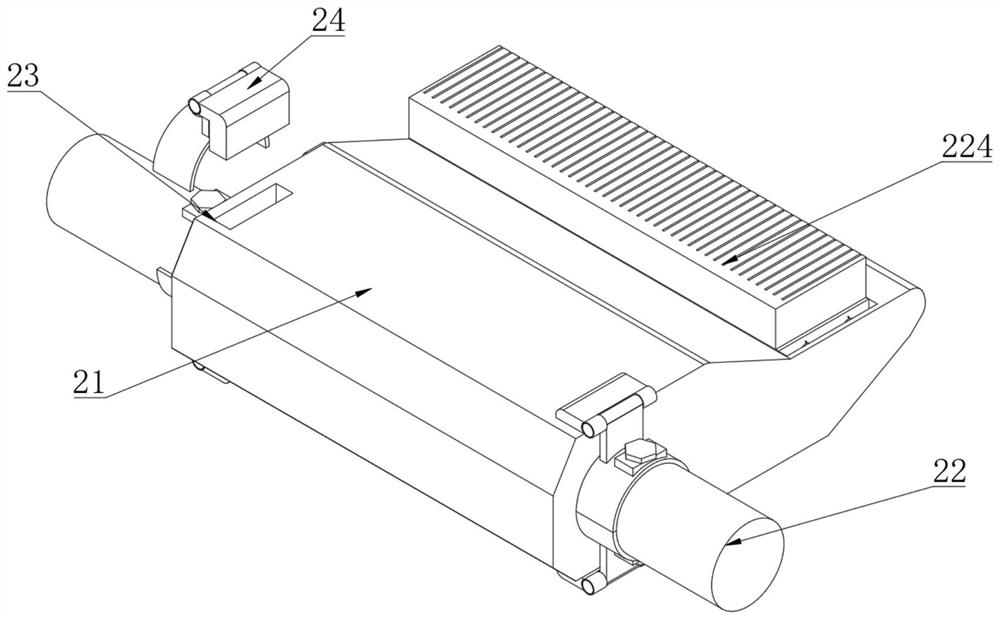

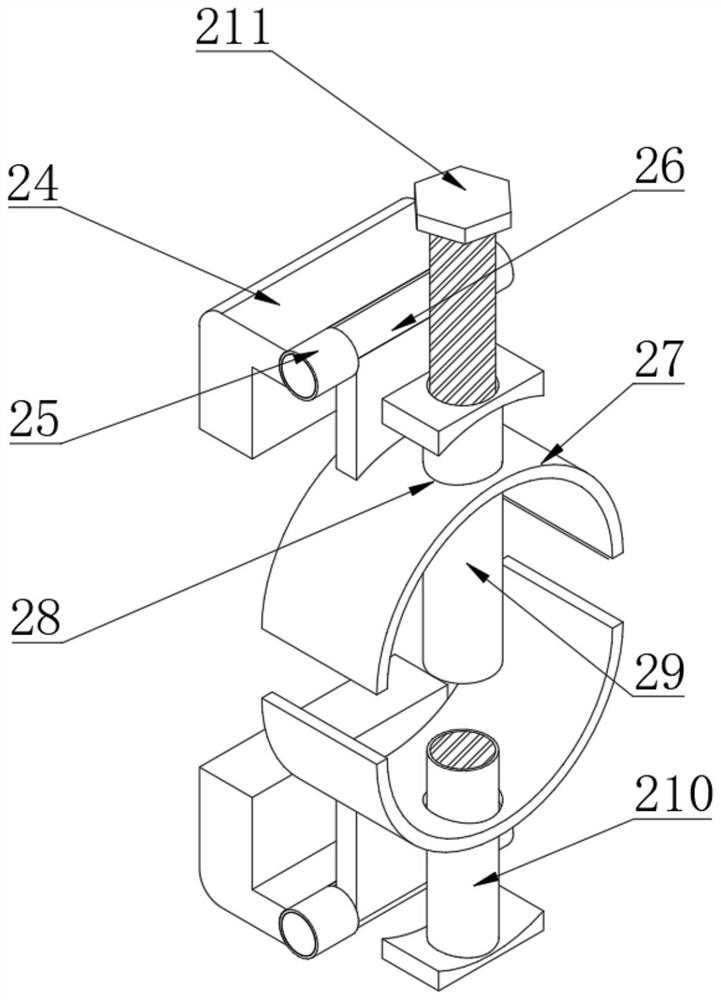

[0039] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a high-speed warp knitting machine with a double-sided fixed needle bed mechanism, including a needle bed mechanism, the needle bed mechanism includes a needle bed 21, and the inner side of the needle bed 21 is embedded with a Shaft 22, the outside equidistant of installation shaft 22 is provided with installation hole, and the other end of installation shaft 22 is connected with external transmission mechanism, facilitates transmission, thereby makes needle bed 21 work normally, and the top and bottom end of both sides of needle bed 21 are A fixed groove 223 is provided, and the inner side of the fixed groove 223 is embedded with a fixed block 224. The side end of the fixed block 224 is fixedly connected with a rotating sleeve 25, and the inner side of the rotating sleeve 25 is rotatably connected with a rotating block 26. The bottom end of the rotating block 26 An arc-shaped pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com