Integral vulcanization construction method for large-diameter rubber-lined pipelines

A technology of integral vulcanization and construction method, which is applied in the field of phosphorus chemical industry, can solve the problems of long time consumption and achieve the effects of simple rubber lining facilities, reliable vulcanization quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

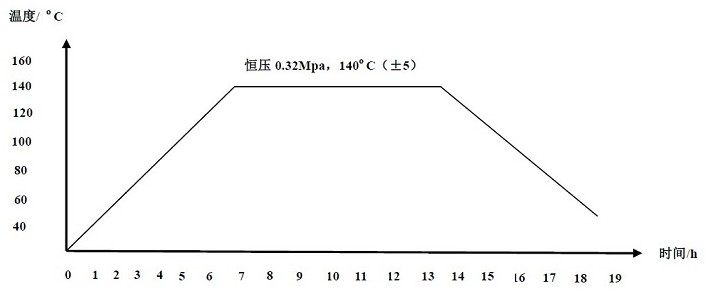

[0027] Example 1: Taking the vulcanization construction of the large-diameter rubber-lined pipeline (1) of the first-phase 300,000-ton / year phosphoric acid plant of Inner Mongolia Dadi Yuntian Chemical Co., Ltd. as an example, the specific construction process is as follows.

[0028] The overall vulcanization construction method of the large-diameter rubber-lined pipeline (1) of the present invention is characterized in that the method is implemented according to the following steps:

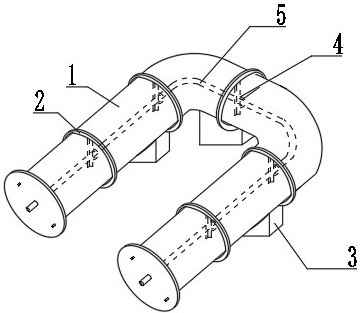

[0029] 1) One rubber-lined pipeline to be vulcanized with qualified rubber lining is connected in U-shape through flanges with bolts, and a circular steel ring 2 made of ø12 round steel is arranged at the joint of the pipeline, and the circular steel ring 2 points Welded outside the waterline of the flange; the rubber-lined pipe 1 completed in series is placed on several support frames 3 and fixed, the support frame 3 is welded by steel plates, the top of the support frame 3 matches the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com