Post-processing system apparatus and control method

一种系统装置、控制方法的技术,应用在排气处理、气体处理、消音装置等方向,能够解决NOx降低率下降、NOx量变少、系统破坏等问题,达到提高降低率、防止结晶化现象、降低率增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The post-processing system device and control method of the embodiment of the present invention will be described in detail below with reference to the accompanying drawings, so that those skilled in the art of the present invention can easily implement it. The present invention is not limited to the embodiments described here, and can be embodied in various forms.

[0031] In order to clearly describe the present invention, parts irrelevant to the description are omitted, and the same reference signs are assigned to the same or similar constituent elements throughout the specification.

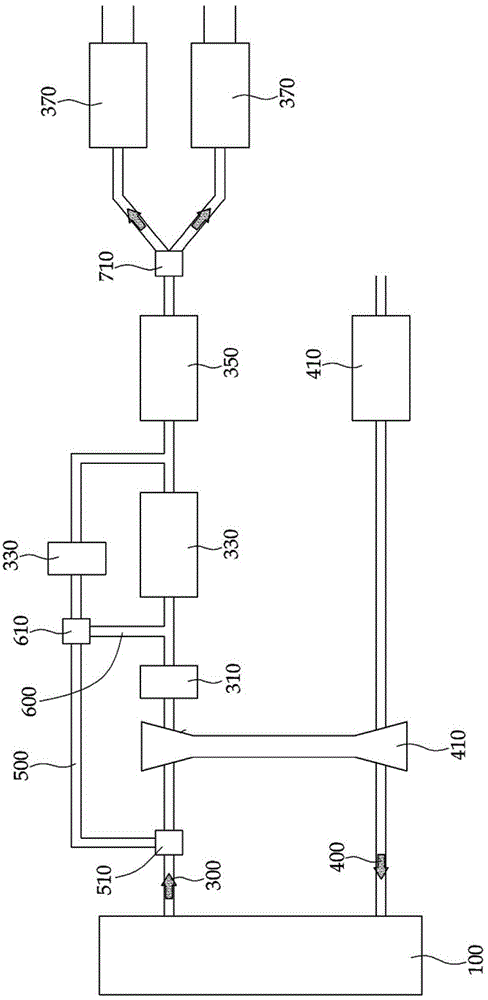

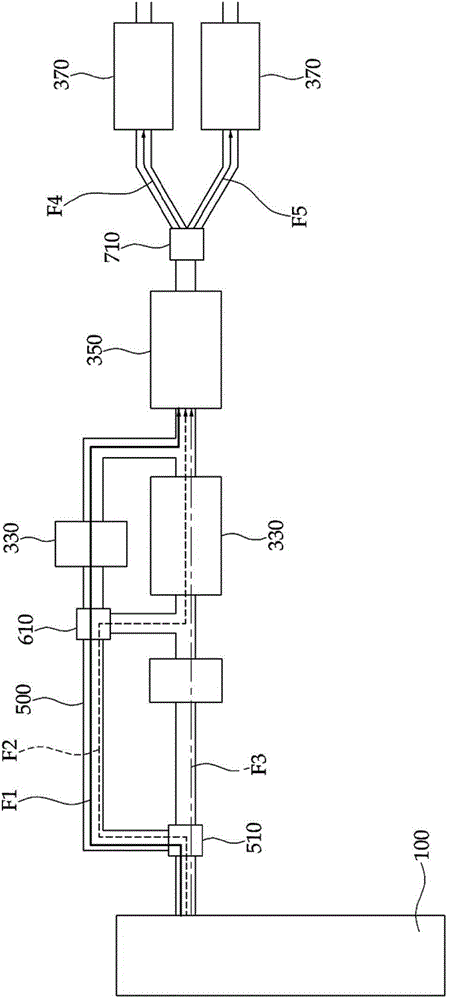

[0032] Such as figure 2 As shown, the aftertreatment (UREA-SCR) device of the present invention includes an exhaust pipe 300 that discharges exhaust gas from the engine 100 to the atmosphere, and an intake pipe 400 that supplies fresh air to the inside of the engine 100 .

[0033] One end of the exhaust pipe 300 is connected to the engine 100 or an exhaust manifold (not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com