Novel method for controlling plate shape of heavy and medium plate mill

A technology for shape control and rolling mill, applied in the field of metallurgy, can solve the problems of economic loss of enterprises and the flatness of steel plates can not meet the product requirements, and achieve the effects of less manual intervention, improving regular benefits and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

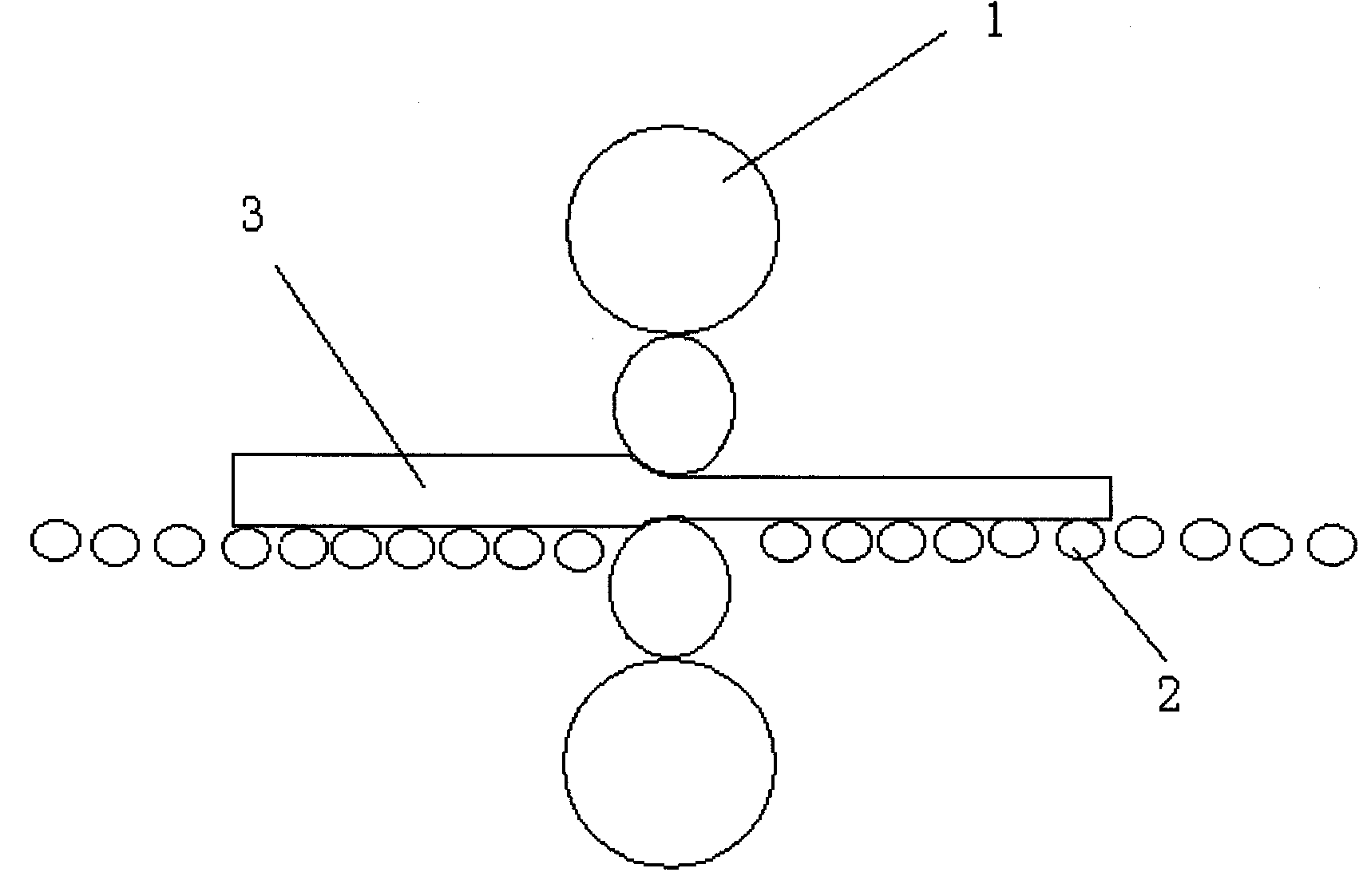

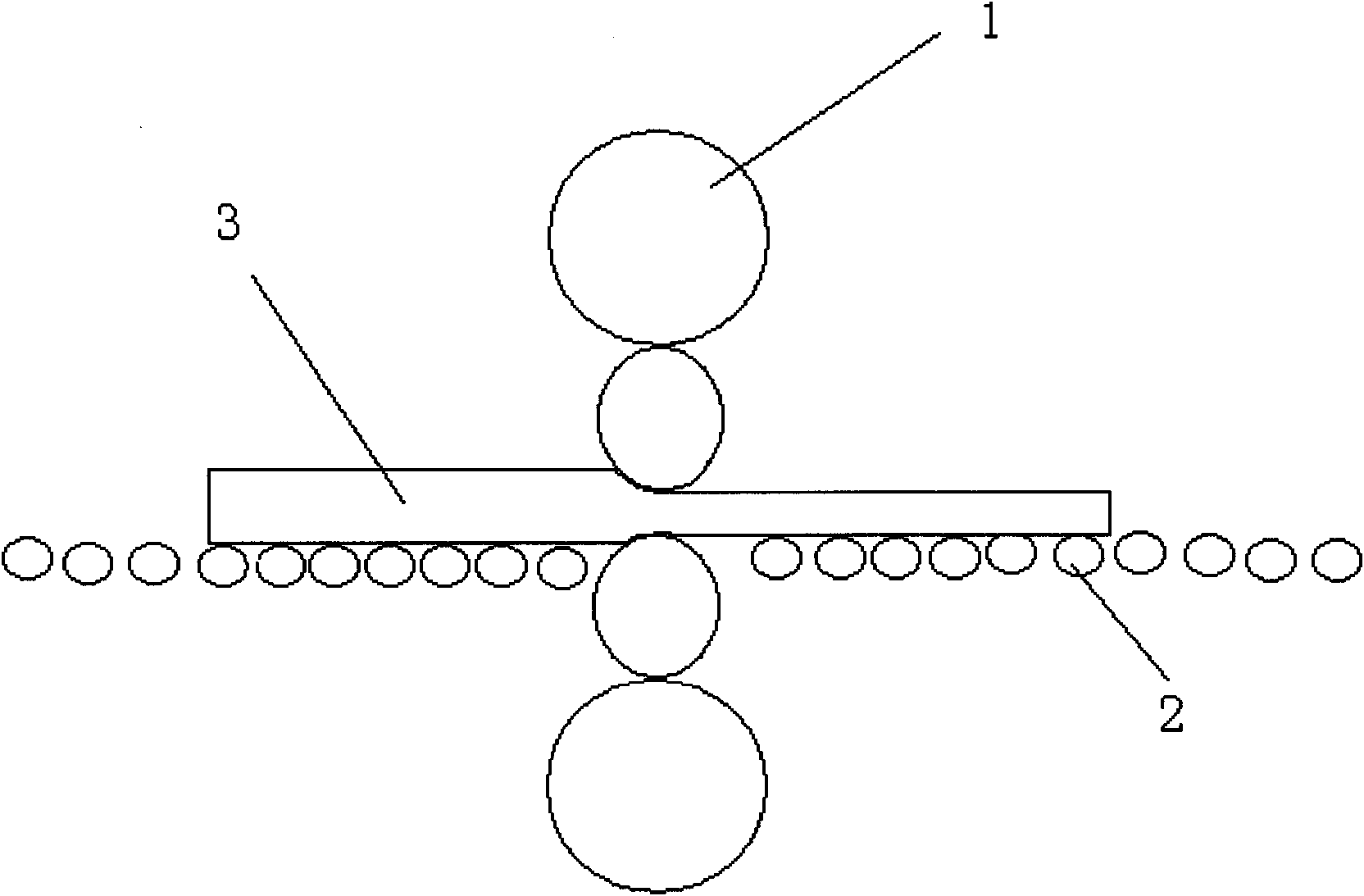

Method used

Image

Examples

Embodiment 1

[0014] A novel shape control method for a medium and heavy plate rolling mill according to the present invention, that is, on the basis of the traditional rolling method, one pass is reduced as a smoothing pass, and the last pass of rolling is used as a method for reducing warping and knocking of the steel plate. For the wave-shaped smoothing pass, by changing the rolling procedure, the reduction rate of the rolling pass is increased, the speed of the smoothing pass is controlled at 2.0m / s, the roll gap is increased by 4mm on the basis of the thickness of the finished steel plate, and the rolling force is 400 Ton. Relevant parameters can be adjusted on the operation interface according to the shape of the strip and the rolling force of the last pass.

[0015] The rolling speed, starting rolling temperature, final rolling temperature, and pass reduction distribution of the present invention can be adjusted through a secondary computer, which is the same as the traditional rolli...

Embodiment 2

