690MPa thick steel plate for ocean engineering and manufacturing method of steel plate

A marine engineering, thick-gauge technology, applied in the field of marine engineering steel with excellent toughness, plasticity and weldability, with a yield strength of 690MPa, it can solve the problems not related to lamellar tear resistance and welding performance, and achieve good impact toughness , Excellent low temperature toughness, and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

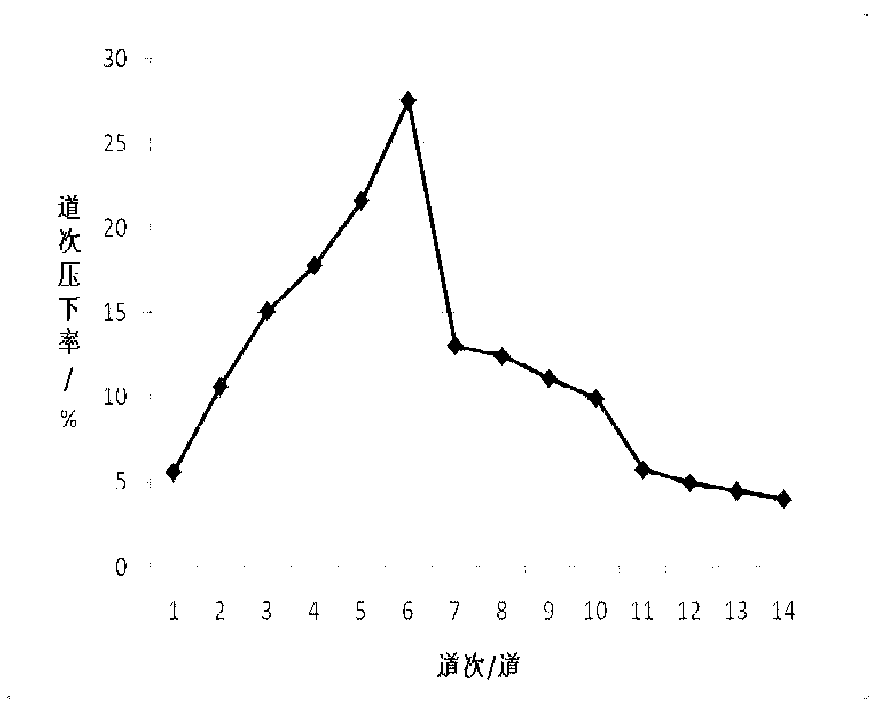

[0030] The thickness of 690MPa steel plate for marine engineering is 50mm, and its chemical composition is: C 0.1%, Si0.20%, Mn1.04%, Alt0.034%, Nb0.02%, V0.05%, Ti0.015%, Mo0 .33%, Ni0.7%, Cu0.28%, Cr0.55%, B0.0012%, P0.008%, S0.002%, and the rest are iron Fe and unavoidable impurities. The size of billet is 300*2400*3000mm, the size of steel plate is 50*2500*17280mm, the segregation of casting billet low-magnification inspection center is C class 0.5, table 1 is the controlled rolling and controlled cooling process parameters under this composition, and the quenching temperature is 930℃ , the tempering temperature is 650°C, and the tempering time is 150min. Table 2 shows the mechanical properties obtained under the process parameters. Table 3 Aging impact performance and Z-direction performance of steel plates. Table 8 -40°C impact energy of welded joints when the line energy is 50kJ / cm. attached figure 1 50mm thick steel plate rolling regulations, attached figure 2 , a...

