Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

A technology for vanadium-titanium magnetite and titanium concentrate, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low grade, difficult extraction technology, and cannot be used economically and effectively, and achieves Improve the utilization rate, improve the technical and economic indicators of beneficiation, and the effect of simple operation of the iron beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

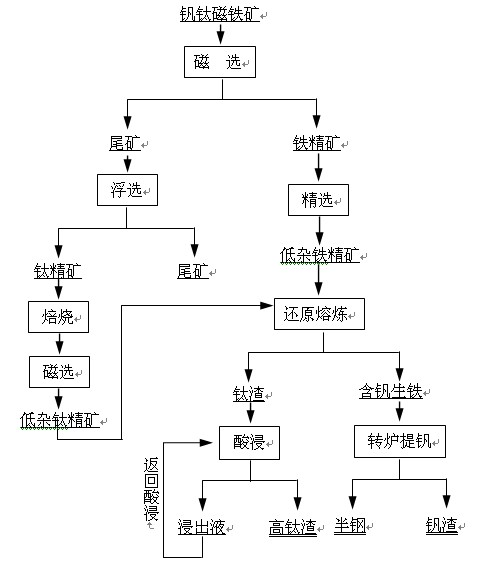

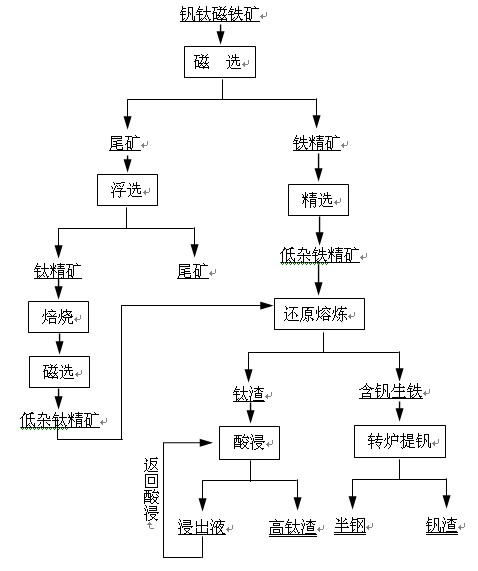

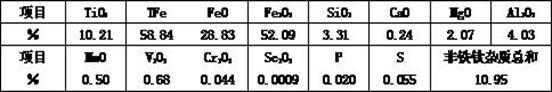

[0037] In the current development and utilization process of vanadium-titanium magnetite, whether it is a blast furnace process or a direct reduction process, the titanium-containing slag obtained after the separation and extraction of iron and vanadium, TiO 2 The grades are all low, the extraction technology is difficult, and they cannot be used economically and effectively. The present invention not only improves the utilization rate of iron and vanadium, but also improves the TiO content of smelting titanium slag by removing the impurities of raw materials and adopting mixed reduction smelting of iron and titanium concentrate. 2 grade, so that the utilization of titanium slag is more economical and reasonable. At the same time, through further impurity removal and purification of titanium slag, TiO-containing 2 >92%, high titanium slag products that can be used in the titanium dioxide chloride industry, broaden the application field of titanium. Technical process compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com