[0018] Yet another new shape control method for medium and heavy plate mills, that is, on the basis of the traditional rolling method, one pass is reduced as a smoothing pass, and the last pass of rolling is used as a method for reducing warping, knocking and wave shape of the steel plate Smooth pass, increase the reduction rate of rolling pass, control the pass speed at 1.0m / s, add 2mm to the thickness of the finished steel plate for the roll gap, and the rolling force at 500 tons.

[0019] By changing the rolling schedule, the reduction rate of the last pass of the traditional rolling method is changed to a smooth pass. The rolling speed, starting rolling temperature, final rolling temperature, and pass reduction rate distribution of the present invention can be passed through two stages. The computer makes adjustments, the same as the traditional rolling process.

Embodiment 3

[0021] Yet another new shape control method for medium and heavy plate mills, that is, on the basis of the traditional rolling method, one pass is reduced as a smoothing pass, and the last pass of rolling is used as a method for reducing warping, knocking and wave shape of the steel plate Smooth pass, increase the reduction rate of rolling pass, control the pass speed at 3.0m / s, add 5mm to the thickness of the finished steel plate for the roll gap, and the rolling force at 600 tons.

[0022] By changing the rolling schedule, the reduction rate of the last pass of the traditional rolling method is changed to a smooth pass. The rolling speed, starting rolling temperature, final rolling temperature, and pass reduction rate distribution of the present invention can be passed through two stages. The computer makes adjustments, the same as the traditional rolling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com