Production method of 83dtex/72f lustrous fine-denier flat FDY fiber

A production method and flat technology, applied in fiber processing, complete sets of equipment for producing artificial threads, filament/thread forming, etc., can solve the problems of poor product quality and high production costs, achieve high product added value, improve competitiveness, The effect of high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

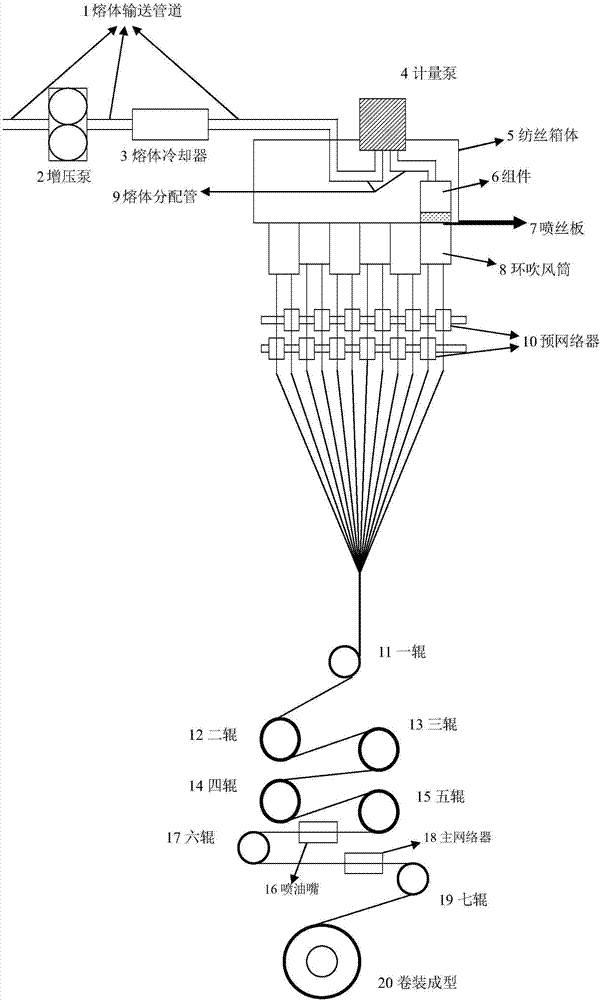

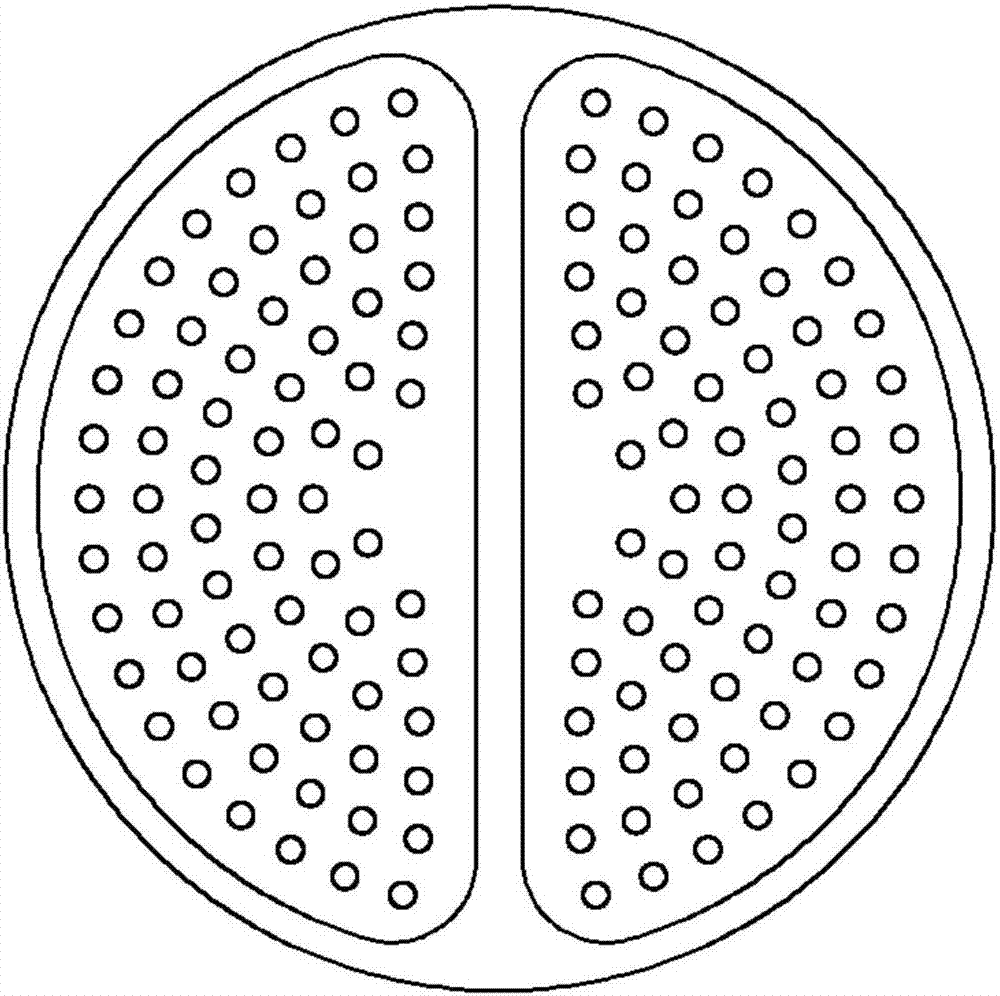

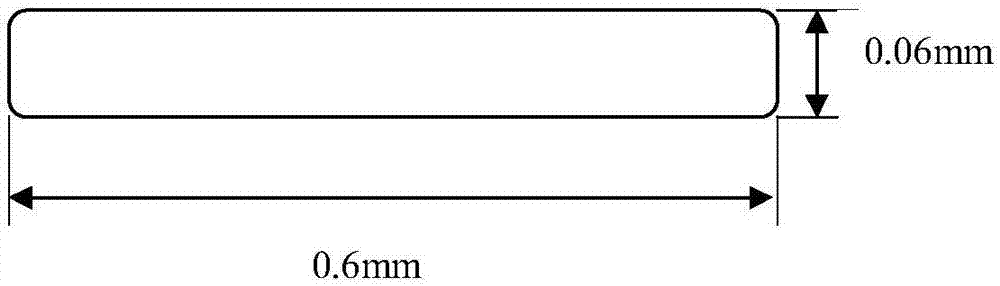

[0030] refer to figure 1 , figure 2 and image 3 , the production device includes a booster pump 2, a melt cooler 3, a metering pump 4, a spinning box 5, a spinning assembly 6, a spinneret 7, a ring blower 8, a pre-internet device 10, a roll 11, two Roll 12, three rolls 13, four rolls 14, five rolls 15, fuel injection nozzle 16, six rolls 17, main network device 18, seven rolls 19, winding head 20; the booster pump 2, melt cooler 3. The metering pump 4 and the spinning assembly 6 are connected sequentially through pipelines. The metering pump 4 and the spinning assembly 6 are arranged in the spinning box, and the spinneret 7 is arranged at the bottom of the spinning assembly 6. The ring blowing drum 8 is located below the spinning box body 5, and the pre-networker 10, a roll 11, two rolls 12, three rolls 13, four rolls 14, five rolls 15, and a spraying machine are successively arranged under the ring blowing drum 8. Grease nozzle 16, six rollers 17, main network device 18,...

Embodiment 2

[0047]In this embodiment, the bright polyester melt is pressurized to 180bar through the melt delivery pipeline through the booster pump, and then sent to the melt cooler to cool the bright polyester melt to 278°C, and then passed through the melt The conveying pipeline is fed into the spinning box whose temperature is kept at 291° C.; other implementation methods are the same as in Example 1.

[0048] A kind of 83dtex / 72f bright fine denier flat FDY fiber that present embodiment produces, its main technical index: intensity is 4.85cn / dtex, and elongation at break is 27%, and evenness unevenness (CV% value) is 1.15% , The oil content is 1.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com