Method for pumping gas of protected layer by layer penetration and hole drilling on high-position drilling fields of protecting layer machinery tunnel

A technology of drilling through layers and protected layers, which is applied in drilling equipment and methods, gas discharge, earth-moving drilling, etc., can solve the problems of long construction period, potential safety hazards, and large amount of construction roadway engineering, and achieves a reduction in The effect of construction cost, convenient safety management and shortening of mining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

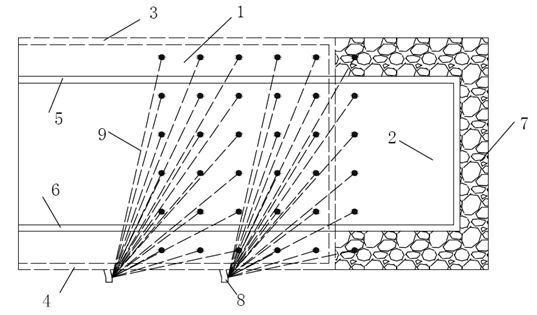

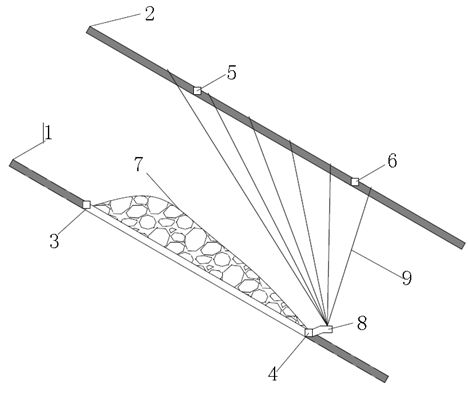

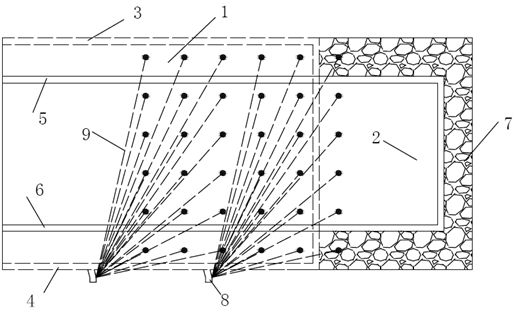

[0016] Such as figure 1 As shown, the method for drilling gas in the protected layer through layer drilling in the high-level drilling field of the protective layer machine roadway of the present invention, firstly, in the protective layer machine roadway 4 corresponding to the protective layer airway 3, along the direction of the coal seam every 90m A high-level drilling site 8 is arranged on the outside. After the construction of each high-level drilling site 8 is completed, three rows of multiple layer-penetrating drilling holes 9 passing through the protected layer 2 are arranged along the direction in each high-level drilling site 8, such as figure 2 As shown, when arranging the layer-penetrating drill 9, it should avoid passing through the goaf caving zone 7. The three rows of layer-penetrating drilling 9 in each high-level drilling field 8 have a strike spacing of 30m, and the first row of layer-penetrating drilling 9 The strike of the advanced high-level drilling site...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com