Spray head for gaseous fire extinguishing equipment having silencing function

A technology of fire extinguishing equipment and spray head, which is applied in the field of spray head with noise reduction function, can solve the problems of cost increase and installation site constraints, and achieve the effect of improving the reduction rate, eliminating the installation site constraints, and preventing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Next, embodiments of the spray head having a noise reduction function for gas fire extinguishing equipment according to the present invention will be described with reference to the drawings.

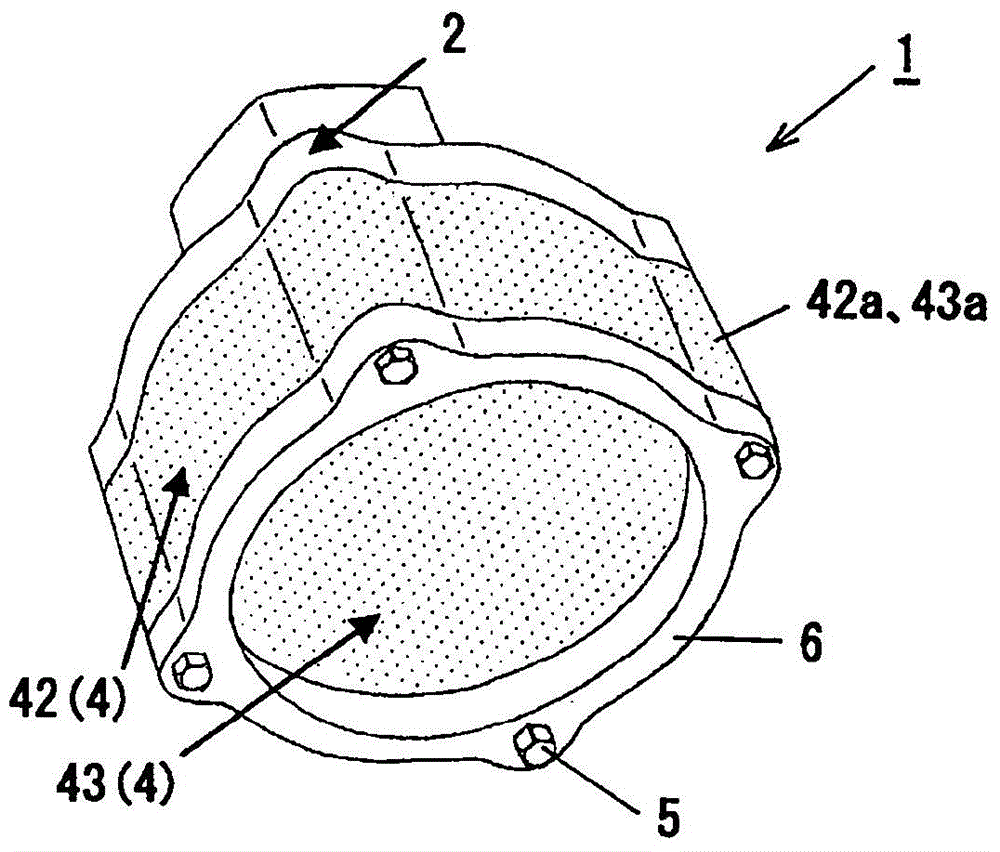

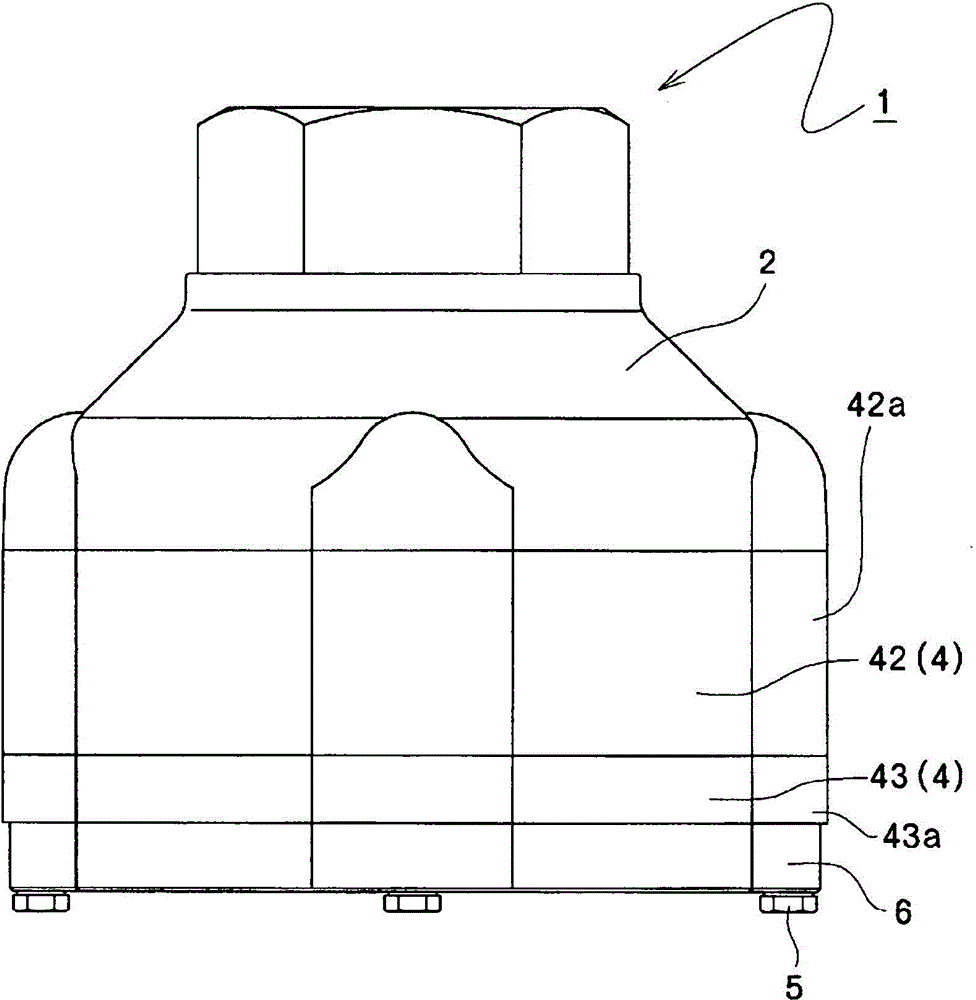

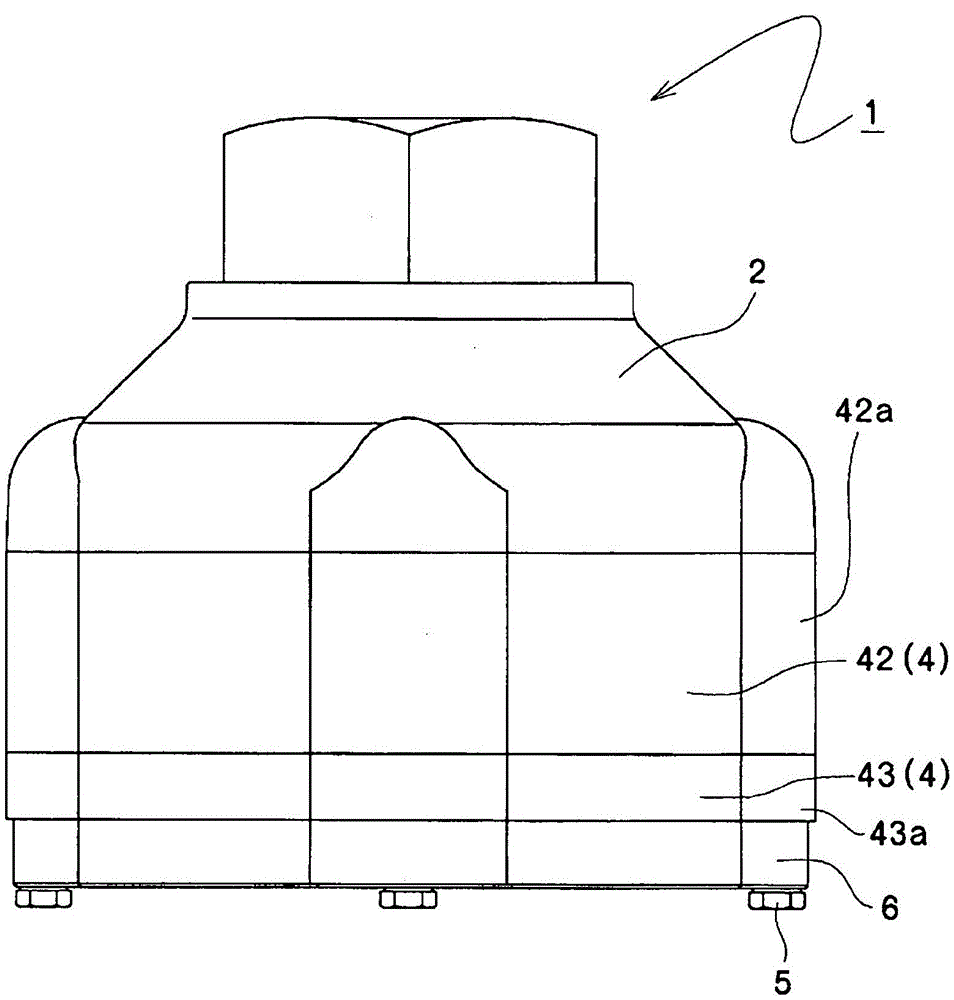

[0063] Figure 1 to Figure 6 It shows the first embodiment of the spray head with noise reduction function for the gas fire extinguishing equipment of the present invention.

[0064] The spray head 1 with a sound-absorbing function for gas fire extinguishing equipment is a spray head provided for discharging fire extinguishing agent gas to a fire extinguishing target area in gas fire extinguishing equipment using fire extinguishing agent gas. (Illustration omitted) connected head main body 2, orifice plate 3 with a plurality of orifice holes 31 formed on the stepped portion 21 formed in the internal space of the head main body 2, detachably arranged A block-shaped sound-absorbing member 4 made of a gas-permeable porous material arranged at the outlet of the orifice 31 and an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com