Technique for CSP sheet billet production line cold rolling feeding

A process method and production line technology, applied in the field of metallurgical steel rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

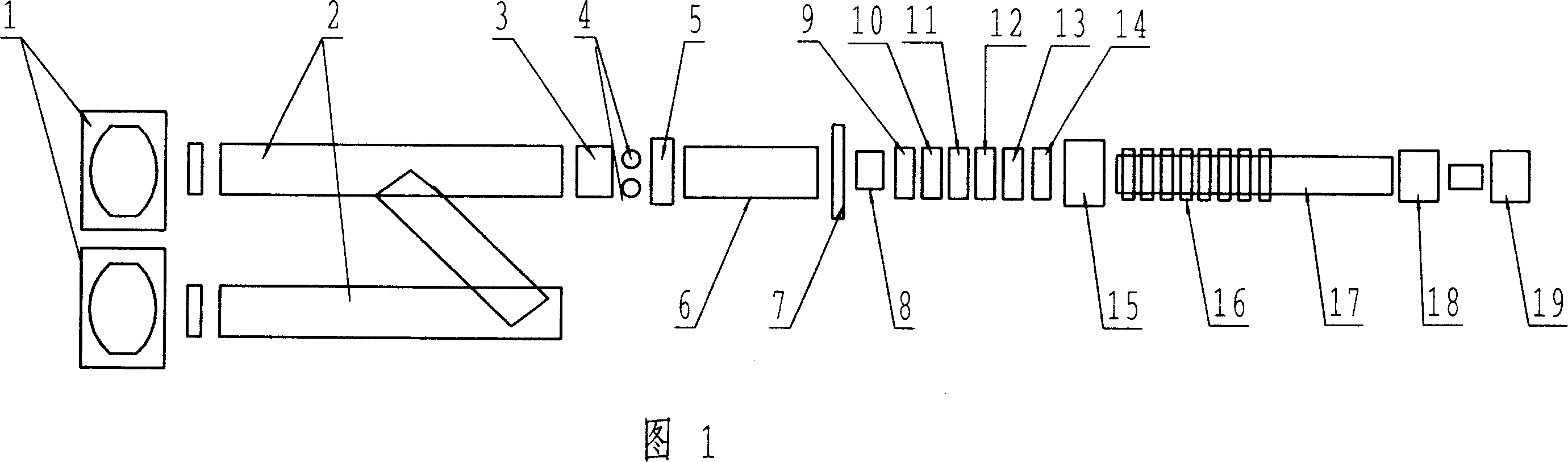

Image

Examples

Embodiment Construction

[0012] The present invention aims at the low-carbon steel produced by the CSP conventional process, which is easy to generate cementite at the ferrite grain boundary and the reduction rate of the roughing mill is too small, resulting in fine grains, which is not conducive to the subsequent processing requirements. The coiling temperature and The rolling reduction rate was optimized by process parameters. In terms of coiling temperature, a large number of comparative tests were carried out on the room temperature microstructure of low carbon steel with different coiling temperatures, and combined with the actual working capacity of the laminar cooling line to find out the optimized cold-rolled feeding material coiling temperature process parameters. The main improvements are: breakthrough The production of low-carbon steel by CSP conventional process generally adopts a high-temperature coiling process plan higher than 670°C, and implements coiling at a lower temperature of about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com