Eccentric engine using magnetic suspension object system time at same point in vertical surface

A technology of system timing and magnetic levitation, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., and can solve the problems of large projects and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

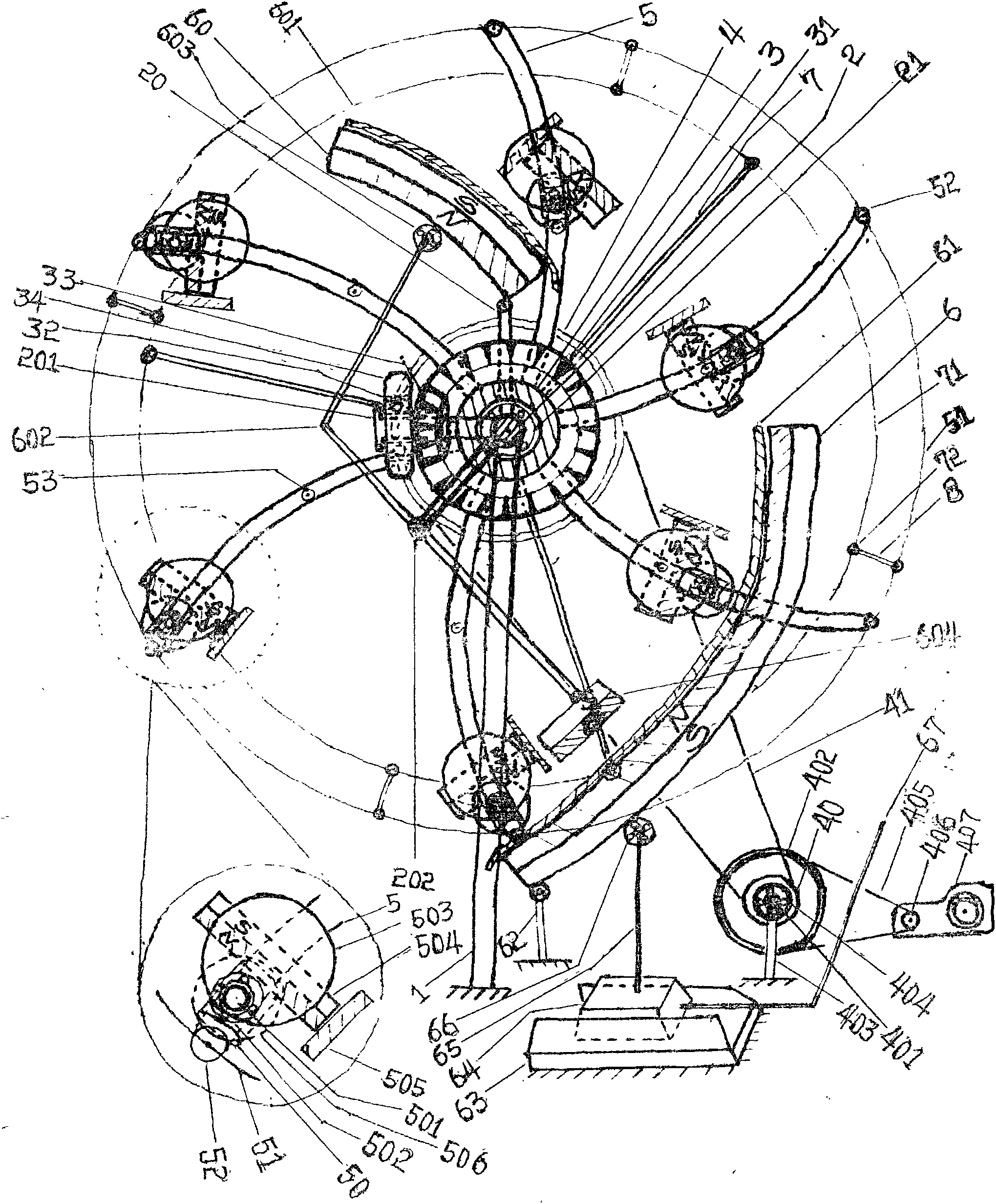

[0100] Embodiment 1, such as figure 1 Shown, the present invention comprises six major mechanisms by means of the eccentric motor at the same point in the vertical plane at all times by means of the magnetic levitation object system.

[0101] Slider action synchronous mechanism: the "parallel and opposite" slide bar 5 equipped with two rotating sleeves 3 on the same circumference of the single machine is equipped with a 50-action "synchronous" mechanism. The main bevel gear 31 is to mesh with the respective auxiliary bevel gear 32, which is conjoined with the auxiliary bevel gear 32 and coaxial with two straight (or helical) gears 34 that are just meshed, and on the same circumference in the middle of the outer surfaces of the two rotating sleeves 3, The sliding fitting 50 fitted on the sliding rod 5 of the inlaid pliers, and the horizontal rod 501 connected by the sliding fitting 50 on the sliding rod 5 with the same shape and the same arrangement posture of the two swivel sl...