Embodiment 2

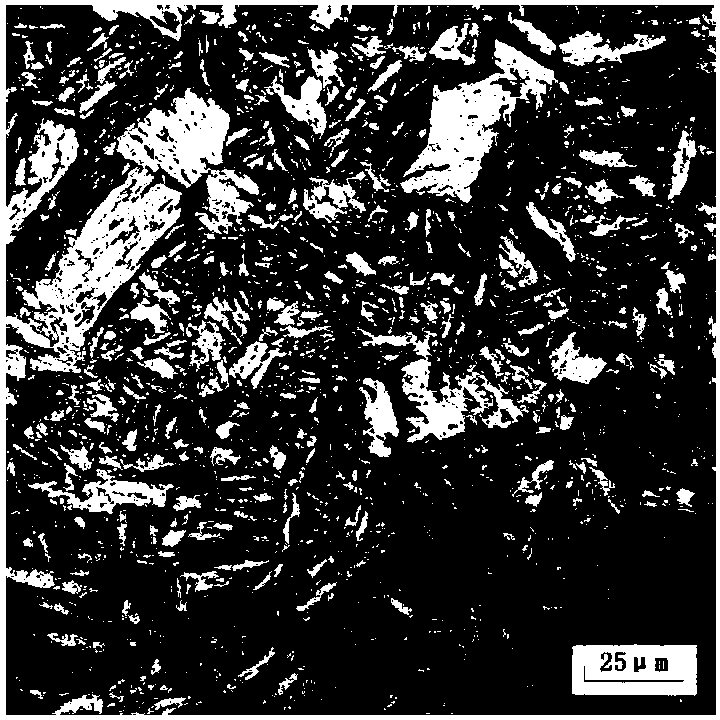

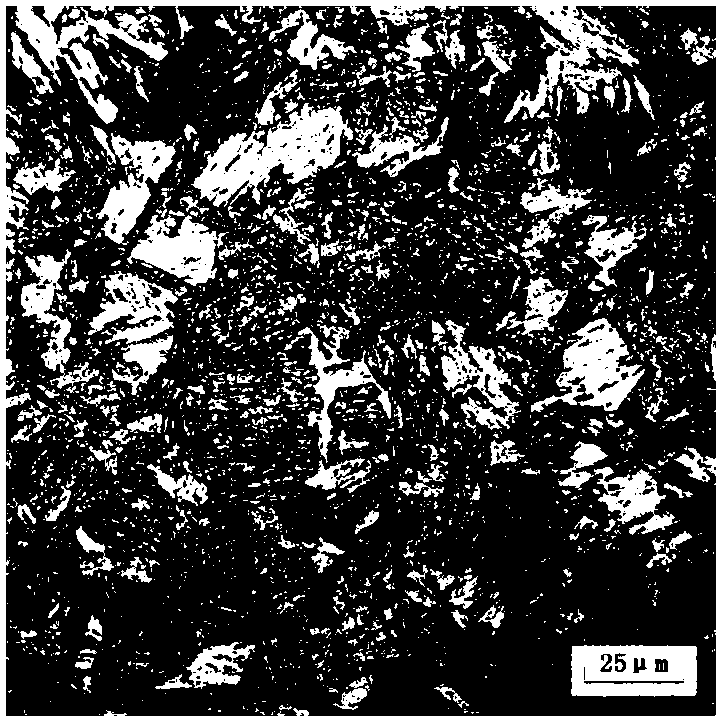

[0040] The thickness of 690MPa steel plate for marine engineering is 120mm, and its chemical composition is: C 0.13%, Si0.2%, Mn1.0%, Alt0.039%, Nb0.022%, V0.04%, Ti0.01%, Mo0 .42%, Cu0.27%, Ni1.5%, Cr1.12%, B0.0017%, P0.009%, S0.001%, the rest is iron Fe and unavoidable impurities. The size of billet is 400*2200*3000mm, the size of steel plate is 120*2700*8148mm, and the segregation of low power inspection center of billet is C class 0.5. Table 5 is the controlled rolling and controlled cooling process parameters under this composition, and the quenching temperature is 930℃ , the tempering temperature is 620°C, and the tempering time is 360min. Table 6 shows the mechanical properties obtained under this process parameter. Table 7 Aging impact performance and Z-direction performance of steel plates. attached Figure 5 120mm thick steel plate rolling regulations, attached Figure 6 , attached Figure 7 And attached Figure 8 It is the microstructure of 120mm thick steel pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com