Embodiment approach 2

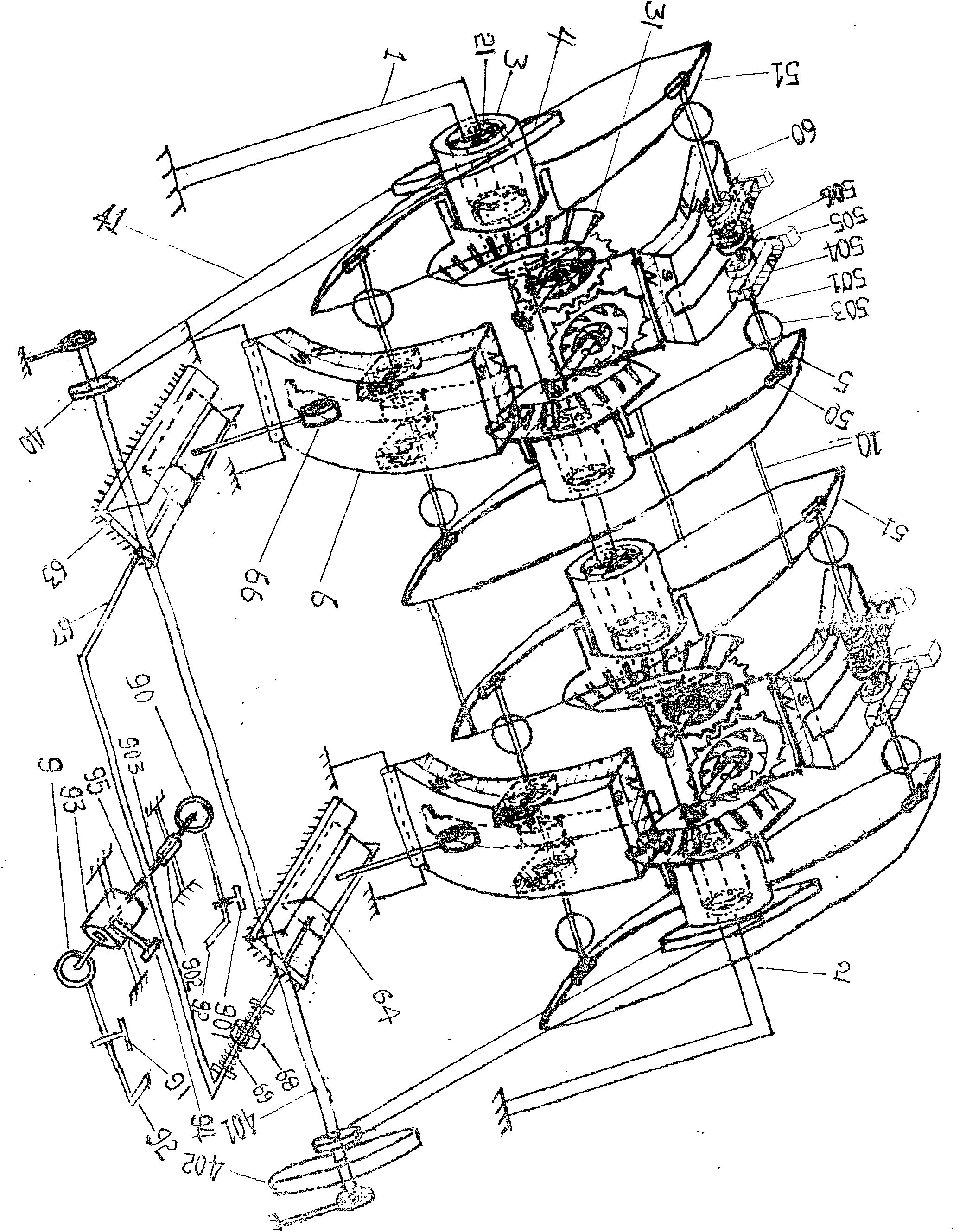

[0104] Implementation mode two: if figure 2 As shown, the "multi-unit linkage" mechanism of the present invention includes a plurality of stand-alone machines sharing an inverted "U"-shaped bracket at the same point in the vertical plane by means of the magnetic levitation object system at all times. The same two rotary sleeves 3 assemblies of multiple single machines are connected in series on the horizontal support 2, and the adjacent two single machines can only have the slide bar 5 on one side, and the closed circular metal rod 51 fixedly connected by the outermost end uses a cross bar 10 Come to Gulian. and share a power take-off shaft 401.

[0105] The operation control mechanism includes the driven wheel of the automatic transmission 407, which is driven by a belt to drive the "air compressor". "Air duct normally closed switch 91, then to the "start" air pump 9, the start air pump 9 drives the traction guide rod 95 that is sleeved in the fixed sliding sleeve 93, and ...

Embodiment approach 3

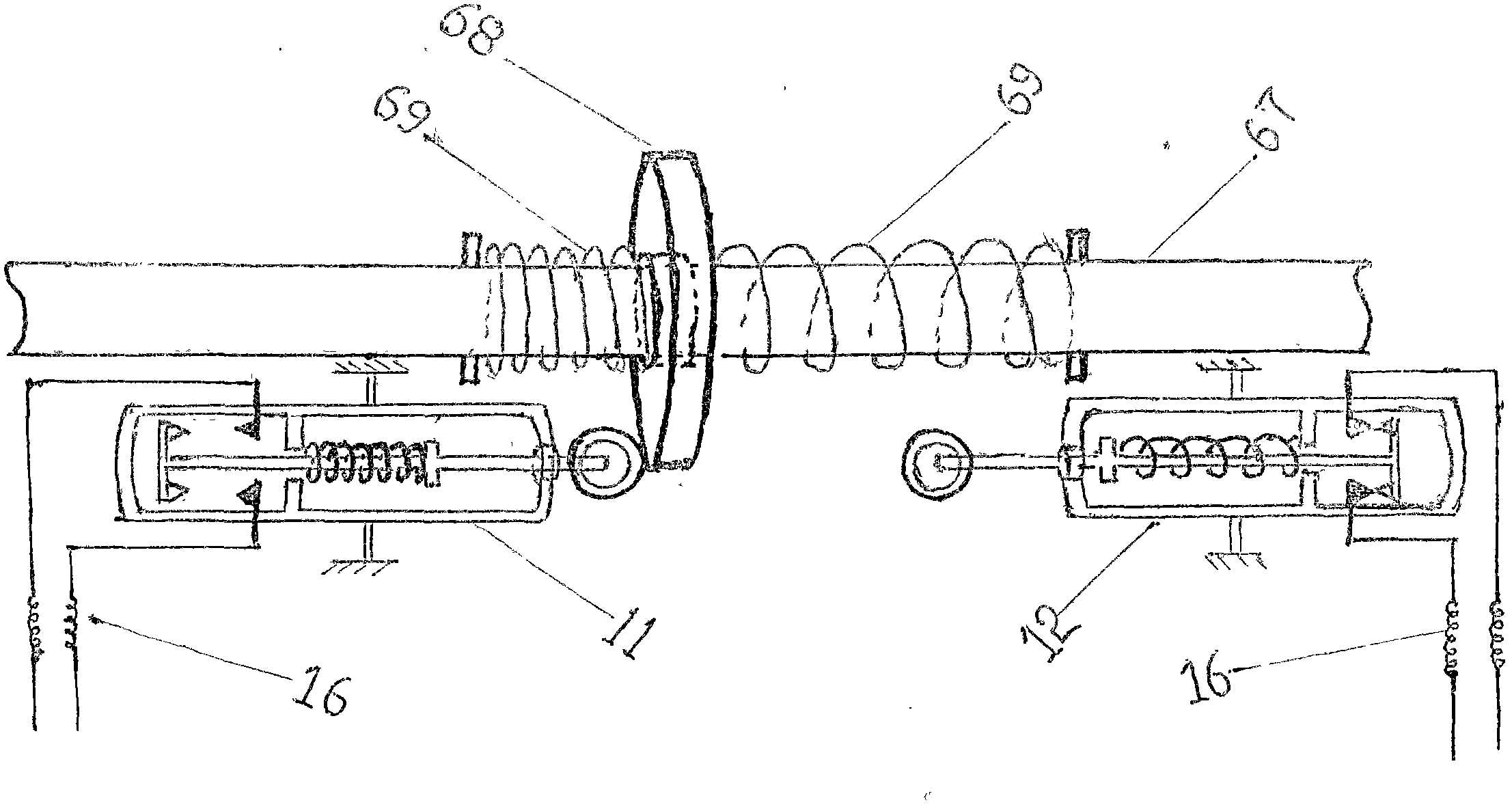

[0107] Embodiment 3; if image 3 and 4As shown, the present invention is eccentric at the same point in the vertical plane by means of the operation control mechanism of the eccentric motor at all times of the magnetic levitation object system. Including electronically controlled air pressure, and air pressure control operation (start up or stop operation). First, after the electric control electromagnet 13 is energized, the locking pin 94 of the armature conjoined body is completely separated from the starting traction guide rod 95, and after the dynamic and static contacts (14 and 15) on the electromagnet 13 are in contact, the starting valve 9 circuit is started again. Or shut down the air valve 90 circuit to make it work, and then move through the sliding assembly (trigger slide block) 68 set on the pneumatic guide rod 67 to trigger the travel switch 11 of the air pump 9 circuit that is controlled to start or to control the stroke of the air pump circuit 90 that is shut d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com